Summary of Contents for Toro 02835

- Page 1 Form No. 3459-226 Rev A F60 Flail Mower Groundsmaster ® 3200 or 3300 Series All-Wheel Drive Traction Unit Model No. 02835—Serial No. 400000000 and Up *3459-226* Register at www.Toro.com. Original Instructions (EN)

- Page 2 Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 g000502...

-

Page 3: Table Of Contents

Contents Sharpening the Blades ........28 Replacing the Blades........29 Cleaning Under the Cutting Unit......29 Safety ............... 4 Storage ..............30 General Safety ........... 4 Cutting Unit Safety..........4 Blade Safety ............4 Safety and Instructional Decals ......5 Setup ................ -

Page 4: Safety

Cutting Unit Safety Safety • The cutting unit is only a complete machine when This machine has been designed in accordance with installed on a traction unit. Read the traction ANSI B71.4-2017 and Safety Directive 2006/46/EC. unit Operator’s Manual carefully for complete instructions on the safe use of the machine. -

Page 5: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. decal134-5119 134-5119 1. Height of cut 3. Mounting hole locations 2. - Page 6 decal139-6303 139-6303 1. Entanglement hazard—read the Operator’s Manual; stay away from moving parts; keep all guards and shields in place. decal120-6604 120-6604 1. Thrown object hazard—keep bystanders away from the machine. 2. Cutting/dismemberment hazard of hand, mower blade—stay away from moving parts; keep all guards and shields in place.

-

Page 7: Setup

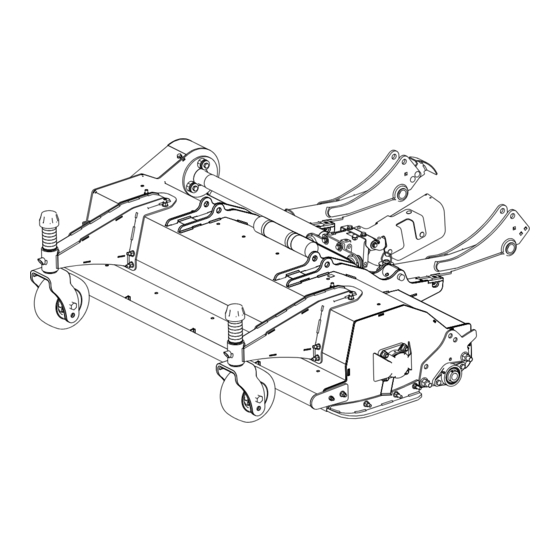

Setup Preparing the Machine No Parts Required Procedure Note: Retain all removed parts unless otherwise noted. g300498 Park the machine on a level surface, disengage Figure 3 the PTO, move the lift arms to the lowest position, engage the parking brake, shut off the 1. -

Page 8: Assembling The Caster Arms And Casters

g295790 g319436 Figure 5 Figure 6 3. Large pin 1. Lift arm 1. Castor bolt 4. Bearing spacer 2. Machine frame 2. Castor fork 5. Large locknut 3. Bearing Assemble each caster arm to the cutting unit with 6 carriage bolts (M10) and 6 locknuts (M10) as shown in Figure 7;... -

Page 9: Installing The Debris Guard To The Front

Assemble the casters to the cutting unit with a shim on both sides of the caster shaft hub as shown in Figure Note: You can adjust the height-of-cut setting Installing the Debris Guard by changing the amount of spacers on either side of the caster shaft hub;... - Page 10 Secure the large pin to the lift arm using a pair of nuts and bolts as shown in Figure Installing the Cutting Unit to the Machine Parts needed for this procedure: Lift arm Large pin Long bolt (3/8 x 2-3/4 inches) Nut (3/8 inch) Small pin Bolt (3/8 x 1-1/4 inches)

- Page 11 Ensure that the sensor bracket does not interfere with the sensor; refer to 7 Adjusting the Sensor Bracket (page 13). When installing the sensor bracket, rotate the bracket up (as shown in Figure 12) before clamping. Align the cutting unit in front of the machine frame and PTO shaft.

-

Page 12: Installing The Debris Skirt To The Traction Unit

Installing the Debris Skirt to the Traction Unit Parts needed for this procedure: Flap mount Carriage bolt (M8) Flange nut (M8) Procedure Use 6 carriage bolts (M8), 6 flange nuts (M8), and the flap mount to secure the debris skirt to the axle bracket. Note: For easier access to this area, you may remove a front wheel or both front wheels. -

Page 13: Installing The Pto Guard

Installing the PTO Guard Adjusting the Sensor Bracket Parts needed for this procedure: No Parts Required PTO guard assembly Screw (3/8 x 3/4 inch) Procedure Washer (3/8 inch) The sensor and the sensor-bracket plate should have a 6 mm (0.24 in) clearance between them (Figure 16). -

Page 14: Checking The Gearbox Lubricant

Checking the Gearbox Greasing the Cutting Unit Lubricant No Parts Required No Parts Required Procedure Procedure Grease the cutting unit before the first operation; refer Lubricating the Cutting Unit (page 22). Failure to Ensure that the gearbox has the correct amount properly grease the machine will result in premature of lubricant;... -

Page 15: Reducing The Engine Speed Before Pto Engagement

Important: Reducing the engine speed prior to engaging the PTO with the flail helps prevent premature driveline wear. Reducing the Engine Speed Engaging the L RPM PTO Mode NGAGE before PTO Engagement For Traction Unit Models 31902 and 31903 Use the traction-unit display screen to engage L No Parts Required RPM PTO E mode;... - Page 16 g383974 Figure 17 Several traction-unit parts removed for clarity. 1. Rubber pads 3. Spacers 2. Existing screws (1/4 inch) 4. Screws (1/4 x 1-1/4 inch)

-

Page 17: Product Overview

Operate the cutting unit at full engine speed. your Authorized Service Dealer or authorized the Adjust the forward speed to suit the grass manufacturer distributor or go to www.Toro.com for a conditions and to not overload the cutting unit. list of all approved attachments and accessories. -

Page 18: Inspecting The Blades

Position the machine on a level surface, raise To adjust the position of the caster fork, remove the cutting unit and support it with jack stands, the height-of-cut caps from the front caster shut off the engine, set the parking brake, and shafts and adjust the amount of spacers on remove the key from the ignition switch. -

Page 19: Operating Tips

Cutting Speed To improve cut quality, use a slower ground speed. Avoid Cutting Too Low If the cutting width of the cutting unit is wider than the mower you previously used, raise the cutting height to ensure that uneven turf is not cut too short. g034634 Select the Proper Height-of-Cut Figure 22... -

Page 20: Maintenance

Maintenance Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Tighten the caster wheel nuts. After the first 2 hours • Tighten the caster wheel nuts. After the first 10 hours • Check the height-of-cut setting. • Inspect the flail rotors and blades for damage, cracks, and loose fasteners. Replace any damaged or cracked parts. -

Page 21: Daily Maintenance Checklist

Daily Maintenance Checklist Duplicate this page for routine use. Maintenance Check Item For the week of: Mon. Tues. Wed. Thurs. Fri. Sat. Sun. Check the condition of the blades and rotors. Check the height-of-cut setting. Check the debris skirt for debris or damage. -

Page 22: Lubricating The Cutting Unit

Lubricating the Cutting Unit Service Interval: Before each use or daily Grease Type: No. 2 lithium grease Replace any damaged grease fittings. Refer to Figure 23 for the location of each pair of grease fittings on the cutting unit. g311728 Figure 23 Left side shown 1. -

Page 23: Checking The Lubricant In The Gearbox

Checking the Lubricant in Changing the Lubricant in the Gearbox the Gearbox Service Interval: Every 50 hours Service Interval: Every 400 hours Park the machine on a level surface, lower the The gearbox is designed to operate on either cutting unit, engage the parking brake, shut off petroleum or synthetic SAE 80W–90 gear lube. -

Page 24: Checking The Belt Tension

Checking the Belt Tension Note: To loosen the idler pulley nut, you will need to hold the bolt that secures it in place on the inside of the deck. Service Interval: Every 250 hours Adjust the nut on the idler pulley post to tension Park the machine on a level surface, lower the the belt (Figure... -

Page 25: Checking The Belt Drive And Taper Lock Hardware

Checking the Belt Drive and Removing the Cutting Unit Taper Lock Hardware from the Machine Park the machine on a level surface, lower the Service Interval: Every 250 hours—Ensure that the cutting unit, engage the parking brake, shut off belt drive and taper-lock bushing set the engine, and remove the key. -

Page 26: Servicing The Bushings In The Caster Arms

Servicing the Bushings in Servicing the Caster the Caster Arms Wheels and Bearings Park the machine on a level surface, raise and The caster arms have bushings pressed into the top support the cutting unit with jack stands, engage and bottom of the tube, and after many hours of the parking brake, shut off the engine, and operation, the bushings wear. -

Page 27: Checking The Blade Bolts

Remove the wooden pole from the cutting unit Important: If you cannot correct the cause before you start the engine. of unusual rotor vibration, contact your Repair or adjust the cutting unit if necessary. authorized Toro distributor. -

Page 28: Sharpening The Blades

While grinding the blade, keep the cutting edge authorized Toro distributor. perfectly horizontal and the angled surface flat to the ground (Figure 33). -

Page 29: Replacing The Blades

Replacing the Blades Note: Pay attention to the bolt-head-position markings so that you replace the bolt in the Service Interval: Yearly—Replace the blades. same direction. Torque the fasteners to 45 N∙m (33 ft-lb). To maintain balance, replace blades only as an opposed pair or a whole rotor at a time. -

Page 30: Storage

Storage Park the machine on a level surface, raise the cutting unit to the T position, engage RANSPORT the parking brake, shut off the engine, and remove the key. Thoroughly clean the cutting unit, paying special attention to these areas: •... - Page 31 Notes:...

- Page 32 Notes:...

- Page 33 The method of transmission shall be electronic transmittal. This machinery shall not be put into service until incorporated into approved Toro models as indicated on the associated Declaration of Conformity and in accordance with all instructions, whereby it can be declared in conformity with all relevant Directives.

- Page 34 The method of transmission shall be electronic transmittal. This machinery shall not be put into service until incorporated into approved Toro models as indicated on the associated Declaration of Conformity and in accordance with all instructions, whereby it can be declared in conformity with all relevant Directives.

- Page 35 The Toro Company (“Toro”) respects your privacy. When you purchase our products, we may collect certain personal information about you, either directly from you or through your local Toro company or dealer. Toro uses this information to fulfil contractual obligations - such as to register your warranty, process your warranty claim or to contact you in the event of a product recall - and for legitimate business purposes - such as to gauge customer satisfaction, improve our products or provide you with product information which may be of interest.

- Page 36 Countries Other than the United States or Canada Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor's service or have difficulty obtaining guarantee information, contact your Authorized Toro Service Center.