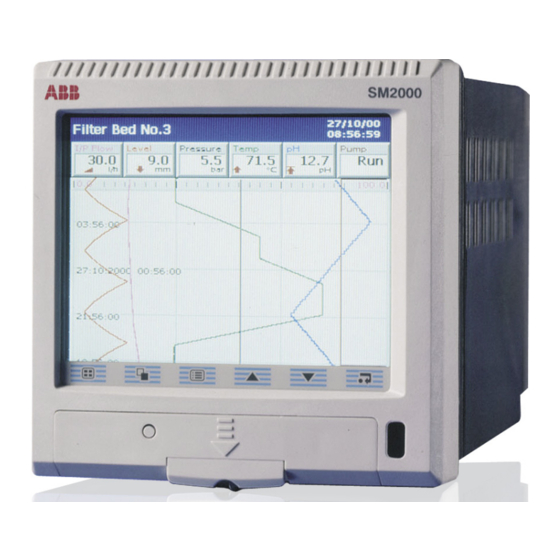

ABB SM2000 User Manual

Inform it advanced videographic

Hide thumbs

Also See for SM2000:

- User manual (138 pages) ,

- User manual supplement (25 pages) ,

- Hardware installation (12 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

Advertisement

Table of Contents

Summary of Contents for ABB SM2000

- Page 1 Inform User Guide Advanced Videographic Recorder SM2000...

- Page 2 We are an established world force in the design and manufacture of instrumentation for industrial process control, flow measurement, gas and liquid analysis and environmental applications. Cert. No. Q05907 As a part of ABB, a world leader in process automation technology, we offer customers application expertise, service and support worldwide. EN 29001 (ISO 9001) We are committed to teamwork, high quality manufacturing, advanced technology and unrivalled service and support.

-

Page 3: Table Of Contents

CONTENTS Functions ................79 INTRODUCTION ................. 2 4.8.1 Custom Linearizers ..........79 OPERATION ................3 4.8.2 Real Time Alarms ............ 80 Powering Up the Instrument ............ 3 Displays and Controls ............. 3 INSTALLATION ................. 81 Chart Views (Horizontal and Vertical) ........4 Siting .................. -

Page 4: Introduction

1 INTRODUCTION Functional Overview – Fig. 1.1. • 12 Recording Channels as standard, divided into 2 Process • Recording sources derived from universal analog inputs, the Groups, each with 6 Recording Channels. Modbus serial link, optional digital inputs or internal analog and digital signals. -

Page 5: Operation

2 OPERATION 2.1 Powering Up the Instrument When power is first applied to the instrument, its processor carries out a number of self-tests and displays the start up screen. At the end of the start up sequence the instrument displays the Operator View that was being displayed when the instrument was powered down. -

Page 6: Chart Views (Horizontal And Vertical)

…2 OPERATION …2.2 Displays and Controls Process Group 2 Process Group 1 (Recording Channels 2.1 to 2.6) (Recording Channels 1.1 to 1.6) 28/03/00 28/03/00 Process Group 1 Chart View 28/03/00 14:52:00 12:00:45 Instrument Status 14:52:00 Level Pressure In Flow Out Flow Temp Alarm 1 Level... - Page 7 2 OPERATION… 2.3 Chart Views (Horizontal and Vertical) – Fig. 2.3 Title Bar Group Tag Current Date and Time Status Icons Units Short Channel Tag 28/03/00 Process Group 1 12:00:45 Digital On/Off Tag Current Value Level Pressure In Flow Out Flow Alarm 1 (see Note 1 on page 6) 2.08...

- Page 8 …2 OPERATION …2.3 Chart View Notes. 1. Current Values The Current Value, shown on the digital indicators at the top of the screen, is the latest instantaneous value and its update rate is not affected by the recording sample rate. If the current value in the digital indicator is displayed in red, recording has been stopped for that channel –...

- Page 9 2 OPERATION… …2.3 Chart View Notes. While in Historical Review mode: • Recording of new data continues unless stopped from the Set Up Menu – see Section 3.3. • Invalid historical data (e.g. when recording has stopped) is denoted by '– – – –' in the digital indicator.

- Page 10 …2 OPERATION …2.3 Chart View Add one of 24 predefined Operator Messages (see Section 4.4.5) or one User Defined Operator Messages Message to the alarm event log. If User Defined is selected, a data entry keyboard appears 1 - 6 Start of batch to enable the message to be entered –...

- Page 11 2 OPERATION… …2.3 Chart View Scales Scales Select Select Select the scale displayed in the scale bar at the top of the chart window. For digital channels, the On and Off tags are displayed at the corresponding position on the scale bar. Ch 1.1 Level Select Autoscroll to display the scale for each channel in turn for a few seconds.

-

Page 12: Bargraph Views (Horizontal And Vertical)

…2 OPERATION 2.4 Bargraph Views (Horizontal and Vertical) Status Icons – see Rear Foldout Short Channel Tag Current Value 28/03/00 Process Group 1 14:52:00 Alarm Status – Level Pressure In Flow Out Flow Temp Alarm 1 Digital On or Off tag, 2.08 204.9 198.9... - Page 13 2 OPERATION… …2.4 Bargraph Views (Horizontal and Vertical) Select the Configuration level – See Section 4. Configuration Select the Set Up level – see Section 3. Setup Add one of 24 predefined Operator Messages (see Section 4.4.5) or one User Defined Operator Messages Message to the alarm event log.

-

Page 14: Digital Indicator View

…2 OPERATION 2.5 Digital Indicator View – Fig. 2.5 Status Icons 28/03/00 Process Group 1 Short Channel Tag 14:52:00 Level Level Pressure 2.08 Current Value 2.08 2.08 metres metres metres Alarm Status – 578494 578494 see Rear Fold-out Out Flow In Flow Engineering Units 198.4... - Page 15 2 OPERATION… …2.5 Digital Indicator View Select the Configuration level – see Section 4. Configuration Select the Set Up level – see Section 3. Setup Add one of 24 predefined Operator Messages (see Section 4.4.5) or one User Defined Operator Messages Message to the alarm event log.

- Page 16 …2 OPERATION …2.5 Digital Indicator View Stop and start individual totalizers. Totalizer stop/go Channel totalizers that have not been enabled in the configuration level are shown greyed Ch 1.1 Level out. Ch 1.2 Pressure Ch 1.3 In Flow Ch 1.4 Out Flow Stop Note.

-

Page 17: Process View

2 OPERATION… 2.6 Process View – Fig. 2.6 Alarm Tag Alarm Trip Level Alarm Acknowledged 28/03/00 Short Channel Tag Process Group 1 14:52:00 Totalizer not Level Tank 1 Low Level 1.25 Instantaneous Value enabled in 2.08 configuration level Tank 1 High Level 4.75 metres Alarm Status... - Page 18 …2 OPERATION …2.6 Process View Select the Configuration level – see Section 4. Configuration Select the Set Up level – see Section 3. Setup Switch between the Alarm View and Statistics View. View Select Alarms Note. If a channel's totalizer has not been enabled in the Configuration level, Alarm trip Statistics levels are shown in place of the channels statistics.

-

Page 19: Alarm Event Log

2 OPERATION… 2.7 Alarm Event Log – Fig. 2.7 Note. This view provides an historical log of all alarm events in the sequence in which they occurred. To view the current status of all alarms, choose the Process View – see Section 2.6. Short tag of the alarm's source 28/03/00 Alarm Event Log... - Page 20 …2 OPERATION …2.7 Alarm Event Log Select the Configuration level – see Section 4. Configuration Select the Set Up level – see Section 3. Set Up Select the entries displayed in the log. Indicates categories currently displayed. Filter Notes. Group 1 Alarms •...

-

Page 21: Totalizer Log

2 OPERATION… 2.8 Totalizer Log – Fig. 2.8 Notes. • This view provides an historical log of totalizer activity. To view the current totalizer status, choose the Process or Digital View. • When the totalizer log has reached the maximum number of entries defined in the Configuration level (see Section 4.4.3), the oldest data is overwritten by the newest. - Page 22 …2 OPERATION …2.8 Totalizer Log Select the Configuration level – see Section 4. Configuration Select the Set Up level – see Section 3. Setup Select the log entries that are displayed. This does not affect which events are recorded in Filter the log.

-

Page 23: Audit Log

2 OPERATION… 2.9 Audit Log – Fig. 2.9 Notes. • This view provides an historical log of system activity. • When the audit log has reached the maximum number of entries, the oldest data is overwritten by the newest. View previous page of data 28/03/00 Audit Log... -

Page 24: Status View

…2 OPERATION 2.10 Status View – Fig. 2.10 Note. This view provides an overview of the instrument's status. 28/03/00 Instrument Status 14:52:00 VERSION CJ TEMPERATURES Cold junction temp Instrument Software Version 25°C / 77°F Software 2002.7.233 for Modules A & B; by the built-in cold Operating System Version 25°C / 77°F... -

Page 25: Set Up

3 SET UP 3.1 Introduction Note. Users with Set Up access can: • Start/Stop recording. • Switch between primary and secondary recording rates. • Set archiving 'on-line' and 'off-line'. • View internal and external archive media file directories and delete files 3.2 Accessing the Set Up Level –... -

Page 26: Set Up Menu

…3 SETUP 3.3 Set Up Menu Use this menu to stop and start recording or change the sample rate on one or more Recording Control channels in the current Process Group. Ch 1.1 Level The Primary and Secondary sample rates allow a slow rate to be selected for normal Ch 1.2 Pressure conditions and a faster rate for abnormal alarm conditions in order to record the maximum Ch 1.3 In Flow... - Page 27 Use the file viewer to view a list of the files stored in internal memory and on external archive Internal media. External Note. Files stored in internal memory cannot be deleted. External File Viewer Name Size SM2000.cfg 17848 12_10_59 011100 SM2000.cfg 17848 13_09_48 311200 SM2000.cfg 17848 13_59_37 280800 SM2000.cfg 17848 21_49_58 010100 SM2000.cfg 17848 Delete Exit...

-

Page 28: Archiving

…3 SET UP 3.4 Archiving Recorded data, logs and configuration files stored on the instrument's internal memory can be archived to files created on removable media. Parameters for archiving Process Groups 1 and 2 data are set up independently. Note. For further information on Archiving refer to Section 4.5.6 – Archiving Configuration. 3.4.1 SmartMedia Handling and Care Note. -

Page 29: Inserting And Removing Media

3 SET UP… 3.4.3 Inserting and Removing Media – Fig. 3.3 Ensure that the media is put off-line – see Section 3.3 Withdraw the media Press the eject button Compact Flash Media SmartMedia Note. When inserting the media into the instrument: Unlock the media door with the key supplied •... -

Page 30: Text Format Archive Files

…3 SET UP 3.4.4 Archive File Types 3.5 Text Format Archive Files 3.5.1 Text Format Channel Data Files Archive files can be created in one of two user-selectable formats: Text format channel data files can be configured to contain data gathered over a predefined period of time using the 'New File Text (comma separated values [.csv]) –... -

Page 31: Text Format Filename Examples

3 SET UP… …3.5.1 Text Format Channel Data Files 3.5.2 Text Format Filename Examples When one of these conditions occurs, new channel data files are 'New file interval' set to hourly, filename tag set to 'Process created for each enabled group and the file extension index on Group 1';... -

Page 32: Text Format Log Files

…3 SET UP 3.5.3 Text Format Log files 3.5.4 Text Format Data File Examples – Figs. 3.4 to 3.7 The Alarm Event and Totalizer Logs for each Process Group are each archived into individual files; the Audit Log is archived into Text format archived data is stored in a comma separated value a separate file. - Page 33 3 SET UP… Fig. 3.5 Alarm Event Log Sample (Text Format) Fig. 3.6 Totalizer Log Sample (Text Format) Fig. 3.7 Audit Log Sample (Text Format)

-

Page 34: Binary Format Archive Files

…3 SETUP 3.6 Binary Format Archive Files – End of daylight saving period: Example 2 3.6.1 Binary Format Archive Filenames Archiving is started at 00:15:00 on 26 October 2003 – Examples of binary archive filenames are shown in Table 3.5: filename: 00150026Oct03Ch1_1AnlgSM2000~DS.B00. - Page 35 3 SETUP… Fig. 3.8 Channel Data File Sample (Binary Format) Fig. 3.9 Alarm Event Log Sample (Binary Format)

- Page 36 …3 SETUP Fig. 3.10 Totalizer Log Sample (Binary Format) Fig. 3.11 Audit Log Sample (Binary Format)

-

Page 37: Archiving Online/Offline

3 SETUP 3.7 Archiving Online/Offline 3.8 Archiving Updates Before data can be archived to external media, the external Data from the instrument's internal memory is archived to media must be placed on-line and one or more archive file external memory in the following circumstances: enables set. -

Page 38: Configuration

4 CONFIGURATION 4.1 Introduction 4.1.3 Configuration Level Access – Figs 4.1 and 4.2 This section details the configuration of the instrument locally To configure an instrument when 'Configuration security' is set using the touch screen. A configuration file can also be created to the factory default setting of 'Password protected': on a PC and transferred to the instrument via one of the archive •... - Page 39 4 CONFIGURATION… …4.1.3 Configuration Level Access – Figs. 4.1 and 4.2 Operator 1 Note. Do not use sharp objects such as screwdrivers, Operator 2 Configuration pen nibs etc. to operate the touch screen. Operator 3 Operator 4 User 1 Displayed only if 'Configuration Security' Use the up and down keys to select your password.

- Page 40 …4 CONFIGURATION …4.1.3 Configuration Level Access – Figs. 4.1 and 4.2 Note. The Internal Security Switch is used only if 'Configuration security' is set to 'Internal switch protected' – see Section 4.4.3. access the switch if 'Configuration security' is set to 'Password protected' (default setting). Do Not Set the yellow Security switch to the 'Configuration Level Not Protected' position...

-

Page 41: Overview Of Configuration

4 CONFIGURATION… 4.2 Overview of Configuration – Fig. 4.3 Select the Common Configuration icon in the main configuration window (see Note 1 below) Close the Configuration Window and Save or Cancel the changes (see Note 2 below) System Configuration Repeat steps for the remaining icons in the Configuration Window Common... -

Page 42: Making Changes To Parameters

…4 CONFIGURATION 4.3 Making Changes to Parameters – Figs. 4.4 to 4.6 Channel Selectors Recording Channel 1.1 (Recording Channel Edit Button configuration only) Analog I/P Alarm A Totalizer Scales Set Up Configuration Tab Input Type 4.0 - 20.0 mA Engineering range 0 to 20000 Litres/sec Parameter Value Short tag 8 Character Long tag 20 Characters... - Page 43 4 CONFIGURATION… …4.3 Making Changes to Parameters – Figs. 4.4 to 4.6 Parameter Limits Numeric (0.0...1000.0) List Box Tick Box 999.9 1. Totalizer reset enable milliAmps 2. Totalizer stop/go enable milliVolts 3. Message select enable Volts 4. Alarm acknowledge enable Resistance Resistance thermometer Thermocouple...

- Page 44 11:57:00 • When saving the current configuration to external storage, the file is saved automatically to internal storage with the 'SM2000.cfg' filename, as well as to the external archive media as <time><date><instrument tag>.cfg. • When 'Save Configuration' is selected the configuration file is stored as <time><date><instrument tag>.cfg on internal or external storage.

-

Page 45: Common Configuration

4 CONFIGURATION… 4.4 Common Configuration System Configuration Common Process Group 1 Process Configuration Group 1 Channels Group 2 Group 2 Functions Commissioning Channels Modules Fig. 4.7 Selecting Common Configuration 4.4.1 Set Up Select the Configuration type required – see Section 4.1.1. •1 Note. -

Page 46: Time

…4 CONFIGURATION 4.4.2 Time Set the current date and time. Note. Enter the required daylight saving settings before setting the time and date as the operation of the internal clock is affected by the daylight saving settings. Notes. • The date and time cannot be adjusted if recording is enabled during configuration, i.e the 'Disable recording in configuration' check box is ticked on entry to the... - Page 47 4 CONFIGURATION… …4.4.2 Time Select the daylight saving method. g i l g i l c i t . y l i t a y l l r i f i t a y l l g i l l a r c i t .

-

Page 48: Security

…4 CONFIGURATION 4.4.3 Security Change the user name and password used to access the configuration level when 'Password protection' is enabled – see below. Note. User 1 has 'administrator' type privileges and is able to change the user names and passwords of all other users. User 2 Other users can change only their own user name and Name Operator 2... -

Page 49: Logs

4 CONFIGURATION… 4.4.4 Logs Set the maximum number of entries in each instrument log. Note. Changing the log size results in the current log entries being deleted. records all process alarm transitions Alarm Event log (inactive to active, unacknowledged to acknowledged or active to inactive), real-time events and Operator Messages –... -

Page 50: Rs485 Communications

…4 CONFIGURATION 4.4.6 RS485 Communications Refer to APPENDIX 2 for information on using the Modbus link. Set according to the number of transmission wires connected to the instrument: 4-wire, 2-wire. Set the Baud rate used by the host system: 1200, 2400, 4800, 9600, 19200, 38400, 115200. -

Page 51: Process Group Configuration

4 CONFIGURATION… 4.5 Process Group Configuration Process Group 1 Group 1 Configuration System Configuration Recording Chart Process Digital Archive Tag 20 Characters Common Process Group 1 Process Configuration Group 1 Channels Group 2 Recording On, Off Primary sample rate HH:MM:SS:ms Secondary sample rate HH:MM:SS:ms Group 2 Functions... - Page 52 …4 CONFIGURATION …4.5.1 Setting the Recording Parameters Set the rate at which all recording channels in the group are Primary sample rate mm:ss sampled and stored to internal memory. With Basic •1 configuration selected, this is also the time interval between samples stored on archive media, if archiving is enabled.

-

Page 53: Configuring The Chart Display

4 CONFIGURATION… 4.5.2 Configuring the Chart Display Minor Chart Divisions Major Chart Divisions 28/03/00 Group 1 12:00:45 Level Pressure In Flow Out Flow Temp Alarm 1 2.08 204.9 198.9 metres l/hr l/hr °C Scale Bar 12:00:30 High Out Flow Rate 12:00:00 Chart Trace Time Stamp... - Page 54 …4 CONFIGURATION …4.5.2 Configuring the Chart Display Set the amount of historical data displayed on the screen. In Basic mode limits are enforced according to the sample rate selected: < > < > < > For optimum performance in Historical Review mode, It is recommended that these limits are also used when Advanced configuration is selected.

-

Page 55: Configuring The Bargraph Display

4 CONFIGURATION… 4.5.3 Configuring the Bargraph display 28/03/00 Group 1 14:52:00 Level Pressure In Flow Out Flow Temp Alarm 1 2.08 204.9 198.9 metres l/hr l/hr °C Engineering High Value Alarm Trip Level (not shown for slow and fast rate alarms) Maximum Value (solid color) Engineering Middle Value... -

Page 56: Configuring The Process View

…4 CONFIGURATION 4.5.4 Configuring the Process View Alarms View – Totalizer Enabled Totalizer Tag Name In Flow Total Daily In Flow Low In Flow Rate Alarm Acknowledged 204.9 0005402801 High In Flow Rate l/hr litres Totalizer Value Alarm Alarm Trip Level Statistics View –... -

Page 57: Digital Indicator View

4 CONFIGURATION… 4.5.5 Digital Indicator View 28/03/00 Group 1 Short Channel Tag 14:52:00 Level Level Pressure Current Value 2.08 2.08 2.08 metres metres metres 578494 Alarm Status 578494 578494 In Flow Out Flow 204.4 198.4 Units Channel Units l/hr l/hr 0005402801 0005402060 Totalizer Units... -

Page 58: Archiving

…4 CONFIGURATION 4.5.6 Archiving Introduction Recorded data, logs and configuration files stored in the instrument's internal memory can be archived to files created in removable media in either text or binary encoded format. Parameters for archiving Process Group 1 are set up independently from Process Group 2 parameters. - Page 59 4 CONFIGURATION… …4.5.6 Archiving Set the frequency with which new channel data files are Off, Hourly, Daily, Monthly New file interval created. Note. Not applicable when 'Archive file format' (below) is set to 'Binary format'. e l i e l i y l r <...

-

Page 60: Channel Configuration

…4 CONFIGURATION 4.6 Channel Configuration System Configuration Common Process Group 1 Process Configuration Group 1 Channels Group 2 Group 2 Functions Channels Modules Process Group 1, Process Group 2, Channels 1.1 to 1.6 Channels 2.1 to 2.6 Recording Channel 1.1 Recording Channel 1.2 Recording Channel 1.6 Fig. -

Page 61: Recording Channel Set Up

4 CONFIGURATION… 4.6.1 Recording Channel Set Up Note. Parameters applying only to Advanced configuration are identified •1 Select the signal source for the selected channel. This can be any external analog or digital signal. See APPENDIX 1 for full list. Note. - Page 62 …4 CONFIGURATION …4.6.1 Recording Channel Set Up Select the filter to be applied to the electrical input prior to •1 sampling. Notes. • Applicable to analog sources only. • Filters are applied to the recorded values shown on the chart view only, not to instantaneous values displayed on the channel indicators or bargraphs.

- Page 63 4 CONFIGURATION… …4.6.1 Recording Channel Set Up Set the rate at which the channel source is to be sampled •1 and stored to internal memory. Note. Sample rates must be set using one of the following combinations of units: • Minutes or minutes and seconds •...

-

Page 64: Analog Input Configuration

…4 CONFIGURATION 4.6.2 Analog Input Configuration Note. • This tab is displayed only if the Source ID is set to an analog signal – see Section 4.6.1. • If an analog input is assigned to more than one recording channel, changes to any of its parameters and tags are applied to each channel the input is assigned to. - Page 65 4 CONFIGURATION… …4.6.2 Analog Input Configuration Specify the display range and units of the engineering value •1 corresponding to the electrical high and low values, within the limits defined below: °C °F Engineering range THC/RTD Type Min. Max. Min. Max. Type B –18 1800...

-

Page 66: Digital Input Configuration

…4 CONFIGURATION …4.6.2 Analog Input Configuration Set the time period over which the process variable is to be filtered prior to being sampled (0 to 60 seconds). Set a tolerance level (between 0 and 100% of the engineering range) to allow for deviation of the input signal above or below the input span before an input failure is detected. -

Page 67: Alarm Configuration

4 CONFIGURATION… 4.6.4 Alarm Configuration Hysteresis Trip Point Hysteresis Process Variable Alarm On High Process Alarm Off Alarm On Low Process Alarm Off Fig. 4.11 High/Low Process Alarms Trip Point Hysteresis Process Variable Alarm On Alarm Latched Alarm Off Alarm acknowledged by operator High Latch Alarm Action Process... - Page 68 …4 CONFIGURATION …4.6.4 Alarm Configuration Process Variable Trip Point Hysteresis Hysteresis Trip Point Process Variable Alarm On Alarm On Alarm Off Alarm Off Alarm acknowledged Alarm acknowledged by operator by operator High Annunciate Alarm Action Low Annunciate Alarm Action Fig. 4.13 High/Low Annunciate Alarms Deviation exceeded –...

- Page 69 4 CONFIGURATION… …4.6.4 Alarm Configuration Process variable goes Process variable goes Process variable goes above trip point but above trip point but Process variable goes above trip point, alarm is alarm is not activated alarm is not activated below trip (hysteresis) activated (alarm is because enable signal because alarm delay...

- Page 70 …4 CONFIGURATION …4.6.4 Alarm Configuration Note. This tab is displayed only if the Recording Channel source is an Analog signal. Set the alarm type: High/Low process – see Fig. 4.11 High/Low latch – see Fig. 4.12 High/Low annunciate – see Fig 4.13 Fast/Slow rate –...

- Page 71 4 CONFIGURATION… …4.6.4 Alarm Configuration Note. Delayed process alarms only – see Fig. 4.15. Set the value, in engineering units, at which the alarm is to activate. Set the hysteresis value in engineering units and the delay time in seconds. Output Alarm Trip Point...

- Page 72 …4 CONFIGURATION …4.6.4 Alarm Configuration When the 'Enable source' is active, the alarm is enabled. When the source is inactive the alarm is disabled. If set to 'None' the alarm is always enabled. Note. For Delayed Process alarm operation, Fig. 4.15. Set to 'On' to record all changes in the alarm state in the Alarm event log –...

-

Page 73: Totalizer Configuration

4 CONFIGURATION… 4.6.5 Totalizer Configuration Notes. • Current totalizer values are displayed in the Digital Indicator View and Process View – see Sections 2.5 and 2.6 (Operation), and Sections 4.5.4 and 4.5.5 (Configuration). • For analog sources, the total value of a signal is calculated by counting pulses produced at a rate proportional to the input. For digital sources, off/on transistions are scaled to produce a batch total. - Page 74 …4 CONFIGURATION …4.6.5 Totalizer Configuration Set the Preset count – the value the totalizer counts from and 0 to 100000000 Count range the value applied when the totalizer is reset. Count range Set the Predetermined count – the value at which the totalizer stops or wraps.

- Page 75 4 CONFIGURATION... …4.6.5 Totalizer Configuration Note. Analog Sources only. The Count rate is determined by Count rate/cut-off 0.01, 9999 the maximum number of engineering units (or pulses) per second and the smallest totalizer increment: engineering full scale value (rate) Count rate / Cut off engineering units (in seconds) Count rate 10.000 –...

-

Page 76: Scales

…4 CONFIGURATION 4.6.6 Scales Note. The scales configured here are used to scale analog channel data on the Chart View when Advanced configuration is selected. It has no effect on the Bargraph View (which always uses the engineering range of the analog signal displayed) or on digital channels. -

Page 77: I/O Module Configuration

4 CONFIGURATION… 4.7 I/O Module Configuration I/O Module Configuration System Configuration Relay B1 Alarm 1.1A, Positive Common Process Group 1 Process Configuration Group 1 Channels Group 2 Relay B2 Totalizer 1.2 Intermediate, Relay B3 None, Positive Group 2 Functions Channels Modules Modules Relay B4 None, Positive... - Page 78 …4 CONFIGURATION …4.7.1 Analog Inputs Offset adjust / Span adjust These are calculated values applied to the raw input signal. Cannot be adjusted by the user. Note. If simulating thermocouple inputs, connect the millivolt source using appropriate compensating cable – see Section 5.4.2.

-

Page 79: 3-Relay And 6-Relay Modules

4 CONFIGURATION… 4.7.2 3-Relay and 6-Relay Modules A:- Analog I/P B: Relay C:-Hybrid The Relay Source is a digital source used to energize/ Alarm 1.1A, Positive Relay B1 de-energize the relay. Totalizer 1.2 Intermediate, Relay B2 Note. If the relay is used to provide a totalizer count pulse, the maximum pulse frequency is 5Hz. -

Page 80: Ethernet Modules

…4 CONFIGURATION …4.7.3 Hybrid Modules The Analog output source can be any internal or external analog signal. Analog output C1 source None Analog output C1 range Off The Analog output range is the engineering range of the output signal – see below. Analog output C2 source Analog i/p A1 Analog output C2 range 0.0-100.0, 4.0-20.0mA The 'Engineering low' and 'Engineering high' settings allow... -

Page 81: Functions

4 CONFIGURATION… 4.8 Functions Functions Configuration System Configuration Custom Linearizer RTA 1 RTA 2 RTA 3 RTA 4 Adjust custom linearizer A Common Process Group 1 Process Configuration Group 1 Channels Group 2 Adjust custom linearizer B Group 2 Functions Functions Channels Modules... -

Page 82: Real Time Alarms

…4 CONFIGURATION 4.8.2 Real Time Alarms Custom Linearizer RTA 1 RTA 2 RTA 3 RTA 4 Enter the Tag that is displayed in the Alarm Event log. Tag Real Time Alarm 1 Set the day(s) on which the alarm is activated. Daily enables None Daily enables Sunday... -

Page 83: Installation

5 INSTALLATION EC Directive 89/336/EEC In order to meet the requirements of EC Directive 89/ 50°C 336/EEC for EMC regulations, this product must not be (122°F) used in a non-industrial environment. Max. 0°C (32°F) Min. End of Life Disposal A – Within Temperature Limits •... -

Page 84: Mounting

…5 INSTALLATION 5.2 Mounting – Figs. 5.3 and 5.4 Dimensions in mm (in.) AC Power Supply Gasket Earth (Ground) Stud (0.27) 155.0 (6.1) 40 (1.57) +1.0 –0.0 144.0 Panel Cut-out (5.67) +0.04 (5.43 –0.0 +1.0 –0.0 144.0 (5.67) (1.2) 3 (0.12) +0.04 (5.43 29 (1.14) -

Page 85: Electrical Connections

5 INSTALLATION… 5.3 Electrical Connections – Fig 5.5 Warnings. • The instrument is not fitted with a switch therefore a disconnecting device such as a switch or circuit breaker conforming to local safety standards must be fitted to the final installation. It must be fitted in close proximity to the instrument within easy reach of the operator and must be marked clearly as the disconnection device for the instrument. - Page 86 …5 INSTALLATION …5.3 Electrical Connections – Fig 5.5 Warnings. Module Positions 1 The AC power supply earth (ground) cable must be connected to the earth (ground) stud 2 An external voltage divider (part no. GR2000/0375) is required for each channel for voltage input ranges above 2V, on which 'Input type' is set to 'Voltage' –...

-

Page 87: Analog Inputs

5 INSTALLATION… 5.4 Analog Inputs 5.4.1 Current and Voltage – Fig. 5.6 – – – Warnings. • When the 'Input type' is set to 'Voltage', inputs 10Ω Resistor supplied Voltage divider in accessory pack. must be connected through a 500kΩ voltage (GR2000/0375) required for divider (part no. -

Page 88: Rs422/485 Serial Communications

…5 INSTALLATION 5.5 RS422/485 Serial Communications The serial interface fitted to this instrument has been designed to Host Computer operate using the Modbus Remote Terminal Unit (RTU) Master/ Slave protocol. Terminal Block F An appropriate RS422/485 communications driver must fitted to the host (Master) computer. -

Page 89: Mains Power Connections

5 INSTALLATION… 5.6 Mains Power Connections – Fig 5.9 5.8 Hybrid I/O Module Connections 5.8.1 Digital Output Connections – Fig 5.11 Six digital outputs are provided on the Hybrid option board. Fuse, 315mA, Type T Line 85 min. – 265V max. Neutral 50/60Hz Terminal Block E... -

Page 90: Appendix 1 - Signal Sources

APPENDIX 1 – SIGNAL SOURCES o i t t i f o i t a t i t i f . ) e a l i o i t t l o a t i t i f o i t i g i l a t . -

Page 91: Appendix 2 - Modbus Guide

APPENDIX 2 – MODBUS GUIDE A2.1 Introduction A2.4 Modbus Exception Responses This instrument is fitted with a Modbus/RS485 serial If the instrument detects one of the errors listed in Table A2.1 communications link as standard. while receiving a message from the host system, it replies with a response message consisting of the instrument's Modbus The instrument is designed to act as a Remote Terminal Unit address, the function code, the error code and error check... - Page 92 …APPENDIX 2 – MODBUS GUIDE …A2.5 Operating Mode Modbus Coils r a l i t c t i r i t c r a l i t c i t c i t c e f f r a l r a l r a l Table A2.4 Operator Messages...

- Page 93 APPENDIX 2 – MODBUS GUIDE… …A2.5 Operating Mode Modbus Coils > i t c i t c < i t c i t c e l i z i l z i l z i l z i l z i l z i l z i l z i l...

-

Page 94: Operating Mode Modbus Registers

…APPENDIX 2 – MODBUS GUIDE A2.6 Operating Mode Modbus Registers Tables A2.8 to A2.10 detail the contents of the Modbus registers o l f n i t accessible while the instrument is in the operating mode. – t i r –... - Page 95 APPENDIX 2 – MODBUS GUIDE… …A2.6 Operating Mode Modbus Registers , y l , y l , y l , y l o l f n i t – o l f n i t – z i l z i l z i l z i l z i l...

-

Page 96: A2.7 Comms Analog And Digital Inputs

APPENDIX 3 – STORAGE CAPACITY …APPENDIX 2 – MODBUS GUIDE A2.7 Comms Analog and Digital Inputs A3.1 Internal Storage Capacity t i r n i t t n i v i t i t c – ( Table A2.11 Modbus Inputs Table A3.1 Internal Storage Capacity... -

Page 97: Archive Storage Capacity

APPENDIX 3 – STORAGE CAPACITY… A3.2 Archive Storage Capacity Note. The times shown are for archiving of a single group. If two groups are archived, the durations must be halved. Table A3.2 External (Archive) Storage Capacity (Text Formatted Archive Files) - Page 98 …APPENDIX 3 – STORAGE CAPACITY Table A3.3 External (Archive) Storage Capacity (Binary Formatted Archive Files)

-

Page 99: Appendix 4 - Default Settings

Language English Message select False Global alarm Alarm acknowledge True acknowledge source None Max./min. reset False Instrument tag SM2000 Process View Time Process view enable Time format hhmmss View select Statistics Date format ddmmyy Menu enables Daylight saving Message select... -

Page 100: A4.1.4 I/O Modules

…APPENDIX 4 – DEFAULT SETTINGS …A4.1.3 Recording Channels A4.1.4 I/O Modules Analog Inputs (A1 to A6 and B1 to B6) Relay modules (all sources) Type Source None Electrical range (high) Polarity Positive Electrical range (low) Hybrid modules Engineering range (high) Digital outputs Engineering range (low) Source... -

Page 101: A4.2.2 Qsflow

APPENDIX 4 – DEFAULT SETTINGS… A4.2.2 QSFlow A4.2.7 QSDEMO As A4.2.1 QSMilliAmp, except: Operator messages Analog inputs Message source ID Engineering range (high) Message 1 Start of batch Engineering units Message 2 End of batch Totalizers Message 3 Standby mode active Count enable Message 4 Cleaning in progress... -

Page 102: A4.2.8 Qsdairy

…APPENDIX 4 – DEFAULT SETTINGS …A4.2.7 QSDEMO A4.2.8 QSDAIRY Digital channel Inputs Long tag Valve status Type Short tag Valve Linearizer type Pt100 °C On tag Open Linearizer units Off tag Close Engineering range (high) 90°C Alarms Engineering range (low) –10°C Alarm 1.1A type High process... -

Page 103: Appendix 5 - Spare Parts & Accessories

Floppy Disk Drive Adapter B11826 USB SmartMedia Card Reader B12027 USB Compact Flash Card Reader B12028 Parallel Port Compact Flash Card Reader B11827 Documentation Pack User Guide (this manual) IM/SM2000 Quick Reference Guide IM/SM2000–Q End User Licence Agreement IM/SM2000–L... - Page 104 …APPENDIX 5 – SPARE PARTS & ACCESSORIES 20-way Terminal Block for analog input modules GR2000/0726 for other modules GR2000/0727 8-way Terminal Block GR2000/0728 Instrument to Panel Seal PR100/0186 Terminal Compartment GR2000/0716 Removeable Media Options (in place of existing option, if fitted) for instruments manufactured before April 2002: Compact Flash upgrade pack GR2000/0700...

-

Page 105: Appendix 6 - Error & Diagnostics Information

APPENDIX 6 – ERROR & DIAGNOSTICS INFORMATION T " i n i n i t l i f u l i t l u " . " e i l , y l ? t i l l a l i f n i t . -

Page 106: Index

INDEX Advanced Configuration ........36, 43, 56 Bargraph Views ............... 10 Alarm Event Log .............. 17 Configuration ............. 53 Archiving ..............56 Basic Configuration ..........36, 43 Log Size ..............47 Binary Format Archive Files ..........32 Alarm View ..............16 Broken Sensor Direction .......... - Page 107 INDEX… Data Entry Dialog Boxes ..........41 High/Low Annunciate Alarms ........... 66 Date and Time ..............44 High/Low Latch Alarms ........... 65 Daylight Saving ............44, 45 High/Low Process Alarms ..........65 DataManager ............. 44 Historical Review Mode ............. 6 Digital Hybrid I/O Modules ............

- Page 108 …INDEX Parameters Tags Changing ............40 to 43 Alarm Tags ..............68 Passwords ............... 37, 46 Instrument ..............43 Power Supplies ............... 87 Long ................63 Predetermined Count ............72 Process Groups ............49 Preset Count ..............72 Short ................. 63 Primary/Secondary Totalizer ..............

- Page 109 SYMBOLS AND ICONS Process Group Name 28/03/00 Process Group 1 14:52:00 Status Icons Process Group 1 Configuration Historical Review Active Process Group 2 Configuration Archive media on-line (green icon – shaded area indicates % used) Channel 1.1 to 1.6 Configuration Archive media off-line Channel 2.1 to 2.6 Configuration (grey shaded area indicates % used)

- Page 110 – Food & Beverage – Manufacturing United Kingdom – Metals and Minerals – Oil, Gas & Petrochemical ABB Limited – Pulp and Paper Tel: +44 (0)1480 475 321 Fax: +44 (0)1480 470 787 Drives and Motors United States of America •...

- Page 111 ABB has Sales & Customer Support The Company’s policy is one of continuous product improvement and the right is reserved to modify the expertise in over 100 countries worldwide information contained herein without notice. www.abb.com Printed in UK (01.04) © ABB 2004 ABB Limited ABB Inc.