ABB SM2000 User Manual Supplement

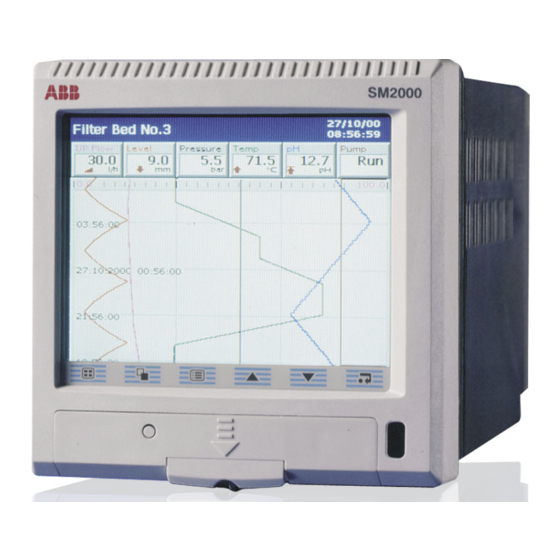

Advanced videographic recorder

Hide thumbs

Also See for SM2000:

- User manual (138 pages) ,

- User manual supplement (24 pages) ,

- Hardware installation (12 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

Advertisement

Table of Contents

Summary of Contents for ABB SM2000

- Page 1 Advanced Videographic Recorder User Guide Supplement – Advanced Software Options SM2000 IM/SM2000ADV_5...

- Page 2 Cert. No. Q05907 As a part of ABB, a world leader in process automation technology, we offer customers application expertise, service and support worldwide. EN 29001 (ISO 9001) We are committed to teamwork, high quality manufacturing, advanced technology and unrivalled service and support.

- Page 3 Math Block Description .......... 2 The instructions contained herein should be read in conjunction Typical Math Block ..........2 with the instrument User Guide (IM/SM2000 issue 2 or later). Operators ............... 2 Instruments with the optional math and logic equations Constants ..............

-

Page 4: Operators

2 MATH CONFIGURATION 2.1 Math Block Description 2.2 Typical Math Block – Fig. 2.1 Each math block comprises any number of sources, constants, Notes. operators and functions, to a maximum length of 40 characters, • Up to twelve Math Blocks, configured individually as indicated in Fig. - Page 5 2 MATH CONFIGURATION… 2.7 Functions – Table 2.4 2.5 Analog Sources – Table 2.2 Sources can be either analog or digital. All functions begin with an uppercase character to distinguish them from sources. Analog sources are identified within a math block by the preset mnemonic shown in Table 2.2.

- Page 6 …2 MATH CONFIGURATION 2.8 Creating Math Blocks – Figs. 2.2 and 2.3 Select math blocks 7 to 12 Math Blocks System Configuration Math 1 ---> Math2 Math3 Math4 Math5 Math6 Launches Math a1+52.4*Log(a2)-md2 Equation Common Process Group 1 Process Pad – see Fig 2.3 Configuration Group 1 Channels...

- Page 7 2 MATH CONFIGURATION… …2.8 Creating Math Blocks Math1 Select the Math Block to configure – M1 to M12 Math2 Math3 Math4 Math5 Math6 ---> a1+52.4*log(a2)-md2 Set the equation using the math pad – see Fig. 2.4 Equation Note. Digital sources must first be assigned to a valid digital signal –...

- Page 8 …2 MATH CONFIGURATION …2.8 Creating Math Blocks Maths Equations Source Id Analog I/P None Input Type 4.0 - 20.0 mA Analog i/p A1 Analog i/p A2 Engineering range 0 to 20000 Litres/sec Analog i/p A3 Short tag 8 Character Analog i/p A4 Analog i/p A5 Long tag 20 Characters...

- Page 9 2 MATH CONFIGURATION… …2.8 Creating Math Blocks Specify the display range and units of the engineering value -90 to 999.9 Engineering range corresponding to the electrical high and low values, within the limits defined below: – Maximum and minimum calculated values Example Engineering range function.

-

Page 10: Trigonometric Functions

…2 MATH CONFIGURATION 2.9 Standard Functions 2.9.3 Logarithmic Functions The following examples, using preset functions available on the The logarithmic functions Log(x), Ln(x) and e can be used to Math Pad, are included for easier reference. scale process inputs. 2.9.1 Trigonometric Functions –... - Page 11 2 MATH CONFIGURATION..2.9.4 Relative Humidity – Fig. 2.6 System Configuration Common Process Group 1 Process Configuration Group 1 Channels Group 2 Group 2 Functions Logic Channels Modules Equations Math Blocks Math1 Math2 Math3 Math4 Math5 Math6 ---> Equation Select the RH fuction Select the wet bulb source Maths Equations Source Id...

-

Page 12: Sterilization Fvalue Calculation

...2 MATH CONFIGURATION 2.9.5 Sterilization Fvalue Calculation – Fig. 2.8 It is important to note the large change in equivalent sterilizing The ability of heat to kill micro-organisms varies with the type of time which results from a small increase in the sterilizing organism and increases exponentially with rising temperature. - Page 13 2 MATH CONFIGURATION..2.9.5 Sterilization Fvalue Calculation – Fig 2.8 System Configuration Common Process Group 1 Process Configuration Group 1 Channels Group 2 Group 2 Functions Logic Channels Modules Equations Math Blocks Math1 Math2 Math3 Math4 Math5 Math6 ---> Equation Select the F0 function Select the temperature source Maths Equations...

-

Page 14: Switch Functions

...2 MATH CONFIGURATION 2.9.6 Switch Functions – Figs. 2.9 and 2.10 2.10 Application Examples 2.10.1 Liquid Flow – Fig. 2.12 Switch functions are used to select between the highest, lowest and median of three analog values. Liquid Flow is measured in two ways: a. - Page 15 2 MATH CONFIGURATION... …2.10.1 Liquid Flow – Fig. 2.12 Mass Flow Calculation – Average density correction The average density over a given temperature range is usd to Math1 Math2 Math2 Math3 Math4 Math5 Math6 ---> calculate the mass flow as follows: Equation Qma = Qc x Da, Reference...

-

Page 16: Ideal Gas Flow

...2 MATH CONFIGURATION …2.10.1 Liquid Flow – Fig. 2.12 2.10.2 Ideal Gas Flow Mass Flow – Derived density correction Gas flow is usually measured using a differential pressure device This method uses a preset table of temperature and density across orifice plates and wedges. values to define the correction, which is calculated as follows: Corrections can be applied to compensate for variations in Qmd = Qc x density correction... -

Page 17: Logic Configuration

3 LOGIC CONFIGURATION 3.1 Logic Equation Description 3.2 Worked Example – Reservoir Level Control – Fig. 3.1 Note. • 12 logic equations Note. This example uses an optional Hybrid I/O Module in position C – see Appendix 5. • Up to 6 operands and 5 operators per equation •... - Page 18 …3 LOGIC CONFIGURATION 3.3 Creating Logic Equations – Fig. 3.2 Select Logic Equations 7 to 12 System Configuration Group 1 Configuration Eqn 1 ---> Eqn2 Eqn3 Eqn4 Eqn5 Eqn6 Alarm State 1.1A and Operand/Operator 1 Common Process Group 1 Process Configuration Group 1 Channels...

-

Page 19: Diagnostics

4 DIAGNOSTICS 4.1 Introduction Note. Math blocks and logic equations can be tested for correct operation and monitored using the diagnostics facility in the Set Up level. For information on accessing the Set Up level, see Section 3 of the User Guide. Math block equation and result when the key was last... - Page 20 NOTES...

- Page 21 NOTES…...

- Page 22 …NOTES...

- Page 23 Service and Repair Centre. – Food & Beverage – Manufacturing United Kingdom – Metals and Minerals – Oil, Gas & Petrochemical ABB Limited – Pulp and Paper Tel: +44 (0)1480 475321 Fax: +44 (0)1480 217948 Drives and Motors United States of America •...

- Page 24 ABB has Sales & Customer Support The Company’s policy is one of continuous product improvement and the right is reserved to modify the expertise in over 100 countries worldwide information contained herein without notice. www.abb.com Printed in UK (07.05) © ABB 2005 ABB Limited ABB Inc.