Table of Contents

Summary of Contents for Toro 07411EX

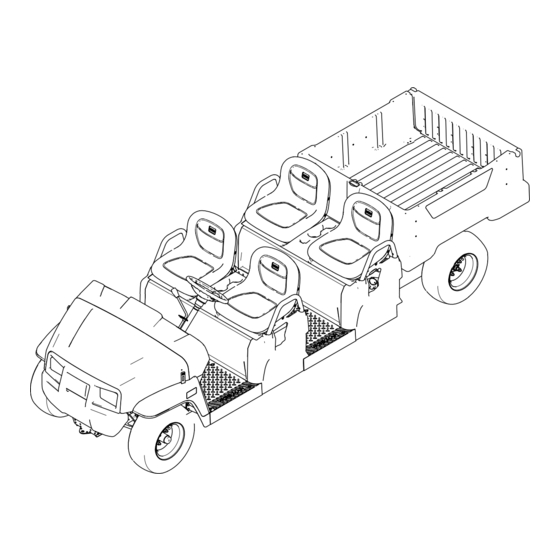

- Page 1 All manuals and user guides at all-guides.com Form No. 3438-278 Rev A Workman ® GTX EFI Utility Vehicle with Extended Chassis Model No. 07411EX—Serial No. 400000000 and Up *3438-278* A Register at www.Toro.com. Original Instructions (EN)

- Page 2 Whenever you need service, genuine Toro parts, or additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model and serial numbers of your product ready. Figure 1 © 2020—The Toro® Company Contact us at www.Toro.com.

-

Page 3: Table Of Contents

All manuals and user guides at all-guides.com Contents Servicing the Air Cleaner ........35 Servicing the Engine Oil........37 Servicing the Spark Plug........38 Safety ............... 4 Adjusting the High/Low Idle ......39 General Safety ........... 4 Fuel System Maintenance ........39 Safety and Instructional Decals ...... -

Page 4: Safety

All manuals and user guides at all-guides.com Safety This machine has been designed in accordance with the requirements of SAE J2258 (Nov 2016). General Safety This product is capable of causing personal injury. Always follow all safety instructions to avoid serious personal injury. -

Page 5: Safety And Instructional Decals

All manuals and user guides at all-guides.com Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. decal99-7345 99-7345 1. - Page 6 All manuals and user guides at all-guides.com 200 LBS 1500 LBS 91 KG 680 KG 137-9984 decal137-9984 137-9984 decal131-8463 131-8463 1. Do not exceed a tongue 2. Do not exceed a transport weight of 91 kg (200 lb). load of 680 kg (1,500 lb). 1.

- Page 7 All manuals and user guides at all-guides.com decal138-3528 138-3528 EFI Models Only 1. Read the Operator’s 5. Spark plug air gap Manual before performing maintenance. 2. Engine intake/air filter 6. Engine oil 3. Fuel filter 7. Transmission fluid 4. Spark plug 8.

-

Page 8: Setup

All manuals and user guides at all-guides.com Setup Loose Parts Use the chart below to verify that all parts have been shipped. Procedure Description Qty. Steering wheel Steering wheel cover Install the steering wheel (International models only). Washer (1/2 inch) Dust cover –... -

Page 9: Burnishing The Brakes

All manuals and user guides at all-guides.com Checking the Fluid Levels Reading the Manual and and Tire Pressure Viewing the Setup Material No Parts Required Parts needed for this procedure: Operator's Manual Procedure Engine owner's manual Check the engine-oil level before and after Registration card you first start the engine;... -

Page 10: Product Overview

All manuals and user guides at all-guides.com Product Overview Controls Become familiar with all the controls before you start the engine and operate the machine. Control Panel g033921 Figure 4 1. Steering wheel 6. USB power point 7. Parking-brake lever 2. - Page 11 All manuals and user guides at all-guides.com Key Switch Choke Control The key switch is located at the lower, right corner of The choke control is located on the control panel. Use the dash panel (Figure the choke to help start a cold engine by pulling the choke control outward (Figure 4).

- Page 12 All manuals and user guides at all-guides.com Light Switch Fuel Gauge The light switch is located to the left of the steering The fuel gauge (Figure 9) is located on the fuel tank column (Figure 8). Use the light switch to illuminate in the filler cap, at the left side of the machine.

-

Page 13: Specifications

High idle: 3,650 to 3,750 rpm Attachments/Accessories A selection of Toro approved attachments and accessories is available for use with the machine to enhance and expand its capabilities. Contact your Authorized Service Dealer or authorized Toro distributor or go to www.Toro.com for a list of all approved attachments and accessories. -

Page 14: Before Operation

Operation section (if applicable) in the Installation Instructions. Visit www.Toro.com for your instructions or scan the QR code (if applicable) on Performing Daily your attachment. -

Page 15: Adding Fuel

All manuals and user guides at all-guides.com Adding Fuel Recommended Fuel • For best results, use only clean, fresh (less than 30 days old), unleaded gasoline with a cetane rating of 87 or higher ((R+M)/2 rating method). • Ethanol: Gasoline with up to 10% ethanol (gasohol) or 15% MTBE (methyl tertiary butyl ether) by volume is acceptable. -

Page 16: During Operation

All manuals and user guides at all-guides.com • • A break-in oil for the engine is not required. Before you start the machine, ensure that the Original engine oil is the same type specified for transmission is in neutral, the parking brake is regular oil changes. - Page 17 Do not engage the • Use accessories and attachments approved by brakes suddenly when rolling rearward, as this The Toro® Company only. may cause the machine to overturn. Multi-Passenger Safety Loading and Dumping Safety •...

-

Page 18: Operating The Cargo Bed

All manuals and user guides at all-guides.com Operating the Cargo Bed Raising the Cargo Bed to the Dump Position WARNING A raised bed could fall and injure persons that are working beneath it. • Always use the prop rod to hold the bed up before working under the bed. - Page 19 All manuals and user guides at all-guides.com Raising the Cargo Bed to the Opening the Tailgate Service Position Ensure that the cargo bed is down and latched. Pull the lever on left, inside of the cargo bed Using both hands, raise the tailgate using the toward you and lift the cargo bed up (Figure 13).

-

Page 20: Using The Rear Cargo Bed Accessory Mount

All manuals and user guides at all-guides.com Closing the Tailgate Using the Rear Cargo Bed Accessory Mount If you unloaded loose material such as sand, landscaping rock, or wood chips from the cargo bed of the machine, some of the material that you unloaded Use the rear cargo bed accessory mount to attach may have lodged in the hinge area of the tailgate. -

Page 21: Loading The Cargo Bed

All manuals and user guides at all-guides.com Loading the Cargo Bed Material Density Maximum Cargo Bed Capacity (on level ground) Use the following guidelines when loading the cargo bed and operating the machine: Full Gravel, dry 1522 kg/m lb/ft • Observe the weight capacity of the machine and Gravel, wet 1922 kg/m... -

Page 22: Stopping The Machine

All manuals and user guides at all-guides.com After Operation Disengage the parking brake. Slowly step on the accelerator pedal. Note: After Operation Safety If the engine is cold, press and hold the accelerator pedal about half-way down, and pull the choke knob out to the O position. -

Page 23: Towing The Machine

The machine is capable of pulling trailers. A tow hitch 1. Rear tie-down points is available for the machine. Contact your authorized Toro distributor for details. When hauling cargo or towing a trailer, do not overload your machine or trailer. Overloading either... -

Page 24: Maintenance

Altering this machine in any manner may affect the operation of the machine, performance, durability, Maintenance Safety or its use may result in injury or death. Such use could void the product warranty of The Toro® • Do not allow untrained personnel to service the Company. -

Page 25: Recommended Maintenance Schedule(S)

• Complete all of the yearly maintenance procedures that are specified in the engine Yearly owner's manual. Note: Download a free copy of the electrical schematic by visiting www.Toro.com and searching for your machine from the Manuals link on the home page. Important: Refer to your engine owner’s manual for additional maintenance procedures. - Page 26 All manuals and user guides at all-guides.com WARNING Failing to properly maintain the machine could result in premature failure of machine systems, causing possible harm to you or bystanders. Keep the machine well maintained and in good working order as indicated in these instructions. CAUTION Only qualified and authorized personnel should maintain, repair, adjust, or inspect the machine.

-

Page 27: Daily Maintenance Checklist

All manuals and user guides at all-guides.com Daily Maintenance Checklist Duplicate this page for routine use. Maintenance Check Item For the week of: Monday Tuesday Wednesday Thursday Friday Saturday Sunday Check the brake and parking brake operation. Check the gear shift/neutral operation. -

Page 28: Pre-Maintenance Procedures

All manuals and user guides at all-guides.com Pre-Maintenance Procedures Preparing the Machine for Maintenance Park the machine on a level surface. Engage the parking brake. g034043 Shut off the engine and remove the key. Figure 21 Empty and raise the cargo bed; refer to Raising 1. -

Page 29: Accessing The Hood

All manuals and user guides at all-guides.com Accessing the Hood Raising the Hood Lift up the handle of the rubber latches on each side of the hood (Figure 23). g190066 Figure 24 Removing a Bucket Seat g034045 Figure 23 Push the seat assembly forward to the raised position (Figure 24). -

Page 30: Installing A Bucket Seat

All manuals and user guides at all-guides.com Installing a Bucket Seat Installing a Bench Cushion Slide the seat assembly onto the pins and lower the Slide the bench cushion onto the pins and lower the seat assembly (Figure 26). cushion (Figure 28). -

Page 31: Lubrication

All manuals and user guides at all-guides.com Lubrication Greasing the Front Wheel Bearings Greasing the Machine Service Interval: Every 300 hours Service Interval: Every 100 hours/Yearly (whichever Grease specification: Mobilgrease XHP™-222 comes first)—Grease the bearings and bushings. Grease the machine Removing the Hub and Rotor more frequently when using it for heavy-duty operations. - Page 32 All manuals and user guides at all-guides.com g192347 Figure 34 1. Spindle 2. Hub and rotor assembly g033047 Figure 32 Wipe clean the spindle with a rag. 1. Flange-head bolts (3/8 x 3. Caliper bracket (brake Repeat steps through to the hub and rotor at 3/4 inch) assembly) the other side of the machine.

- Page 33 All manuals and user guides at all-guides.com Installing the Hub and Rotor Greasing the Wheel Bearings Remove the outboard bearing and bearing race Apply a light coat of the specified grease to the from the hub (Figure 35). spindle (Figure 36).

- Page 34 All manuals and user guides at all-guides.com g192345 Figure 37 1. Cotter pin 3. Dust cap 2. Nut retainer Install the cotter pin and bend each legs around the retainer (Figure 37). Install the dust cap onto the hub (Figure 37).

-

Page 35: Engine Maintenance

All manuals and user guides at all-guides.com Engine Maintenance Engine Safety • Shut off the engine, remove the key, and wait for all moving parts to stop before checking the oil or adding oil to the crankcase. • Keep your hands, feet, face, clothing, and other body parts away from the muffler and other hot surfaces. - Page 36 All manuals and user guides at all-guides.com Replacing the Air-Cleaner Element Service Interval: Every 50 hours—Under special operating conditions (refer to Maintaining the Machine under Special Operating Conditions)—replace the air-cleaner element. Replace the air-cleaner element sooner if dirty or damaged. Every 100 hours—Under normal operating conditions—replace the air-cleaner element.

-

Page 37: Servicing The Engine Oil

All manuals and user guides at all-guides.com Servicing the Engine Oil Engine-Oil Specifications Crankcase Capacity: 1.0 L (1.1 US qt) Oil Type: API service class SJ or higher detergent oil Viscosity: See the table below. g192771 g034082 Figure 41 Figure 40 Checking the Engine-Oil Level Service Interval: Before each use or daily Note:... -

Page 38: Servicing The Spark Plug

All manuals and user guides at all-guides.com Changing the Engine Oil Servicing the Spark Plug Service Interval: After the first 5 hours—Change the Checking and Replacing the Spark engine oil. Plug Every 50 hours—Under special operating conditions (refer to Maintaining the Machine Service Interval: Every 100 hours/Yearly (whichever under Special Operating Conditions)—change comes first) Replace the spark plug... -

Page 39: Adjusting The High/Low Idle

All manuals and user guides at all-guides.com Fuel System Install the spark-plug wire. Repeat steps through for the other spark Maintenance plug. Adjusting the High/Low Idle Inspecting Fuel Lines and Connections Lift the cargo bed and secure it with the prop rod. At the throttle cable housing, loosen the forward Service Interval: Every 400 hours/Yearly (whichever jam nut and tighten the rear jam nut to increase... -

Page 40: Replacing The Fuel Filter

All manuals and user guides at all-guides.com Replacing the Fuel Filter Servicing the Carbon Canister Service Interval: Every 400 hours/Yearly (whichever comes first) Park the machine on a level surface. Checking the Air Filter for the Engage the parking brake. Carbon Canister Shut off the engine and remove the key. -

Page 41: Electrical System Maintenance

All manuals and user guides at all-guides.com Disconnecting the Battery Electrical System Maintenance WARNING Incorrect battery cable routing could damage the machine and cables, causing sparks. Electrical System Safety Sparks can cause the battery gasses to • Disconnect the battery before repairing the explode, resulting in personal injury. - Page 42 All manuals and user guides at all-guides.com Removing the Battery Installing the Battery Disconnect the battery cables; refer to Install the battery as shown in Figure Disconnecting the Battery (page 41). Remove the battery as shown in Figure g034327 Figure 49 g034326 Connect the battery cables;...

-

Page 43: Replacing The Fuses

All manuals and user guides at all-guides.com Replacing the Fuses Connecting the Battery Connect the battery as shown in Figure There are 5 fuses in the electrical system; the other slots are open for options. They are located beneath the seat assembly (Figure 51). -

Page 44: Maintaining The Headlights

All manuals and user guides at all-guides.com Maintaining the Headlights Secure the headlight assembly with the speed clips that you removed in step 4. Connect the electrical connector for the harness Replacing the Headlight to the connector of the lamp assembly (Figure Specification: See your Parts Catalog. -

Page 45: Drive System Maintenance

All manuals and user guides at all-guides.com Drive System Maintenance Maintaining the Tires Service Interval: Every 100 hours—Check the condition of the tires and rims. Every 100 hours—Torque the wheel-lug nuts. Inspect the tires and rims for signs of wear and damage. -

Page 46: Adjusting The Front Wheel Alignment

2. Tire center line—front Adjusting the Camber If the measurement does not fall within 0 to Owner provided tools: spanner wrench, Toro Part 6 mm (0 to 1/4 inch), loosen the jam nuts at the No. 132-5069; refer to your Authorized Service... -

Page 47: Checking The Transaxle-Fluid Level

All manuals and user guides at all-guides.com Checking the Changing the Transaxle Transaxle-Fluid Level Fluid Service Interval: Every 100 hours Service Interval: Every 800 hours/Yearly (whichever comes first) Fluid Type: SAE 80W-90 (API MT-1) or SAE 80W-90 (API GL-5) Fluid Type: SAE 80W-90 (API MT-1) or SAE 80W-90 (API GL-5) Park the machine on a level surface. -

Page 48: Checking The Neutral Gear-Shift Position

All manuals and user guides at all-guides.com Adjusting the Neutral Checking the Neutral Gear-Shift Position Gear-Shift Position Loosen the jam nuts on the gear-shift cable and Service Interval: Every 100 hours adjust them as necessary (Figure 60). When performing routine maintenance and/or engine diagnostics, shift the transaxle into N . -

Page 49: Maintaining The Primary Drive Clutch

All manuals and user guides at all-guides.com Maintaining the Primary Reducing the Top Speed Drive Clutch CAUTION Service Interval: Every 400 hours/Yearly (whichever The dust in the clutch will become airborne comes first) and could damage your eyes or you could inhale it, causing breathing difficulties. -

Page 50: Cooling System Maintenance

All manuals and user guides at all-guides.com Cooling System Important: Ensure that the X is placed back in the original location. Maintenance Torque the bolts to 179 to 228 N∙m (132 to 168 in-lb). Cooling System Safety • Swallowing engine coolant can cause poisoning; keep out of reach from children and pets. -

Page 51: Brake Maintenance

All manuals and user guides at all-guides.com Brake Maintenance Verify that the parking brake is adjusted to the proper tension; refer to Checking the Parking Brake (page 51). Checking the Parking Brake Note: If you cannot adjust the parking brake to the required tension, the brake pads may Engage the parking brake by pulling the be worn and need to be replace. -

Page 52: Inspecting The Brakes

Figure 65 Service Interval: Every 1,000 hours 1. Brake-fluid reservoir 2. Minimum line Contact your authorized Toro distributor. If the fluid level is low, perform the following: Clean the area around the reservoir cap and remove the cap (Figure 64). -

Page 53: Belt Maintenance

All manuals and user guides at all-guides.com Belt Maintenance Replacing the Drive Belt Raise the cargo bed; refer to Raising the Cargo Bed to the Dump Position (page 18). Servicing the Drive Belt Shift the transmission into the N position, EUTRAL engage the parking brake, rotate the key switch Checking the Drive Belt... -

Page 54: Chassis Maintenance

All manuals and user guides at all-guides.com Chassis Maintenance Cleaning Adjusting the Cargo-Bed Washing the Machine Latches Service Interval: Before each use or daily—Wash the machine. If the cargo-bed latch is out of adjustment, the cargo Wash the machine as needed using water alone bed vibrates up and down as you drive the machine. -

Page 55: Storage

Change the engine oil; refer to Servicing the Paint all scratched or bare metal surfaces Engine Oil (page 37). with paint available from your authorized Toro Check the tire pressure; refer to Checking the distributor. Tire Pressure (page 14). - Page 56 All manuals and user guides at all-guides.com Notes:...

- Page 57 While the exposure from Toro products may be negligible or well within the “no significant risk” range, out of an abundance of caution, Toro has elected to provide the Prop 65 warnings. Moreover, if Toro does not provide these warnings, it could be sued by the State of California or by private parties seeking to enforce Prop 65 and subject to substantial penalties.

- Page 58 The Toro Company (“Toro”) respects your privacy. When you purchase our products, we may collect certain personal information about you, either directly from you or through your local Toro company or dealer. Toro uses this information to fulfil contractual obligations - such as to register your warranty, process your warranty claim or to contact you in the event of a product recall - and for legitimate business purposes - such as to gauge customer satisfaction, improve our products or provide you with product information which may be of interest.

- Page 59 Countries Other than the United States or Canada Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor's service or have difficulty obtaining guarantee information, contact your Authorized Toro Service Center.

- Page 60 All manuals and user guides at all-guides.com...