Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for AnyCubic VYPER

- Page 2 Thank you for choosing ANYCUBIC products. Maybe you are familiar with 3D printing technology or have purchased ANYCUBIC printers before, but we still highly recommend that you read this manual carefully. The installation techniques and precautions in this manual can help you avoid any unnecessary damage or frustration.

- Page 3 Contents Safety Instructions Technical Specification Packing List Product Overview Menu Directory Installation Leveling Loading Filament Printing Models Introduction to Slicing Software Resume from Outage Maintenance Troubleshooting...

- Page 4 It is recommended to use protection glasses when cleaning/sanding the printed models to avoid small particles in eyes. Keep the ANYCUBIC 3D printer and its accessories out of the reach of children. Vapors or fumes may be irritating at operating temperature.

- Page 5 Technical Specification Printing Technology FDM (Fused Deposition Modeling) Build Size 245 mm(L) × 245 mm(W) × 260 mm(H) Print Accuracy ±0.1 mm Positioning Accuracy X / Y / Z 0.0125 / 0.0125 / 0.002 mm Extruder Quantity Single Nozzle Diameter 0.4 mm...

- Page 6 Technical Specification Electrical Power Input 110 V / 220 V AC, 50 / 60 Hz Output rating 24V/14.6A (350W) Physical Dimensions Printer Dimensions 508 mm(L) × 457 mm(W) × 516 mm(H) Net Weight ~10 kg...

- Page 7 Packing List Washers (4PCS) Frame Base M5 x 45 Screws (4PCS) M5 x 14 Screw (1PCS) Touchscreen Filament Holder Nozzle M5 x 6 Screws (2PCS) Power Cord Data Cable Card Reader Memory Card Assembly Filament (Random Instruction Color) Tips: Some accessories are placed in the toolbox on the right front of the machine base (see the position of toolbox on the next page).

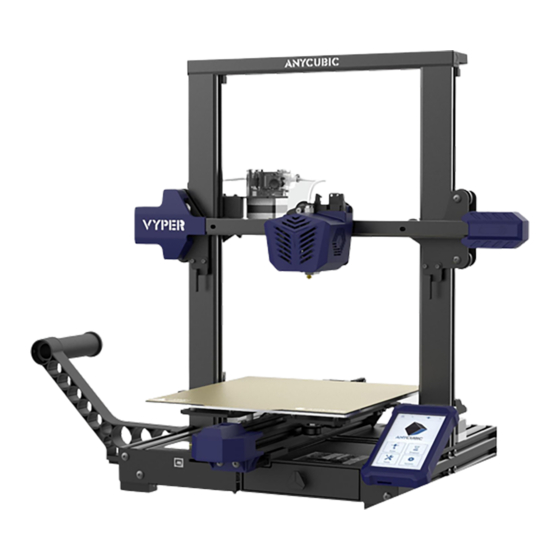

- Page 8 Product Overview Front view Aluminum beam Teflon feeding tube Print head Printing platform Filament holder Touchscreen Data cable port Toolbox Memory card slot Y belt tensioner Back view Extruder Lead screw Filament sensor X belt tensioner X motor Extrude...

- Page 9 Menu Directory Main menu...

- Page 10 Menu Directory Print File List: Return to main menu File list Refresh the list Page up Page down Print the selected file in memory card Resume form outage (only valid for offline print via memory card) Prepare Leveling: Click to level the...

- Page 11 Menu Directory Preheat: Display current / Display current / target temp of nozzle target temp of bed Click to preheat PLA Click to preheat PLA Filament: Display current / 23/230 target temp of Click to automatically heat extrusion the print head to target temp,...

- Page 12 Menu Directory Tools Move Axis: Set the step distance of motor Move the platform forward Move the print head up Move print head to the Move print head to the left right Move the platform Move the print head down...

- Page 13 Menu Directory Speed: Click to set fan speed(0-100%) Increase fan speed Decrease fan speed Click to set print rate(0-100%) Increase print rate Decrease print rate Light: Turn on/off the light of the print head Motor: Disable all motors (only valid when machine is not printing).

- Page 14 The aluminum beam has slight scratches or slight unevenness on the platform, which is normal if it does not affect normal printing. Thank you very much for your kind understanding. Team ANYCUBIC...

- Page 15 Installation * Take tools from the toolbox on the front right side of the machine base for assembly. 1. Install frame. Z aluminum beams must align with the groove of the base aluminum beam. Washer M5*45 screw...

- Page 16 Installation 2. Install touchscreen. M5*14 screw X M5*6 screw X 3. Install the filament holder.

- Page 17 Installation 4. Insert the teflon tubing into the extruder.

- Page 18 Installation 5. Wiring: connect all these wires to their corresponding ports by the label respectively. 2. Screen wires 1. Print head wires 3. Extruder/X motor wires 4. Right Z limit switch 6. Left Z limit switch 5. Right Z motor...

- Page 19 Installation 6. Use zip ties to fasten the print head wire harness and the Teflon tube.

- Page 20 Installation Check before using 1. Make sure that the 4 zip ties shown below have been cut off before operating the machine. 2. D-shape wheels of the base may be loosened due to transportation, please check it after unpacking.

- Page 21 Installation ② Tighten the hexagonal pillar clockwise with a 10mm open end wrench. ① Fix the nut with a hex key.

- Page 22 Once leveled, it is not necessary to level every time before each printing. Vyper supports auto-leveling, which is easy to level the platform. * Before leveling, please ensure that the platform and nozzle are clean and free of foreign matters to avoid affecting the leveling effect.

- Page 23 Leveling 2. Return to main menu, then click Prepare → Leveling → Auto-leveling. The confirm interface will pop up, click “OK” and the print head will automatically probe the spots on the platform. * The print head will heat up before probing the platform. Please do not...

- Page 24 Loading Filament 1. Return to main menu, click Prepare → Filament → Filament In, and the heating up interface will pop up, click “OK”. 23/230 2. Straighten the end of filament, and place the filament on the filament holder (Please note the feeding direction of filament). Then pass the filament through filament sensor, and insert it to the extruder till the gear.

- Page 25 Loading Filament Insert the filament into the extruder till the gear. 3. When the nozzle reaches to the target temperature, click “Filament In” again. The filament would be automatically fed in by the extruder and it would be melted through the nozzle. Now, click “Stop”. You may use...

- Page 26 Loading Filament Note: During feeding, if the melted filament is not smooth or too thin, please adjust the extrusion force by rotating the knob as shown below. If the melted filament is If the melted filament is not smooth, please...

- Page 27 Printing Models After the leveling and filament feeding are completed, the printing can be started. A printable file "owl.gcode" has been preloaded in the memory card and the users can print it directly. * In order to let the printer better recognize the GCode file in the memory card, you need to back up all the files in the memory card to the computer, and keep the memory card only for the GCode files.

- Page 28 Printing Models * Before printing, the nozzle only start to heat up after the heated bed reaches the target temperature. After the nozzle and heated bed are heated to the target temperature, the printer will start printing. 2. There might be three kinds of results for the first or second layer of the test print: ①...

- Page 29 Printing Models The printing effect ① and ③ can be improved by adjust Z-offset during printing. ( * In most cases, there is no need to adjust Z-offset after auto-leveling.) How to adjust the Z-offset: Click Settings on printing status interface, then click “+” or “—” of the Z- offset to adjust the distance between nozzle and printing platform and observe the printing effect.

- Page 30 Printing Models Please adjust the Z-offset patiently until the effect likes ②. If the printing effect is still not good after multiple adjustments, please stop printing and level the platform again. The nozzle and heated bed are still at a high temperature when printing is finished.

- Page 31 Introduction to slicing software 3D printer reads GCode file and prints. It is necessary to convert 3D files (such as stl file) into GCode files for machine to recognize. Software that convert 3D files into GCode files is called slicing software.

- Page 32 Introduction to slicing software ③ ④ ⑤ ⑥ * Printing online requires the installation of a driver, as shown below. If you don't print online, you don't need to install it.

- Page 33 Introduction to slicing software 2. Machine Settings Upon completion of installation, the first launch of the software will display the following welcome screen. Click Get started to start the machine settings. ① ②...

- Page 34 Introduction to slicing software ③ ④ ⑤ ⑥ According to the wizard, we have selected the Anycubic i3 Mega printer. Now, we will set the parameters of Vyper based on the printer.

- Page 35 Introduction to slicing software (1) Click Anycubic i3 Mega → Manage printers on the top left corner, and rename the printer to Anycubic Vyper. (2) In the same interface opened in Step (1), click Machine Settings and set the X (Widch) / Y (Depth) / Z (Height) parameters of printer as 250,...

- Page 36 3. Import the Configuration File After continuous testing, we provided users the suggested printing parameters of different filaments for Vyper, and the user could directly import the parameter files to the software. (1) Click Settings → Configure setting visibility..., and then tick Check all...

- Page 37 (2) In the same interface opened in Step (1), click Profiles on the left side. Then click Import button to import the desired print profile. * Choose different parameter profiles according to different filament types. * Profile path: Memory card → "Files _ English _Vyper" → “Suggested parameters for Vyper”...

- Page 38 Introduction to slicing software (3) Select the profile that you just imported, and then click the Activate button。 * Note: An interface may pop up after clicking the Activate button. If so, please check the values of listed parameters. You can click Keep to keep...

- Page 39 Introduction to slicing software Supplementary Explanation ① You can customize some parameters after importing the profile, but we still recommend that you use the parameters in the profile that we provide. ② The paremeter Build Plate Adhesion → Build Plate Adhesion Type...

- Page 40 Introduction to slicing software 4. Manipulate 3D model in Cura * Model files can be downloaded from www.anycubic.com (ANYCUBIC website) and www.thingiverse.com. (1) Click the open file button in the top left corner to import the model file or directly drag the file into the software.

- Page 41 Introduction to slicing software Other operations: Press the mouse wheel and move the mouse to move the platform. ① Scroll the mouse wheel to zoom in and out the platform. ② Right click and move the mouse to change the viewing angle.

- Page 42 Introduction to slicing software Use the layer slider and simulation view to check important parts of your 3D slice. Layer Slider...

- Page 43 Introduction to slicing software 6. Print offline and online There are two operational modes for Vyper: print offline and print online. • Print offline: Insert memory card into the memory card slot, click on the Home Menu “Print” to enter the file list, and print a selected file (GCode files ONLY).

- Page 44 “Device manager”, if there is an exclamation mark as shown below, then it needs to be installed manually. * Vyper uses CH340 chip for communication. * CH340 driver file path: “Files_English_Vyper” → “Driver_CH341”. There are two versions, Windows and Mac version. (* CH341 driver file is suitable for CH340 chip).

- Page 45 Introduction to slicing software (2) Here we take Windows PC system for example. Double click “CH341SerSetup.exe” and follow the wizard to install it. If the driver has installed automatically in step (1), skip this step. * After the installation is completed, refer to the method in step (1) to see if the driver has been identified (no exclamation mark).

- Page 46 Resume from Outage In case of a power loss during printing, the machine will automatically save the printing status. After restarting, you will see the interface shown below, please click "Continue" to continue your printing or “Cancel” to cancel it.

- Page 47 Maintenance It is necessary to perform routine maintenance to the 3D printer to achieve consistent and quality results. Some maintenance suggestions are shown as below: 1. Clean the nozzle with a needle under preheating conditions. If the filament residue in the nozzle could not be cleared 100%, please replace the nozzle.

- Page 48 Troubleshooting 1. Motor shaking or abnormal sound The corresponding limit switch could not be triggered when home. ① Please check the wirings, and inspect any obstacles by manually moving the corresponding axis. The motor cable are not connected properly. Please Check each ②...

- Page 49 Troubleshooting Nozzle clogged. Please try to briefly heat the print head to a ③ temperature higher than 230°C and manually push the filament into the extruder. You can also clean it with 0.4mm nozzle cleaning needle. If it doesn’t work, you may need to replace it.

- Page 50 Troubleshooting 7. Freezing screen Please check if the soft cable above the screen is loose. ① Inspect if the touchscreen has been pressed by something. ② Check if screen has cracks, if so, please contact our after sale service ③...

- Page 51 Click “Settings” → “Z offset -” to lower the nozzle. Thank you for purchasing ANYCUBIC products! Under normal usage and service, the products and its parts have a warranty period up to one year. Please visit ANYCUBIC official website (https://www.anycubic.com) for more details and report any issues with ANYCUBIC products.

Need help?

Do you have a question about the VYPER and is the answer not in the manual?

Questions and answers