Zenith HydroTap G4 Installation Instructions Manual

Filtered boiling and chilled drinking water for residential use

Hide thumbs

Also See for HydroTap G4:

- User manual (29 pages) ,

- Installation and operating instructions manual (28 pages) ,

- Installation instructions manual (20 pages)

Table of Contents

Summary of Contents for Zenith HydroTap G4

- Page 1 Installation Instructions HydroTap G4 ® Filtered boiling and chilled drinking water for residential use. Affix Model Number Label Here 802253NZ 802253NZ - HydroTap BC, BCHA -AV, AIO, Installation Instructions - Aug 2015 - V2.01 Page 1 of 36...

-

Page 2: Table Of Contents

Index HydroTap Specifications Installation check list ........................3 General Product Features ......................4 Important Safety Instructions ....................... 5 Warnings and Regulatory Information ..................6 Major components and Accessories .................... 7 Technical Specification ........................ 8 Before Installation and site requirements ..................9 Installation Instructions STEP 1 - Measure and cut all the tap holes before fitting the taps... -

Page 3: Installation Checklist

Installation checklist Before Installation: Read the instructions and check if there is adequate space to mount all of the components. Note: Not all fittings are supplied with the appliance kit. Isolation valves are not supplied. Check the mains water pressure is between 172 - 700kPa and 200 - 700kPa when a booster and /or filter softener is fitted Check the water quality to determine if extra filtration will be required. -

Page 4: General Product Features

Disabled use. The disabled levers are supplied with Braille caps for the visually impaired. Usage: The Zenith HydroTap is intended for use in residential household and similar applications such as, Rural and urban residential Kitchens, Hotels, Motels, Bed and Breakfast and other residential type environments. -

Page 5: Important Safety Instructions

Lifting Take care when lifting the Zenith HydroTap unit. Some units may exceed safe lifting limits. If you feel this is beyond your personal capabilities, please seek assistance with the lift. The weights of the units are marked on the packaging. -

Page 6: Warnings And Regulatory Information

See section 1 for details. WARNINGS The Zenith HydroTap unit must be earthed. The resistance of the earth connection from each exposed metal part must be less than 1 ohm. All Installation and service work must be completed by trained and suitably qualified Tradespeople. -

Page 7: Major Components And Accessories

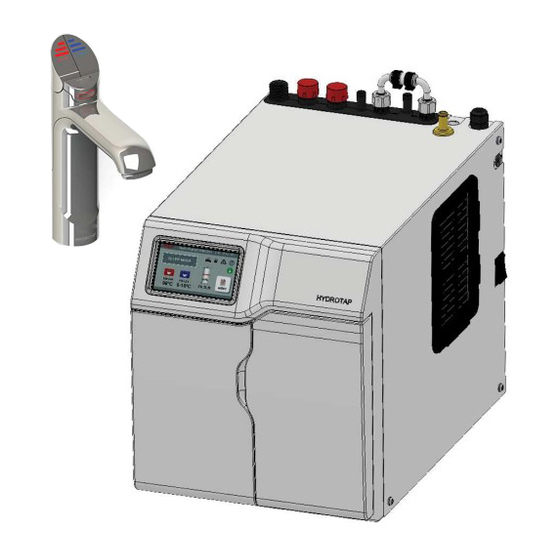

Major components and accessories Parts supplied Description Accessories Description 1 x Tap option with hoses HydroTap Booster Water System with (Classic tap shown) connection hoses 1 x HydroTap Undersink Unit with Font Kit for air and water filters Arc & Cube Models 1 x Mains water connection hose Font Kit for Classic &... -

Page 8: Technical Specification

Technical Specifications Models Boiling and Chilled BCHA 4 in 1 All in One - Mains All in One - Vented Disabled lever controls (optional accessory) GPO's Power Boost Unit Dimensions **Dry Required Rating Rating W x D x H (mm) Weight (kW) (kW) -

Page 9: Before Installation And Site Requirements

• For BC HydroTaps & BCHA-A (Mains) models, a 220-240Vac, 10A GPO will be required. For BCHA 4-In-1 & BCHA-AV (Vented) models, two 220-240Vac, 10A GPOs will be required. (One GPO is for the Zenith HydroTap and the other for the Booster heater). Note: Check all cable and hose lengths against inlet /outlet positions before pro- ceeding (See section 4 for general layout). -

Page 10: Section 1 - Tap Installation Instructions 1.1 - Hydrotap Tap Classic & Elite Tap Installations

Position the tap such that it dispenses into the sink bowl with ample clearance for a cup or tea pot. Alternatively, the tap could be mounted away from the sink using a Zenith Font, available as an accessory. Recommended dispensing distance **... -

Page 11: Installation Instructions

HydroTap & Elite Installation EliteTap HydroTap Classic ALL THREAD STAINLESS STEEL BLACK PLASTIC SPACER SPACER SPIDER CLAMP 470mm Tap assembly exploded view and kitchen layout side view. BENCH TOP Ø35mm Apply a light smearing of silicon sealant on the underside of the spacer to ensure a watertight fit. Cut a 35mm hole in the bench / sink top. -

Page 12: Installation Instructions

Installation Instructions BLACK PLASTIC STAINLESS SPACER STEEL WASHER Fit the STAINLESS STEEL WASHER, SPIDER CLAMP SPIDER CLAMP, AND 6mm NUT. 6mm NUT 35mm hole Note: feed each of the three tubes and electrical cable evenly in between the legs of Pass all the hoses, tubes and USB lead the SPIDER CLAMP when installing. -

Page 13: Hydrotap Arc/Cube Tap Installations

HydroTap Arc/Cube The HydroTap Arc/Cube has a spout that may be fixed in one of 6 angular positions (depending on the position of the rotary control) and fixed in one of two height positions. The spout is fixed and does not swivel. NOTE: The tube kit must be fitted after the HydroTap has been mounted on the benchtop or sink. -

Page 14: Installation Instructions

Installation Instructions Height adjustment (Fixed position options) 50mm Angular adjustment (Fixed position options) Left Hand Control Right Hand Control NOTE: Position A is not recommended with Boiling water units Mounting (See table on Page 10 ) O-RING BENCH TOP LOWER Ø35mm RUBBER WASHER... -

Page 15: Mixer Tap Installation

Blue Band Red band Mixer Out Note: External The mixer tap requires a Zenith Restrictafl ow Mains valve, as supplied, to be fi tted in the cold water supply line, from the isolation valve tee Blue band Mixer IN piece, to the mixer tap. -

Page 16: Installation Instructions

Installation Instructions 1.12 Installing the Mixer Tap (Classic, Arc and Cube) • Fit the O-ring into the recess on the underside of the Mixer tap. (Note: If mounting on an uneven surface, a light smear of silicone on the O-ring will ensure a water tight seal) •... -

Page 17: Installation Instructions

Installation Instructions 1.13 Typical 4-In-1 Installation (see section 4) Booster Note: All HT Mixer silicon tubes connections must be cut to size. They must have a constant fall back to the unit. BOILING POWER MIXER BYPASS VENT BYPASS MAINS MIXER CORD CHILLED Note:... -

Page 18: All-In-One Tap With Mains And Vented Installation

All-In-One Tap Installation 1.14 470mm 1.15 SINK TOP 50mm Cut a 50mm hole in the bench / sink top. Note: make sure the tap location will allow the nozzle to drain into the sink. (See Page 11) Installation Procedure • Fit the seal ring to the base of the tap and If mounting on an uneven surface, apply a light smear of silicone sealant to ensure a watertight seal •... -

Page 19: Installation Instructions

Installation Instructions 1.16 Clamp Block markings and silicon tube positions, viewed from underneath BLUE mark WHITE mark BLUE mark RED mark SILICON TUBES USB CABLE AIO Vented assy AIO Mains assy CLAMP BLOCK O-RING 1.17 Mains IN To Mixer From HWS Mains IN FIXING NUT connection... -

Page 20: Installation Instructions

Installation Instructions Typical Vented assembly Vented braided hose positions 1.18 WHITE Mains IN • Screw the braided hoses into the extension tubes. Ensure the o-rings CLAMP RED from are lubricated prior to BLOCK Mixer OUT assembly and that the BLUE to braided hoses, with Mixer IN coloured markings,... -

Page 21: Installation Instructions

Restrictaflow valve Note: The All-In-One vented taps require a Zenith Restrictafl ow valve and Tee piece, as supplied, to be fi tted in the cold water supply line, from the isolation valve (Not supplied), to the mixer tap. (See diagrams) 802253NZ - HydroTap BC, BCHA -AV, AIO, Installation Instructions - Aug 2015 - V2.01... -

Page 22: Section 2- Ventilation

Section 2 Ventilation Ventilation for All Models Proper air circulation must be provided for all Boiling and Chilled models. The system will operate correctly only if the recommended air gaps are achieved during Installation. The minimum requirement is for a 50mm air gap either side and 300mm above of the undersink unit. - Page 23 Ventilation When installing air flow ducts, the following tools will be required: • Jigsaw and 12mm Drill • Keyhole or Wall Board saw. The following instructions are critical if there is insufficient cupboard air circulation. If the air flow, using the silicon door buffers, is insufficient, it will be necessary to fit a standard HydroTap vent kit, which ensures heat dissipation through natural convection via installed vents.

-

Page 24: Installation Instructions

Ventilation Typical Cut out procedure for Mark out and cut the air inlet and door outlet holes as shown Ensure the air inlet vent and air outlet vent are positioned at opposite ends of the same cupboard space. Fit the inlet vent, as shown and secure with 5 screws If required, fit the outlet vent, as shown in the hottest part (top) of the cupboard and secure with 4 screws Air inlet vent... -

Page 25: Section 3 - Booster Heater Installation 3.1- Booster Heater Specifications And Installation

It is intended to provide pre heating of water before it enters the Zenith HydroTap G4 boiling tank. The Booster is supplied as standard equipment with all 4-In-1 & BCHA-AV models. However, it may be later installed, as an accessory to increase boiling water delivery. -

Page 26: Installation Instructions

Booster Installation Installation Procedure Site requirements • Appliance must only be installed in a frost-free area. Never expose appliance to frost. • The Appliance is designed for wall mounted Installation and must to be installed with water connectors facing upwards. •... -

Page 27: Installation Instructions

NOTE1: This appliance is intended for use with the Zenith HydroTap under sink unit. NOTE2: Water connections must be pointing vertically upwards. NOTE3: The booster unit should be installed as close as possible to the Zenith HydroTap Unit as the 400mm connection hoses cannot be lengthened. Braided hose connections The cold water inlet (blue) and hot water outlet (red) are marked on the rating plate. -

Page 28: Section 4 - Undersink Unit Installation

The diverter bypass valve allows the user to choose to have the boiling water filtered either by the internal or by an optional external filter.This diverter valve is located at the rear panel of the Zenith HydroTap undersink unit on the filter door side, see the image below. -

Page 29: Model Bc 160/125 And Bc 160/175

Installation Instructions Model: Boiling Chilled Note: All silicon tubes must be cut to size. They must have a constant fall back to the unit. BOILING BYPASS VENT BYPASS POWER MAINS MIXER MIXER CORD CHILLED Note: - Mains hose length is 750mm - Plug and Cord length is 1800mm Max. -

Page 30: Model Aio Mains

Installation Instructions Model: All-In-One Mains Pressure Note: All silicon tubes must be cut to size. They must have a constant fall back to the unit. BOILING POWER BYPASS VENT BYPASS MAINS MIXER MIXER CORD CHILLED Note: - Mains hose length is 750mm - Plug and Cord length is 1800mm Position the under... -

Page 31: Model Aio Vented

Installation Instructions Model: All-In-One Vented Booster HT Mixer Note: All connections silicon tubes must be cut to size. They must have a constant fall back to the unit. BOILING POWER MIXER BYPASS VENT BYPASS MAINS MIXER CORD CHILLED Note: - Mains hose length is 750mm - Plug and Cord length is 1800mm... -

Page 32: Model 4-In-1 Vented

Installation Instructions Model: 4-In-One Vented Booster Note: All HT Mixer silicon tubes connections must be cut to size. They must have a constant fall back to the unit. BOILING BYPASS VENT BYPASS POWER MAINS MIXER MIXER CORD CHILLED Note: - Mains hose length is 750mm - Plug and Cord length is 1800mm... -

Page 33: Section 5 - Commissioning

Section 5 Commissioning • Turn ON the water and check for any leaks. • Turn the power ON at the GPO and at the side of the undersink unit • If fitted, ensure the Booster is turned OFF. (The Booster is commissioned, later, at section 5.4) •... -

Page 34: Boiling Calibration

Commissioning Boiling Calibration • Press the calibration button and the system will commence the Boiling calibration procedure. This will take aprox 5-6 minutes. Booster • Upon completion, a Booster reminder screen will appear and allow you to return home by pressing the [Home] button. -

Page 35: Trouble Shooting

Internal fault Call Zenith Service Call an electrician, a plumber, or Zenith for a free call on 0800 558055 for assistance, service, spare parts or enquiries. 802253NZ - HydroTap BC, BCHA -AV, AIO, Installation Instructions - Aug 2015 - V2.01... -

Page 36: End Of Life Disposal

The standard cup referred to in this publication is 167 ml (6 fl oz). The standard glass is 200 ml (7 fl oz). The terms “Zenith” and “HydroTap” are registered trade marks of Zip Heaters (Aust) Pty Ltd. Zenith products described in this publication are manufactured under one or more of the following patents: AU675601, AU637412, AU635979, GB0422305, GB2065848, US4354049, US5103859, US5099825 and SA2006/08043.