Summary of Contents for Miller Dialarc 250 AC/DC

- Page 1 OM-321 202730R 2016−09 Processes Stick (SMAW) Welding Description Arc Welding Power Source Dialarc 250/250P AC/DC For product information, File: Stick (SMAW) Owner’s Manual translations, and more, visit www.MillerWelds.com...

- Page 2 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING ........1-1. -

Page 5: Section 1 − Safety Precautions - Read Before Using

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING som 2015−09 Protect yourself and others from injury — read, follow, and save these important safety precautions and operating instructions. 1-1. Symbol Usage DANGER! − Indicates a hazardous situation which, if Indicates special instructions. - Page 6 D Remove stick electrode from holder or cut off welding wire at FUMES AND GASES can be hazardous. contact tip when not in use. D Wear body protection made from durable, flame−resistant material Welding produces fumes and gases. Breathing (leather, heavy cotton, wool). Body protection includes oil-free these fumes and gases can be hazardous to your clothing such as leather gloves, heavy shirt, cuffless trousers, high health.

-

Page 7: Additional Symbols For Installation, Operation, And Maintenance

1-3. Additional Symbols For Installation, Operation, And Maintenance FIRE OR EXPLOSION hazard. MOVING PARTS can injure. D Do not install or place unit on, over, or near D Keep away from moving parts such as fans. combustible surfaces. D Keep all doors, panels, covers, and guards D Do not install unit near flammables. -

Page 8: California Proposition 65 Warnings

1-4. California Proposition 65 Warnings Welding or cutting equipment produces fumes or gases This product contains chemicals, including lead, known to which contain chemicals known to the State of California to the state of California to cause cancer, birth defects, or other cause birth defects and, in some cases, cancer. -

Page 9: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION fre_som_2015−09 Pour écarter les risques de blessure pour vous−même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives aux précautions de sécurité et au mode opératoire. 2-1. - Page 10 chauffement ou un incendie. Avant de commencer le soudage, vérifier LES PIÈCES CHAUDES peuvent et s’assurer que l’endroit ne présente pas de danger. provoquer des brûlures. D Déplacer toutes les substances inflammables à une distance de D Ne pas toucher à mains nues les parties chaudes. 10,7 m de l’arc de soudage.

-

Page 11: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

D Tenir les bouteilles éloignées des circuits de soudage ou autres LE BRUIT peut endommager l’ouïe. circuits électriques. D Ne jamais placer une torche de soudage sur une bouteille à gaz. Le bruit des processus et des équipements peut affecter l’ouïe. D Une électrode de soudage ne doit jamais entrer en contact avec D Porter des protections approuvées pour les une bouteille. -

Page 12: Proposition Californienne 65 Avertissements

RAYONNEMENT HAUTE LE SOUDAGE À L’ARC risque de FRÉQUENCE (H.F.) risque provoquer des interférences. provoquer des interférences. D L’énergie électromagnétique risque D Le rayonnement haute fréquence (H.F.) peut provoquer des interférences pour l’équipement provoquer des interférences avec les équi- électronique sensible tel que les ordinateurs et l’équipement commandé... -

Page 13: Section 3 − Definitions

A complete Parts List is available at www.MillerWelds.com SECTION 3 − DEFINITIONS 3-1. Additional Safety Symbols And Definitions Some symbols are found only on CE products. Warning! Watch Out! There are possible hazards as shown by the symbols. Safe1 2012−05 Disconnect input plug or power before working on machine. -

Page 14: Section 4 − Installation

SECTION 4 − INSTALLATION 4-1. Serial Number And Rating Label Location The serial number and rating information for this product is located on the front . Use rating label to determine input power requirements and/or rated output. For future reference, write serial number in space provided on back cover of this manual. 4-2. -

Page 15: Environmental Specifications

4-3. Environmental Specifications Operating Temperature Range Storage/Transportation Temperature Range -4 to 131 °F (-20 to 55°C) 14 to 104 °F (-10 to 40°C) Temp1_016- 08 4-4. Duty Cycle And Overheating Duty Cycle is percentage of 10 min- utes that unit can weld at rated load without overheating. -

Page 16: Volt-Ampere Curves

4-5. Volt-Ampere Curves The volt-ampere curves show the minimum and maximum voltage and amperage output capabilities of the welding power source. Curves of other settings fall between the curves shown. A. DC Mode B. AC Mode ssb1.1 10/91 − 002 696-A / 002 689-A 4-6. -

Page 17: Selecting A Location

**Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. ( ) = mm for metric use. ***For distances longer than those shown in this guide, call a factory applications rep. at 920-735-4505 (Miller) or 1-800-332-3281 (Hobart). Ref. S-0007-L 2015−02 OM-321 Page 13... -

Page 18: Connecting Weld Output Cables

4-9. Connecting Weld Output Cables Do not place anything between weld cable terminal and copper bar. Tools Needed: 3/4 in. (19 mm) 803 778-B Correct Installation Incorrect Installation Weld Output Terminal output terminal and secure with nut so that Turn off power before connecting to weld cable terminal is tight against copper Supplied Weld Output Terminal Nut weld output terminals. -

Page 19: Electrical Service Guide

4-11. Electrical Service Guide Failure to follow these electrical service guide recommendations could create an electric shock or fire hazard. These recommenda- tions are for a dedicated branch circuit sized for the rated output and duty cycle of the welding power source. With Power Factor Correction Without Power Factor Correction 60 Hertz, 1 Phase Models... -

Page 20: Placing Jumper Links

4-12. Placing Jumper Links Disconnect and lockout/tag- out input power before installing or moving jumper links. Check input voltage available at site. Remove side panel. Jumper Link Label Check label − only one is on unit. Jumper Links Move jumper links to match input voltage and label on unit. - Page 21 Notes OM-321 Page 17...

-

Page 22: Connecting Input Power

4-13. Connecting Input Power =GND/PE Earth Ground Tools Needed: 3/8, 7/16, 1/2 in. input3 2015−01 − Ref. 803 766-C / 800 103-D / Ref. 801 116-A OM-321 Page 18... - Page 23 4-13. Connecting 3-Phase Input Power (Continued) national, state, and local electrical codes. If Close and secure access door on welding Installation must meet all National applicable, use lugs of proper amperage power source. and Local Codes − have only qualified capacity and correct hole size.

-

Page 24: Section 5 − Operation

SECTION 5 − OPERATION 5-1. Controls 202 313-D Range Selector Switch Amperage Adjustment Control Circuit Breaker CB1 Use control to adjust amperage within range Use switch to select ac or dc weld amperage If CB1 opens, weld output drops to the mini- selected by Range Selector switch. -

Page 25: Section 6 − Maintenance & Troubleshooting

SECTION 6 − MAINTENANCE & TROUBLESHOOTING 6-1. Routine Maintenance Disconnect power Maintain more often before maintaining. during severe conditions. 3 Months Repair Or Replace Replace Unreadable Cracked Labels Weld Cable 3 Months 6 Months Clean Blow Out During Heavy Service, Tighten Vacuum Clean Monthly... - Page 26 Trouble Remedy Low weld output; Amperage Adjustment control does Reset control circuit overload breaker CB1 (see Section 5-1). not control weld output. For GTAW, output current does not match the Amper- The amperage adjustment scale applies to the SMAW process only. The scale does not age Adjustment control setting.

-

Page 27: Section 7 − Electrical Diagrams

SECTION 7 − ELECTRICAL DIAGRAMS 202 718-A Figure 7-1. Circuit Diagram For 60 Hertz Models OM-321 Page 23... -

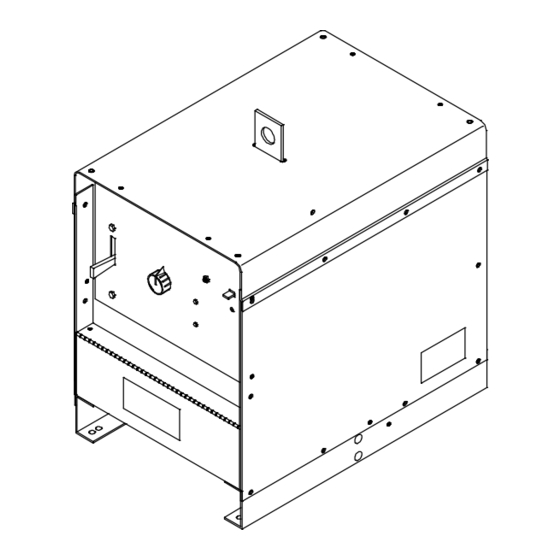

Page 28: Section 8 − Parts List

SECTION 8 − PARTS LIST Hardware is common and not available unless listed. Fig 7-4 Fig 7-2 802 879 Figure 8-1. Main Assembly OM-321 Page 24... - Page 29 Item Diagram Part marking Description Quantity Figure 8-1. Main Assembly ... . . 202390 COVER, top ............

- Page 30 Hardware is common and 3 Fig. 7−3 not available unless listed. 802 880-A Figure 8-2. Panel, Front w/Components Item Diagram Part Description Quantity marking 8-2. Panel, Front w/Components (Fig 8-1 Item 16) ......NAMEPLATE, (order by model and serial number) .

- Page 31 Item Part Description Quantity 088 087 8-3. Switch, Range 2 Position (Fig 8-2 Item 3) ....072026 BRACKET, mtg switch ..........

- Page 32 Notes...

- Page 33 Notes...

- Page 34 Notes...

- Page 35 Effective January 1, 2016 (Equipment with a serial number preface of MG or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other guarantees or warranties expressed or implied. Warranty Questions? LIMITED WARRANTY − Subject to the terms and conditions below, 6 Months —...

-

Page 36: Options And Accessories

Contact the Delivering Carrier to: File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. © ORIGINAL INSTRUCTIONS − PRINTED IN USA 2016 Miller Electric Mfg. Co. 2016−01...

Need help?

Do you have a question about the Dialarc 250 AC/DC and is the answer not in the manual?

Questions and answers