Siemens SINAMICS S120 Manual

Entering limit values for safely limited speed (sls) into a sinamics s120 via profisafe with profinet

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Summary of Contents for Siemens SINAMICS S120

- Page 1 Entering limit values for safely limited speed (SLS) into a SINAMICS S120 via PROFIsafe with PROFINET SINAMICS S120 Application example February 2014 Applications & Tools Answers for industry.

- Page 2 Siemens Industry Online Support This article is taken from Siemens Industry Online Support. The following link takes you directly to the download page for this document: http://support.automation.siemens.com/WW/view/en/81682475 Caution: The functions and solutions described in this article are limited primarily to the implementation of the automation task.

-

Page 3: Table Of Contents

Configuration and project engineering SINAMICS S120 Safety Integrated Installation Entering limit values for safely limited speed (SLS) Commissioning the into a SINAMICS S120 via PROFIsafe with PROFINET application Operating the application References Contact persons History PROFIsafe SLS Override Version 1.0, Entry ID: 81682475... -

Page 4: Warranty And Liability

By using these application examples, you agree that Siemens cannot be made liable for possible damage beyond the mentioned liability clause. We reserve the right to make changes to these application examples at any time and without prior notice. - Page 5 Table of contents Table of contents Warranty and liability ....................4 Task ........................6 Overview....................6 Solution......................10 Overview of the overall solution ............10 Description of the core functionality ........... 12 Hardware and software components used......... 13 Basic principles ....................15 PROFIsafe communication ..............

-

Page 6: Task

Task Overview Introduction The following safety functions according to DIN EN 61800-5-2 are currently integrated in SINAMICS S120 drives: Table 1-1: SINAMICS S120 safety functions according to DIN EN 61800-5-2 Name Function Description Safe disconnection of the torque-generating power supply to the motor. - Page 7 1 Task In addition to the functions defined in standard DIN EN 61800-5-2, the following safety functions are also available in SINAMICS S120. Table 1-2: SINAMICS S120 safety functions not specified by DIN EN 61800-5-2 Name Function Description The safety-relevant position values of the SINAMICS...

- Page 8 1 Task Overview of the automation task The following diagram provides an overview of the automation task. Figure 1-1: Concept of the safety functions The following safety functions are used as basis for further consideration. Table 1-3: Safety functions of the application example Safety function Description Response...

- Page 9 1 Task Safety function Description Response When the light barrier is interrupted, it is not SLS: permissible that the drive Monitoring of the drive exceeds the velocity/speed speed. configured by the user. (low limit value) Description of the automation task In this example, STO and SLS are to be controlled via PROFIsafe with PROFINET.

-

Page 10: Solution

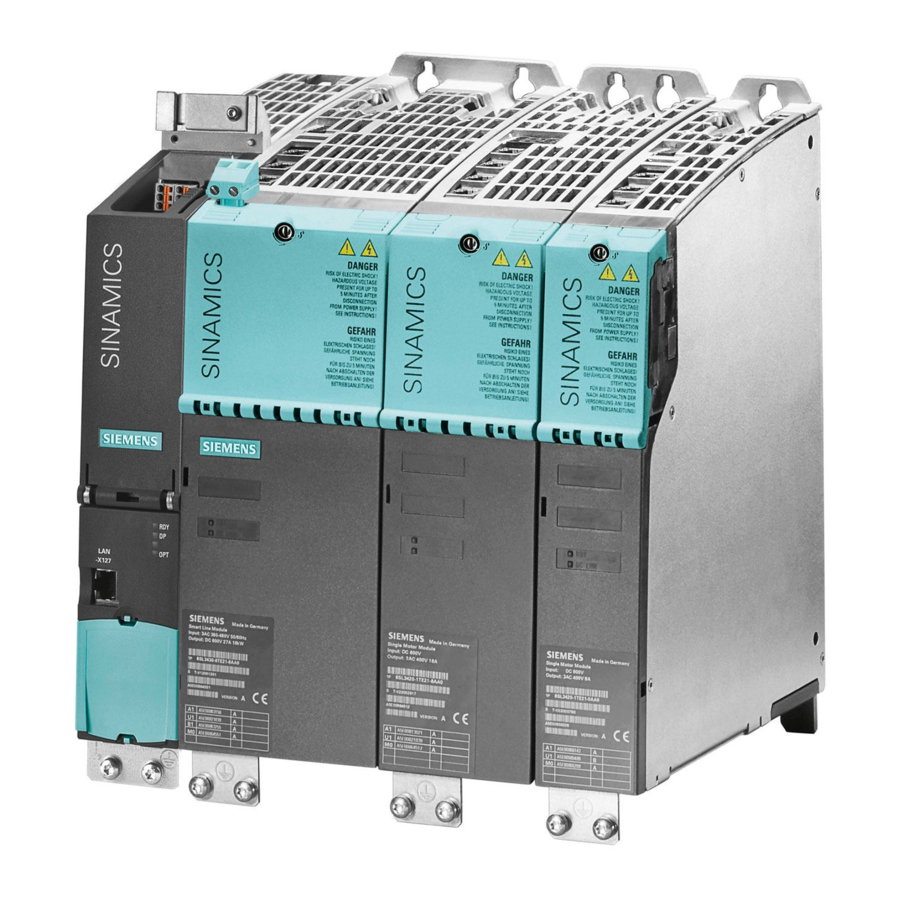

Figure 2-1: Relative components of the safety functions Controlling safety functions STO and SLS via PROFIsafe with PROFINET for a SINAMICS S120 drive line-up is demonstrated using this application example. PROFIsafe telegram 901 can be used to control the safety function and also enter a safety-relevant speed limit. - Page 11 (-S3), transfers the override value (100 or 40%) for SLS level 1. The F-CPU is the F host as well as also the PROFINET controller. Design This application example is based on the SINAMICS S120 training case (6ZB2-480-0BA00) and the SAFETY training case. Advantages The application described here offers you the following advantages: Simple control of the safety functions integrated in the drive.

-

Page 12: Description Of The Core Functionality

2 Solution Description of the core functionality Overview and description of the hardware used Figure 2-2: Hardware components used Sequence of the core functionality Switches -S1 to -S4 are located on a switchbox that belongs to the SAFETY training case. The STO function is initiated using -S1. The SLS safety function is controlled using switch -S2 or -S3. -

Page 13: Sinamics S120

The application was created with the following components: Hardware components Table 2-1: Hardware components Component MLFB/ ordering data Note SAFETY training case SINAMICS S120 6ZB2-480-0BA00 training case As an alternative, a CU320-2 CU320-2 PN 6SL3040-1MA01-0AA0 DP can also be used. -

Page 14: Solution

2 Solution Component Type MLFB/ ordering data Manufacturer Phoenix ST 2.5-QUATTRO-TG 3038451 Terminals for the Contact load resistors P-CO component Phoenix (R1…R8) 3036796 connector Contact RES_MET_FLM_1K2 Load resistor R9 SMA0207 1K2 1% TK Beyschlag 1%_600mW_+50ppm _0207 TERMINALS_ACCES SORY_EMPTY_CON 280-801 WAGO NECTOR_TYPE1_G Terminals for load resistor (R9) -

Page 15: Basic Principles

F host via PROFINET. A suitable PROFIsafe telegram (PROFIsafe slot) is created for each drive. SIEMENS telegram 901 is used in this example. Telegram 901 transfers the S_STW2 (safety control word 2), the variable SLS limit (S_SLS_LIMIT_A), the... -

Page 16: Configuration And Project Engineering

In this chapter, you get to know how the individual components must be parameterized. STARTER is used as the engineering software for SINAMICS S120. How the software project belonging to this application example was set-up is described step-by-step in the following sections. -

Page 17: Preparation

4 Configuration and project engineering Preparation Before configuration can be started, the PROFINET interface of the computer being used must be suitably set. Table 4-1: Setting the PG/PC interface Action Remark To start, please open the SIMATIC Manager. Then create a new project by pressing the "New"... - Page 18 4 Configuration and project engineering Action Remark Here, select the hardware which you wish to use to establish an online connection. In this example, it involves the USB Ethernet adapter "ASIX AX88179 USB 3.0". Open the properties window using the "Properties" button. In the subsequent window, please click on the "Network properties"...

- Page 19 4 Configuration and project engineering Action Remark Now click the "Properties" button. Now select the menu item "Internet Protocol (TCP/IP)" – and press the "Properties" button. PROFIsafe SLS Override Version 1.0, Entry ID: 81682475...

- Page 20 4 Configuration and project engineering Action Remark Now set a fixed IP address. The following setting is used in this example: IP address: 192.168.0.102 Subnet mask: 255.255.255.0 Confirm your entry with "OK." In order to assign the devices the required IP addresses and device names, under "PLC", select the "Edit Ethernet Node"...

- Page 21 4 Configuration and project engineering Action Remark Then click the "Browse" button. All of the nodes/participants that can be reached are listed. First select "S7-300" station and then press "OK". PROFIsafe SLS Override Version 1.0, Entry ID: 81682475...

- Page 22 4 Configuration and project engineering Action Remark In this example, the S7-300 station was assigned the following configuration: IP address: 192.168.0.1 Subnet mask: 255.255.255.0 Now acknowledge the entries that you have made with "Assign IP Configuration", and close the window with "Close". Note: The "Assign Name"...

- Page 23 4 Configuration and project engineering Action Remark In this example, the CU320-2 station was assigned the following configuration: IP address: 192.168.0.2 Subnet mask: 255.255.255.0 Now acknowledge the entries that you have made with "Assign IP Configuration", and close the window with "Close". Note: The "Assign Name"...

-

Page 24: Hardware Configuration

4 Configuration and project engineering Hardware configuration Table 4-2: Hardware configuration Action Remark In the next step, now insert a SIMATIC 300 station into the project. To do this, click on the "Insert" menu item. In the following submenu select the entry "Station"... - Page 25 4 Configuration and project engineering Action Remark First insert a rack in the "HW Config" window. Then please select the F-CPU being used and insert this. To do this you can drag the corresponding F-CPU and drop it into the rack (profile rail).

- Page 26 4 Configuration and project engineering Action Remark Now make the basic settings, with which the safety mode of the F-CPU being used is activated. To do this, open the properties window (by double-clicking on the F- CPU) Here, go to the "Protection" tab. Activate the safety mode by setting a checkmark for "CPU contains safety program".

- Page 27 4 Configuration and project engineering Action Remark Check the address settings for the input and output range of the data. In this example, the following applies: Input address: 0..9 Output address: 0..3 In the property window of the FDI module, make the following adaptations under the "Parameters"...

- Page 28 4 Configuration and project engineering Action Remark Make the settings for the F-DIs, which are highlighted in the adjacent screenshot. Please note, that for all of the other channels, the checkmark is removed for "Activated", as only channels 0, 1, 2, 3 are used. Now insert the F-DO module of the safety demonstration case...

- Page 29 For channel 7, also remove the checkmark for "Diagnostics: wire break". Now insert SINAMICS S120 into the hardware configuration. In the catalog select a SINAMICS S120 with CU320-2 PN and drag the component with version V4.6 and drop at the PROFINET...

- Page 30 4 Configuration and project engineering Action Remark The following window is opened after insertion. Here, please select the subnet on which the SINAMICS S120 is to be operated. In this example, this is the "Ethernet 1" network. Also check the automatically created address.

- Page 31 4 Configuration and project engineering Action Remark Select the newly created interface, and press the "Properties" button to open the window that is displayed. Remove the checkmark for "Set MAC address / use ISO protocol" and set the same network address and subnet mask that you assigned when setting the PC/PG interface in Section 4.2.

- Page 32 4 Configuration and project engineering Action Remark The computer is now inserted with an active connection shown in yellow. Please save and compile the changes that have been made. Then close "NetPro" and return to HW Config. Save and compile the settings in HW Config again.

-

Page 33: Configuring The Basic Drive Functions

4 Configuration and project engineering Configuring the basic drive functions All of the SINAMICS S120 drive lineup settings required to move the axis are explained in this section. The configuration of the safety functions is described in a separate section. - Page 34 4 Configuration and project engineering Action Remark Then press the "Configure" button. The DRIVE-CLiQ nodes are then read out. Select the "Servo" control mode. Then press the "Create" button. Go offline after the automatic configuration has been completed. PROFIsafe SLS Override Version 1.0, Entry ID: 81682475...

- Page 35 4 Configuration and project engineering Action Remark In this application example, only the upper (red) motor is used. As a consequence, the lower (blue) motor should be deleted from the application. To do this, right click on the "SERVO_03" button, and press the "Delete"...

- Page 36 4 Configuration and project engineering Action Remark The extended setpoint channel is used to specify the speed of the drive. Therefore, enable the "Extended setpoint channel" function. Complete your entries by pressing "Next". Note: In the following, only those screen forms are described in which a change is required.

- Page 37 4 Configuration and project engineering Action Remark Since a motor with DRIVE-CLiQ interface is used, this should be read out. To do this, activate the "Read out motor again" checkbox. Press the "Next" button to acknowledge the entries that you have made.

- Page 38 4 Configuration and project engineering Action Remark In the following screen form, please select "Standard Telegram 1" for the drive. Then return to "Free telegram configuring with BICO“; as a consequence, the links of the "Standard Telegram 1" are kept. These can be subsequently adapted for the example.

- Page 39 4 Configuration and project engineering Action Remark The required speed setpoints are entered in the following screen form. To do this, click on "Setpoint channel > Fixed setpoints". Binary logic (bit 0-3) can be implemented here which allows a switchover to various speed setpoints.

- Page 40 4 Configuration and project engineering Action Remark The OFF3 ramp-down time is used for braking when SS1/SS2 is selected. Set parameter (p1135) to 0.5 seconds. For this example, this means that when SS1/SS2 is selected the drive operating at maximum speed (p1082) comes to a standstill in 0.5 seconds.

-

Page 41: Profisafe Configuration To Control The Safety Functions Integrated In The Drive

4 Configuration and project engineering PROFIsafe configuration to control the safety functions integrated in the drive Table 4-4: PROFIsafe configuration Action Remark In the project navigator now change to the menu item "Telegram configuration". Then add a PROFIsafe slot by pressing the "Add PROFIsafe"... - Page 42 4 Configuration and project engineering Action Remark Additional settings can be made under the "PROFIsafe“ tab. In STARTER, the value of "F_Dest_Add" should be entered in the hexadecimal format for the drive. "C6hex" or "198dec" were used in this particular example. Note: The watchdog time ("F_WD_Time"...

-

Page 43: Parameterizing The Safety Functions Integrated In The Drive

4 Configuration and project engineering Parameterizing the safety functions integrated in the drive Table 4-5: Parameterizing the safety functions integrated in the drive Action Remark Now go online with STARTER again. Download the project and copy RAM to ROM. In the project navigator then change to the "Safety Integrated"... - Page 44 4 Configuration and project engineering Action Remark Then select DI3 (r722.3) as signal source for the test stop of the safety functions. This means that the test stop can be controlled using switch - Now press the "PROFIsafe configuration" button. In the PROFIsafe configuration, enter the PROFIsafe address that you defined in HW Config.

- Page 45 4 Configuration and project engineering Action Remark In screen form SS2, please also change the value of the delay time "Delay time SS2/STOP C - > SOS active" to 500ms. This stop response becomes active when the SLS limit is exceeded.

- Page 46 4 Configuration and project engineering Action Remark The parameters must now be copied. To do this please press the "Copy parameters" button. Then click on the "Activate settings" button. You are subsequently prompted to change the password. The default password is "0". Change the password to "1".

-

Page 47: Configuring The F-Cpu

4 Configuration and project engineering Configuring the F-CPU A standard program is not required for this application example, as the drives are exclusively controlled via BICO interconnections in SINAMICS. For most applications in practice, a program – which is independent of the safety program – is expected here, which is based on a standard telegram. - Page 48 4 Configuration and project engineering Action Remark Now insert an additional function. This function is called using what is known as the F call block with the safety program. This is simply created. No changes can be made in this block. Please assign the "FC1"...

- Page 49 4 Configuration and project engineering Action Remark In this example, the actual safety program is created in an FB function block. Please insert such a block into the block folder. Then assign the "FB1" name, and as programming language select "F-FDB"...

- Page 50 4 Configuration and project engineering Action Remark Network 5: Pushbutton -S4 is used to control the acknowledgment bit of the PROFIsafe telegram. Networks 6 and 7: In this network, SLS speed level 1 is permanently selected on the PROFIsafe STW. Network 8: SLP position range 0 is permanently selected...

- Page 51 4 Configuration and project engineering Action Remark Network 12: A jump is made to this network (or to the "SLS" label) if the condition from network 9 is fulfilled. Here, the override (AW 19) is set to a value of 32767 (=100%).

-

Page 52: Acceptance Test

PRODIS entry 52248627 available at no charge in the (link only available in the SIEMENS Intranet) that can be downloaded by authorized personnel. This script conveniently guides the user step by step through the acceptance test. PROFIsafe SLS Override Version 1.0, Entry ID: 81682475... -

Page 53: Installation

5 Installation Installation Hardware installation The following diagrams show the hardware configuration of the application. Figure 5-1: Overview of the test setup (schematic) PROFIsafe SLS Override Version 1.0, Entry ID: 81682475... - Page 54 5 Installation Figure 5-2: Wiring the F-DIs/F-DOs SAFETY demonstration case In this application example, only the upper (red) drive of the two-axis Note demonstration case is used. The DRIVE-CLiQ connection to the encoder of the lower motor (gray cable) should be withdrawn. Topology alarm A1416 is output if this is not done.

-

Page 55: Commissioning The Application

Until now, the configuration of the application example has been described step-by-step. The following steps must be observed if the project example is to be loaded directly to the hardware. First, all components (S7-F-CPU and SINAMICS S120) should be generally reset or reset to factory settings. Preconditions... -

Page 56: Commissioning

6 Commissioning the application Commissioning Table 6-1: Commissioning the sample project Action Remark To start, please open the SIMATIC Manager. Please unzip the project supplied into any directory and then open it. In the SIMATIC Manager, click on "File" followed by "Retrieve". Once the project has been opened, please open the HW config, and carry out a... - Page 57 6 Commissioning the application Action Remark Now open the integrated STARTER project. To do this, double-click on "Commissioning". Then establish an online connection and carry out a download. When using the extended safety functions, the hardware replacement must be acknowledged after the download.

-

Page 58: Operating The Application

7 Operating the application Operating the application Overview Figure 7-1: Overview diagram showing how to operate the application Switches -S1 to -S4 are located on a switchbox that belongs to the SAFETY training case. Switches -S5 to -S8 are located on a switchbox that belongs to the SINAMICS training case. - Page 59 7 Operating the application Emergency Stop If, while the motor is rotating, switch -S1 is actuated, then safety function STO is activated. After selecting STO, the converter safely switches off the torque of the connected motor. Protective door Switch -S2 simulates a protective door. As long as switch -S2 is not actuated (high- level), the protective door is closed.

- Page 60 7 Operating the application Table 7-1: Overview of the SAFETY training case switch functions Switch Function STO activation Select SLS with a speed limit of 750 rpm. Select SLS with a speed limit of 300 rpm. Depassivation and fail-safe acknowledgment Table 7-2: Overview of the switch functions at the SINAMICS training case Switch Digital input...

-

Page 61: References

Related documents This list does not claim to be complete and only provides a selection of suitable references. Table 8-1: Related documents Topic Title SINAMICS S120 SINAMICS S120 Safety Integrated Function Manual Safety Integrated 01/2013 Edition MLFB: 6SL3097-4AR00-0AP4 SINAMICS S120... -

Page 62: Internet Links

This list does not claim to be complete and only provides a selection of suitable information. Table 8-2: Internet links Topic Title Reference to the 81682475 http://support.automation.siemens.com/WW/view/en/ article Siemens Industry http://support.automation.siemens.com Online Support PROFIsafe SLS Override Version 1.0, Entry ID: 81682475... -

Page 63: Contact Persons

9 Contact persons Contact persons Siemens AG Industry Sector I DT MC PMA APC Frauenauracher Strasse 80 D - 91056 Erlangen, Germany E-mail: safety.team.motioncontrol.i-dt@siemens.com PROFIsafe SLS Override Version 1.0, Entry ID: 81682475... -

Page 64: History

10 History History Table 10-1: History Version Date Revision V1.0 02/2014 First Edition PROFIsafe SLS Override Version 1.0, Entry ID: 81682475...