Siemens Sinamics S120 Manual

Booksize power units

Hide thumbs

Also See for Sinamics S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (826 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Siemens Sinamics S120

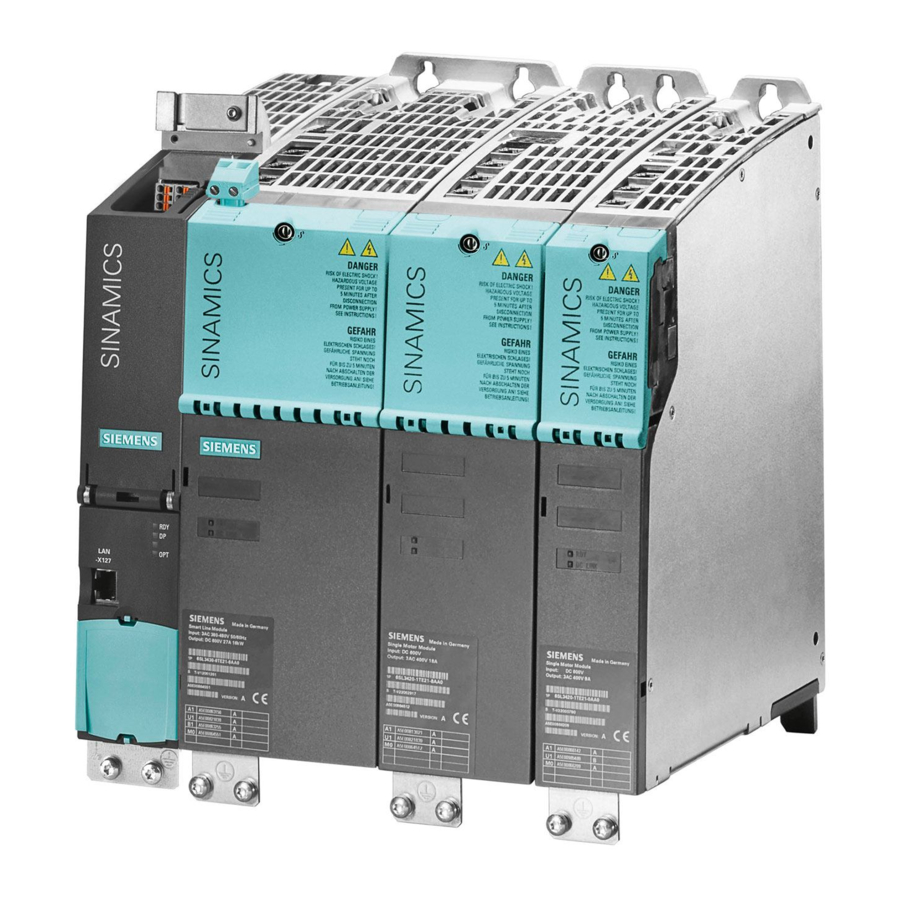

- Page 3 ___________________ Booksize Power Units Preface ___________________ Fundamental safety instructions ___________________ System overview SINAMICS Line connection and line-side ___________________ power components S120 ___________________ Booksize Power Units Line Modules Booksize Line Modules Booksize ___________________ Compact Manual ___________________ Motor Modules Booksize Motor Modules Booksize ___________________ Compact ___________________...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Preface

My Documentation Manager Under the following link there is information on how to create your own individual documentation based on Siemens' content, and adapt it for your own machine documentation: http://www.siemens.com/mdm Training... - Page 6 Equipment for Machine Tools (Catalog NC 61) SINUMERIK 840D sl Type 1B • Equipment for Machine Tools (Catalog NC 62) Installation/assembly SINAMICS S120 Equipment Manual for Control Units and • Additional System Components SINAMICS S120 Equipment Manual for Booksize Power •...

- Page 7 EC Declaration of Conformity The EC Declarations of Conformity for the machinery directive can be found on the Internet http://support.automation.siemens.com/WW/view/de/21901735/67385845 Alternatively, you can contact the Siemens office in your region in order to obtain the EC Declaration of Conformity. Booksize Power Units...

- Page 8 EMC Installation Guideline Configuration Manual. The final statement regarding compliance with the standard is given by the respective label attached to the individual unit. Spare parts Spare parts are available on the Internet at: http://support.automation.siemens.com/WW/view/de/16612315 Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 9 Test certificates for functional safety functions ("Safety Integrated") can be found at: http://support.automation.siemens.com An up-to-date list of currently certified components is also available on request from your local Siemens office. If you have any questions relating to certifications that have not yet been completed, please ask your Siemens contact. Grounding symbols...

- Page 10 Preface Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 11: Table Of Contents

Residual risks of power drive systems ..................30 System overview ........................... 33 Field of application ........................33 Platform Concept and Totally Integrated Automation ..............34 Introduction ..........................36 SINAMICS S120 components ...................... 38 2.4.1 Overview of Line Modules ......................40 2.4.2 Overview of Motor Modules ......................43 System data .......................... - Page 12 Table of contents 3.7.4.3 Dimension drawings ........................71 3.7.4.4 Technical data ..........................75 3.7.5 Basic Line Filter for Basic Line Modules ..................76 3.7.5.1 Description ..........................76 3.7.5.2 Interface description ........................77 3.7.5.3 Dimension drawings ........................78 3.7.5.4 Technical specifications ......................80 3.7.6 Basic Line Filter for Smart Line Modules ..................

- Page 13 Table of contents 3.11.2 Operating line connection components on the line supply ............139 3.11.3 Operation of the line connection components via a transformer ..........140 3.11.3.1 Safety instructions for line connection components..............140 3.11.3.2 Line supply connection conditions for Line Modules ..............141 3.11.3.3 Dimensioning an isolating transformer / autotransformer for several loads ......

- Page 14 Table of contents 4.4.6 Mounting............................ 209 4.4.7 Technical data ........................... 212 4.4.7.1 Characteristics .......................... 214 Active Line Modules Liquid Cooled ................... 217 4.5.1 Description ..........................217 4.5.2 Interface description ........................218 4.5.2.1 Overview ........................... 218 4.5.2.2 X1 line connection ........................219 4.5.2.3 X21 EP terminals ........................

- Page 15 Table of contents 4.8.1 Description ..........................274 4.8.2 Safety instructions for Smart Line Modules Booksize..............274 4.8.3 Interface description ........................276 4.8.3.1 Overview ............................ 276 4.8.3.2 X1 line connection ........................279 4.8.3.3 X21 EP terminals ........................281 4.8.3.4 X22 digital inputs ........................284 4.8.3.5 X24 24 V terminal adapter ......................

- Page 16 Table of contents Line Modules Booksize Compact ......................345 Smart Line Modules Booksize Compact ................... 345 5.1.1 Description ..........................345 5.1.2 Safety instructions for Smart Line Modules Booksize Compact ..........345 5.1.3 Interface description ........................350 5.1.3.1 Overview ........................... 350 5.1.3.2 X1 line connection ........................

- Page 17 Table of contents 6.3.7 Technical data ..........................423 6.3.7.1 Single Motor Modules ........................ 423 6.3.7.2 Double Motor Modules ....................... 426 6.3.7.3 Characteristics ........................... 427 6.3.8 Technical data for Motor Modules Booksize with 300% overload ..........431 6.3.8.1 Single Motor Modules (300% overload) ..................431 6.3.8.2 Characteristics for Motor Modules Booksize with 300% overload ..........

- Page 18 Table of contents Meaning of LEDs ........................499 Dimension drawings ........................500 Mounting............................ 503 Technical data ........................... 505 7.8.1 Single Motor Modules ....................... 505 7.8.2 Double Motor Modules ......................506 7.8.3 Characteristics .......................... 508 DC link components ..........................513 Safety instructions for DC link components ................513 Braking Module Booksize ......................

- Page 19 Table of contents 8.4.6 Connection to the Basic Line Module 100 kW ................550 Capacitor Module ........................552 8.5.1 Description ..........................552 8.5.2 Safety instructions for Capacitor Modules ................. 552 8.5.3 Interface description ........................553 8.5.3.1 Overview ............................ 553 8.5.4 Dimension drawing ........................

- Page 20 Table of contents 10.2.6 Installation ..........................609 10.2.7 Electrical connection ......................... 611 10.2.7.1 Connecting signaling contact X3 ....................612 10.2.7.2 Connecting power cables (using the VPM 200 Dynamik as an example) ........ 613 10.2.8 Technical data ........................... 616 Accessories ............................617 11.1 Shield connecting plates for power supply and motor cables ...........

- Page 21 Table of contents 11.5.7 Technical specifications ......................678 11.6 DRIVE-CLiQ cabinet bushings ....................679 11.6.1 Description ..........................679 11.6.2 Interface description ........................680 11.6.2.1 Overview ............................ 680 11.6.3 Dimension drawings ........................681 11.6.4 Mounting ............................ 682 11.6.4.1 DRIVE-CLiQ cabinet bushing for cables with RJ45 connectors ..........682 11.6.4.2 DRIVE-CLiQ cabinet bushing for cables with M12 plug/socket ..........

- Page 22 Table of contents 12.8 Connection systems ........................731 12.8.1 DRIVE-CLiQ signal cables ......................731 12.8.1.1 Overview ........................... 731 12.8.1.2 DRIVE-CLiQ signal cables without 24 V DC cores ..............732 12.8.1.3 DRIVE-CLiQ signal cables MOTION-CONNECT with RJ45 connectors ........732 12.8.1.4 DRIVE-CLiQ signal cables MOTION-CONNECT with RJ45 plug and M12 socket ....733 12.8.1.5 Comparison of DRIVE-CLiQ signal cables ................

- Page 23 Table of contents 12.13.10 Typical power losses for Motor Modules ................... 793 Cooling circuit and coolant properties ....................795 13.1 Cooling circuit requirements ...................... 795 13.1.1 Technical cooling circuits ......................795 13.1.2 Cooling system requirements ....................796 13.1.3 Cooling circuit configuration ....................... 797 13.1.4 Installation ..........................

- Page 24 Table of contents Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 25: Fundamental Safety Instructions

Fundamental safety instructions General safety instructions DANGER Danger to life due to live parts and other energy sources Death or serious injury can result when live parts are touched. • Only work on electrical devices when you are qualified for this job. •... - Page 26 Fundamental safety instructions 1.1 General safety instructions WARNING Danger to life when live parts are touched on damaged devices Improper handling of devices can cause damage. For damaged devices, hazardous voltages can be present at the enclosure or at exposed components;...

- Page 27 Fundamental safety instructions 1.1 General safety instructions WARNING Danger to life through unexpected movement of machines when using mobile wireless devices or mobile phones Using mobile wireless devices or mobile phones with a transmit power > 1 W closer than approx.

-

Page 28: Safety Instructions For Electromagnetic Fields (Emf)

Fundamental safety instructions 1.2 Safety instructions for electromagnetic fields (EMF) NOTICE Device damage caused by incorrect voltage/insulation tests Incorrect voltage/insulation tests can damage the device. • Before carrying out a voltage/insulation check of the system/machine, disconnect the devices as all converters and motors have been subject to a high voltage test by the manufacturer, and therefore it is not necessary to perform an additional test within the system/machine. -

Page 29: Handling Electrostatic Sensitive Devices (Esd)

Note Industrial security Siemens provides automation and drive products with industrial security functions that support the secure operation of plants or machines. They are an important component in a holistic industrial security concept. With this in mind, our products undergo continuous development. -

Page 30: Residual Risks Of Power Drive Systems

• Keep the software up to date. Information and newsletters can be found at: http://support.automation.siemens.com • Incorporate the automation and drive components into a state-of-the-art, integrated industrial security concept for the installation or machine. For more detailed information, go to: http://www.siemens.com/industrialsecurity... - Page 31 Fundamental safety instructions 1.5 Residual risks of power drive systems 2. In the event of a fault, exceptionally high temperatures, including an open fire, as well as emissions of light, noise, particles, gases, etc. can occur inside and outside the inverter, e.g.: –...

- Page 32 Fundamental safety instructions 1.5 Residual risks of power drive systems Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 33: System Overview

System overview Field of application SINAMICS is the family of drives from Siemens designed for machine and plant engineering applications. SINAMICS offers solutions for all drive tasks: ● Simple pump and fan applications in the process industry. ● Complex single drives in centrifuges, presses, extruders, elevators, as well as conveyor and transport systems ●... -

Page 34: Platform Concept And Totally Integrated Automation

SINAMICS S120 supports as standard PROFIBUS DP, the standard fieldbus for the TIA concept. It provides a high-performance, system-wide communication network which links all automation components: ●... - Page 35 System overview 2.2 Platform Concept and Totally Integrated Automation Figure 2-2 SINAMICS as part of the Siemens modular automation system Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 36: Introduction

SINAMICS S120 system overview Modular system for sophisticated drive tasks SINAMICS S120 solves complex drive tasks for a wide range of industrial applications and is, therefore, designed as a modular system. Users can choose from many different harmonized components and functions to create a solution that best meets their requirements. - Page 37 Electronic rating plates in all components An important digital linkage element of the SINAMICS S120 drive system are the electronic type plates integrated in every component. They allow all drive components to be detected automatically via a DRIVE-CLiQ link. As a result, data does not have to be entered manually during commissioning or component replacement –...

-

Page 38: Sinamics S120 Components

System overview 2.4 SINAMICS S120 components SINAMICS S120 components Figure 2-4 Overview of SINAMICS S120 components Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 39 ● Standardized design, side-by-side mounting Note Installation location in the cabinet The SINAMICS S120 components must always be mounted vertically in the cabinet. Other permissible installation locations are given in the descriptions for the individual components. Booksize format Booksize format units are optimized for multi-axis applications and are mounted adjacent to one another.

-

Page 40: Overview Of Line Modules

System overview 2.4 SINAMICS S120 components 2.4.1 Overview of Line Modules Line Modules generate a DC voltage from the connected rated voltage that is used to power the Motor Modules. All Basic Line Modules and Active Line Modules as well as the 16 kW, 36 kW, and 55 kW Smart Line Modules are equipped with DRIVE-CLiQ interfaces for communicating with the Control Unit. - Page 41 System overview 2.4 SINAMICS S120 components General characteristics of the Line Modules ● Supply voltage, 3 AC 380 V to 480 V ±10 % (-15 % <1 min), 47 to 63 Hz ● Suitable for TN, TT, and IT supply systems ●...

- Page 42 System overview 2.4 SINAMICS S120 components Frequency with which the DC link is precharged The frequency with which the DC link capacitance is precharged via the Line Module is determined using the following formula: The DC link capacitances of the individual components can be taken from the relevant technical data.

-

Page 43: Overview Of Motor Modules

System overview 2.4 SINAMICS S120 components 2.4.2 Overview of Motor Modules The Motor Modules in the SINAMICS S system in booksize format are inverters. They make the energy from the connected motors' DC link available at an adjusted voltage and with variable frequency. - Page 44 System overview 2.4 SINAMICS S120 components Characteristics of the Motor Modules: ● Single type from 3 A to 200 A ● Double type from 1.7 A to 18 A ● Internal/external air cooling ● Liquid cooling and cold plate cooling ●...

-

Page 45: System Data

System overview 2.5 System data System data Unless explicitly specified otherwise, the following technical data is valid for components of the SINAMICS S120 booksize drive system. Table 2- 1 Electrical data Line connection voltage 3 AC 380 … 480 V ±10 % (-15 % < 1 min) Line frequency 47 …... - Page 46 System overview 2.5 System data Table 2- 3 Environmental conditions Degree of protection IPXXB acc. to EN 60529, open type according to UL508 Protection class, line supply circuits I (with protective conductor connection) Electronic circuits safety extra-low voltage PELV / SELV Permissible cooling medium temperature (air) and 0°...

-

Page 47: Derating As A Function Of The Installation Altitude And Ambient Temperature

System overview 2.6 Derating as a function of the installation altitude and ambient temperature Derating as a function of the installation altitude and ambient temperature The Booksize power units are designed for operation at an ambient temperature of 0° C to 40°... - Page 48 System overview 2.6 Derating as a function of the installation altitude and ambient temperature Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 49: Line Connection And Line-Side Power Components

Line connection and line-side power components Introduction The following components should be used to connect a SINAMICS S120 drive line-up in booksize format to the power supply: ● Disconnector unit (for Active Line Modules, Basic Line Modules, Smart Line Modules) ●... -

Page 50: Information On The Disconnector Unit

Line connection and line-side power components 3.2 Information on the disconnector unit Figure 3-2 Overview diagram, line connection with line filter and line reactor Information on the disconnector unit Disconnector units for Active Line Modules, Basic Line Modules, and Smart Line Modules A disconnector unit is required for disconnecting the drive line-up from the supply system correctly. -

Page 51: Overcurrent Protection By Means Of Line Fuses And Circuit Breakers

Line connection and line-side power components 3.3 Overcurrent protection by means of line fuses and circuit breakers Overcurrent protection by means of line fuses and circuit breakers Line fuses or circuit breakers must be used for cable protection/overcurrent protection. NH, D, and DO type fuses with a gL characteristic or suitable circuit breakers according to IEC 60947 can be used for this purpose. - Page 52 Line connection and line-side power components 3.3 Overcurrent protection by means of line fuses and circuit breakers Table 3- 3 Recommended line fuses and circuit breakers for Smart Line Modules booksize and booksize compact format 5 kW 10 kW 16 kW 36 kW 55 kW fuse...

-

Page 53: Line Supply Connection Via Residual-Current Devices

Line connection and line-side power components 3.4 Line supply connection via residual-current devices Line supply connection via residual-current devices Selectively tripping, AC/DC-sensitive residual-current devices (type B) can be used in addition to the overcurrent protection devices. Residual-current devices have to be installed if the power supply conditions in terms of short- circuit power and loop impedance at the infeed point are not such that the installed overcurrent protection devices will trip within the prescribed period if a fault occurs. - Page 54 Connecting a residual-current operated circuit breaker Recommendation SIEMENS selectively switching AC/DC-sensitive residual-current circuit-breakers according to EN 61009-1 of the 5SM series (e.g. 5SM3646-5 or 5SM3646-5+5SW3300 with an auxiliary disconnector (1 NC contact / 1 NO contact) for a rated current of 63 A and rated fault current of 0.3 A (see Catalog "BETA Modular Installation Devices - ET B1")).

-

Page 55: Residual-Current Monitors (Rcm)

Line connection and line-side power components 3.4 Line supply connection via residual-current devices 3.4.2 Residual-current monitors (RCM) Used in conjunction with appropriate circuit breakers, residual-current monitors (RCMs) provide fire and system protection even at high levels of grounding resistance (in TT systems, for example). - Page 56 Line connection and line-side power components 3.4 Line supply connection via residual-current devices Figure 3-4 Connecting a differential current monitoring device Recommendation ● AC/DC-sensitive differential current monitoring device RCMA423-D-2, Bender company, the 230 V supply voltage is tapped using an upstream isolating transformer ●...

-

Page 57: Overvoltage Protection

Line connection and line-side power components 3.5 Overvoltage protection Overvoltage protection To protect the units against line-side surge voltages, you are advised to install an overvoltage protection device directly at the infeed point (upstream of the main switch). To comply with the requirements of CSA C22.2 No. 14-05, a type VZCA or VZCA2 surge arrester is absolutely mandatory. -

Page 58: Line Filters

Line connection and line-side power components 3.7 Line filters Line filters 3.7.1 Safety instructions for line filters WARNING Danger to life if the fundamental safety instructions and remaining risks are not carefully observed If the fundamental safety instructions and remaining risks in Chapter 1 (Page 25) are not observed, accidents involving severe injuries or death may occur. - Page 59 Line connection and line-side power components 3.7 Line filters WARNING Fire hazard due to overheating because of inadequate ventilation clearances Inadequate ventilation clearances cause overheating with a risk for personnel through smoke development and fire. Damage can still occur on the line filter. •...

-

Page 60: Overview Of Line Filters

Line filter ranges that are coordinated with the different power stages are available for the SINAMICS S120 drive system. These line filters differ with regard to the frequency range in which they reduce the conducted emissions. - Page 61 Line connection and line-side power components 3.7 Line filters The line filter versions listed below are available for use with Line Modules. Table 3- 4 Overview of line filters Order number Basic Line Filter for Active Line Modules with line reactor 16 kW 6SL3000-0BE21-6DAx 36 kW...

-

Page 62: Basic Line Filters For Active Line Modules

Line connection and line-side power components 3.7 Line filters 3.7.3 Basic Line Filters for Active Line Modules 3.7.3.1 Description Basic Line Filters for Active Line Modules are designed to attenuate conducted interference emissions in accordance with the specifications contained in the relevant EMC directive. They are mainly effective in the frequency range from 150 kHz to 30 MHz;... -

Page 63: Interface Description

Line connection and line-side power components 3.7 Line filters Maximum total cable length = Σ motor cables, mains supply conductor from line filter to Line Module 3.7.3.2 Interface description Overview Figure 3-5 Interface overview, Basic Line Filter for Active Line Modules (example: 16 kW) Either the upper or lower PE screw can be used for the connection. -

Page 64: Dimension Drawings

Line connection and line-side power components 3.7 Line filters Line/load connection Table 3- 5 Line and load connection, Basic Line Filter for Active Line Modules 6SL3000-0BE21- 6SL3000-0BE23- 6SL3000-0BE25- 6SL3000-0BE28- 6SL3000-0BE31- 6DAx 6DA1 5DAx 0DAx 2DAx Rated power [kW] Line supply Screw terminals: Screw terminals: Screw terminals:... - Page 65 Line connection and line-side power components 3.7 Line filters Figure 3-7 Dimension drawing of Basic Line Filter for Active Line Modules 36 kW, all data in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 66 Line connection and line-side power components 3.7 Line filters Figure 3-8 Dimension drawing of Basic Line Filter for Active Line Modules 55 kW, all data in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 67: Technical Data

Line connection and line-side power components 3.7 Line filters Figure 3-9 Dimension drawing of Basic Line Filter for Active Line Modules 80 kW and 120 kW, all dimensions in mm and (inches) 3.7.3.4 Technical data Table 3- 6 Technical data of the Basic Line Filter for Active Line Modules with Active Interface Module 6SL3000- 0BE21-6DAx 0BE23-6DA1... -

Page 68: Wideband Line Filter For Active Line Modules

Line connection and line-side power components 3.7 Line filters 3.7.4 Wideband Line Filter for Active Line Modules 3.7.4.1 Description Wideband Line Filters for Active Line Modules are mainly effective in the frequency range from 150 kHz to 30 MHz; this is the range relevant to ensure compliance with the appropriate standard. -

Page 69: Interface Description

Line connection and line-side power components 3.7 Line filters 3.7.4.2 Interface description Figure 3-10 Interface overview, Wideband Line Filter for Active Line Modules (example: 16 kW) NOTICE Damage caused by overheating as a result of an inadmissible mounting position If the component is not operated in a vertical position with the line supply terminals at the bottom, then the component can be damaged. - Page 70 Line connection and line-side power components 3.7 Line filters Line/load connection Table 3- 7 Line and load connection, Wideband Line Filter for Active Line Modules 6SL3000-0BE21- 6SL3000-0BE23- 6SL3000-0BE25- 6SL3000-0BE28- 6SL3000-0BE31- 6AAx 6AAx 5AAx 0AAx 2AAx Rated power [kW] Line supply Screw terminals: Screw terminals Screw terminals...

-

Page 71: Dimension Drawings

Line connection and line-side power components 3.7 Line filters 3.7.4.3 Dimension drawings Figure 3-11 Dimension drawing of Wideband Line Filter 16 kW for Active Lines Modules, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 72 Line connection and line-side power components 3.7 Line filters Figure 3-12 Dimension drawing of Wideband Line Filter 36 kW for Active Lines Modules, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 73 Line connection and line-side power components 3.7 Line filters Figure 3-13 Dimension drawing of Wideband Line Filter 55 kW for Active Lines Modules, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 74 Line connection and line-side power components 3.7 Line filters Figure 3-14 Dimension drawing of Wideband Line Filter 80 kW for Active Lines Modules, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 75: Technical Data

Line connection and line-side power components 3.7 Line filters Figure 3-15 Dimension drawing of Wideband Line Filter 120 kW for Active Lines Modules, all dimensions in mm and (inches) 3.7.4.4 Technical data Table 3- 8 Technical data: Wideband Line Filter for Active Line Modules 6SL3000 0BE21-6AAx 0BE23-6AAx... -

Page 76: Basic Line Filter For Basic Line Modules

Line connection and line-side power components 3.7 Line filters 3.7.5 Basic Line Filter for Basic Line Modules 3.7.5.1 Description Basic Line Filters for Basic Line Modules are designed to attenuate conducted interference emissions in accordance with the specifications contained in the relevant EMC legislation. They are mainly effective in the frequency range from 150 kHz to 30 MHz;... -

Page 77: Interface Description

Line connection and line-side power components 3.7 Line filters 3.7.5.2 Interface description Overview Figure 3-16 Interface overview, Basic Line Filter for Basic Line Modules (example: 40 kW) Either the upper or lower PE screw can be used for the connection. One of the screws remains unused. -

Page 78: Dimension Drawings

Line connection and line-side power components 3.7 Line filters Line/load connection Table 3- 9 Line and load connection, Basic Line Filter for Basic Line Modules 6SL3000-0BE21-6DAx 6SL3000-0BE23-6DA1 6SL3000-0BE31-2DAx Rated power [kW] Line supply connection Screw terminals Screw terminals Screw terminals L1, L2, L3 10 mm , 3 pole... - Page 79 Line connection and line-side power components 3.7 Line filters Figure 3-18 Dimension drawing of Basic Line Filter for Basic Line Modules 40 kW, all data in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 80: Technical Specifications

Line connection and line-side power components 3.7 Line filters Figure 3-19 Dimension drawing of Basic Line Filter for Basic Line Modules 100 kW, all data in mm and (inches) 3.7.5.4 Technical specifications Table 3- 10 Technical data for Basic Line Filter for Basic Line Modules 6SL3000- 0BE21-6DAx 0BE23-6DA1... -

Page 81: Basic Line Filter For Smart Line Modules

Line connection and line-side power components 3.7 Line filters 3.7.6 Basic Line Filter for Smart Line Modules 3.7.6.1 Description Basic Line Filters for Smart Line Modules are designed to attenuate conducted interference emissions in accordance with the specifications contained in the relevant EMC legislation. They are mainly effective in the frequency range from 150 kHz to 30 MHz;... -

Page 82: Interface Description

Line connection and line-side power components 3.7 Line filters 3.7.6.2 Interface description Overview Figure 3-20 Interface overview, Basic Line Filter for Smart Line Modules (example: 36 kW) Either the upper or lower PE screw can be used for the connection. One of the screws remains unused. -

Page 83: Dimension Drawings

Line connection and line-side power components 3.7 Line filters Line/load connection Table 3- 11 Line and load connection, Basic Line Filter for Smart Line Modules 6SL3000-0HE15- 6SL3000-0HE21- 6SL3000-0BE21- 6SL3000-0BE23- 6SL3000-0BE25- 0AAx 0AAx 6DAx 6DA1 5DAx Rated power [kW] Line supply Screw terminals Screw terminals Screw terminals... - Page 84 Line connection and line-side power components 3.7 Line filters Figure 3-22 Dimension drawing of Basic Line Filter for Smart Line Modules 16 kW, all data in mm and (inches) Figure 3-23 Dimension drawing of Basic Line Filter for Smart Line Modules 36 kW, all data in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 85: Technical Specifications

Line connection and line-side power components 3.7 Line filters Figure 3-24 Dimension drawing of Basic Line Filter for Smart Line Modules 55 kW, all data in mm and (inches) 3.7.6.4 Technical Specifications Table 3- 12 Technical data for: Basic Line Filter for Smart Line Modules 6SL3000- 0HE15-0AAx 0HE21-0AAx... -

Page 86: Line Reactors

Line connection and line-side power components 3.8 Line reactors Line reactors 3.8.1 Safety instructions for line reactors WARNING Danger to life if the fundamental safety instructions and remaining risks are not carefully observed If the fundamental safety instructions and remaining risks in Chapter 1 (Page 25) are not observed, accidents involving severe injuries or death may occur. - Page 87 Line connection and line-side power components 3.8 Line reactors NOTICE Damage to the system caused by line reactors that are not permissible Line reactors that are not permissible can damage the Line Modules. Line harmonics that damage/disturb other loads connected to the same line supply can also occur.

-

Page 88: Overview Of The Line Reactors

Line connection and line-side power components 3.8 Line reactors 3.8.2 Overview of the line reactors Line reactors limit line harmonics to permissible values. For this reason, line reactors should always be used. They must be used in conjunction with Active Line Modules as an energy storage feature for the step-up converter function. -

Page 89: Line Reactors For Active Line Modules

Line connection and line-side power components 3.8 Line reactors 3.8.3 Line reactors for Active Line Modules 3.8.3.1 Interface description Overview Figure 3-25 Interface overview, HFD line reactor 16 kW Figure 3-26 Interface overview, HFD line reactor 36 kW Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 90 Line connection and line-side power components 3.8 Line reactors Figure 3-27 Interface overview, HFD line reactor 55 kW Figure 3-28 Interface overview, HFD line reactor 80 kW Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 91 Line connection and line-side power components 3.8 Line reactors Figure 3-29 Interface overview, HFD line reactor 120 kW Line/load connection Table 3- 14 Connection of HFD line reactors Order number 6SL3000-0DE21- 6SL3000-0DE23- 6SL3000-0DE25- 6SL3000-0DE28- 6SL3000-0DE31- 6AAx 6AAx 5AAx 0AAx 2AAx Power [kW] Line supply Screw terminal...

-

Page 92: Dimension Drawings

Line connection and line-side power components 3.8 Line reactors 3.8.3.2 Dimension drawings ① Terminal arrangement ② Warning label Figure 3-30 Dimension drawing of HFD line reactor 16 kW, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 93 Line connection and line-side power components 3.8 Line reactors ① Terminal arrangement ② Warning label Figure 3-31 Dimension drawing of HFD line reactor 36 kW, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 94 Line connection and line-side power components 3.8 Line reactors ① Terminal arrangement Figure 3-32 Dimension drawing of HFD line reactor 55 kW, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 95 Line connection and line-side power components 3.8 Line reactors ① End retainers ② Terminal arrangement ③ Warning label Figure 3-33 Dimension drawing of HFD line reactor 80 kW, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 96 Line connection and line-side power components 3.8 Line reactors ① Transport eyebolts 10 x 25 mm (0.39 x 0.98 inch) ② Terminal arrangement ③ Warning label Figure 3-34 Dimension drawing of HFD line reactor 120 kW, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 97: Technical Data

Line connection and line-side power components 3.8 Line reactors 3.8.3.3 Technical data Table 3- 15 Technical data for HFD line reactors 6SL3000– 6SL3000– 6SL3000– 6SL3000– 6SL3000- 0DE21- 0DE23- 0DE25- 0DE28- 0DE31- Unit 6AAx 6AAx 5AAx 0AAx 2AAx Power Rated current Power loss (see power loss tables) -

Page 98: Damping Resistor For Hfd Line Reactors

Line connection and line-side power components 3.8 Line reactors 3.8.4 Damping resistor for HFD line reactors 3.8.4.1 Description Using a damping resistor In some systems, oscillations can be generated which place an impermissibly high strain on the insulation systems of the motors and converters involved. Connecting a damping resistor to the additional winding of the HFD line reactor is an effective means of damping just such system oscillations. -

Page 99: Dimension Drawings

Line connection and line-side power components 3.8 Line reactors 3.8.4.3 Dimension drawings Figure 3-35 300 W damping resistor for HFD line reactors, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 100 Line connection and line-side power components 3.8 Line reactors Figure 3-36 800 W damping resistor for HFD line reactors, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 101 Line connection and line-side power components 3.8 Line reactors Figure 3-37 1500 W damping resistor for HFD line reactors, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 102: Technical Data

Line connection and line-side power components 3.8 Line reactors 3.8.4.4 Technical data Together with the HFD line reactor, an external resistor must be used for damping purposes (refer to Chapter Wiring with the HFD line reactor (Page 103)). Table 3- 16 Technical data for HFD damping resistors Order number 6SN1113-1AA00-0DAx... -

Page 103: Wiring With The Hfd Line Reactor

Line connection and line-side power components 3.8 Line reactors 3.8.4.5 Wiring with the HFD line reactor Figure 3-38 Wiring the HFD line reactor with a damping resistor Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... -

Page 104: Line Reactors For Basic Line Modules

Line connection and line-side power components 3.8 Line reactors 3.8.5 Line reactors for Basic Line Modules 3.8.5.1 Interface description Overview Figure 3-39 Interface overview, line reactor for Basic Line Modules (20 kW) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 105 Line connection and line-side power components 3.8 Line reactors Figure 3-40 Interface overview, line reactor for Basic Line Modules (40 kW) Figure 3-41 Interface overview, line reactor for Basic Line Modules (100 kW) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 106 Line connection and line-side power components 3.8 Line reactors Line/load connection Table 3- 17 Line and load connection line reactors for Basic Line Modules 6SL3000-0CE22-0AAx 6SL3000-0CE24-0AAx 6SL3000-0CE31-0AAx Power 20 kW 40 kW 100 kW Line supply connection Screw terminals Screw terminals Copper busbars with 8.5 mm 1U1, 1V1, 1W1 10 mm...

-

Page 107: Dimension Drawings

Line connection and line-side power components 3.8 Line reactors 3.8.5.2 Dimension drawings Figure 3-42 Dimension drawing of line reactor for Basic Line Module 20 kW, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 108 Line connection and line-side power components 3.8 Line reactors Figure 3-43 Dimension drawing of line reactor for Basic Line Module 40 kW, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 109 Line connection and line-side power components 3.8 Line reactors Figure 3-44 Dimension drawing of line reactor for Basic Line Module 100 kW, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 110: Technical Data

Line connection and line-side power components 3.8 Line reactors 3.8.5.3 Technical data Table 3- 18 Technical data of line reactors for the Basic Line Modules 6SL3000-0CE22-0AAx 6SL3000-0CE24-0AAx 6SL3000-0CE31-0AAx Unit Power Rated current Power loss (see power loss tables (Page 781)) Weight 11.2 21.7... -

Page 111: Line Reactors For Smart Line Modules

Line connection and line-side power components 3.8 Line reactors 3.8.6 Line reactors for Smart Line Modules 3.8.6.1 Interface description Figure 3-45 Interface overview, line reactors for Smart Line Modules (example: 36 kW) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 112 Line connection and line-side power components 3.8 Line reactors Figure 3-46 Interface overview, line reactors for Smart Line Modules (example: 55 kW) Line/load connection Table 3- 19 Line and load connection line reactors for Smart Line Modules 6SL3000-0CE15- 6SL3000-0CE21- 6SL3000-0CE21- 6SL3000-0CE23- 6SL3000-0CE25- 0AAx...

-

Page 113: Dimension Drawings

Line connection and line-side power components 3.8 Line reactors 3.8.6.2 Dimension drawings Figure 3-47 Dimension drawing of line reactor for Smart Line Modules 5 kW and 10 kW Table 3- 20 Dimensions of line reactors for Smart Line Modules (5 kW and 10 kW) Order number B [mm] b [mm]... - Page 114 Line connection and line-side power components 3.8 Line reactors Figure 3-48 Dimension drawing of line reactor for Smart Line Module 16 kW Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 115 Line connection and line-side power components 3.8 Line reactors Figure 3-49 Dimension drawing of line reactor for Smart Line Module 36 kW Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 116: Technical Data

Line connection and line-side power components 3.8 Line reactors Figure 3-50 Dimension drawing of line reactor for Smart Line Module 55 kW, all dimensions in mm and (inches) 3.8.6.3 Technical data Table 3- 21 Technical data of line reactors for the Smart Line Module 6SL3000- 6SL3000- 6SL3000-... -

Page 117: Active Interface Modules Internal Air Cooling

Line connection and line-side power components 3.9 Active Interface Modules internal air cooling Active Interface Modules internal air cooling 3.9.1 Description Active Interface Modules are line-side interfaces for the Active Line Modules. They contain the following functional units: ● Line reactors ●... -

Page 118: Safety Instructions For Active Interface Modules

Line connection and line-side power components 3.9 Active Interface Modules internal air cooling 3.9.2 Safety instructions for Active Interface Modules WARNING Danger to life if the fundamental safety instructions and remaining risks are not carefully observed If the fundamental safety instructions and remaining risks in Chapter 1 (Page 25) are not observed, accidents involving severe injuries or death may occur. - Page 119 Line connection and line-side power components 3.9 Active Interface Modules internal air cooling WARNING Danger to life through electric shock due to unconnected cable shields Hazardous touch voltages can occur through capacitive cross-coupling due to unconnected cable shields. • As a minimum, connect cable shields and the cores of power cables that are not used (e.g.

-

Page 120: Interface Description

Line connection and line-side power components 3.9 Active Interface Modules internal air cooling 3.9.3 Interface description 3.9.3.1 Overview Figure 3-51 Interface overview, Active Interface Module 16 kW Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 121 Line connection and line-side power components 3.9 Active Interface Modules internal air cooling Figure 3-52 Interface overview, Active Interface Module 36 kW Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 122 Line connection and line-side power components 3.9 Active Interface Modules internal air cooling Figure 3-53 Interface overview, Active Interface Module 55 kW Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 123: Line/Load Connection

Line connection and line-side power components 3.9 Active Interface Modules internal air cooling Figure 3-54 Interface overview, Active Interface Module 80 kW and 120 kW 3.9.3.2 Line/load connection Table 3- 22 Line and load connection Active Interface Module 6SL3100-0BE21- 6SL3100-0BE23- 6SL3100-0BE25- 6SL3100-0BE28- 6SL3100-0BE31-... -

Page 124: X121 Temperature Sensor And Fan Control

Line connection and line-side power components 3.9 Active Interface Modules internal air cooling Note The connection terminals of the 36 kW Active Interface Module are only certain to be safe from touch protection according to EN 60529 if cables with a minimum cross-section of 25 mm²... -

Page 125: Connection Example

Line connection and line-side power components 3.9 Active Interface Modules internal air cooling Note The two "+" and "M" terminals are jumpered in the connector. This ensures the supply voltage is looped through. 3.9.4 Connection example Digital output (DO), controlled by the Control Unit Figure 3-55 Connection example: Active Interface Module Booksize Power Units... -

Page 126: Dimension Drawings

Line connection and line-side power components 3.9 Active Interface Modules internal air cooling 3.9.5 Dimension drawings Figure 3-56 Dimension drawing of Active Interface Module 16 kW, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 127 Line connection and line-side power components 3.9 Active Interface Modules internal air cooling Figure 3-57 Dimension drawing of Active Interface Module 36 kW, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 128 Line connection and line-side power components 3.9 Active Interface Modules internal air cooling Figure 3-58 Dimension drawing of Active Interface Module 55 kW, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 129 Line connection and line-side power components 3.9 Active Interface Modules internal air cooling Figure 3-59 Dimension drawing of Active Interface Module 80 kW and 120 kW, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 130: Installation

Line connection and line-side power components 3.9 Active Interface Modules internal air cooling 3.9.6 Installation The Active Interface Modules are designed for installation in the control cabinet. The Active Interface Modules should if possible be mounted directly next to the Active Line Module. ①... - Page 131 Line connection and line-side power components 3.9 Active Interface Modules internal air cooling ① Mounting panel ② M6 screws, Torx T30 (not hexagon-head screws) Figure 3-61 Installation of 36 kW Active Interface Module Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 132 Line connection and line-side power components 3.9 Active Interface Modules internal air cooling ① Mounting panel ② Washer ③ M6 screws, Torx T30 (not hexagon-head screws) Figure 3-62 Installation of 55 kW Active Interface Module Tightening torque for all screws: 6 Nm Table 3- 25 Protective conductor connection Active Interface Module...

-

Page 133: Operation On An Isolated-Neutral System (It System)

Line connection and line-side power components 3.9 Active Interface Modules internal air cooling 3.9.7 Operation on an isolated-neutral system (IT system) IT system In IT systems, all live parts are isolated from ground, or one point is connected to ground through an impedance. -

Page 134: Electrical Tests

Line connection and line-side power components 3.9 Active Interface Modules internal air cooling Remove the connection bracket to the Withdraw the connection bracket. Connection bracket for the noise suppression capacitor using a interference-suppression capacitor Tx25 screwdriver Note Installing the connection bracket for the interference-suppression capacitor For operation in other line supplies, the connection bracket must be reinstalled and fixed with a tightening torque of 1.8 Nm. -

Page 135: Technical Data

Line connection and line-side power components 3.9 Active Interface Modules internal air cooling 3.9.9 Technical data Table 3- 27 Technical data Active Interface Module 6SL3100- 0BE21-6ABx 0BE23-6ABx 0BE25-5ABx 0BE28-0ABx 0BE31-2ABx 16 kW 36 kW 55 kW 80 kW 120 kW rated Current requirement of 0,25... -

Page 136: Combining Line Reactors And Line Filters

Line connection and line-side power components 3.10 Combining line reactors and line filters 3.10 Combining line reactors and line filters Figure 3-63 Combining line reactors and line filters Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... -

Page 137: Line Connection Variants

Line connection and line-side power components 3.11 Line connection variants 3.11 Line connection variants 3.11.1 Ways of connecting the line supply A distinction is made between the following line connection versions: ● Line connection components to be directly connected to the line supply ●... - Page 138 Line connection and line-side power components 3.11 Line connection variants Note Permissible line supplies In combination with the drive system, the motors are generally approved for operation on TN and TT systems with grounded neutral point and on IT systems. WARNING Fire hazard for the motor due to overload of the insulation There is higher stress on the motor insulation through a ground fault in an IT system or...

-

Page 139: Operating Line Connection Components On The Line Supply

Line connection and line-side power components 3.11 Line connection variants 3.11.2 Operating line connection components on the line supply The SINAMICS S Booksize converter system is rated for direct operation on TN, TT, and IT line supply systems with a rated voltage of 380 V 3 AC to 480 V 3 AC. Figure 3-65 Direct operation on the line supply Booksize Power Units... -

Page 140: Operation Of The Line Connection Components Via A Transformer

Line connection and line-side power components 3.11 Line connection variants 3.11.3 Operation of the line connection components via a transformer 3.11.3.1 Safety instructions for line connection components NOTICE Destruction or damage to additional loads as a result of undesirable line harmonics Line harmonics can occur if line filters that differ from those listed in this Manual are used. -

Page 141: Line Supply Connection Conditions For Line Modules

Line connection and line-side power components 3.11 Line connection variants 3.11.3.2 Line supply connection conditions for Line Modules Table 3- 28 Line supply connection conditions for Line Modules Module Description Basic Line Module Operation on line supplies from S ≥ 30 Kline Smart Line Module Operation on line supplies from S... -

Page 142: Dimensioning An Isolating Transformer / Autotransformer For Several Loads

Line connection and line-side power components 3.11 Line connection variants 3.11.3.3 Dimensioning an isolating transformer / autotransformer for several loads A SINAMICS Line Module and other loads/machines should be connected via an isolating transformer / autotransformer (matching transformer) to the line supply. The following diagram shows the connection using an isolating transformer as an example. - Page 143 Line connection and line-side power components 3.11 Line connection variants An isolating transformer / autotransformer (matching transformer) must be dimensioned for the total of all loads connected to it. The apparent power required for the Line Modules must be determined and added as indicated in table "Transformer configuration instructions". If the transformer is underdimensioned (S or S ), this can lead to increased line voltage dips and...

- Page 144 Line connection and line-side power components 3.11 Line connection variants Special case: When operating with only one supply at a transformer, the values may be reduced by the factor 0.73. ≥ 0.73 • 70 • P (for Active Line Module and Smart Line Module) K line ≥...

- Page 145 Line connection and line-side power components 3.11 Line connection variants Rated power of the used Required rated power of the Required short-circuit Minimum system fault level isolating transformer / voltage U required Active Module P autotransformer (70 • P Kline (1.27 •...

- Page 146 Line connection and line-side power components 3.11 Line connection variants > S ⇒ S is decisive. The matching transformer requires a rated power S of 21 kVA for a short-circuit voltage u of 1%. Example 3: If S is smaller, the transformer must be stronger. K plant matching transformer = 3%, = 3,000 kVA...

-

Page 147: Operating Line Connection Components Via An Autotransformer

Line connection and line-side power components 3.11 Line connection variants 3.11.3.4 Operating line connection components via an autotransformer An autotransformer can be used to adapt the voltage in the range up to 3-ph. 480 VAC +10%. DANGER Danger to life due to electric shock in the event that an isolating transformer is not used At high voltages an isolating transformer must be used in order to implement protective separation. - Page 148 Line connection and line-side power components 3.11 Line connection variants Figure 3-67 Operation of a Line Module via an autotransformer Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 149: Operating Line Connection Components Via An Isolating Transformer

Line connection and line-side power components 3.11 Line connection variants 3.11.3.5 Operating line connection components via an isolating transformer An isolating transformer converts the line supply type of the plant or system (e.g. IT system) to a TN system. Additional voltage adaptation to the permissible voltage tolerance range is possible. - Page 150 Line connection and line-side power components 3.11 Line connection variants Figure 3-68 Operation of a Line Module via an isolating transformer Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 151: Line Modules Booksize

Line Modules Booksize Safety instructions for Line Modules Booksize WARNING Danger to life if the fundamental safety instructions and remaining risks are not carefully observed If the fundamental safety instructions and remaining risks in Chapter 1 (Page 25) are not observed, accidents involving severe injuries or death may occur. - Page 152 This can result in serious injury or death. • Only use adapters (DC link adapters and DC link rectifier adapters) released by Siemens for the connection to the DC link. WARNING Danger to life through electric shock due to incorrectly installed DC link bridges Incorrectly installed DC link bridges at the left-hand end of the drive line-up can cause an electric shock.

- Page 153 Line Modules Booksize 4.1 Safety instructions for Line Modules Booksize WARNING Danger to life through electric shock due to missing DC link side covers There is a danger of an electric shock through contact when the side covers of the DC link are missing.

- Page 154 Damage or malfunctions can occur on the devices or system when DRIVE-CLiQ cables are used that are either incorrect or have not been approved for this purpose. • Only use suitable DRIVE-CLiQ cables that have been approved by Siemens for the particular application.

- Page 155 Line Modules Booksize 4.1 Safety instructions for Line Modules Booksize Special features for Line Modules with external air cooling Note Component failure due to the pollution of external heat sinks For components with external air cooling, the fan and the heat sinks can accumulate a lot of pollution.

-

Page 156: Active Line Modules With Internal Air Cooling

Line Modules Booksize 4.2 Active Line Modules with internal air cooling Active Line Modules with internal air cooling 4.2.1 Description Active Line Modules generate a constant, regulated DC voltage in the DC link from the 3- phase line supply voltage that supplies the connected Motor Modules with power. This ensures that they are not influenced by line voltage fluctuations. -

Page 157: Interface Description

Line Modules Booksize 4.2 Active Line Modules with internal air cooling 4.2.2 Interface description 4.2.2.1 Overview Figure 4-1 Interface overview, Active Line Module with internal air cooling (example: 16 kW) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... -

Page 158: X1 Line Connection

Line Modules Booksize 4.2 Active Line Modules with internal air cooling 4.2.2.2 X1 line connection Table 4- 1 X1: Line connection for Active Line Modules 16 kW Terminal Technical data Max. connectable cross-section: 10 mm Type: Screw terminal 6 (Page 755) Tightening torque: 1.5 …... -

Page 159: X12 Fan Connection

Type: Screw terminal 1 (Page 755) Max. cross-section that can be connected: 1.5 mm The temperature sensor type and the temperature output can be selected by parameter (see the SINAMICS S120/S150 List Manual). Temperatures are detected but not evaluated in the Active Line Module. - Page 160 Line Modules Booksize 4.2 Active Line Modules with internal air cooling Terminals X21.3 and X21.4 WARNING Danger to life when live parts are touched when terminals X21.3 and X21.4 are connected For operation, the 24 V DC voltage must be connected to terminal X21.3 and ground to terminal X21.4.

-

Page 161: X24 24 V Terminal Adapter

Line Modules Booksize 4.2 Active Line Modules with internal air cooling 4.2.2.5 X24 24 V terminal adapter Table 4- 5 X24: 24 V terminal adapter Terminal Designation Technical data 24 V power supply 24 V DC supply voltage Ground Electronics ground Type: Screw terminal 5 (Page 755) Max. -

Page 162: Connection Example

Line Modules Booksize 4.2 Active Line Modules with internal air cooling 4.2.3 Connection example Figure 4-2 Example connection of Active Line Module Note If you are using a VSM10 Voltage Sensing Module, the leading opening contact can be omitted. Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... -

Page 163: Meaning Of Leds

Both options depend on the LED status when component recognition is activated. See SINAMICS S120/S150 List Manual for the parameters to activate the recognition of components via LED WARNING Danger of death when live parts of the DC link are touched Irrespective of the state of the LED "DC LINK", hazardous DC link voltages can be present. -

Page 164: Dimension Drawings

Line Modules Booksize 4.2 Active Line Modules with internal air cooling 4.2.5 Dimension drawings Figure 4-3 Dimension drawing of 16 kW Active Line Module with internal air cooling, all dimensions in mm and (inches) Note The shield connecting plate is supplied as standard with a 100 mm Line Module. For more information, see Chapter Shield connecting plates for power supply and motor cables (Page 617). - Page 165 Line Modules Booksize 4.2 Active Line Modules with internal air cooling Figure 4-4 Dimension drawing of 36 kW and 55 kW Active Line Modules with internal air cooling (example, 36 kW), all dimensions in mm and (inches) Table 4- 8 Dimensions of 36 kW and 55 kW Active Line Modules with internal air cooling Active Line Module Order number...

- Page 166 Line Modules Booksize 4.2 Active Line Modules with internal air cooling Figure 4-5 Dimension drawing of 80 kW and 120 kW Active Line Modules with internal air cooling, all dimensions in mm and (inches) Table 4- 9 Dimensions of 80 kW and 120 kW Active Line Modules with internal air cooling Active Line Module Order number B [mm] (inches)

- Page 167 Line Modules Booksize 4.2 Active Line Modules with internal air cooling Figure 4-6 Dimension drawing of fan for 80 kW and 120 kW Active Line Modules with internal air cooling, all dimensions in mm and (inches) Note The fans for the 80 kW and 120 kW Active Line Modules are included in the scope of delivery.

-

Page 168: Installation

Line Modules Booksize 4.2 Active Line Modules with internal air cooling 4.2.6 Installation Active Line Modules are designed for installation in the control cabinet. They are fixed to the control cabinet panel or a mounting panel using M6 screws. ① Control cabinet panel/mounting panel ②... - Page 169 Line Modules Booksize 4.2 Active Line Modules with internal air cooling Installing the sub-chassis fan Figure 4-8 Mounting the fan for Active Line Modules 80 kW and 120 kW 1. Fix the fan with M6 screws (tightening torque: 6 Nm). 2.

-

Page 170: Technical Data

Line Modules Booksize 4.2 Active Line Modules with internal air cooling 4.2.7 Technical data Table 4- 10 Technical data of Active Line Modules Internal air cooling 6SL3130– 7TE21–6AAx 7TE23–6AAx 7TE25–5AAx 7TE25–5AA3 + Active Interface Module Rated power Infeed Rated power (S1) kW (P Infeed power (S6 - 40 %) kW (P... - Page 171 Line Modules Booksize 4.2 Active Line Modules with internal air cooling Internal air cooling 6SL3130– 7TE21–6AAx 7TE23–6AAx 7TE25–5AAx 7TE25–5AA3 + Active Interface Module Rated power Circuit breaker See Section Overcurrent protection using line fuses and circuit (IEC 60947 and UL) breakers (Page 51) Rated short-circuit current SCCR...

- Page 172 Line Modules Booksize 4.2 Active Line Modules with internal air cooling Internal air cooling 6SL3130– 7TE28–0AAx 7TE31–2AAx Rated power DC link currents Rated DC link current: for 600 V: DC link current: for 600 V DC; for S6 - 40 % for 600 V DC;...

-

Page 173: Characteristics

Line Modules Booksize 4.2 Active Line Modules with internal air cooling 4.2.7.1 Characteristics Rated duty cycles for Active Line Modules Figure 4-9 Rated duty cycles for Active Line Modules (exception: not applicable for 55 kW Active Line Module with Active Interface Module) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 174 Line Modules Booksize 4.2 Active Line Modules with internal air cooling Rated duty cycles for Active Line Modules with Active Interface Modules Figure 4-10 Load cycles for 55 kW Active Line Modules with Active Interface Module Figure 4-11 Peak load cycle with initial load for 55 kW Active Line Modules with Active Interface Module Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 175 Line Modules Booksize 4.2 Active Line Modules with internal air cooling Derating characteristics Note For additional information, see chapter Derating as a function of the installation altitude and ambient temperature (Page 47). Figure 4-12 Output current as a function of the ambient temperature Figure 4-13 Output current as a function of the installation altitude Booksize Power Units...

-

Page 176: Active Line Modules With External Air Cooling

Line Modules Booksize 4.3 Active Line Modules with external air cooling Active Line Modules with external air cooling 4.3.1 Description The Motor Modules are connected to the power supply network via the Active Line Modules with external air cooling which provide the Motor Modules with a constant DC link voltage. This ensures that they are not influenced by line voltage fluctuations. -

Page 177: Interface Description

Line Modules Booksize 4.3 Active Line Modules with external air cooling 4.3.2 Interface description 4.3.2.1 Overview Figure 4-14 Interface overview, Active Line Module with external air cooling (example: 16 kW) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... -

Page 178: X1 Line Connection

Line Modules Booksize 4.3 Active Line Modules with external air cooling 4.3.2.2 X1 line connection Table 4- 12 X1: Line connection for Active Line Modules 16 kW Terminal Technical data Max. connectable cross-section: 10 mm Type: Screw terminal 6 (Page 755) Tightening torque: 1.5 …... -

Page 179: X12 Fan Connection

Type: Screw terminal 1 (Page 755) Max. cross-section that can be connected: 1.5 mm The temperature sensor type and the temperature output can be selected by parameter (see the SINAMICS S120/S150 List Manual). Temperatures are detected but not evaluated in the Active Line Module. - Page 180 Line Modules Booksize 4.3 Active Line Modules with external air cooling Terminals X21.3 and X21.4 WARNING Danger to life when live parts are touched when terminals X21.3 and X21.4 are connected For operation, the 24 V DC voltage must be connected to terminal X21.3 and ground to terminal X21.4.

-

Page 181: X24 24 V Terminal Adapter

Line Modules Booksize 4.3 Active Line Modules with external air cooling 4.3.2.5 X24 24 V terminal adapter Table 4- 16 X24: 24 V terminal adapter Terminal Designation Technical data 24 V power supply 24 V DC supply voltage Ground Electronics ground Type: Screw terminal 5 (Page 755) Max. -

Page 182: Connection Example

Line Modules Booksize 4.3 Active Line Modules with external air cooling 4.3.3 Connection example Figure 4-15 Example connection of Active Line Module Note If you are using a VSM10 Voltage Sensing Module, the leading opening contact can be omitted. Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... -

Page 183: Meaning Of Leds

Both options depend on the LED status when component recognition is activated. See SINAMICS S120/S150 List Manual for the parameters to activate the recognition of components via LED WARNING Danger of death when live parts of the DC link are touched Irrespective of the state of the LED "DC LINK", hazardous DC link voltages can be present. -

Page 184: Dimension Drawings

Line Modules Booksize 4.3 Active Line Modules with external air cooling 4.3.5 Dimension drawings Figure 4-16 Dimension drawing of 16 kW Active Line Module with external air cooling, all dimensions in mm and (inches) Table 4- 19 Dimensions of 16 kW Active Line Module with external air cooling Active Line Module Order number B [mm] (inches) b [mm] (inches) - Page 185 Line Modules Booksize 4.3 Active Line Modules with external air cooling Figure 4-17 Dimension drawing of 36 kW, 55 kW, 80 kW, and 120 kW Active Line Modules with external air cooling (example 36 kW), all dimensions in mm and (inches) Table 4- 20 Dimensions of 36 kW, 55 kW, 80 kW, and 120 kW Active Line Modules with external air cooling Active Line...

- Page 186 Line Modules Booksize 4.3 Active Line Modules with external air cooling Figure 4-18 Dimension drawing of fan for 80 kW and 120 kW Active Line Modules with external air cooling, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

-

Page 187: Mounting

Line Modules Booksize 4.3 Active Line Modules with external air cooling 4.3.6 Mounting ① Mounting plate with openings for mounting ② M6 studs ③ M6 nut ④ Spring washer ⑤ Washer ⑥ Fan assembly Figure 4-19 Mounting an Active Line Module with external air cooling (example: 36 kW) Tightening torques: ●... - Page 188 Line Modules Booksize 4.3 Active Line Modules with external air cooling Help with the mechanical control cabinet design is available from: Siemens AG Industry Sector, IA DT MC MF - WKC AS TCCCC (Technical Competence Center Cabinets Chemnitz) Postfach 1124 09070 Chemnitz, Germany e-mail: cc.cabinetcooling.aud@siemens.com...

- Page 189 Line Modules Booksize 4.3 Active Line Modules with external air cooling ① Insert plate or mounting plate ② Cross-piece ③ Reinforcing bracket Figure 4-21 Openings to mount an Active Line Module 300 mm with external air cooling, all data in mm and (inches) Table 4- 21 Dimensions of openings to mount Active Line Modules with external air cooling Component width...

- Page 190 Line Modules Booksize 4.3 Active Line Modules with external air cooling ① Insert plate or mounting plate ② Threaded bolts M5 x 28 Figure 4-22 Example of a mounting plate for a drive line-up with external air cooling When mounting it must be ensured that the component's seal is tight throughout. The cross- pieces must have the appropriate stability.

- Page 191 Line Modules Booksize 4.3 Active Line Modules with external air cooling ① Mounting plate ② Cover ③ Rear panel ④ Air discharge ⑤ Air inlet - filter with filter fan ⑥ ⑥ To comply with degree of protection IP54, the surfaces between the mounting plate and the cabinet strip must be sealed all round.

- Page 192 Line Modules Booksize 4.3 Active Line Modules with external air cooling ① Insert plate ② Mounting plate ③ Cover ④ Rear panel ⑤ Air discharge ⑥ Air inlet - filter with filter fan ⑦ ⑦ To maintain the degree of protection IP54, the surfaces between the mounting plate and the cabinet strip as well as between the mounting plate and insert plate must be sealed all around.

-

Page 193: Technical Data

Line Modules Booksize 4.3 Active Line Modules with external air cooling Note If the cooling air requirement is not covered by the filtered fan, the components cannot output their specified power. The filters with filter fan must be regularly checked for dirt and cleaned if necessary. 4.3.7 Technical data Table 4- 22... - Page 194 Line Modules Booksize 4.3 Active Line Modules with external air cooling External air cooling 6SL3131– 7TE21–6AAx 7TE23–6AAx 7TE25–5AAx 7TE25–5AA3 + Active Interface Module Rated power Total power loss 282,8 945,6 945,6 (including electronics losses, see Power loss tables (Page 781)) Max.

- Page 195 Line Modules Booksize 4.3 Active Line Modules with external air cooling External air cooling 6SL3131– 7TE28–0AAx 7TE31-2AAx Rated power DC link voltage 510 … 720 Overvoltage trip 820 ± 2 % Undervoltage trip 360 ± 2 % Input currents Rated input current at AC 400 V: Input current at AC 380 V / AC 480 V...

-

Page 196: Characteristics

Line Modules Booksize 4.3 Active Line Modules with external air cooling 4.3.7.1 Characteristics Rated duty cycles for Active Line Modules Figure 4-25 Rated duty cycles for Active Line Modules (exception: not applicable for 55 kW Active Line Module with Active Interface Module) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 197 Line Modules Booksize 4.3 Active Line Modules with external air cooling Rated duty cycles for Active Line Modules with Active Interface Modules Figure 4-26 Load cycles for 55 kW Active Line Modules with Active Interface Module Figure 4-27 Peak load cycle with initial load for 55 kW Active Line Modules with Active Interface Module Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 198 Line Modules Booksize 4.3 Active Line Modules with external air cooling Derating characteristics Note For additional information, see chapter Derating as a function of the installation altitude and ambient temperature (Page 47). Figure 4-28 Output current as a function of the ambient temperature Figure 4-29 Output current as a function of the installation altitude Booksize Power Units...

-

Page 199: Active Line Modules With Cold Plate

Line Modules Booksize 4.4 Active Line Modules with cold plate Active Line Modules with cold plate 4.4.1 Description Active Line Modules generate a constant, regulated DC voltage in the DC link from the 3- phase line supply voltage that supplies the connected Motor Modules with power. This ensures that they are not influenced by line voltage fluctuations. -

Page 200: Interface Description

Line Modules Booksize 4.4 Active Line Modules with cold plate 4.4.2 Interface description 4.4.2.1 Overview Figure 4-30 Interface overview, Active Line Module with cold plate (example: 16 kW) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... -

Page 201: X1 Line Connection

Line Modules Booksize 4.4 Active Line Modules with cold plate 4.4.2.2 X1 line connection Table 4- 24 X1: Line connection for Active Line Modules 16 kW Terminal Technical data Max. connectable cross-section: 10 mm Type: Screw terminal 6 (Page 755) Tightening torque: 1.5 …... -

Page 202: X21 Ep Terminals

Type: Screw terminal 1 (Page 755) Max. cross-section that can be connected: 1.5 mm The temperature sensor type and the temperature output can be selected by parameter (see the SINAMICS S120/S150 List Manual). Temperatures are detected but not evaluated in the Active Line Module. -

Page 203: X24 24 V Terminal Adapter

Line Modules Booksize 4.4 Active Line Modules with cold plate NOTICE Damage to the drive electronics when switching the line contactor under load When switching the line contactor (type according to the recommended selection) under load, then the contacts will be subject to premature wear. This can cause the contactor to malfunction, with subsequent damage to the drive electronics. -

Page 204: X200-X202 Drive-Cliq Interfaces

Line Modules Booksize 4.4 Active Line Modules with cold plate 4.4.2.5 X200-X202 DRIVE-CLiQ interfaces Table 4- 28 X200-X202: DRIVE-CLiQ interfaces Signal name Technical data Transmit data + Transmit data - Receive data + Reserved, do not use Reserved, do not use Receive data - Reserved, do not use Reserved, do not use... -

Page 205: Connection Example

Line Modules Booksize 4.4 Active Line Modules with cold plate 4.4.3 Connection example Figure 4-31 Connection example: Active Line Module with cold plate Note If you are using a VSM10 Voltage Sensing Module, the leading opening contact can be omitted. Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... -

Page 206: Meaning Of Leds

Both options depend on the LED status when component recognition is activated. See SINAMICS S120/S150 List Manual for the parameters to activate the recognition of components via LED WARNING Danger of death when live parts of the DC link are touched Irrespective of the state of the LED "DC LINK", hazardous DC link voltages can be present. -

Page 207: Dimension Drawings

Line Modules Booksize 4.4 Active Line Modules with cold plate 4.4.5 Dimension drawings Figure 4-32 Dimension drawing of 16 kW Active Line Module with cold plate, all dimensions in mm and (inches) Table 4- 30 Dimensions of 16 kW Active Line Module with cold plate Active Line Module Order number B [mm] (inches) - Page 208 Line Modules Booksize 4.4 Active Line Modules with cold plate Figure 4-33 Dimension drawing of 36 kW, 55 kW, 80 kW, and 120 kW Active Line Modules with cold plate, all dimensions in mm and (inches) Table 4- 31 Dimensions of 36 kW, 55 kW, 80 kW, and 120 kW Active Line Modules with cold plate Active Line Module Order number B [mm] (inches)

-

Page 209: Mounting

Note the mounting position of the heat-conducting foil (see diagram below). Note • Also replace the heat-conducting foil when replacing a component. • Only use heat-conducting foil released or supplied by Siemens. Table 4- 32 Overview of heat-conducting foils Order number... - Page 210 Line Modules Booksize 4.4 Active Line Modules with cold plate Mounting ① External heat sink (air or liquid) ② M6 studs ③ Heat-conducting foil ④ Cold plate ⑤ M6 nut ⑥ Spring washer ⑦ Washer Figure 4-34 Mounting an Active Line Module with cold plate on an external heat sink (example: 36 Tightening torques: ●...

- Page 211 Line Modules Booksize 4.4 Active Line Modules with cold plate Help with the mechanical control cabinet design is available from: Siemens AG Industry Sector, IA DT MC MF - WKC AS TCCCC (Technical Competence Center Cabinets Chemnitz) Postfach 1124 09070 Chemnitz, Germany e-mail: cc.cabinetcooling.aud@siemens.com...

-

Page 212: Technical Data

Line Modules Booksize 4.4 Active Line Modules with cold plate 4.4.7 Technical data Table 4- 33 Technical data for Active Line Modules with cold plate cooling Cold plate 6SL3136- 21-6AAx 23-6AAx 25-5AAx 25-5AA3 + 28-0AAx 31-2AAx Active Interface Module Rated power 80 (64) 120 (84) Infeed... - Page 213 Line Modules Booksize 4.4 Active Line Modules with cold plate Cold plate 6SL3136- 21-6AAx 23-6AAx 25-5AAx 25-5AA3 + 28-0AAx 31-2AAx Active Interface Module DC link capacitance Active Line Module μF 1410 1880 1880 2820 3760 Drive line-up, max. μF 20000 20000 20000 20000...

-

Page 214: Characteristics

Line Modules Booksize 4.4 Active Line Modules with cold plate 4.4.7.1 Characteristics Rated duty cycles for Active Line Modules Figure 4-35 Rated duty cycles for Active Line Modules (exception: not applicable for 55 kW Active Line Module with Active Interface Module) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... - Page 215 Line Modules Booksize 4.4 Active Line Modules with cold plate Rated duty cycles for Active Line Modules with Active Interface Modules Figure 4-36 Load cycles for 55 kW Active Line Modules with Active Interface Module Figure 4-37 Peak load cycle with initial load for 55 kW Active Line Modules with Active Interface Module Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6...

- Page 216 Line Modules Booksize 4.4 Active Line Modules with cold plate Derating characteristics Note For additional information, see chapter Derating as a function of the installation altitude and ambient temperature (Page 47). Figure 4-38 Output current as a function of the ambient temperature Figure 4-39 Output current as a function of the installation altitude Booksize Power Units...

-

Page 217: Active Line Modules Liquid Cooled

Line Modules Booksize 4.5 Active Line Modules Liquid Cooled Active Line Modules Liquid Cooled 4.5.1 Description Active Line Modules generate a constant, regulated DC voltage in the DC link from the 3- phase line supply voltage that supplies the connected Motor Modules with power. This ensures that they are not influenced by line voltage fluctuations. -

Page 218: Interface Description

Line Modules Booksize 4.5 Active Line Modules Liquid Cooled 4.5.2 Interface description 4.5.2.1 Overview Figure 4-40 Interface overview, Active Line Module Liquid Cooled (120 kW) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... -

Page 219: X1 Line Connection

Type: Screw terminal 1 (Page 755) Max. cross-section that can be connected: 1.5 mm The temperature sensor type and the temperature output can be selected by parameter (see the SINAMICS S120/S150 List Manual). Temperatures are detected but not evaluated in the Active Line Module. - Page 220 Line Modules Booksize 4.5 Active Line Modules Liquid Cooled Terminals X21.1 and X21.2 When using an Active Interface Module, the temperature output of the Active Interface Module must be connected at terminals X21.1 and X21.2. Terminals X21.3 and X21.4 WARNING Danger to life when live parts are touched when terminals X21.3 and X21.4 are connected For operation, the 24 V DC voltage must be connected to terminal X21.3 and ground to terminal X21.4.

-

Page 221: X24 24 V Terminal Adapter

Line Modules Booksize 4.5 Active Line Modules Liquid Cooled 4.5.2.4 X24 24 V terminal adapter Table 4- 36 X24: 24 V terminal adapter Terminal Designation Technical data 24 V power supply 24 V DC supply voltage Ground Electronics ground Type: Screw terminal 5 (Page 755) Max. -

Page 222: Connection Example

Line Modules Booksize 4.5 Active Line Modules Liquid Cooled 4.5.3 Connection example Figure 4-41 Example connection of Active Line Module Note If you are using a VSM10 Voltage Sensing Module, the leading opening contact can be omitted. Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... -

Page 223: Meaning Of Leds

Both options depend on the LED status when component recognition is activated. See SINAMICS S120/S150 List Manual for the parameters to activate the recognition of components via LED WARNING Danger of death when live parts of the DC link are touched Irrespective of the state of the LED "DC LINK", hazardous DC link voltages can be present. -

Page 224: Dimension Drawing

Line Modules Booksize 4.5 Active Line Modules Liquid Cooled 4.5.5 Dimension drawing ① Pipe thread ISO 228 G ½ B. Figure 4-42 Dimension drawing of Active 120 kW Line Module Liquid Cooled, all dimensions in mm and (inches) Booksize Power Units Manual, (GH2), 04/2014, 6SL3097-4AC00-0BP6... -

Page 225: Installation

Line Modules Booksize 4.5 Active Line Modules Liquid Cooled 4.5.6 Installation ① Mounting surface ② M6 studs ③ Heat sink ④ Washer ⑤ Spring washer ⑥ M6 nut Figure 4-43 Mounting an Active Line Module Liquid Cooled Tightening torques: ● Firstly, tighten the nuts by hand. Tightening torque: 0.5 Nm ●... -

Page 226: Technical Data