Siemens SINAMICS S120 Manual

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Summary of Contents for Siemens SINAMICS S120

- Page 1 Control of a SINAMICS S120 with an Allen- Bradley controller (Compact/ControlLogix) via EtherNet/IP Siemens Industry Online https://support.industry.siemens.com/cs/ww/en/view/92045369 Support...

- Page 2 The foregoing provisions do not imply any change in the burden of proof to your detriment. You shall indemnify Siemens against existing or future claims of third parties in this connection except where Siemens is mandatorily liable.

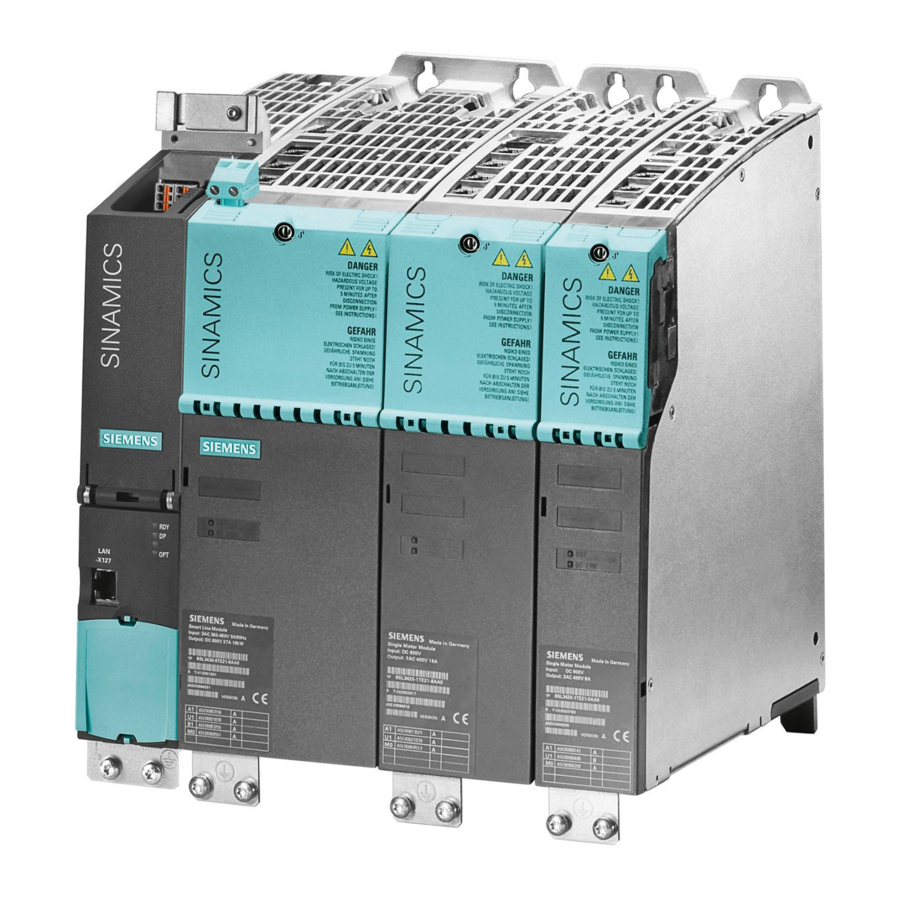

- Page 3 SINAMICS drive through the built in X150 ports on CU310-2 or CU320-2 and set IP address. The SINAMICS S120 multi-axis drive system can contain up to six vector or servo axis controlled by a single CU320-2 control unit. This allows one IP address for the CU320-2 to control multiple drive objects thus cutting down on the number of IP addresses and Ethernet connections required for drive systems.

- Page 4 Reference Actual values values Control Status word word SINAMICS S120 SINAMICS S120 CU320-2 CU310-2 Used Components The application was generated with the following components: Table 2-1 Hardware components Component CU320-2 PN or CU310-2 PN with Firmware version 5.1SP1 or later...

- Page 5 SINAMICS S120 drives connected to an AB Logix’s automation systems over EtherNet/IP. The EtherNet/IP telegrams to the SINAMICS S120 drives can be freely configured using the free telegram structure for the message frame type. Alternatively in an effort to seamlessly integrate the communication between an S120 drive object and...

- Page 6 For additional information on this telegram and its detailed function, refer to the SINAMICS S120 List Manual and Function Manual.

- Page 7 4.2.3 Telegram 111 for EPOS mode Telegram 111 is a standard Siemens Telegram for a positioning drive. It allows sequence and control of the drive functions in addition to control of the positioning function EPOS. This interface is used for “EPOS” AOI. 12 Words of data are exchanged with the drive where the 12th word is reserved as a user selectable value.

- Page 8 4 SINAMICS S120 Add-On Instructions Basic Speed Control 4.3.1 Functionality The S120 Speed Block provides an interface for basic speed control of a Servo or Vector drive object in SINAMICS via EtherNet/IP. The Drive object is configured for control using Standard telegram type 1.

- Page 9 4 SINAMICS S120 Add-On Instructions Table 4-6 IN/OUT Parameters Variable Name Data Type Description DRV_CONTROL ARRAY Array of 2 integers referenced to the two output words of the drive telegram DRV_STATUS ARRAY Array of 2 integers referenced to the two input...

- Page 10 4 SINAMICS S120 Add-On Instructions Vector Speed_T352 4.4.1 Functionality The Vector speed block is very useful for a lot of speed control applications. This telegram is only available for S120 Drive Objects of the Type Vector and not Servo. The control is similar to Telegram 1 (Simple Speed) but there are 4 additional Setpoints words that can be connected to functionality in a S120 Vector Drive Object.

- Page 11 4 SINAMICS S120 Add-On Instructions 4.4.3 Input and Output Parameters Table 4-8 Input Parameters Variable Name Data Type Description Vector_Speed_T352 Instance Data ON_OFF1 BOOL ON_OFF1 Drive Enable (ON/OFF1) 1 = Enable Drive 0 = Ramp Down and Disable drive OFF2...

- Page 12 4 SINAMICS S120 Add-On Instructions Variable Name Data Type Description FAULTED BOOL Fault is Active ALARM BOOL Alarm is Present FAULT BOOL Fault is Present INHIBITED BOOL Drive is Inhibited (Fault or No Positive transition to OFF1 MTR_OVERTEMP_OK BOOL Motor Temperature Normal...

- Page 13 EPOS Positioner is used for the absolute and relative positioning of linear and rotary axes. The AOI provides a direct interface to EPOS control. The SINAMICS S120 List manual provides detailed explanation of all functionality available. Note that drive must be referenced before absolute positioning is allowed. State control and sequencing is not provided.

- Page 14 4 SINAMICS S120 Add-On Instructions 4.5.2 Input and Output Parameters Table 4-11 Inputs Parameters Variable Name Data Type Description S120_EPOS_BLOCK Instance Data BOOL Drive Enable (ON/OFF1) FAULT_RESET BOOL Reset Active Fault(s) 0 = No Fault Reset 1 = Reset Fault on Rising Edge...

- Page 15 4 SINAMICS S120 Add-On Instructions Table 4-12 IN/OUT Parameters Variable Name Data Type Description DRV_CONTROL ARRAY Array of 12 integers referenced to the twelve output words of the drive telegram DRV_STATUS ARRAY Array of 12 integers referenced to the twelve input words of the drive telegram...

- Page 16 4 SINAMICS S120 Add-On Instructions Advanced Speed 4.6.1 Functionality The Advance Speed Block provides an interface to the S120 Drive in speed mode for Servo mode of operation. It implements Standard Telegram 102. The AOI provides additional functionality beyond the Basic Speed AOI. A 32 bit (DINT) speed setpoint value is used for improved resolution and speed control for high performance applications.

- Page 17 4 SINAMICS S120 Add-On Instructions 4.6.3 Input and Output Parameters Table 4-14 Inputs Parameters Variable Name Data Type Description AdvSpeedBlock Instance Data ON_OFF1 BOOL Drive Enable (ON/OFF1) 1 = Enable Drive 0 = Ramp Down and Disable drive OFF2 BOOL...

- Page 18 4 SINAMICS S120 Add-On Instructions Line Module Control 4.7.1 Functionality The line module control AOI allow for simple control and monitoring of a line module for the S120 drives. The line module can be enabled via AOI inputs and an output signals the current state.

- Page 19 The main function of Control Unit (CUIO) AOI is easy access to the digital IO on the CU320-2 controller. The instruction’s parameters provide individual access to each digital IO point. In the case of a programmable IO point both Inputs and Outputs are provided. The interface is accomplished using Siemens Standard Telegram 390. 4.8.2...

- Page 20 IO data sent and received by the drive. The user application is able to directly control the telegram words and bits to accomplish control concepts not included in the AOIs provided by Siemens. This is the case when using user defined telegrams (free telegram configuration with BICO) to exchange data with the drives.

- Page 21 “Getting Started with S120 with Starter” to assist in the commissioning of the drive(s). https://support.industry.siemens.com/cs/ae/en/view/109754314 A sample application referenced in this document utilizes the 2 axis SINAMICS S120 training unit. The Red Wheel drive on the training unit is configured as a speed controlled drive and the Blue wheel drive is configured for positioning using the EPOS technology module.

- Page 22 5 Drives Configuration 3. Set IP Address for CU320-2 Dual Axis set as shown. 4. Update or use Accessible Nodes again to find drive after address setting. 5. Bring Drive Unit into Project. Choose Select and then Accept. 6. Go Online with Starter and Complete Automatic Configuration. For S120 dual axis demo the choice Servo must be used.

- Page 23 5 Drives Configuration 7. Commission Drive Object(s) as needed. Note the message frame in next section for the Example Dual Axis Demo program. Refer to documentation link in previous section if commissioning assistance is needed. Configure Message Frame Open Message Configuration and Select Telegrams needed. For this example the Drive Objects and Telegrams were used.

- Page 24 5 Drives Configuration To adjust Drive Object Number order, Highlight Drive Object and then use Up and Down arrows to move Position (“-No.” field). Figure 5-3 Set to EIP Communication 1. Open expert List for CU and Set P2030 to [10] Ethernet/IP. This works the same for the CU310-2 PN as well.

- Page 25 5 Drives Configuration Using a Freely Configurable Telegram It is possible to configure a custom telegram to fit a specific application requirement. The custom configuration can be accomplished by one of several methods listed. 1. Using a standard telegram as a template and changing the configuration manually.

- Page 26 6 Configuring a Generic Ethernet Module Configuring a Generic Ethernet Module Adding a new module A Generic IO module is used to configure the cyclic data exchange between the automation controller and the SINAMICS drive without the need for an EDS file. 6.1.1 Inserting the module Table 6-1...

- Page 27 6 Configuring a Generic Ethernet Module Enter the IP Address of the CU320-2 PN or CU310-2 PN. The Connection Parameters section configures the IO Assemblies for the CU320-2. The Assembly Instances should always be 101 through 103 for the Input, Output and Configuration Assembly respectively.

- Page 28 6 Configuring a Generic Ethernet Module 6.1.4 Using the IO Data The IO data is available as an array of integers in the controller tags section of the project tree. Figure 6-1 Controller Tags for new module SINAMICS S: Speed control of a S120 with an Allen-Bradley controller (Compact/ ControlLogix with RSLogix 5000) via EtherNet/IP Entry-ID: 92045369, V4.0,...

- Page 29 7 Using AOIs in a New Application Using AOIs in a New Application Importing AOIs The AOIs provided with the sample application can be easily integrated into a new or existing user program by importing the instructions using L5K files. 7.1.1 Installing L5K Files Table 7-1 Steps to Importing the AOIs...

- Page 30 7 Using AOIs in a New Application The Project should now show the imported Instruction. Notice that UDTs required for the instruction have also been imported. These UDTs can also be used to create additional variables and aliases. Using the AOI 7.2.1 Adding AOI to a Program Table 7-2 Using the S120 Speed Block...

- Page 31 7 Using AOIs in a New Application 7.2.2 I/O Interface Connecting the instruction to the Controller IO tags is accomplished by moving the IO data into the AOI Interface. Figure 7-1 The second rung holds the AOI. The local variables “InputDataBuffer” and “OutputDataBuffer”...

- Page 32 8 Drive Parameter Access Drive Parameter Access Explicit Messaging In many applications it is necessary to read or write parameters in the drive. This allows increased flexibility in implementation of the machine functionality. To allow this occasional (acyclic) data exchange of drive and motor parameters, the CU310-2 PN and Cu320-2 PN support explicit messaging.

- Page 33 8 Drive Parameter Access Using the MSG Instruction Table 8-1 Parameterizing the MSG Instruction MSG Instruction: Insert the MSG instruction. Instruction Tag: Create a controller scope tag for the instruction in the Tag tab of the message configuration dialog box. This tag contains the working memory area for the MSG instruction.

- Page 34 8 Drive Parameter Access To figure out what the drive object number is, navigate to “telegram configuration”. Find the corresponding drive object number (e.g. Red_Wheel = drive object 2 hex). Class: 400 + drive object number (hex) Instance: This is the parameter number of the object, in Starter.

- Page 35 8 Drive Parameter Access Attribute: This is the parameter index. For parameters without an index, use “0”. Destination: For reading a parameter select a Controller scope tag where the value will be written If writing a value to the parameter, select a tag in the Source element entry.

- Page 36 8 Drive Parameter Access To figure out the data type of the parameter, Open the Expert List and Highlight the Parameter to read as shown. Right Click on the parameter and open “Parameter Help”. The Data Type is in the Parameter Description.

- Page 37 9 Trouble Shooting Tips Trouble Shooting Tips The drive and the PLC are not communicating. Figure 9-1 1. Check the LED lights. a. PLC: Is the I/O light solid green? b. Is the COM LED on CU310-2 or PN Light LED on Cu320-2 Solid Green? c.

- Page 38 9 Trouble Shooting Tips 4. Did you parameterize the Generic Ethernet Module correctly? Check Section on Generic Ethernet Module to be sure. a. Do you have the “Comm. Format” set to Data –INT, or accidentally set to Data-DINT? b. Do the Connection Parameters (addresses and length) match the drive telegram? 5.

- Page 39 Object can be used as well as a Telegram (Discrete IO Status and Control) for the CU (Control Unit). Firmware version 5.1SP1 is needed. DO (Drive Object): The SINAMICS S120 multi-axis drive system typically consists of several drive objects for each control unit. The length and order of each drive object is set in the message frame.

- Page 40 11 History History Version Date Changes V0.1 04.06.2012 PreRelease V1.0 05.18.2012 Initial Release V1.1 06.04.2012 Changes and corrections. V2.0 06.14.2012 Add Explicit messaging Added Free telegram CU320-2PN difference V3.0 03.26.2015 Remove explicit messaging tables Update drive parameter access (explicit messaging) Added Frequently Asked Questions V4.0 09.01.2018...