Siemens SINAMICS S120 Equipment Manual

Booksize power units

Hide thumbs

Also See for SINAMICS S120:

- Function manual (1094 pages) ,

- Diagnostic manual (947 pages) ,

- Manual (848 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Siemens SINAMICS S120

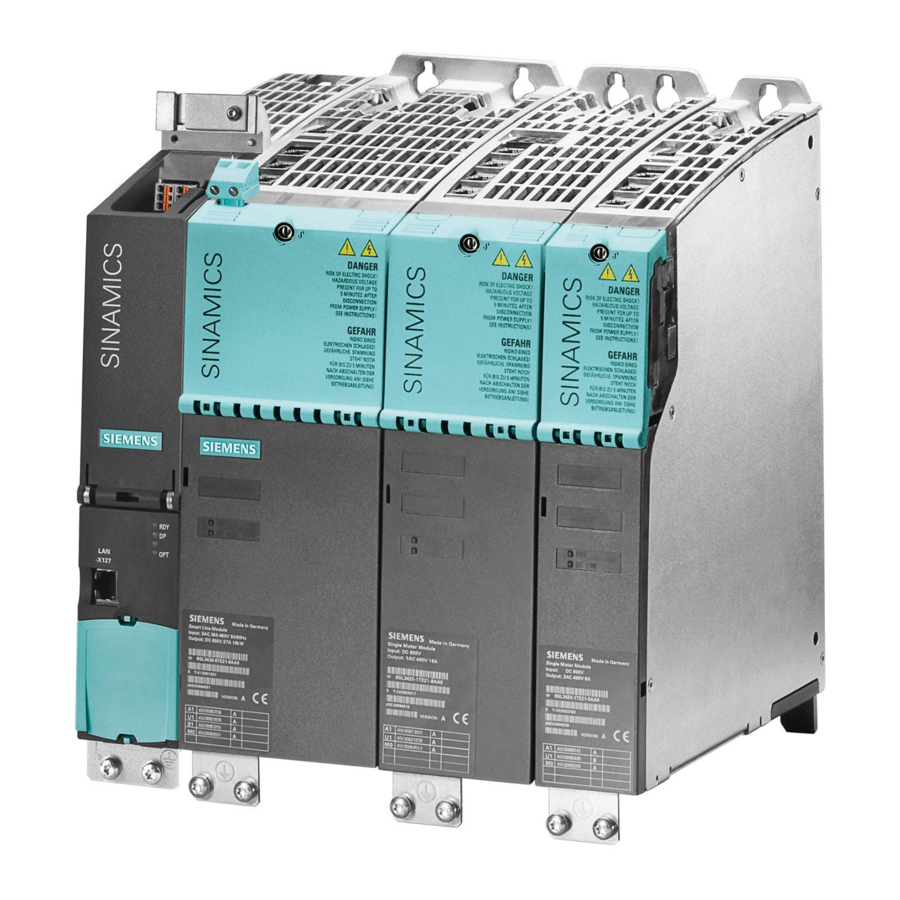

- Page 1 SINAMICS S120 Booksize Power Units sinamics...

-

Page 3: Line Modules Booksize

Foreword System Overview Line Connection Booksize SINAMICS Line Modules Booksize S120 SINAMICS S120 Booksize Power Motor Modules Booksize Units Booksize DC Link Components Equipment Manual Motor-Side Power Components Accessories Cabinet Design and EMC Booksize Service and Support Booksize Appendix A... - Page 4 Trademarks All names identified by ® are registered trademarks of the Siemens AG. The remaining trademarks in this publication may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

-

Page 5: Foreword

Orientation SINAMICS S Sales Documentation Planning/configuration SIZER Configuration Tool Decision/ordering SINAMICS S Catalogs SINAMICS S120 Equipment Manual for Control Units and Installation/assembly • Supplementary System Components SINAMICS S120 Equipment Manual Power Modules Booksize • SINAMICS S120 Equipment Manual Power Modules Chassis •... -

Page 6: Components

Foreword Usage phase Tools SINAMICS S120 Commissioning Manual Usage/operation • SINAMICS S List Manual • SINAMICS S150 Operating Instructions • SINAMICS S120 Commissioning Manual Maintenance/servicing • SINAMICS S List Manual • SINAMICS S150 Operating Instructions • Target group This Manual addresses planners, installation technicians, design engineers. - Page 7 If you have any questions (suggestions, corrections) regarding this documentation, please fax or e-mail us at: +49 9131 98 63315 E-mail E-mail to: docu.motioncontrol@siemens.com A fax form is available in the appendix of this document. Internet address for SINAMICS http://www.siemens.com/sinamics.

-

Page 8: Booksize

● in the Internet: http://support.automation.siemens.com under the Product/Order No. 15257461 ● with the responsible branch office of the A&D MC Business Division of Siemens AG. The EC Declaration of Conformity for the Low Voltage Directive can be found/obtained ● on the Internet http://support.automation.siemens.com... - Page 9 Foreword ESD information CAUTION Electrostatic sensitive devices (ESDs) are individual components, integrated circuits, or boards that may be damaged by either electrostatic fields or electrostatic discharge. Regulations for handling ESD components: When handling components, make sure that personnel, workplaces, and packaging are well earthed.

- Page 10 Foreword DANGER Correct and safe operation of SINAMICS S units assumes correct transportation in the transportation packaging, correct long-term storage in the transport packaging, setup and installation, as well as careful operation and maintenance. The details in the catalogs and proposals also apply to the design of special equipment versions.

- Page 11 Foreword Explanation of symbols The symbols are in accordance with IEC 617-2. Table 2 Symbols Symbol Description Protective earth (PE) Ground (e.g. M 24 V) Functional ground (e.g. shield) Equipotential bonding Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 12 Foreword Residual risks of power drive systems When carrying out a risk assessment of the machine in accordance with the EU Machinery Directive, the machine manufacturer must consider the following residual risks associated with the control and drive components of a power drive system (PDS). 1.

-

Page 13: Table Of Contents

Table of contents Foreword ..............................5 System Overview............................. 21 Field of application ........................21 Versions ............................22 Platform concept and Totally Integrated Automation..............23 Introduction ..........................24 SINAMICS S120 components......................27 Power sections..........................29 System data ..........................30 Standards.............................32 Line Connection Booksize ........................35 Introduction ..........................35 Overview: Line filters........................37 Combining line reactors and line filters..................39... - Page 14 Table of contents Basic Line Filter for Basic Line Modules ..................62 2.7.1 Description ..........................62 2.7.2 Safety information ........................62 2.7.3 Interface description........................64 2.7.3.1 Overview ............................. 64 2.7.3.2 Line/power connection ........................ 65 2.7.4 Dimension drawing........................65 2.7.5 Technical data..........................66 Basic Line Filter for Smart Line Modules ..................

- Page 15 Table of contents 2.13 Line connection variants ......................104 2.13.1 Ways of connecting the line supply ...................104 2.13.2 Operating line connection components on the line supply ............105 2.13.3 Operating line connection components via a matching transformer..........106 2.13.3.1 Safety information ........................106 2.13.3.2 Line supply connection conditions for Line Modules ..............106 2.13.3.3 Operation of the line connection components via an autotransformer ........113 2.13.3.4 Assignment of autotransformers to Active Line Modules ............115 2.13.3.5 Assignment of autotransformers to Smart Line Modules............117...

- Page 16 Table of contents 3.4.3.1 Overview ........................... 189 3.4.3.2 Connection example ......................... 192 3.4.3.3 X1 line connection........................194 3.4.3.4 X24 24 V terminal adapter ......................195 3.4.3.5 X200-X202 DRIVE-CLiQ interfaces ..................196 3.4.3.6 X2 braking resistor connection....................196 3.4.3.7 X21 EP terminals ........................197 3.4.3.8 Meaning of the LEDs on the Basic Line Module...............

- Page 17 Table of contents 3.7.4 Dimension drawing ........................261 3.7.5 Installation ..........................262 3.7.6 Electrical connection ........................268 3.7.7 Technical data..........................269 Motor Modules Booksize ........................273 Introduction ..........................273 Motor Modules with internal air cooling ..................275 4.2.1 Description ..........................275 4.2.2 Safety information ........................275 4.2.3 Interface description........................278 4.2.3.1 Overview ............................278 4.2.3.2...

- Page 18 Table of contents 5.2.3 Interface description........................344 5.2.3.1 Overview ........................... 344 5.2.4 Dimension drawing........................345 5.2.5 Installation ..........................346 5.2.6 Technical data........................... 347 Control Supply Module......................348 5.3.1 Description ..........................348 5.3.2 Safety information ........................348 5.3.3 Interface description........................350 5.3.3.1 Overview ...........................

- Page 19 Table of contents 7.3.4 Dimension drawing ........................406 7.3.5 Mounting ............................407 7.3.6 Electrical connection ........................409 Reinforced DC-link busbars .......................410 7.4.1 Description ..........................410 7.4.2 Safety information ........................411 7.4.3 Dimension drawings........................412 7.4.4 Removing the DC link busbars ....................414 7.4.5 Mounting the reinforced DC link busbars...................414 DRIVE-CLiQ cabinet gland ......................415 7.5.1 Description ..........................415...

- Page 20 Table of contents Connection systems........................455 8.6.1 Spring-loaded terminals/screw terminals .................. 455 8.6.2 Connectable cable cross-sections .................... 456 8.6.3 Motor connector ........................459 8.6.4 Power connector (X1/X2) ......................461 8.6.5 24 V terminal adapter........................ 464 Cooling ............................465 8.7.1 General............................465 8.7.2 Information about ventilation .....................

-

Page 21: System Overview

System Overview Field of application SINAMICS is the new range of drives from Siemens designed for mechanical and plant engineering applications. SINAMICS offers solutions for all drive tasks: ● Simple pump and fan applications in the process industry. ● Complex individual drives in centrifuges, presses, extruders, elevators, as well as conveyor and transport systems. -

Page 22: Versions

System Overview 1.2 Versions Versions SINAMICS offers different versions designed to meet a range of requirements: ● SINAMICS G is designed for standard applications with induction motors. These applications have less stringent requirements regarding the dynamics and accuracy of the motor speed. ●... -

Page 23: Platform Concept And Totally Integrated Automation

The different SINAMICS versions can be easily combined with each other. SINAMICS is part of the Siemens "Totally Integrated Automation" concept. Integrated SINAMICS systems covering configuration, data storage, and communication at automation level, ensure low-maintenance solutions with SIMATIC, SIMOTION, and SINUMERIK. -

Page 24: Introduction

System Overview 1.4 Introduction Introduction Figure 1-3 SINAMICS S120 system overview Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... - Page 25 Inter-axis connections can be established within a component and easily configured in the STARTER commissioning tool using a mouse. Simple technological tasks can be carried out by the SINAMICS S120 Control Unit itself. For complex numerical or motion-control tasks, high-performance SINUMERIK or SIMOTION D modules are used instead.

- Page 26 1.4 Introduction Electronic type plates in all components All SINAMICS S120 components have an electronic type plate. This electronic type plate contains all the relevant technical data about that particular component. In the motors, for example, this data includes the parameters of the electric equivalent circuit diagram and characteristic values for the built-in motor encoder.

-

Page 27: Sinamics S120 Components

System Overview 1.5 SINAMICS S120 components SINAMICS S120 components This overview features the SINAMICS S120 components that are primarily used for multi- axis drive tasks. Figure 1-5 SINAMICS S120 component overview Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... - Page 28 ● Supplementary system components that enhance functionality and offer different interfaces for encoders and process signals. SINAMICS S120 components were developed for installation in cabinets. They have the following features and characteristics: ● Easy to handle, simple installation and wiring ●...

-

Page 29: Power Sections

System Overview 1.6 Power sections Power sections Line Modules Convert the three-phase supply into a DC voltage for the DC link. ● Smart Line Modules The Smart Line Modules generate a non-stabilized DC link voltage and are capable of regenerative feedback. ●... -

Page 30: System Data

1.7 System data System data Technical data Unless explicitly specified otherwise, the following technical data are valid for components of the SINAMICS S120 booksize drive system. Electrical data Line connection voltage 380 V to 480 V 3 AC ±10 % (-15 % <... - Page 31 System Overview 1.7 System data Environmental conditions Degree of protection IP20 or IPXXB to EN 60529, open type to UL508 Protection class for network current circuits I (with protective conductor connection) and Protection class for electronic circuits III (protective extra low voltage DVC A / PELV) acc. to EN 61 800-5-1 Permissible coolant temperature (air) and installation 0 °C to +40 °C and an installation altitude of up to 1000 m...

-

Page 32: Standards

System Overview 1.8 Standards Standards Table 1-1 Essentially the application-relevant standards Standards Title EN ISO 12100-1 Safety of Machinery; General Design Guidelines; Part 1: Basic terminology, methodology EN ISO 12100-2 Safety of Machinery; General Design Guidelines; Part 2: Technical Principles and Specifications EN 563 Safety of machinery;... - Page 33 System Overview 1.8 Standards Standards Title EN 61800-5-X Adjustable-speed electrical power drive systems; Part 5: Safety requirements; Main section 1: Electrical, thermal and energy requirements Main section 2: Functional safety requirements VDE 0100 Teil X Erection of power installations with nominal voltages up to 1000 V; (IEC 60364-X-X) Part 200: Definitions Part 410: Protection for safety, protection against electric shock...

- Page 34 System Overview 1.8 Standards Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 35: Line Connection Booksize

● Line reactor variants: – Line reactors for Active Line Modules – Line reactors for Smart Line Modules – Line reactor for Basic Line Modules Figure 2-1 Overview: Line connection SINAMICS S120 Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... - Page 36 Overview: line connection with Active Interface Module CAUTION Using line filters not approved by SIEMENS for SINAMICS can lead to damage/ interference to the Line Modules and line-side harmonics that can interfere with or damage other loads operated by the network.

-

Page 37: Overview: Line Filters

2.2 Overview: Line filters Overview: Line filters A separate line filter (see catalog) must be used for the SINAMICS S120 drive line-up. An additional line filter must be used to suppress interference in other loads. To prevent mutual interference, this line filter must not be equipped with line-side capacitors with respect to ground. - Page 38 Line Connection Booksize 2.2 Overview: Line filters Basic Line Filter for Smart Line Modules Basic Line Filters for Smart Line Modules are specified for total cable lengths of up to 150 m (shielded) of category C2 to EN 61800-3. Basic Line Filters 16 kW and 36 kW for Smart Line Modules are specified for total cable lengths of up to 350 m (shielded) of category C2 to EN 61800-3.

-

Page 39: Combining Line Reactors And Line Filters

Line Connection Booksize 2.3 Combining line reactors and line filters Combining line reactors and line filters Figure 2-3 Combining line reactors and line filters Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 40: Basic Line Filter For Active Line Modules With Line Reactor

Line Connection Booksize 2.4 Basic Line Filter for Active Line Modules with line reactor Basic Line Filter for Active Line Modules with line reactor 2.4.1 Description The Basic Line Filters for Active Line Modules are designed for limiting the cable-borne interference in accordance with the specifications of the EMC legislation. - Page 41 Line Connection Booksize 2.4 Basic Line Filter for Active Line Modules with line reactor DANGER The line filters listed conduct a high leakage current via the PE conductor. A permanent PE connection for the line filter or control cabinet is required due to the high leakage current of the line filters.

-

Page 42: Interface Description

Line Connection Booksize 2.4 Basic Line Filter for Active Line Modules with line reactor 2.4.3 Interface description 2.4.3.1 Overview Figure 2-4 Basic Line Filter for Active Line Modules (example: 36 kW) WARNING The line/load connection must not be interchanged. Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 43: Line Supply/Load Connection

Line Connection Booksize 2.4 Basic Line Filter for Active Line Modules with line reactor 2.4.3.2 Line supply/load connection Table 2-2 Type of connection Terminals Designations Line supply connection (line supply) L1, L2, L3, PE Load connection (load) L1´, L2´, L3´, PE Basic Line Filter for Active Line Modules 16 kW Screw terminal: 10 mm... -

Page 44: Dimension Drawing

Line Connection Booksize 2.4 Basic Line Filter for Active Line Modules with line reactor 2.4.4 Dimension drawing Figure 2-5 Dimension drawing: Basic Line Filter for Active Line Modules (16 kW to 55 kW) Table 2-3 Dimensions: Basic Line Filter for Active Line Modules Basic Line Order number W [mm]... -

Page 45: Technical Data

Line Connection Booksize 2.4 Basic Line Filter for Active Line Modules with line reactor 2.4.5 Technical data Table 2-4 Technical data of Basic Line Filter for Active Line Modules with line reactor 6SL3000 0BE21-6DAx 0BE23-6DAx 0BE25-5DAx unit Rated power Connection voltage: Supply voltage 380 V 3 AC -10 % (-15 % <... -

Page 46: Basic Line Filter For Active Line Modules With Active Interface Module

Line Connection Booksize 2.5 Basic Line Filter for Active Line Modules with Active Interface Module Basic Line Filter for Active Line Modules with Active Interface Module 2.5.1 Description Basic Line Filters are mainly effective in the frequency range from 150 kHz to 30 MHz; this is the range relevant to ensure compliance with the appropriate standard. - Page 47 Line Connection Booksize 2.5 Basic Line Filter for Active Line Modules with Active Interface Module NOTICE The associated Line Module must only be connected to the SINAMICS line filter via the associated line reactor. Additional loads must be connected upstream of the SINAMICS line filter (if required, via a separate line filter).

-

Page 48: Interface Description

Line Connection Booksize 2.5 Basic Line Filter for Active Line Modules with Active Interface Module 2.5.3 Interface description 2.5.3.1 Overview Figure 2-6 Interface description: Basic Line Filter 55 kW Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... - Page 49 Line Connection Booksize 2.5 Basic Line Filter for Active Line Modules with Active Interface Module Figure 2-7 Interface description: 80 kW and 120 kW Basic Line Filter NOTICE The line/load connection must not be interchanged. Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 50: Line/Power Connection

Line Connection Booksize 2.5 Basic Line Filter for Active Line Modules with Active Interface Module 2.5.3.2 Line/power connection Table 2-5 Connection type Terminals Designations Line supply connection (line supply) L1, L2, L3, PE Load connection (load) L1´, L2´, L3´, PE Basic Line Filter for Active Line Module with Active Interface Module 55 kW Screw terminal: 95 mm... -

Page 51: Technical Data

Line Connection Booksize 2.5 Basic Line Filter for Active Line Modules with Active Interface Module Figure 2-9 Dimension drawing: 80 kW and 120 kW Basic Line Filter Table 2-7 Dimensions: Basic Line Filter for Active Line Modules Basic Line Order number W [mm] w [mm] a [mm]... -

Page 52: Wideband Line Filter For Active Line Modules

Line Connection Booksize 2.6 Wideband Line Filter for Active Line Modules Wideband Line Filter for Active Line Modules 2.6.1 Description The damping characteristics of Wideband Line Filters for Active Line Modules not only conform with the requirements of EMC standards for the frequency range of 150 kHz to 30 MHz but also include low frequencies as of 2 kHz. - Page 53 Line Connection Booksize 2.6 Wideband Line Filter for Active Line Modules DANGER The line filters listed conduct a high leakage current via the protective ground conductor. A permanent PE connection for the line filter or control cabinet is required due to the high leakage current of the line filters.

-

Page 54: Interface Description

Line Connection Booksize 2.6 Wideband Line Filter for Active Line Modules 2.6.3 Interface description Figure 2-10 Wideband Line Filter for Active Line Module (example: 16 kW) NOTICE The line/load connection must not be interchanged. Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 55: Line/Power Connection

Line Connection Booksize 2.6 Wideband Line Filter for Active Line Modules 2.6.3.1 Line/power connection Table 2-9 Type of connection Terminals Designations Line supply connection (line supply) L1, L2, L3, PE Load connection (load) U, V, W Wideband Line Filter for Active Line Modules 16 kW Screw terminal: 10 mm 3-pin/1.5 -1.8 Nm (see Screw Terminals chapter) -

Page 56: Dimension Drawings

Line Connection Booksize 2.6 Wideband Line Filter for Active Line Modules 2.6.4 Dimension drawings Figure 2-11 Dimension drawing: 16 kW Wideband Line Filter for Active Line Modules Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... - Page 57 Line Connection Booksize 2.6 Wideband Line Filter for Active Line Modules Figure 2-12 Dimension drawing: 36 kW Wideband Line Filter for Active Line Modules Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 58 Line Connection Booksize 2.6 Wideband Line Filter for Active Line Modules Figure 2-13 Dimension drawing: 55 kW Wideband Line Filter for Active Line Modules Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 59 Line Connection Booksize 2.6 Wideband Line Filter for Active Line Modules Figure 2-14 Dimension drawing: 80 kW Wideband Line Filter for Active Line Modules Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 60 Line Connection Booksize 2.6 Wideband Line Filter for Active Line Modules Figure 2-15 Dimension drawing: 120 kW Wideband Line Filter for Active Line Modules Table 2-10 Wideband Line Filter For Active Line Modules Order no. 16 kW 6SL3000-0BE-21-6AAx 36 kW 6SL3000-0BE-23-6AAx 55 kW 6SL3000-0BE-25-5AAx...

-

Page 61: Technical Data

Line Connection Booksize 2.6 Wideband Line Filter for Active Line Modules 2.6.5 Technical data Table 2-11 Technical data: Wideband Line Filter for Active Line Modules 6SL3000 0BE21- 0BE23- 0BE25- 0BE28- 0BE31- unit 6AAx 6AAx 5AAx 0AAx 2AAx Rated power Connection voltages: Supply voltage 380 V 3 AC -10 % (-15 % <... -

Page 62: Basic Line Filter For Basic Line Modules

Line Connection Booksize 2.7 Basic Line Filter for Basic Line Modules Basic Line Filter for Basic Line Modules 2.7.1 Description The Basic Line Filters for Basic Line Modules are designed for limiting the cable-borne interference in the frequency range in accordance with the specifications of the EMC legislation. - Page 63 Line Connection Booksize 2.7 Basic Line Filter for Basic Line Modules DANGER The line filters listed conduct a high leakage current via the protective ground conductor. A permanent PE connection for the line filter or control cabinet is required due to the high leakage current of the line filters.

-

Page 64: Interface Description

Line Connection Booksize 2.7 Basic Line Filter for Basic Line Modules 2.7.3 Interface description 2.7.3.1 Overview Figure 2-16 Line filters for Basic Line Modules (example: 40 kW) NOTICE The line/load connection must not be interchanged. Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 65: Line/Power Connection

Line Connection Booksize 2.7 Basic Line Filter for Basic Line Modules 2.7.3.2 Line/power connection Table 2-12 Connection type Terminals Designations Line supply connection (line supply) L1, L2, L3, PE Load connection (load) L1´, L2´, L3´, PE Basic Line Filter for Basic Line Modules 20 kW Screw terminal: 10 mm 3-pin / 1.5 - 1.8 Nm (see Screw Terminals chapter) -

Page 66: Technical Data

Line Connection Booksize 2.7 Basic Line Filter for Basic Line Modules Figure 2-18 Dimension drawing of Basic Line Filter for 100 kW Basic Line Modules Table 2-14 Dimensions of Basic Line Filter for Basic Line Modules Basic Line Order number B [mm] b [mm] a [mm]... -

Page 67: Basic Line Filter For Smart Line Modules

Line Connection Booksize 2.8 Basic Line Filter for Smart Line Modules Basic Line Filter for Smart Line Modules 2.8.1 Description In conjunction with the associated line reactors, the Basic Line Filters for Smart Line Modules limit the cable-borne interference to a level in compliance with EN61800-3 category In conjunction with the line filters and the associated line reactors, drive line-ups with Smart Line Modules fulfill the requirements of category C2 to EN 61800-3. - Page 68 Line Connection Booksize 2.8 Basic Line Filter for Smart Line Modules DANGER Risk of electric shock. Dangerous voltages are still present for up to 5 minutes after the power supply has been switched off. Note If a high-voltage test is conducted with alternating voltage in the system, the line filters must be disconnected in order to obtain accurate measurements.

-

Page 69: Interface Description

Line Connection Booksize 2.8 Basic Line Filter for Smart Line Modules 2.8.3 Interface description 2.8.3.1 Overview Figure 2-19 Basic Line Filter for Smart Line Modules (example: 36 kW) NOTICE The line/load connection must not be interchanged. Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 70: Line/Power Connection

Line Connection Booksize 2.8 Basic Line Filter for Smart Line Modules Line voltage 415 V 3 AC to 480 V AC + 10 % ● Controlled DC link voltage required, or ● limitation of the DC link voltage required due to motor isolation 2.8.3.2 Line/power connection Table 2-16... -

Page 71: Dimension Drawings

Line Connection Booksize 2.8 Basic Line Filter for Smart Line Modules 2.8.4 Dimension drawings Figure 2-20 Dimension drawing: Basic Line Filter for Smart Line Modules (5 and 10 kW) Table 2-17 Basic Line Filter for Smart Line Modules Basic Line Filter for Smart Line Modules Order number 5 kW 6SL3000-0HE15-0AAx... -

Page 72: Technical Data

Line Connection Booksize 2.8 Basic Line Filter for Smart Line Modules Figure 2-21 Dimension drawing: Basic Line Filter for Smart Line Modules (16 kW and 36 kW) Table 2-18 Dimensions of Basic Line Filter for Smart Line Modules Basic Line Order number W [mm] b [mm]... -

Page 73: Active Interface Modules (Internal Cooling)

Line Connection Booksize 2.9 Active Interface Modules (internal cooling) Active Interface Modules (internal cooling) 2.9.1 Description Active Interface Modules are line-side interfaces for the Active Line Modules. They contain the following functional units: ● Line reactors ● Low-frequency/switching frequency filters ●... -

Page 74: Safety Information

Line Connection Booksize 2.9 Active Interface Modules (internal cooling) 2.9.2 Safety information CAUTION Active Interface Modules must only be operated if the option "Line filter available" has been set for the Active Line Module in the commissioning wizard, and if "AIM 400 V xxkW (6SL3100-0BE**-*AB*)"... -

Page 75: Interface Description

Line Connection Booksize 2.9 Active Interface Modules (internal cooling) 2.9.3 Interface description 2.9.3.1 Overview Figure 2-22 Interface description: Active Interface Module 55 kW Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... - Page 76 Line Connection Booksize 2.9 Active Interface Modules (internal cooling) Figure 2-23 Interface description: Active Interface Module (80 kW and 120 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 77: Connection Example

Line Connection Booksize 2.9 Active Interface Modules (internal cooling) 2.9.3.2 Connection example Figure 2-24 Connection example: Active Interface Module Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 78: Electronics Power Supply X124

Line Connection Booksize 2.9 Active Interface Modules (internal cooling) 2.9.3.3 Electronics power supply X124 Table 2-20 Terminal block X124 Terminal Function Technical specifications Electronics power supply Voltage: 24 V DC (20.4 V - 28.8 V) Current consumption: max. 1.6 A Electronics power supply Max. -

Page 79: X121 Alarm Contacts For Temperature Switch

Line Connection Booksize 2.9 Active Interface Modules (internal cooling) 2.9.3.5 X121 alarm contacts for temperature switch Table 2-22 Plug-in screw terminal X121 Terminal Designation Technical specifications +Temp Rated current at cosφ 1: 2.5 A (max. 5 A) Voltage: 12 - 250 V (12 - 100 V Temperature switch output -Temp... -

Page 80: Dimension Drawings

Line Connection Booksize 2.9 Active Interface Modules (internal cooling) 2.9.4 Dimension drawings Figure 2-25 Dimension drawing: Active Interface Module 55 kW Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... - Page 81 Line Connection Booksize 2.9 Active Interface Modules (internal cooling) Figure 2-26 Dimension drawing: Active Interface Module (80 kW and 120 kW) Table 2-23 Active Interface Modules Active Interface Module 6SL3100-0BE25-5ABx 6SL3100-0BE28-0ABx 6SL3100-0BE31-2ABx 55 kW 80 kW 120 kW Table 2-24 Shield connecting plates for Active Interface Modules Shield connecting plate 6SL3163-1AH00-0AAx...

-

Page 82: Installation

Line Connection Booksize 2.9 Active Interface Modules (internal cooling) 2.9.5 Installation The Active Interface Modules are designed for installation in the control cabinet. The components are secured onto the control cabinet installation panel next to the line filter using four M6 screws (not hexagon-head screws). Figure 2-27 Mounting: Active Interface Module Table 2-25... - Page 83 Line Connection Booksize 2.9 Active Interface Modules (internal cooling) Operating an Active Interface Module from an insulated network (IT system) When a 55 kW, 80 kW and 120 kW Active Interface Module is operated from an insulated supply (IT system), the connection bracket for the interference-suppression capacitor must be removed.

- Page 84 Line Connection Booksize 2.9 Active Interface Modules (internal cooling) Replacing the fan in an Active Interface Module NOTICE When replacing the fan, you must observe the ESD regulations. NOTICE Parts must only be replaced by trained personnel (danger of damage to sensitive components due to static electricity)! DANGER Before replacing the fan, you must switch off the power supplies (24 V DC and 400 V AC).

- Page 85 Line Connection Booksize 2.9 Active Interface Modules (internal cooling) Table 2-26 Replacing the fan in an Active Interface Module, 55 kW Open the fan cover. Unscrew the combination screws Open the fan cover and remove the connector M5 / 3 Nm Unscrew the screws M3 / 1.8 Nm Remove the fan Booksize Power Units...

- Page 86 Line Connection Booksize 2.9 Active Interface Modules (internal cooling) Table 2-27 Replacing the fan in an Active Interface Module, 80 kW, 120 kW Open the fan cover. Unscrew the Open the fan cover. Remove the connector. combination screws M5 / 3 Nm Unscrew the screws M3 / 1.8 Nm Release the connection cables Remove the fan.

-

Page 87: Technical Data

Line Connection Booksize 2.9 Active Interface Modules (internal cooling) 2.9.6 Technical data Table 2-28 Technical data Active Interface Module 6SL3100- 0BE25-5ABx 0BE28-0ABx 0BE31-2ABx 55 kW 80 kW 120 kW rated Current requirements of the 24 V DC electronics power supply Mains voltage 380 V to 480 V 3 AC ±10 % Line frequency... -

Page 88: Line Reactors For Active Line Modules

Only the line reactors or Active Interface Modules described in this Manual should be used. The following can occur if line reactors are used that have not been approved for SINAMICS S120 by SIEMENS: - The Line Modules may become damaged/faulty. -

Page 89: Connection Description

Line Connection Booksize 2.10 Line reactors for Active Line Modules 2.10.3 Connection description Figure 2-28 Line reactor (example: 16 kW) 2.10.3.1 Line/power connection Table 2-29 Connection types for line reactors Terminals Designations Line supply connection 1U1, 1V1, 1W1, PE Load connection 1U2, 1V2, 1W2 Line reactors for Active Line Modules 16 kW... -

Page 90: Dimension Drawings

Line Connection Booksize 2.10 Line reactors for Active Line Modules 2.10.4 Dimension drawings Figure 2-29 Dimension drawing: Line reactor for Active Line Modules (up to 55 kW) Table 2-30 Dimensions of the line reactor for Active Line Modules Order number L [mm] W [mm] h [mm]... -

Page 91: Technical Data

Line Connection Booksize 2.10 Line reactors for Active Line Modules Figure 2-30 Dimension drawing: Line reactor for Active Line Modules (as of 80 kW) Table 2-31 Dimensions of the line reactor for Active Line Modules Order L [mm] W [mm] h1 [mm] h2 [mm] H [mm]... -

Page 92: Line Reactors For Smart Line Modules

Only the line reactors or Active Interface Modules described in this Manual should be used. The following can occur if line reactors are used that have not been approved for SINAMICS S120 by SIEMENS: - The Line Modules may become damaged/faulty. -

Page 93: Connection Description

Line Connection Booksize 2.11 Line reactors for Smart Line Modules 2.11.3 Connection description Figure 2-31 Line reactors for Smart Line Modules (example: 36 kW) 2.11.3.1 Line/power connection Table 2-33 Connection types for line reactors Terminals Designations Line supply connection 1U1, 1V1, 1W1, PE Load connection 1U2, 1V2, 1W2 Line reactors for Smart Line Modules... -

Page 94: Dimension Drawings

Line Connection Booksize 2.11 Line reactors for Smart Line Modules 2.11.4 Dimension drawings Figure 2-32 Dimension drawing: Line reactor for Smart Line Modules (5 and 10 KW) Table 2-34 Dimensions of the line filter for Smart Line Modules Order number W [mm] b [mm] H [mm]... - Page 95 Line Connection Booksize 2.11 Line reactors for Smart Line Modules Figure 2-33 Dimension drawing of line reactor for the Smart Line Module 16 kW Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 96 Line Connection Booksize 2.11 Line reactors for Smart Line Modules Figure 2-34 Dimension drawing of the line reactor for the Smart Line Module 36 kW Table 2-35 Line reactor for the Smart Line Modules 16 kW and 36 kW Order No. 16 kW 6SL3000-0CE-21-6AAx 36 KW...

-

Page 97: Technical Data

Line Connection Booksize 2.11 Line reactors for Smart Line Modules 2.11.5 Technical data Table 2-36 Technical data of line reactors for the Smart Line Module 6SL3000 0CE15-0AAx 0CE21-0AAx 0CE22-0AAx 0CE24-0AAx unit Power Rated current Power loss Weight 1 For an overview, see the power loss tables in chapter Cabinet Design Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 98: Line Reactors For Basic Line Modules

Only the line reactors described in this Manual must be used. The following can occur if line reactors are used that have not been approved for SINAMICS S120 by SIEMENS: - The Line Modules may become damaged/faulty. - Line reactions can occur that can damage or interfere with other loads powered from the same network. -

Page 99: Connection Description

Line Connection Booksize 2.12 Line reactors for Basic Line Modules 2.12.3 Connection description 2.12.3.1 Overview Figure 2-35 Line reactor for Basic Line Module (20 kW) Figure 2-36 Line reactor for Basic Line Module (40 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 100: Line/Power Connection

Line Connection Booksize 2.12 Line reactors for Basic Line Modules Figure 2-37 Line reactor for Basic Line Module (100 kW) 2.12.3.2 Line/power connection Table 2-37 Connection types for line reactors Terminals Designations Power connection L1, L2, L3 Load connection 1L1, 1L2, 1L3 Line reactors for Basic Line Modules 20 kW Max. -

Page 101: Dimension Drawings

Line Connection Booksize 2.12 Line reactors for Basic Line Modules 2.12.4 Dimension drawings Figure 2-38 Dimension drawing: Line reactor for Basic Line Module (20 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... - Page 102 Line Connection Booksize 2.12 Line reactors for Basic Line Modules Figure 2-39 Dimension drawing: Line reactor for Basic Line Module (40 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 103: Technical Data

Line Connection Booksize 2.12 Line reactors for Basic Line Modules Figure 2-40 Dimension drawing: Line reactor for Basic Line Module (100 kW) 2.12.5 Technical data Table 2-38 Technical data of line reactors for the Basic Line Modules 6SL3000 0CE22-0AAx 0CE24-0AAx 0CE31-0AAx unit Power... -

Page 104: Line Connection Variants

Line Connection Booksize 2.13 Line connection variants 2.13 Line connection variants 2.13.1 Ways of connecting the line supply A distinction is made between: ● Direct operation of the line connection components on the supply ● Operating line connection components via an autotransformer ●... -

Page 105: Operating Line Connection Components On The Line Supply

Line Connection Booksize 2.13 Line connection variants 2.13.2 Operating line connection components on the line supply The SINAMICS S Booksize converter system is rated for direct operation on TN, TT, and IT line supply systems with a rated voltage of 380 V 3 AC to 480 V 3 AC. Figure 2-42 Direct operation on the line supply Booksize Power Units... -

Page 106: Operating Line Connection Components Via A Matching Transformer

Safety information NOTICE If line filters are used that SIEMENS has not certified for use with SINAMICS S120, this can result in harmonics being fed back into the line supply. These harmonics can damage/disturb other equipment connected to this line supply. - Page 107 Line Connection Booksize 2.13 Line connection variants Dimensioning and selecting the matching transformer for several loads A SINAMICS Line Module and other loads / machines are connected to the matching transformer. Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 108 Line Connection Booksize 2.13 Line connection variants A matching transformer must be dimensioned for the total of all loads connected to it. The apparent power required for the Line Modules must be determined and added as indicated in table "Transformer configuration instructions". If the transformer S or S is too small, this can lead to increased line voltage dips and faults in the system and in other loads at this...

- Page 109 Line Connection Booksize 2.13 Line connection variants Note: The system fault level (short-circuit power) at the plant connection S plays a decisive K plant role in dimensioning/selecting the matching transformer. From the rated power (S or S ) calculated under a) and b), the higher value must be used for the matching transformer.

- Page 110 Line Connection Booksize 2.13 Line connection variants Example 1 matching transformer = 3 %, = 50,000 kVA K plant = 16 kW • 70 • 0.73 = 820 kVA K line According to a) = 1.27 • 16 kW = 21 kVA According to b) >...

- Page 111 Line Connection Booksize 2.13 Line connection variants = 3,000 kVA K plant = 16 kW • 70 • 0.73 = 820 kVA K line According to a) = 1.27 • 16 kW = 21 kVA According to b) > S ⇒...

- Page 112 Line Connection Booksize 2.13 Line connection variants Fuses For timely tripping of fuses, the loop resistance as well as the vector group of the line supply transformer being fed must satisfy the requirement that the touch voltage of the devices is switched off by the provided fuses within the permissible tripping time (see figure below, in accordance with EN 61800-5-1 Ed.

-

Page 113: Operation Of The Line Connection Components Via An Autotransformer

Line Connection Booksize 2.13 Line connection variants 2.13.3.3 Operation of the line connection components via an autotransformer An autotransformer can be used to adapt the voltage in the range up to 480 V 3 AC +10 %. DANGER To ensure protective separation an isolating transformer must be used for voltages greater than 480 V 3 AC +10 %. - Page 114 Line Connection Booksize 2.13 Line connection variants Figure 2-44 Autotransformer Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 115: Assignment Of Autotransformers To Active Line Modules

Line Connection Booksize 2.13 Line connection variants 2.13.3.4 Assignment of autotransformers to Active Line Modules Table 2-41 Autotransformers for 480 / 440 V input voltage Active Line Module 16 kW 36 kW 55 kW 80 kW 120 kW Rated power [kVA] Autotransformer IP00 46.5 70.3... - Page 116 Line Connection Booksize 2.13 Line connection variants Table 2-42 Autotransformers for 220 V input voltage Active Line Module 16 kW 36 kW 55 kW 80 kW 120 kW Rated power [kVA] Autotransformer IP00 46.5 70.3 Input voltage [V] 220 V 3 AC ± 10 %; 50 Hz - 5 % to 60 Hz + 5 % Output voltage [V] 400 V 3 AC Vector group...

-

Page 117: Assignment Of Autotransformers To Smart Line Modules

Line Connection Booksize 2.13 Line connection variants 2.13.3.5 Assignment of autotransformers to Smart Line Modules Table 2-43 Autotransformers for 480 / 440 V input voltage Smart Line Module 5 kW /10 kW /16 kW 36 kW Rated power [kVA] Autotransformer IP00 46.5 Input voltage [V] 480 / 440 V 3 AC ±... - Page 118 Line Connection Booksize 2.13 Line connection variants Table 2-44 Autotransformers for 220 V input voltage Smart Line Module 5 kW /10 kW /16 kW 36 kW Rated power [kVA] Autotransformer IP00 46.5 Input voltage [V] 220 V 3 AC ± 10 %; 50 Hz - 5 % to 60 Hz + 5 % Output voltage [V] 400 V 3 AC Vector group...

-

Page 119: Assignment Of Autotransformers To Basic Line Modules

Line Connection Booksize 2.13 Line connection variants 2.13.3.6 Assignment of autotransformers to Basic Line Modules Table 2-45 Autotransformers for 480 / 440 V input voltage Basic Line Modules 20 kW 40 kW 100 kW Rated power [kVA] Autotransformer IP00 46.5 70.3 Input voltage [V] 480 / 440 V 3 AC ±... - Page 120 Line Connection Booksize 2.13 Line connection variants Table 2-46 Autotransformers for 220 V input voltage Basic Line Modules 20 kW 40 kW 100 kW Rated power [kVA] Autotransformer IP00 46.5 70.3 Input voltage [V] 220 V 3 AC ± 10 %; 50 Hz - 5 % to 60 Hz + 5 % Output voltage [V] 400 V 3 AC Vector group...

-

Page 121: Operating Line Connection Components Via An Isolating Transformer

Line Connection Booksize 2.13 Line connection variants 2.13.3.7 Operating line connection components via an isolating transformer The isolating transformer converts the network configuration of the system (e.g. IT/TT system) to a TN system. Additional voltage adaptation to the permissible voltage tolerance range is possible. - Page 122 Line Connection Booksize 2.13 Line connection variants Figure 2-45 Isolating transformer Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 123: Assignment Of Isolating Transformers To Active Line Modules

Line Connection Booksize 2.13 Line connection variants 2.13.3.8 Assignment of isolating transformers to Active Line Modules Table 2-47 Matching transformers with isolated windings for 50/60 Hz supply systems Active Line Module 16 kW 36 kW 55 kW 80 kW 120 kW Rated power [kVA] Power loss, max. -

Page 124: Assignment Of Isolating Transformers To Smart Line Modules

Line Connection Booksize 2.13 Line connection variants 2.13.3.9 Assignment of isolating transformers to Smart Line Modules Table 2-48 Matching transformers with isolated windings for 50/60 Hz supply systems Smart Line Module 5 kW 10 kW 16 kW 36 kW Rated power [kVA] Power loss, max. -

Page 125: 2.13.3.10 Assignment Of Isolating Transformers To Basic Line Modules

Line Connection Booksize 2.13 Line connection variants 2.13.3.10 Assignment of isolating transformers to Basic Line Modules Table 2-49 Matching transformers with isolated windings for 50/60 Hz supply systems Basic Line Modules 20 kW 40 kW 100 kW Rated power [kVA] Power loss, max. -

Page 126: 2.13.3.11 Technical Specifications Of The Transformers

Line Connection Booksize 2.13 Line connection variants 2.13.3.11 Technical specifications of the transformers Basic reference conditions under which the transformers can be loaded with the rated power indicated in the selection tables: ● Continuous operation P ● Frequency 50 Hz to 60 Hz ●... -

Page 127: 2.13.3.12 Dimension Drawings Of The Transformers

Line Connection Booksize 2.13 Line connection variants 2.13.3.12 Dimension drawings of the transformers Safety, isolating, control and line transformers 4AP, 4AU Safety, isolating, control and line transformers 4AP and safety, isolating, control and mains transformers as well as autotransformers with selectable voltages 4AP ≤... - Page 128 Line Connection Booksize 2.13 Line connection variants Safety, isolating, control and line transformers 4AP, 4AU ≤ 16 kVA (continued) Safety, isolating, control and line transformers 4AU and Safety, isolating, control and line transformers as well as autotransformers with selectable voltages 4AU ≤ 16 kVA Figure 2-49 Dimension drawing: 4AU30 to 4AU39 Table 2-52...

- Page 129 Line Connection Booksize 2.13 Line connection variants Power transformers 4BU > 16 kVA Matching transformers and transformers with selectable voltages 4BU > 16 kVA Figure 2-50 Dimension drawing: 4BU Terminal size Screw connection for cross section Current capacity solid stranded fine-stranded = 40 °C = 55 °C...

- Page 130 Line Connection Booksize 2.13 Line connection variants Table 2-55 Dimensions 4BU, part 2 Type Max. no. of terminals for terminal size 4BU43 4BU45 4BU47 4BU52 4BU54 4BU55 4BU58 4BU60 Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 131: Line Connection Via A Residual-Current Circuit-Breaker

Line Connection Booksize 2.13 Line connection variants 2.13.4 Line connection via a residual-current circuit-breaker In addition to the implemented protective measures against direct and indirect contact, selectively tripping AC/DC-sensitive residual-current circuit-breakers (Type B) can be used. DANGER Residual-current circuit-breakers alone are not permissible to provide protection against direct and indirect contact. - Page 132 Recommendation SIEMENS selectively switching AC/DC-sensitive residual-current circuit-breakers in accordance with EN 61009-1 of the 5SM series (e.g. 5SM3646-4 or 5SM3646-4+5SW3300 with an auxiliary disconnector (1 NC contact / 1 NO contact) for a rated current of 63 A and rated fault current of 0.3 A (see catalog "BETA Modular Installation Devices - ET B1")).

-

Page 133: Line Modules Booksize

Line Modules Booksize Introduction Line Modules generate a DC voltage from the connected line voltage that is used to power the Motor Modules. All Basic Line Modules and Active Line Modules as well as the 16 kW and 36 kW Smart Line Modules are equipped with DRIVE-CLiQ interfaces for communicating with the Control Unit. - Page 134 Line Modules Booksize 3.1 Introduction Figure 3-1 Overview of Line Modules General characteristics of the Line Modules ● Connection voltage 380 V 3 AC -10 % (-15 % <1 min) to 480 V 3 AC +10 % (47 to 63 Hz) ●...

- Page 135 Line Modules Booksize 3.1 Introduction Characteristics of the Active Line Modules ● Regulated DC link voltage ● Regenerative feedback capability ● Sinusoidal line currents ● Electronic type plate ● DRIVE-CLiQ interface for communicating with the Control Unit and/or other components in the drive line-up.

-

Page 136: Active Line Modules With Internal Air Cooling

Line Modules Booksize 3.2 Active Line Modules with internal air cooling Active Line Modules with internal air cooling 3.2.1 Description Active Line Modules generate a constant, regulated DC voltage in the DC link from the three- phase line supply voltage that supplies the connected Motor Modules with power. This ensures that they are not influenced by network fluctuations. - Page 137 DANGER It is only permissible to establish connections to the DC link using the adapters that SIEMENS has recommended (DC link adapter and DC link rectifier adapter). CAUTION The tightening torque of the DC link busbar screws (1.8 Nm, tolerance: +30 %) must be checked before commissioning is carried out when the system is disconnected from the power supply and the DC link is discharged.

- Page 138 1000 m in Active Mode combined with Active Interface Module and Basic Line Filter. CAUTION Only cables from Siemens must be used for DRIVE-CLiQ connections. DANGER If the Line Module is not disconnected from the network (e.g. via the main contactor or main circuit-breaker), the DC link remains charged.

-

Page 139: Interface Description

Line Modules Booksize 3.2 Active Line Modules with internal air cooling 3.2.3 Interface description 3.2.3.1 Overview Figure 3-2 Active Line Module with internal air cooling (example: 16 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 140: Connection Example

Line Modules Booksize 3.2 Active Line Modules with internal air cooling 3.2.3.2 Connection example Figure 3-3 Example connection of Active Line Module Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 141: X1 Line Connection

Line Modules Booksize 3.2 Active Line Modules with internal air cooling 3.2.3.3 X1 line connection Table 3-1 Terminal block X1 Active Line Module 16 kW Terminal Technical specifications Max. connectable cross-section: 10 mm Type: Screw terminal 6 (see Connection systems) Tightening torque: 1.5 - 1.8 Nm PE connection Threaded hole M5/3 Nm... -

Page 142: X200-X202 Drive-Cliq Interfaces

Line Modules Booksize 3.2 Active Line Modules with internal air cooling 3.2.3.4 X200-X202 DRIVE-CLiQ interfaces Table 3-3 DRIVE-CLiQ interface X200-X202 Signal name Technical specifications Transmit data + Transmit data - Receive data + Reserved, do not use Reserved, do not use Receive data - Reserved, do not use Reserved, do not use... -

Page 143: Ep Terminals X21

Line Modules Booksize 3.2 Active Line Modules with internal air cooling 3.2.3.5 EP terminals X21 Table 3-4 Terminal block X21 Terminal Designation Technical specifications + Temp For the temperature sensor connection on the Active Interface Module - Temp EP +24 V (enable pulses) Voltage 24 V DC Current consumption: 10 mA EP M (enable pulses) -

Page 144: X24 24 V Terminal Adapter

Line Modules Booksize 3.2 Active Line Modules with internal air cooling 3.2.3.6 X24 24 V terminal adapter Table 3-5 Terminal block X24 Terminal Designation Technical specifications 24 V power supply 24 V DC supply voltage Ground Electronics ground The 24 V terminal adapter is supplied as standard Max. -

Page 145: Description Of The Leds On The Active Line Module

Line Modules Booksize 3.2 Active Line Modules with internal air cooling 3.2.3.7 Description of the LEDs on the Active Line Module Table 3-6 Active Line Module - description of the LEDs Status Description, cause Remedy Ready (H200) DC link (H201) Electronics power supply is missing or outside –... -

Page 146: Dimension Drawing

Line Modules Booksize 3.2 Active Line Modules with internal air cooling 3.2.4 Dimension drawing Figure 3-4 Dimension drawing of Active Line Module with internal air cooling (16 kW) Table 3-7 Dimensions of Active Line Module with internal air cooling Active Line Module Order number: W [mm] (inches) b [mm] (inches) - Page 147 Line Modules Booksize 3.2 Active Line Modules with internal air cooling Figure 3-5 Dimension drawing of Active Line Module with internal air cooling (36 kW and 55 kW) Table 3-8 Dimensions of Active Line Module with internal air cooling Active Line Module Order number W [mm] (inches) b [mm] (inches)

- Page 148 Line Modules Booksize 3.2 Active Line Modules with internal air cooling Figure 3-6 Dimension drawing of Active Line Modules with internal air cooling (80 kW and 120 kW) Table 3-9 Dimensions of Active Line Module with internal air cooling Active Line Module Order number W [mm] (inches) b [mm] (inches)

-

Page 149: Installing

Line Modules Booksize 3.2 Active Line Modules with internal air cooling 3.2.5 Installing Installing the fan on Active Line Modules (80 kW and 120 kW) Figure 3-7 Installing the fan for 300 mm modules 1) Secure with M6 / 6 Nm screws 2) Connect the power supply for the fan Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... - Page 150 Line Modules Booksize 3.2 Active Line Modules with internal air cooling Note The fans are power-up and power-down as a function of the heatsink temperature. The fans start up at the heat-sink temperature specified in the power stack data (normally 56 °C) and are switched off with a slight hysteresis when the heat-sink temperature decreases again.

-

Page 151: Electrical Connection

Line Modules Booksize 3.2 Active Line Modules with internal air cooling 3.2.6 Electrical connection Figure 3-8 Busbar connections for booksize components DANGER The 24 V terminal adapter must not be removed or plugged in with 24 V applied. Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 152: Technical Data

Line Modules Booksize 3.2 Active Line Modules with internal air cooling NOTICE The 24 V terminal adapter may only be withdrawn vertically to the front panel (i.e. not at an angle)! 3.2.7 Technical data Table 3-10 Technical data of Active Line Modules Internal air cooling 6SL3130–... - Page 153 Line Modules Booksize 3.2 Active Line Modules with internal air cooling Internal air cooling 6SL3130– 7TE21–6AAx 7TE23–6AAx 7TE25–5AAx 7TE25–5AA3 + Active Interface Module Rated power DC link capacitance μF 1 410 1 880 1 880 Maximum permissible DC link μF 20 000 20 000 20 000...

- Page 154 Line Modules Booksize 3.2 Active Line Modules with internal air cooling Internal air cooling 6SL3130– 7TE28–0AAx 7TE31–2AAx Rated power DC link voltage 510 - 720 Overvoltage trip threshold 820 ± 2 % Undervoltage trip threshold 360 ± 2 % Rated input current: at 380 V at 480 V /528 V...

- Page 155 Line Modules Booksize 3.2 Active Line Modules with internal air cooling Rated duty cycles of Active Line Modules Figure 3-9 Rated duty cycles of Active Line Modules (exception: not applicable for 55 kW Active Line Module with Active Interface Module) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 156 Line Modules Booksize 3.2 Active Line Modules with internal air cooling Rated duty cycles of 55 kW Active Line Modules with Active Interface Module Figure 3-10 Rated duty cycles of 55 kW Active Line Modules with Active Interface Module Figure 3-11 Rated duty cycle of 55 kW Active Line Modules with Active Interface Module Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 157 Line Modules Booksize 3.2 Active Line Modules with internal air cooling Derating as a function of the ambient temperature Figure 3-12 Derating as a function of the ambient temperature Derating as a function of the installation altitude Figure 3-13 Derating as a function of the installation altitude Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 158 Line Modules Booksize 3.2 Active Line Modules with internal air cooling Voltage derating as a function of the installation altitude Figure 3-14 Voltage derating as a function of the installation altitude Output power as a function of the total cable length Figure 3-15 Output power as a function of the total cable length Booksize Power Units...

-

Page 159: Active Line Modules With External Air Cooling

Line Modules Booksize 3.3 Active Line Modules with external air cooling Active Line Modules with external air cooling 3.3.1 Description The Motor Modules are connected to the power supply network via the Active Line Modules with external air cooling, which provide the Motor Modules with a constant DC link voltage. This ensures that they are not influenced by network fluctuations. - Page 160 DANGER It is only permissible to establish connections to the DC link using the adapters that SIEMENS has recommended (DC link adapter and DC link rectifier adapter). CAUTION The tightening torque of the DC link busbar screws (1.8 Nm, tolerance: +30 %) must be checked before commissioning when the system is disconnected from the power supply and the DC link is discharged.

- Page 161 The total length of all the power cables (motor supply cables and DC link cables) must not exceed 350 m in active mode. CAUTION Only cables from Siemens must be used for DRIVE-CLiQ connections. NOTICE The external air cooling can cause the fans and the heat sink to become heavily contaminated, which may trigger the temperature monitor in the power unit.

-

Page 162: Interface Description

Line Modules Booksize 3.3 Active Line Modules with external air cooling 3.3.3 Interface description 3.3.3.1 Overview Figure 3-16 Active Line Module with external air cooling (example: 16 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 163: Connection Example

Line Modules Booksize 3.3 Active Line Modules with external air cooling 3.3.3.2 Connection example Figure 3-17 Example connection of Active Line Module Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 164: Line Supply Connection

Line Modules Booksize 3.3 Active Line Modules with external air cooling 3.3.3.3 Line supply connection Table 3-12 Terminal block X1 Active Line Module 16 kW Terminal Technical specifications Supply voltage: 480 V 3 AC +10 % (-15 % < 1 min) for 47 Hz to 63 Hz Max. -

Page 165: X200-X202 Drive-Cliq Interfaces

Line Modules Booksize 3.3 Active Line Modules with external air cooling 3.3.3.4 X200-X202 DRIVE-CLiQ interfaces Table 3-14 DRIVE-CLiQ interface X200-X202 Signal name Technical specifications Transmit data + Transmit data - Receive data + Reserved, do not use Reserved, do not use Receive data - Reserved, do not use Reserved, do not use... -

Page 166: Ep Terminals X21

Line Modules Booksize 3.3 Active Line Modules with external air cooling 3.3.3.5 EP terminals X21 Table 3-15 Terminal block X21 Terminal Designation Technical specifications + Temp For the temperature sensor connection on the Active Interface Module - Temp EP +24 V (enable pulses) Voltage 24 V DC Current consumption: 10 mA EP M (enable pulses) -

Page 167: X24 24 V Terminal Adapter

Line Modules Booksize 3.3 Active Line Modules with external air cooling 3.3.3.6 X24 24 V terminal adapter Table 3-16 Terminal block X24 Terminal Designation Technical specifications 24 V power supply 24 V DC supply voltage Ground Electronics ground The 24 V terminal adapter is supplied as standard Max. -

Page 168: Meaning Of The Leds On The Active Line Module

Line Modules Booksize 3.3 Active Line Modules with external air cooling 3.3.3.7 Meaning of the LEDs on the Active Line Module Table 3-17 Active Line Module - description of the LEDs Status Description, cause Remedy Ready (H200) DC link (H201) Electronics power supply is missing or outside –... -

Page 169: Dimension Drawings

Line Modules Booksize 3.3 Active Line Modules with external air cooling 3.3.4 Dimension drawings Figure 3-18 Dimension drawing of Active Line Module with external air cooling (16 kW) Table 3-18 Dimensions of Active Line Module with external air cooling (16 kW) Line module type Order number W [mm]... - Page 170 Line Modules Booksize 3.3 Active Line Modules with external air cooling Figure 3-19 Dimension drawing of active line with external air cooling (36 kW, 55 kW, 80 kW, and 120 kW) Table 3-19 Dimensions of Active Line Modules with external air cooling (36 kW, 55 kW, 80 kW, and 120 kW) Line module type Order number W [mm] (inches) b [mm] (inches)

-

Page 171: Installation

3.3 Active Line Modules with external air cooling 3.3.5 Installation Figure 3-20 Example: Installing the power unit with external air cooling Help with the mechanical cabinet design is available from: Siemens AG A&D SE WKC CoC CabinetCooling P.O. Box 1124 D-09070 Chemnitz, Germany E-mail: cc.cabinetcooling@siemens.com... - Page 172 Line Modules Booksize 3.3 Active Line Modules with external air cooling Figure 3-21 Installation openings for the power unit with external air cooling, 50 mm to 200 mm Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 173 Line Modules Booksize 3.3 Active Line Modules with external air cooling Figure 3-22 Installation openings for the power unit with external air cooling, 300 mm Table 3-20 Dimensions of the installation openings for the power unit with external air cooling Component width W [mm] (inches) w1 [mm] (inches)

- Page 174 Line Modules Booksize 3.3 Active Line Modules with external air cooling Figure 3-23 Example: Mounting plate with a drive line-up During installation it must be ensured that the component's seal is tight throughout. Note A set of seals consisting of spare seals for 50 mm, 100 mm, 150 mm, 200 mm and 300 mm wide components can be ordered with order number: 6SL3162-5BU00-0AA0.

- Page 175 Line Modules Booksize 3.3 Active Line Modules with external air cooling Figure 3-24 Example 1: Installation in cabinet with mounting plate Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 176 Line Modules Booksize 3.3 Active Line Modules with external air cooling Figure 3-25 Example 2: Installation in cabinet with mounting plate We recommend that you attach a cover and filtered fan to the cabinet. The filtered fan must be fitted in such a way that the cooling air required by the drive line-up is not restricted.

- Page 177 Line Modules Booksize 3.3 Active Line Modules with external air cooling Remove the holder for securing the Control Unit. If an additional component is to be flush-mounted to the left of the component, the holders for securing the Control Unit must be removed. Use suitable tools to lift the latching device Remove the holder.

-

Page 178: Electrical Connection

Line Modules Booksize 3.3 Active Line Modules with external air cooling 3.3.6 Electrical connection Figure 3-26 Busbar connections for booksize components DANGER The 24 V terminal adapter must not be removed or plugged in with 24 V applied. Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 179: Technical Data

Line Modules Booksize 3.3 Active Line Modules with external air cooling NOTICE The 24 V terminal adapter may only be withdrawn vertically to the front panel (i.e. not at an angle)! 3.3.7 Technical data Table 3-21 Technical data for Active Line Modules with external air cooling, part 1 Internal air cooling 6SL3131–... - Page 180 Line Modules Booksize 3.3 Active Line Modules with external air cooling Internal air cooling 6SL3131– 7TE21–6AAx 7TE23–6AAx 7TE25–5AAx 7TE25–5AA3 + Active Interface Module Rated power DC link capacitance μF 1 410 1 880 1 880 Maximum permissible DC link μF 20 000 20 000 20 000...

- Page 181 Line Modules Booksize 3.3 Active Line Modules with external air cooling Table 3-22 Technical data for Active Line Modules with external air cooling, part 2 Internal air cooling 6SL3131– 7TE28–0AAx 7TE31-2AAx Rated power Infeed: Rated power (S1) kW (Pn) Infeed power (S6-40 %) kW (Ps6) Peak infeed power kW (Pmax)

- Page 182 Line Modules Booksize 3.3 Active Line Modules with external air cooling Internal air cooling 6SL3131– 7TE28–0AAx 7TE31-2AAx Rated power UL safety fuse type AJT Class J AJT175 AJT250 Rated current Short-circuit current rating SCCR at 600 V Sound pressure level dB(A) <73 <73...

- Page 183 Line Modules Booksize 3.3 Active Line Modules with external air cooling Rated duty cycles of 55 kW Active Line Modules with Active Interface Module Figure 3-28 Rated duty cycles of 55 kW Active Line Modules with Active Interface Module Figure 3-29 Rated duty cycle of 55 kW Active Line Modules with Active Interface Module Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 184 Line Modules Booksize 3.3 Active Line Modules with external air cooling Derating as a function of the ambient temperature Figure 3-30 Derating as a function of the ambient temperature Derating as a function of the installation altitude Figure 3-31 Derating as a function of the installation altitude Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 185 Line Modules Booksize 3.3 Active Line Modules with external air cooling Voltage derating as a function of the installation altitude Figure 3-32 Voltage derating as a function of the installation altitude Output power as a function of the total cable length Figure 3-33 Output power as a function of the total cable length Booksize Power Units...

-

Page 186: Basic Line Modules With Internal Air Cooling

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Basic Line Modules with internal air cooling 3.4.1 Description The Basic Line Modules provide an unregulated DC link voltage that matches the rectified line input voltage. One or more Motor Modules can be connected to the power supply network via the Basic Line Module. -

Page 187: Safety Information

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling 3.4.2 Safety information DANGER Risk of electric shock. Dangerous voltages are still present for up to 5 minutes after the power supply has been switched off. The protective cover must not be opened until this time has elapsed. - Page 188 DANGER It is only permissible to establish connections to the DC link using the adapters that SIEMENS has recommended (DC link adapter and DC link rectifier adapter). CAUTION The tightening torque of the DC link busbar screws (1.8 Nm, tolerance: +30 %) must be checked before commissioning is carried out when the system is disconnected from the power supply and the DC link is discharged.

-

Page 189: Interface Description

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling 3.4.3 Interface description 3.4.3.1 Overview Figure 3-34 Interface description: Basic Line Module with internal air cooling (20 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... - Page 190 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Figure 3-35 Interface description: Basic Line Module with internal air cooling (40 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 191 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Figure 3-36 Interface description: Basic Line Module with internal air cooling (100 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 192: Connection Example

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling 3.4.3.2 Connection example Figure 3-37 Connection example: Basic Line Module (20 kW and 40 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... - Page 193 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Figure 3-38 Connection example: Basic Line Module (100 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 194: X1 Line Connection

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling 3.4.3.3 X1 line connection Table 3-23 Terminal block X1 Basic Line Module 20 kW Terminal Technical specifications Max. connection voltage: 480 V 3 AC +10 % at 47 Hz to 63 Hz Max. -

Page 195: X24 24 V Terminal Adapter

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Table 3-25 Terminal block X1 Basic Line Module 100 kW Terminal Technical specifications Max. connection voltage: 480 V 3 AC +10 % at 47 Hz to 63 Hz Max. connectable cross-section: 120 mm Type: Threaded bolt M8 (see Connection systems) Tightening torque: 13 Nm... -

Page 196: X200-X202 Drive-Cliq Interfaces

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling 3.4.3.5 X200-X202 DRIVE-CLiQ interfaces Table 3-27 DRIVE-CLiQ interface X200-X202 Signal name Technical specifications Transmit data + Transmit data - Receive data + Reserved, do not use Reserved, do not use Receive data - Reserved, do not use Reserved, do not use... -

Page 197: X21 Ep Terminals

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling 3.4.3.7 X21 EP terminals Table 3-30 Terminal block X21 Terminal Designation Technical specifications + Temp Temperature switch type: Bimetallic-element switch with NC contact - Temp Response threshold of the temperature input: Temperature at the braking resistor in the operating range →... -

Page 198: Meaning Of The Leds On The Basic Line Module

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling 3.4.3.8 Meaning of the LEDs on the Basic Line Module Table 3-31 Basic Line Module - description of the LEDs Status Description, cause Remedy Ready (H200) DC link (H201) Electronics power supply is missing or outside –... -

Page 199: Dimension Drawings

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling 3.4.4 Dimension drawings Figure 3-39 Dimension drawing: Basic Line Module with internal air cooling (20 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... - Page 200 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Figure 3-40 Dimension drawing: Basic Line Module with internal air cooling (40 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 201 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Figure 3-41 Dimension drawing: Basic Line Module with internal air cooling (100 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 202: Mounting

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling 3.4.5 Mounting Basic Line Modules are installed in the same way as Active Line Modules and Booksize Motor Modules. The Basic Line Modules are designed for installation in the control cabinet. The components are secured onto the control cabinet installation panel using M6 screws. - Page 203 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Operating a 100 kW Basic Line Module from an insulated supply (IT system) When the 100 kW Basic Line Module is operated from an insulated supply (IT system), the connection bracket for the interference-suppression capacitor must be removed.

- Page 204 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Remove the holder for securing the Control Unit. The plastic retaining element must be removed due to the different expansion variants: ● If the component to be installed comes into contact with the left-hand cabinet panel ●...

- Page 205 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Open the right device cover by loosening the six marked Pull the first fan cable by pressing it slightly screws Pull the second fan cable Unlatch the fan module Completely pull out the fan module Slightly push the fan holder apart and pull out the fan Booksize Power Units...

- Page 206 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Observe the air flow direction markings when inserting the Observe the cable guide new fan Push in the fan in guide rails 1 and 2. Connect the two fan cables. Close the device cover and tighten the six screws with 0.8 Nm Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 207: Electrical Connection

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling 3.4.6 Electrical connection Figure 3-43 Busbar connections for booksize components DANGER The 24 V terminal adapter must not be removed or plugged in with 24 V applied. Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 208: Technical Data

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling NOTICE The 24 V terminal adapter may only be withdrawn vertically to the front panel (i.e. not at an angle)! 3.4.7 Technical data Table 3-32 Technical data: Basic Line Modules Internal air cooling 6SL3130- 1TE22-0AA0... - Page 209 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Internal air cooling 6SL3130- 1TE22-0AA0 1TE24-0AA0 1TE31-0AA0 Maximum permissible DC link μF 20 000 20 000 50 000 capacitance Power factor cosϕ 0.98 0.98 0.98 Circuit-breaker type designation 3RV1042-4MA10 3VL2110-3KN30- 3VL3125-3KN30- (status 07/2007 and later)

- Page 210 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Rated duty cycles for Basic Line Modules Figure 3-44 Rated duty cycles of 20 kW and 40 kW Basic Line Modules Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 211 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Figure 3-45 Rated duty cycles of 100 kW Basic Line Module Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 212 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Braking duty cycle for Basic Line Modules Figure 3-46 Braking duty cycle for Basic Line Modules Derating as a function of the ambient temperature Figure 3-47 Derating as a function of the ambient temperature Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

- Page 213 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Derating as a function of the installation altitude Figure 3-48 Derating as a function of the installation altitude Voltage derating as a function of the installation altitude Figure 3-49 Voltage derating as a function of the installation altitude Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 214: Braking Resistors For Basic Line Modules

Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Output power as a function of the total cable length Figure 3-50 Output power as a function of the total cable length 3.4.8 Braking resistors for Basic Line Modules Figure 3-51 Dimension drawing: Braking resistor 7.5 kW and 15 kW Table 3-33... - Page 215 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Figure 3-52 Dimension drawing: Braking resistor 30 kW and 75 kW ① T1 / T2 tunnel terminals ② Stud terminals Table 3-34 Dimensions of braking resistor 30 kW and 75 kW Order No.

- Page 216 Line Modules Booksize 3.4 Basic Line Modules with internal air cooling Braking duty cycles for braking resistors Figure 3-53 Braking duty cycles for braking resistors Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5...

-

Page 217: Smart Line Modules (5 Kw Und 10 Kw) With Internal Air Cooling

Line Modules Booksize 3.5 Smart Line Modules (5 kW und 10 kW) with internal air cooling Smart Line Modules (5 kW und 10 kW) with internal air cooling 3.5.1 Description The Smart Line Module is an unregulated infeed/regenerative feedback unit. The Smart Line Module supplies the Motor Module(s) with an unregulated DC voltage at the DC output. - Page 218 DANGER It is only permissible to establish connections to the DC link using the adapters that SIEMENS has recommended (DC link adapter and DC link rectifier adapter). CAUTION The tightening torque of the DC link busbar screws (1.8 Nm, tolerance +30 %) must be checked before commissioning and with the complete system in a no-voltage condition (powered-down) and with the DC link discharged.

- Page 219 Line Modules Booksize 3.5 Smart Line Modules (5 kW und 10 kW) with internal air cooling CAUTION The DC link side covers are supplied as standard with the components; they can also be ordered separately, if required (order no.: 6SL3162-5AA00-0AA0). WARNING If the Line Module is not disconnected from the network (e.g.

-

Page 220: Interface Description

Line Modules Booksize 3.5 Smart Line Modules (5 kW und 10 kW) with internal air cooling 3.5.3 Interface description 3.5.3.1 Overview Figure 3-54 Smart line module with internal air cooling (example 5 kW) Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 221: Connection Example

Line Modules Booksize 3.5 Smart Line Modules (5 kW und 10 kW) with internal air cooling 3.5.3.2 Connection example Figure 3-55 Example connection of Smart Line Module Booksize Power Units Equipment Manual, (GH2), 07/2007, 6SL3097-2AC00-0BP5... -

Page 222: X1 Line Connection

Line Modules Booksize 3.5 Smart Line Modules (5 kW und 10 kW) with internal air cooling 3.5.3.3 X1 line connection Table 3-36 Terminal block X1 of Smart Line Module (5 kW and 10 kW) Terminal Technical data Max. connection voltage: 3 AC 480 V +10 % at 47 Hz to 63 Hz Max. -

Page 223: X21 Terminals: Smart Line Module

Line Modules Booksize 3.5 Smart Line Modules (5 kW und 10 kW) with internal air cooling 3.5.3.4 X21 terminals: Smart Line Module Table 3-37 Terminal block X21 Terminal Designation Technical specifications DO: Ready Checkback: Smart Line Module ready The signal switches to high level when the following conditions have been met: Electronics power supply (X24) OK •... -

Page 224: X22 Terminals: Smart Line Module

Line Modules Booksize 3.5 Smart Line Modules (5 kW und 10 kW) with internal air cooling 3.5.3.5 X22 terminals: Smart Line Module Table 3-38 Terminal block X22 Terminal Designation Technical specifications 24 V power supply Electronics power supply for controlling digital inputs X22.2 and 3. -

Page 225: Meaning Of The Leds On The Smart Line Module

Line Modules Booksize 3.5 Smart Line Modules (5 kW und 10 kW) with internal air cooling 3.5.3.7 Meaning of the LEDs on the Smart Line Module Table 3-40 5 kW and 10 kW Smart Line Modules – description of the LEDs Color Status Description, cause... -

Page 226: Dimension Drawing

Line Modules Booksize 3.5 Smart Line Modules (5 kW und 10 kW) with internal air cooling 3.5.4 Dimension drawing Figure 3-56 Dimension drawing of the 5 kW and 10 kW Smart Line Modules with internal air cooling Table 3-41 Dimensions of 5 kW and 10 kW Smart Line Modules with internal air cooling Line module type Order number W [mm] (inches) -

Page 227: Mounting

Line Modules Booksize 3.5 Smart Line Modules (5 kW und 10 kW) with internal air cooling 3.5.5 Mounting Remove the holder for securing the Control Unit. The plastic retaining element must be removed due to the different expansion variants: ● If the component to be installed comes into contact with the left-hand cabinet panel ●... -

Page 228: Electrical Connection