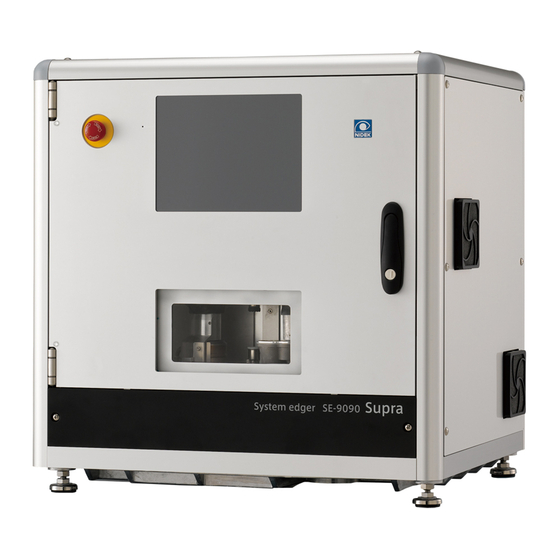

Nidek Medical SE-9090 Supra Manuals

Manuals and User Guides for Nidek Medical SE-9090 Supra. We have 1 Nidek Medical SE-9090 Supra manual available for free PDF download: Service Manual

Nidek Medical SE-9090 Supra Service Manual (350 pages)

SYSTEM EDGER

Brand: Nidek Medical

|

Category: Edger

|

Size: 61.52 MB

Table of Contents

-

Introduction

13 -

-

-

Assys109

-

-

Cable Assys139

-

-

Boards147

-

Electrical Parts152

-

-

Mechanical Parts173

-

-

Adjustment

179-

Calibration201

-

-

Axis Adjustment210

-

Bevel Axis Check210

-

Flat Axi Check213

-

Flat Axis Check213

-

Bevel Axis Check216

-

Flat Axi Check219

-

Flat Axis Check219

-

-

-

Retouch Check224

-

-

Bevel Position227

-

-

-

-

Step Bevel Check282

-

Network Setting288

-

EEPROM Data296

-

Upgrade298

-

Program Upgrade298

-

Version Check301

-

-

-

Trip Check303

-

Supplement

305-

Appearance305

-

Wiring Diagram310

-

Connector Cable311

-

Layout Drawing313

-

Assys313

-

Boards318

-

Cable Assys320

-

-

-

Error Code List324

-

Parameter List329

-

Jigs and Tools336

-

Jig and Tool336

-

Jigs336

-

-

-

Adjustment List338

-

-

-

Screw List349

-

-

Advertisement