Table of Contents

Advertisement

Natural Gas

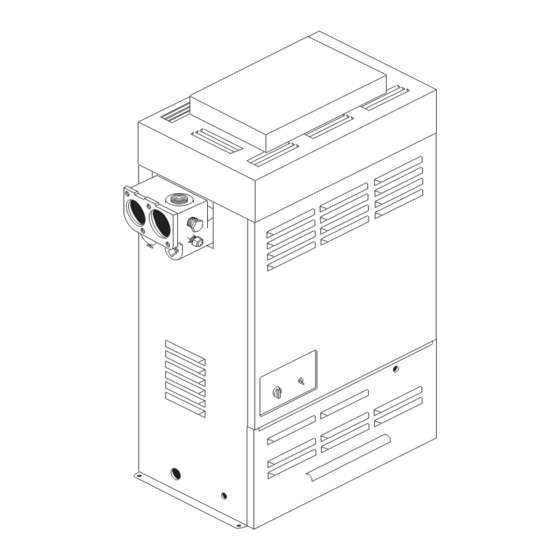

MB055PEH MB055

MODEL:

WARNING: If the information in these instructions are not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

-

Do not store or use gasoline or other flammable vapours and liquids in the vicinity

of

this or any other appliance.

-

WHAT TO DO IF YOU SMELL GAS

•

Do not try to light any appliance.

•

Do not touch any electrical switch; do not use any phone in your building.

•

Immediately call your gas supplier from a neighbour's phone. Follow the gas

supplier's instructions.

-

Installation and service must be performed by a Corgi registered installer, service

agency or the gas supplier.

MB055

MB105

Operating, Installation and

Servicing Instructions for

Pool & Spa Heaters

L.P.G.

MB105 MB155

MB155

MB185

MB265

MB185 - MB265 - MB405

MB055PEH

MB055

MB105

MB155

MB185

MB265

MB405

MB405

M3556

Advertisement

Table of Contents

Summary of Contents for Certikin MB055PEH

- Page 1 Natural Gas L.P.G. MB055PEH MB055 MB105 MB155 MB185 MB265 MB405 MODEL: WARNING: If the information in these instructions are not followed exactly, a fire or explosion may result causing property damage, personal injury or death. Do not store or use gasoline or other flammable vapours and liquids in the vicinity this or any other appliance.

-

Page 2: Table Of Contents

PART ONE - OWNER'S OPERATING INSTRUCTIONS Contents SECTION 1 / START-UP PROCEDURES Before Start-Up Operating Instruction & Shut-Off Procedures After Start-Up SECTION 2 / CAUTION SECTION 3 / MAINTENANCE & CARE PROCEDURE Pool & Spa Water Chemistry Cold Weather Operation Winterizing the Pool &... -

Page 3: Part One - Owner's Operating Instructions

PART ONE - OWNER'S OPERATING INSTRUCTIONS FOR YOUR SAFETY - READ BEFORE OPERATING WARNING: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION MAY RESULT, CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE. SECTION 1 / START-UP PROCEDURES BEFORE START-UP BURNERS WATER... -

Page 4: Operating Instructions

CAUTION: Propane gas is heavier than air and will settle on the ground. Since propane can accumulate in confined areas, extra care should be exercised when lighting propane heaters. FOR YOUR SAFETY READ BEFORE OPERATING WARNING: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE. -

Page 5: After Start-Up

AFTER START-UP SECTION 2/CAUTION Feel the inlet and outlet pipes. Outlet pipe should be Elevated water temperature can be hazardous, and only slightly warmer than the inlet. It should not be the U. S. Consumer Product Safety Commission hot. recommends the following guidelines: WARNING: Should overheating occur or the gas 1. -

Page 6: Pool & Spa Water Chemistry

Make visual check of the burner and pilot COLD WEATHER OPERATION flame. Flame pattern on the main burner and pilot is indicated in the previous illustra- MODERATE CLIMATE: Heater operation can tion. Yellow flame means restriction of the continue during short term cold spells. When air openings. -

Page 7: Part Two - Installation/Service Instructions

PART TWO - INSTALLATION/SERVICE INSTRUCTION SECTION 1 / RECEIVING EQUIPMENT WARNING: This appliance must be installed and serviced by a CORGI registered installer. On receipt of your equipment it is suggested that you visually check for external damage to the carton. If the carton is damaged, a note should be made on the delivery note when signing for equipment. - Page 8 PERFORMANCE SPECIFICATIONS GAS CATEGORY, TYPE, AND G20 @ 20 mbar (8 in. wg) 2H3P SUPPLY PRESSURE. G31 @ 37 mbar (14.8 in. wg) PERFORMANCE SPECIFICATIONS - NATURAL GAS GAS TYPE AND SUPPLY PRESSURE G20 @ 20 mbar (8 in. wg) MODEL BURNER mbar...

-

Page 9: Section 3 / Installation Instructions

SECTION 3 / INSTALLATION Models 185, 265 & 405 BS. 6891; Installation of low pressure pipework. INSTRUCTIONS BS. 6644; Installation of Gas Fired Hot Water Boilers 60kW to 2MW. IMPORTANT NOTICE CP 341; Water Supply. British Gas Publications: IM2; Purging Procedures on Non-domestic These instructions are intended for the use of quali- Gas Installations. - Page 10 CLEARANCES ALL HEATERS For servicing, provide at least 600mm (24") in front of For clearances from combustible surfaces, see the the heater for burner tray removal, and at least chart below. 450mm (18") on water connection side of the heater to inspect and delime the heat exchanger.

-

Page 11: Outdoor Heaters

OUTDOOR HEATERS 105 & 155 Models FLUE TERMINAL (Outdoor) Stackless Top Illustra- These heaters are certified by British Gas plc for tion outdoor installation, when equipped with the approved tops designated for outdoor use. Top Vent Opening WARNING: The heater shall not be located in an area where water sprinklers, or other devices, may cause water to spray through the cabinet louvres and into the heater. -

Page 12: Indoor Heaters

INDOOR HEATER 185, 265 & 405 Models FLUE TERMINAL (Indoor) Draught Diverter The design is also certified by British Gas plc for Illustration indoor installation when fitted with the appropriate draught diverter and a suitable flue system to outside. 1. Remove the louvred jacket top by removing Note that the heater must be in a room separated four (4) No.10 flat head screws. - Page 13 SPECIFICATIONS & DIMENSIONS 055 - 105 - 155 MODEL FLUE DIA WATER CONNECTIONS SHIPPING WEIGHT kg (lbs) mm (in.) APPLIANCE DIVERTER 100 (4) 1-1/2" NPT 31.8 (70) 2.3 (5) 127 (5) 1- 1/2" NPT (105) 3.5 (8) 152 (6) 2" NPT (135) 3.5 (8) 055 Model Only...

- Page 14 155 Model Only DIMENSIONS - 220mm (8 - ") 85mm (3 - ") 900mm (35 - ") 1140mm (44 - ") 770mm (30 - ") 680mm (26 - ") 390mm (15 - ") Connection 370mm 610mm (14 - ") (24") SPECIFICATIONS &...

-

Page 15: Combustion Air

VENTILATION REQUIREMENTS The flue/chimney design should avoid the formation of excessive quantities of condensate and for this The heater must have both ventilation and reason it is recommended that all chimneys are combustion air. Safe and efficient operation of the suitably insulated and lined. -

Page 16: Gas Supply Connections

Honeywell Gas Valve GAS SUPPLY CONNECTIONS Burner Pressure Gas piping must have a manual shut-off valve located Adjustment outside the heater jacket. All gas piping should be tested after installation in accordance with local codes. CAUTION: The heater and its manual shut off valve must be disconnected from the gas supply during any pressure testing of that system at test pressures in excess of 150mbar (2.2psi). -

Page 17: Plumbing For Water Connections

PLUMBING FOR WATER CONNECTIONS Figure 2 Rain Shield Front Panel LEFT SIDE WATER CONNECTION CONVERSION Front Screws 185, 265 & 405 Models Only fig2.tif Dis-assembly: 1. Remove the jacket top, upper side panels, right and left side access panel (see figure 1). 2. - Page 18 7. a) Disconnect the three (3) pin sensor plug 14. OPTIONAL, re-route the AGS wires to the left from the poolstat circuit board (see figure side and overheat thermostat capillary to the right side. Connect the wires to the sensors in b) Push the connector plug and wires down the header castings.

- Page 19 CONNECTIONS 2" CPVC Adapters All Models LOCATION The heater requires water flow and pressure to operate properly. It must therefore be installed downstream of the discharge side of the filter pump. A typical installation is plumbed as follows: 1. The inlet side of the filter is plumbed to the discharge side of the filter pump.

- Page 20 055 Models Only gasket.tif UNITHERM GOVERNOR OPERATION Does not apply to 105 Model 055hdr.tif The patented Unitherm Governor is a thermostatic mixing valve specifically designed to maintain con- stant heater internal temperature between 40.6 to 46.1°C despite continually changing flow rates from the filter and changing pool temperatures.

-

Page 21: Electrical Wiring

EXTERNAL AUXILIARY BYPASS VALVE The Electronic Intermittent Ignition Device automati- (Where Required) cally lights the pilot and main burners upon a call for the heat. The heater is supplied with a transformer An auxiliary bypass valve should be used when flow for 230V mains input. - Page 22 WIRING DIAGRAM 055-105-155 MODELS ONLY IGNITION DEVICE-ROBERTSHAW versa_wiring_08.01.tif 24V 150ºC BLACK BROWN YELLOW G/Y- GREEN & YELLOW BLUE 08-08-01 08-08-01...

- Page 23 WIRING DIAGRAM 185-265-405 MODELS ONLY IGNITION DEVICE-ROBERTSHAW Rpwiring.tif 08-08-01...

-

Page 24: Section 4 / Servicing Instructions

SECTION 4 / SERVICING INSTRUCTIONS GENERAL LOCATION OF CONTROLS 055 MODEL Manual High Limit Reset Button 105 MODEL Pressure Switch Burners & Pilot Drain Valve Unitherm Governor Gas Valve (Bronze Units Only) Bypass Valve Solid State Thermostat & High Limits Ignition Control &... - Page 25 GENERAL LOCATION OF CONTROLS - continued. 185-265-405 MODEL Overheat Thermostat Capillary (Located in Return Header) Bypass Drain Plug (Located in Return Header) AGS Hi-Limit (Located in Ignition Control (IID) Inlet/Outlet Header) Solid State Thermostat Module Unitherm Governor Ranco LM7 Drain Valve Overheat Thermostat Pressure Switch Transformer...

-

Page 26: Temperature Controls

185,265 & 405 Models 185,265 & 405 Models O F F S P A P O O L On/Off Switch Service Pressure/High Limit Thermostat Call forHeat Power Knob & Knobstop Ring E L E C T R O N I C rpcont.tif There are four operational indicator lamps located on the 185, 265 &... - Page 27 All Models FLAME ROLL-OUT SAFETY SWITCH PRESSURE SWITCH ADJUSTMENT 1. With pump and heater on, turn adjustment knob (clockwise) until a click is heard from the gas valve. 2. Turn adjustment knob (counter clockwise) rollout.tif 1/4 turn. 3. Turn pump off and on several times. The heater is equipped with a thermal cutoff device to Heater should shut off immediately.

-

Page 28: High Limit

3. To remove the manual reset high limit, follow the 055, 105 & 155 Models procedure for the high limit thermostat but in GAS VALVE REMOVAL addition, disconnect the electrical connections and release its mounting bracket from the side 1. Remove burner tray. (See burner drawer panel by removing the M4 nut at the front of the removal procedure). -

Page 29: Heat Exchanger Removal

185, 265 & 405 Models All Models PILOT REMOVAL AND CLEANING CONTROL IMMERSION WELL REPLACEMENT 1. Disconnect pilot tubing, and wires from 1. Shut water off to heater and drain heat gas valve. exchanger. 2. Remove pilot assembly from burner tray. 2. -

Page 30: Desooting Procedure

All Models To test the operation of the Unitherm Governor, place in hot water (over 43°C) and watch for movement DESOOTING PROCEDURE against spring. If there is no movement, replace unit. CAUTION: SOOT IS COMBUSTIBLE. EXERCISE EXTREME CARE. NEVER USE A WIRE BRUSH. 055, 105 &... -

Page 31: Section 5 / Trouble Shooting Guide

SECTION 5 / TROUBLE SHOOTING GUIDE These instructions are primarily intended for the use of qualified personnel specifically IMPORTANT NOTICE: trained and experienced in the installation of this type of heating equipment and related system components. Installation and service personnel must be Corgi Registered. Persons not qualified shall not attempt to install this equipment nor attempt repairs according to these instructions. - Page 32 PROBLEM CAUSE SOLUTION Pilot outage. Low gas pressure..... Adjust gas pressure. Restricted pilot......Clean pilot. Weak pilot generator....Replace pilot. Faulty Detection Electrode or PCB Yellow lazy flame Low gas pressure...... Adjust gas pressure. *Insects or debris clogging burner intake ports.....Clean burners. Inner &...

- Page 33 055, 105 & 155 Models WARNING ELECTRICAL (ELECTRONIC IGNITION IID) HIGH VOLTAGE For qualified Technicians ONLY NOTE: This heater is equipped with an ignition module that shuts off pilot gas if pilot START fails to light after the third attempt. This is identified by the green LED flashing on the ignition module.

- Page 34 ELECTRICAL (SOLID STATE THERMOSTAT IID) 055, 105 & 155 Models If the pool/spa water is too cold, troubleshoot the system as follows: Check voltage at 24 V terminals. VOLTAGE BETWEEN 21.5-28.5 V. VOLTAGE OUTSIDE RANGE 21.5-28.5 V. Set control to max. temperature. After 2-3 Check transformer, 23•20 V supply, correct as necessary.If 230 V side of transformer is open circuit, cycles, check water temperature.

- Page 35 185, 265 & 405 Models - IID DIAGNOSTIC FLOW CHART HEATER WILL NOT FIRE • Check for 230 V Power to Transformer (Circuit Breaker,Time Clock, Wire Connections) • Check for Fireman Switch/Remote Thermostat Operation (Red Jumper Wire from TP4 to TP5) Temporary Condition may Bypass If Necessary.

- Page 36 • Check for 24 VAC Power to IID - (24 V to 24V GND Terminals on IID). If No Power, From Pg 34 Replace heater Control Board, or wire harness to IID. • Check for Spark at IID Spark Terminal (Remove Hi-Tension Lead from IID Module- Position end near spark terminal.

-

Page 37: Section 6 / Replacement Parts

SECTION 6 REPLACEMENT PARTS LIST 055 Model NOTE: To supply the correct part it is important that you state the model number, serial number and type of gas when applicable. spares2.pcx Pilot ( Silver ) Pilot ( Black ) europilot.tif softlite.tif inject.tif 17-08-00... - Page 38 Description - 055 Model Part Code BURNER TRAY Burner Tray w/Gas Valve Natural Burner Tray w/Gas Valve Propane Burner 301210 Burner Injector Natural No.50 350079 Burner Injector Propane No.57 350083 CONTROLS High Limit 57ºC (135ºF) 600889B High Limit Manual Reset 102ºC M3029 Thermostat Control (Solid State) 600960...

-

Page 39: Replacement Parts List - 055

REPLACEMENT PARTS LIST 105 Model 16-H softlite.tif 11-H 14-H 12-H 10-M Pilot (Silver) inject.tif spares105_2.tif Pilot (Black) 10-12-01 europilot.tif... - Page 40 Description - 105 Model Part Code BURNER TRAY Burner Tray w/Gas Valve Natural Burner Tray w/Gas Valve Propane Burner 301210 Burner Orifice Natural No.50 350079 Burner Orifice Propane No.59 350350 CONTROLS Automatic Reset Thermostat 601549 High Limit Manual Reset 102ºC M3029 Thermostat Control (Solid State) 600960...

-

Page 41: Replacement Parts List - 105

REPLACEMENT PARTS LIST 155 Model 12-H bits.tif Pilot (Silver) Pilot (Black) inject.tif europilot.tif softlite.tif 17-08-00... - Page 42 Description - 155 Model Part Code BURNER TRAY Burner Tray w/Gas Valve Natural Burner Tray w/Gas Valve Propane Burner 301210 Burner Orifice Natural No.49 350078 Burner Orifice Propane No.57 350083 CONTROLS Thermostat Pocket, High Limit M3028 High Limit 60ºC (140ºF) 600893B High Limit Manual Reset 102ºC M3029...

-

Page 43: Replacement Parts List - 155

REPLACEMENT PARTS LIST 185, 265 & 405 Model 17-H 16-H 15-H 13-H 11-H 14-H 12-H 14-M 10-H 18-H 10-S 12-S 13-M 11-M 18-H Pilot (Silver) Pilot (Black) europilot.tif inject.tif softlite.tif 08-08-01... - Page 44 Description - 185, 265 & 405 Models BURNER TRAY Burner Tray w/Burners Burner Tray w/o Burners Burner Tray w/Gas Valve Natural SPMB405 Burner Tray w/Gas Valve Propane SPMB403 Burner 301210 301210 301210 Burner Orifice Natural No.50 350079 350079 350079 Burner Orifice Propane No.59 350350 350350 350350...

- Page 45 185, 265 & 405 Replacement Parts List (continued) Description PILOT (Silver) Pilot Natural/Propane 600799 600799 600799 Pilot Orifice Natural M3274 M3274 M3274 Pilot Orifice Propane 601218 601218 601218 Pilot Tube 400607 400607 400607 Hi-Tension Wire 650998 650998 650998 PILOT (Black) Pilot Natural/Propane M3685 M3685...

- Page 46 Station Lane Industrial Estate Witney Oxon. Tel. 01993 778855 Fax. 01993 703407 Booklet issue 12 27-08-03...

Need help?

Do you have a question about the MB055PEH and is the answer not in the manual?

Questions and answers