Summary of Contents for ABB ControlMaster Series

- Page 1 ABB Measurement Products ABB ControlMaster universal process controllers Making process control easy...

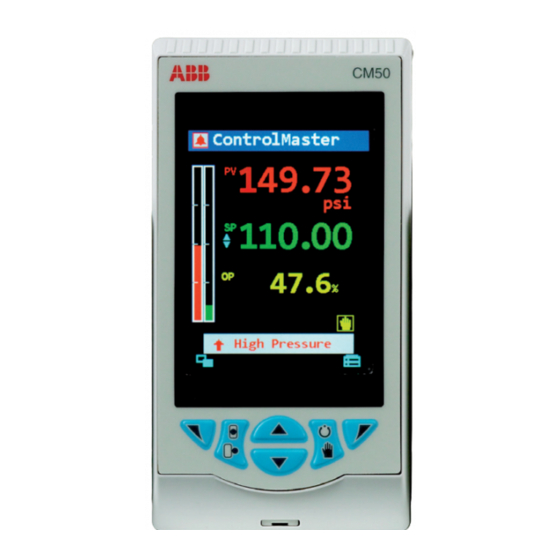

- Page 2 ABB’s new ControlMaster range elevates process monitoring and control to an altogether higher level. ABB has used its experience in controllers and indicators to create a new generation of process control instruments that are more intuitive, easier to operate and significantly more powerful in use.

- Page 3 A line up of 4 new instruments with the functionality and capability you need to meet the challenges of an information hungry process control industry. From ABB’s legacy in controllers and indicators, the new ControlMaster range of distinctive, accomplished and innovative instruments not only focuses on...

- Page 4 Each ControlMaster has an innovative HMI at the heart of its operation, providing a common link with other instrumentation products from ABB. So, if you know one, you know them all. Operation is so easy that you will be impressed by the efficiency of it all.

- Page 5 Template based configuration ControlMaster configuration is vastly simplified by using application templates. Selecting the template best suited to your process requirements automatically configures I/O and control functionality while display templates are selected automatically. ABB I Measurement Products - ControlMaster...

- Page 6 Temperature control of electrically or gas heated furnaces pH control of effluent flow via acid or alkaline dosing Ratio control of product blending Boiler drum level control Independent dual loop control of temperature and humidity in a climatic chamber ABB I Measurement Products - ControlMaster...

-

Page 7: Product Selection Guide

● ● Delay Timers ● ● ● ● Real-time Alarms ● ● ● ● Totalization ✔ ● ● Historical Trending ● ● Communications Ethernet ● ● ● ● RS485 MODBUS ● ● ● ● ABB I Measurement Products - ControlMaster... - Page 8 Contact us To find your local ABB contact visit: Notes: www.abb.com/contacts We reserve the right to make technical changes or modify the contents of this document without For more product information visit: prior notice. With regard to purchase orders, the www.abb.com/instrumentation...

- Page 9 Data sheet DS/CM30–EN Rev. L ControlMaster CM30 Universal process controller, Measurement made easy Making process control easy Comprehensive display of process status Powerful control functionality — Crystal-clear, full-color TFT display — Cascade, feed-forward, ratio, predictive and adaptive — User-customizable control strategies —...

- Page 10 ControlMaster CM30 Universal process controller, Overview The ControlMaster CM30 is a highly versatile, DIN, universal PID process controller. Detailed process information is presented clearly on the CM30's full-color TFT display and an intuitive operator interface simplifies configuration and operation. Highly scalable in both hardware and software functionality, a CM30 can be specified easily to meet the needs of virtually any process control application –...

- Page 11 Highly scalable The CM30 is highly scalable in terms of both hardware and software, to fulfill the demands of the simplest to the most complex process. The basic CM30 meets the needs of a simple control loop. Templates and control functionality can be increased by adding function keys to the basic model.

- Page 12 ControlMaster CM30 Universal process controller, Powerful operator display Diagnostics and alarm status display The diagnostics and alarm status display provides detailed The CM30 features a full-color 9 cm (3.5 in.) display for information on any active alarm or diagnostic condition. The displaying detailed process information to the user.

- Page 13 Exceptionally easy to use Trend display Any 2 analog values within the CM30 can be plotted on the trend display to give a short-term process history. This feature The CM30's full text display and simple-to-navigate, pop-up enables control efficiency to be monitored against setpoint and menu makes operation exceptionally easy.

- Page 14 ControlMaster CM30 Universal process controller, Advanced control functionality Predictive control (dead-time compensation) Control of processes with long dead-times, such as pH dosing The CM30 features many advanced control functions providing in a pipeline, is addressed easily using pPI control. Configured the power to bring even the most complex process under via only 3 parameters (gain, integral time and dead-time), pPI control.

- Page 15 Split output control External setpoint selection The CM30 can also be configured to perform split output The CM30's control setpoint can be selected via external control, for example, when both heating and cooling of a single digital signals, for example, simplifying operation by selecting process is required.

- Page 16 ControlMaster CM30 Universal process controller, Problem solving flexibility Math 8 math blocks provide arithmetic, averaging, min. / max. hold, Extensive functionality is available to provide flexible problem- square root and signal switching functionality. Simple solving capability; making the CM30 much more than just a equations can be performed in a single math block or multiple process controller.

- Page 17 Communications Extensive communication options enable the CM30 to be integrated into larger control systems easily or connected to other process instrumentation. Ethernet Optional Ethernet communications enable the CM30 to be integrated in to an Ethernet network quickly. The following functionality is provided: —...

- Page 18 In addition to configuration via the front panel, the CM30 can transferred to the controller via its front panel infrared port. be configured offline using ABB's Asset Vision Basic, a Device Type Manager (DTM)-based configuration package. Fig. 15: PC configuration software Fig.

-

Page 19: Application Templates

Application templates To minimize commissioning time, the CM30 features up to 20 preconfigured control strategy templates. By selecting the required control strategy, the template configures the CM30's function blocks and display automatically. Customization of the preconfigured templates is also possible, providing the flexibility to create customized solutions. Single loop This template provides standard, single-loop process control and is available with or without a remote setpoint. - Page 20 ControlMaster CM30 Universal process controller, Cascade The cascade template connects two PID loops together to enhance the control of a master variable (master loop) by manipulation of a slave loop. In this example, the temperature of a furnace is regulated (master loop) by monitoring and controlling the gas flow rate to the burner (slave loop).

- Page 21 Ratio controller The ratio controller template configures the CM30 to regulate one process variable against another based on a specified ratio. When using the ratio control template, the CM30's display shows the required ratio (setpoint) and the actual ratio achieved (process variable).

- Page 22 ControlMaster CM30 Universal process controller, Auto / Manual station and analog backup station These templates configure the CM30 to backup a master controller, typically a PLC or DCS. A fault condition is detected via a low output signal from the master controller or a digital signal. On detection of a fault signal, the CM30 can take control of the process (analog backup template), freeze its output or switch to a safe output (auto / manual station template).

-

Page 23: Technical Specification

Technical specification Extended templates: — Single loop with feedforward — Single loop with feedforward and remote setpoint — Cascade Operation — Cascade with remote setpoint Display Color, VGA TFT, liquid crystal display (LCD) with built-in — Cascade with feedforward backlight —... - Page 24 ControlMaster CM30 Universal process controller, Setpoints Math blocks Local: Number: — 4, selectable via digital input or front panel — 8 Remote: Operators: — selectable via digital input or front panel keys — +, –, x, / — Average, Maximum, Minimum —...

- Page 25 Analog inputs Display range –9999 to 99999 Universal process inputs Number: — 2 (1 standard, 1 optional) Update rate 125 ms Type: — Voltage Common mode noise rejection > 120 dB at 50 / 60 Hz with 300 imbalance resistance —...

- Page 26 ControlMaster CM30 Universal process controller, Inputs Thermocouple Maximum range °C (°F) Accuracy (% of reading) Digital inputs –18 to 1800 0.1 % or ±2 °C (3.6 °F) Type Volt-free or 24 V (0 to 3270) (above 200 °C [392 °F]) * Minimum pulse Analog inputs 1 and 2: –100 to 900...

- Page 27 Relays Digital I/O Number: Number: — 4 (1 standard, 3 optional) — 6 (2 standard, 4 optional) Type: Type: — Standard with changeover contacts — User-programmable as input or output — Optional contacts selectable as NO or NC (by jumper) —...

- Page 28 ControlMaster CM30 Universal process controller, Communications MODBUS * RTU (optional) Note. Only one communications option can be fitted per Baud rate: controller. — Up to 115 kBaud Isolation: IrDA service port (standard) Baud rate: — Galvanically isolated from the rest of the circuitry, —...

- Page 29 Electrical Emissions & immunity Supply ranges Meets requirements of IEC 61326 for an Industrial Environment 100 V to 240 V AC ±10 % (90 V min. to 264 V max.) 50 / 60 Hz 10 to 36 V DC (optional) Environmental Power consumption 10 W max.

- Page 30 ControlMaster CM30 Universal process controller, Electrical connections Rear View Rear View Rear View Rear View Standard Connections Option Board 1 Option Board 1a Option Board 2 Tx PSU Analog Output 2 – Relay Analog Analog Input 1 Input 3 Output 2 Digital Output +24 V Ext.

-

Page 31: Ordering Information

Ordering information ControlMaster CM30 universal process controller, CM30/ /XXX I/O build 2 analog inputs, 1 analog O/P and 1 relay (Basic) 2 analog inputs, 1 analog output and 2 relays (Basic + option board 1a) 2 analog inputs, 2 analog outputs, 2 digital I/O and 4 relays (Basic + option board 1) 4 analog inputs, 2 analog outputs, 6 digital I/O and 4 relays (Basic + option boards 1 and 2) Template / Functionality level Base... - Page 32 Howard Road notice. With regard to purchase orders, the agreed St. Neots particulars shall prevail. ABB does not accept any Cambridgeshire PE19 8EU responsibility whatsoever for potential errors or possible lack of information in this document.

- Page 33 Data sheet DS/CM15–EN Rev. J ControlMaster CM15 Universal process indicator, Making process control easy Comprehensive display of process status Totalization and counter functions — Crystal-clear, full-color TFT display — Calculation and display of flow total values — User-customizable — Pulse counting capability Exceptionally easy to use Problem-solving capability —...

- Page 34 ControlMaster CM15 Universal process indicator, Overview The ControlMaster CM15 is a feature-packed, DIN, universal process indicator. A crystal-clear, full-color, TFT display shows operators exactly the information they need to know and provides operation and configuration menus in full text making the CM15 intuitive to use and very quick to install and commission.

- Page 35 Highly scalable The CM15 is highly scalable in terms of both hardware and software, enabling it to meet the demands of simple indication duties through to more complex applications. The basic CM15 provides basic indication, totalization and level functionality. Templates and functionality can be increased by adding function keys to the basic model as shown in Fig.

- Page 36 ControlMaster CM15 Universal process indicator, Powerful operator display Diagnostics and alarm status display The diagnostics and alarm status display provides detailed The CM15 features a full-color 5.5 cm (2.2 in.) display for information on any active alarm or diagnostic condition. The displaying detailed process information to the user.

- Page 37 Exceptionally easy to use The CM15's full text display and simple-to-navigate, pop-up menu makes operation exceptionally easy. A programmable soft key enables commonly used functions, such as alarm acknowledgement and display selection, to be accessed easily by the operator. Fig. 5: Pop-up menu Configuration Operator Pages Alarm Acknowledge...

- Page 38 ControlMaster CM15 Universal process indicator, Problem solving flexibility Math 8 math blocks provide arithmetic, averaging, min. / max. hold, Extensive functionality is available to provide flexible problem- square root and signal switching functionality. Simple solving capability; making the CM15 much more than just a equations can be performed in a single math block or multiple process indicator.

- Page 39 Communications Extensive communication options enable the CM15 to be integrated into larger control systems easily or connected to other process instrumentation. Ethernet Optional Ethernet communications enable ControlMaster to be integrated in to an Ethernet network quickly. The following functionality is provided: —...

- Page 40 In addition to configuration via the front panel, the CM15 can transferred to the indicator via its front panel infrared port. be configured offline using ABB's Asset Vision Basic, a Device Type Manager (DTM)-based configuration package. Fig. 9: PC Configuration software Fig.

-

Page 41: Application Templates

Application templates To minimize commissioning time, the CM15 features up to 8 preconfigured templates. Simply selecting the required template configures the CM15's function blocks and display automatically. Customization of the preconfigured templates is also possible, providing the flexibility to create customized solutions. Single PV indication This template provides indication of a single process value. - Page 42 ControlMaster CM15 Universal process indicator, Single totalizer This template provides totalization only. Fig. 13 shows the CM15 being used to count the number of products passing a specific point on a production line. Fig. 13: Single totalizer Single level with volume The single level with volume template adds level specific functions to the single PV indication template.

- Page 43 Dual indication This template provides indication of 2 process values. Variations of this template are available providing dual PV with totalization, dual totalization or dual level indication. The example in Fig. 15 shows a single CM15 providing indication of both the flow through, and temperature of, a heat exchanger.

-

Page 44: Technical Specification

ControlMaster CM15 Universal process indicator, Technical specification Process alarms Number: — 8 Operation Types: Display Color, VGA TFT, liquid crystal display (LCD) with built-in — High / Low process backlight — High / Low latch Language English, German, French, Italian and Spanish Source —... - Page 45 Math blocks * Analog inputs Number: Universal process inputs — 8 Number: — 1 standard Operators: — +, –, x, / Type: — Average, Maximum, Minimum — Voltage — High / Low / Median select — Current — Square root —...

- Page 46 ControlMaster CM15 Universal process indicator, Display range Inputs –9999 to 99999 Thermocouple Maximum range °C (°F) Accuracy (% of reading) –18 to 1800 0.1 % or ±2 °C (3.6 °F) Update rate 125 ms (0 to 3270) (above 200 °C [392 °F]) * –100 to 900 0.1 % or ±0.5 °C (0.9 °F) (–140 to 1650)

- Page 47 Outputs Digital I/O Number: Retransmission outputs Number: — 2 (optional) — 2 (1 standard, 1 optional) Type: Isolation: — User-programmable as input or output — Galvanically isolated from the rest of the circuitry, — Minimum input pulse duration – 125 ms 500 V for 1 minute Input: Analog range:...

- Page 48 ControlMaster CM15 Universal process indicator, Communications MODBUS * RTU (optional) Note. Only one communications option can be fitted per Baud rate: indicator. — Up to 115 kBaud Isolation: IrDA service port (standard) Baud rate: — Galvanically isolated from the rest of the circuitry, —...

- Page 49 Electrical Emissions & immunity Supply ranges Meets requirements of IEC 61326 for an Industrial Environment 100 V to 240 V AC ±10 % (90 V min. to 264 V max.) 50 / 60 Hz 10 to 36 V DC (optional) Environmental Power consumption 10 W max.

- Page 50 ControlMaster CM15 Universal process indicator, Electrical connections Rear View Rear View Option Board 1 Standard Connections Tx PSU Analog Output 2 Option Board 1a Analog Input 1 – – Digital Output +24 V Ext. Digital I/O 1 Analog Input 2 Relay Output 2 –...

-

Page 51: Ordering Information

Ordering information ControlMaster CM15 universal process indicator, CM15/ /XXX I/O build 2 analog inputs, 1 analog O/P and 1 relay (Basic) 2 analog inputs, 1 analog output and 2 relays (Basic + option board 1a) 2 analog inputs, 2 analog outputs, 2 digital I/O and 4 relays (Basic + option board 1) Template / Functionality level Base Standard... - Page 52 Howard Road notice. With regard to purchase orders, the agreed St. Neots particulars shall prevail. ABB does not accept any Cambridgeshire PE19 8EU responsibility whatsoever for potential errors or possible lack of information in this document.

- Page 53 Data sheet DS/CMF160–EN Rev. B ControlMaster CMF160 Universal process indicator, fieldmount Making process indication easy Measurement made easy Cost saving field-mount design Scalable to match application requirements — Wall-, pipe- or panel-mountable — Comprehensive hardware- and software-options — No need for an instrument panel —...

- Page 54 ControlMaster CMF160 Universal process indicator, fieldmount Overview The ControlMaster CMF160 is a feature-packed, DIN, universal process indicator. With a unique field-mountable design that enables wall-, or pipe-mounting without the need for an additional enclosure. A crystal-clear, full-color, TFT display shows operators exactly the information they need to know and provides operation and configuration menus in full text, making the CMF160 intuitive to use and very quick to install and commission.

- Page 55 Highly scalable The CMF160 is highly scalable in terms of both hardware and software, enabling it to meet the demands of simple indication duties through to more complex applications. The base CMF160 provides basic indication, totalization and level functionality. Templates and functionality can be increased by adding function keys to the basic model as shown in Fig. 1, while retaining previous templates and functionality.

- Page 56 ControlMaster CMF160 Universal process indicator, fieldmount Powerful operator display Diagnostics and alarm status display The diagnostics and alarm status display provides detailed The CMF160 features a full-color 5.5 cm (2.2 in.) display for information on any active alarm or diagnostic condition. The displaying detailed process information to the user.

- Page 57 Exceptionally easy to use The CMF160's full text display and simple-to-navigate, pop-up menu makes operation exceptionally easy. A programmable soft key enables commonly used functions, such as alarm acknowledgement and display selection, to be accessed easily by the operator. Fig. 5: Pop-up menu Configuration Operator Pages Alarm Acknowledge...

- Page 58 ControlMaster CMF160 Universal process indicator, fieldmount Problem solving flexibility Math 8 math blocks provide arithmetic, averaging, min. / max. hold, Extensive functionality is available to provide flexible square root and signal switching functionality. Simple problem-solving capability; making the CMF160 much more equations can be performed in a single math block or multiple than just a process indicator.

- Page 59 Communications Extensive communication options enable the CMF160 to be integrated into larger control systems easily or connected to other process instrumentation. Ethernet Optional Ethernet communications enable ControlMaster to be integrated in to an Ethernet network quickly. The following functionality is provided: —...

-

Page 60: Bank Control

ControlMaster CMF160 Universal process indicator, fieldmount Bank control Inlet Outlet Bank control enables improved control of multi-element output devices such as banks of heaters, pumps and fans. Aimed at minimizing wear caused by over-use of one specific 'duty' device, bank control enables wear to be levelled by sharing duty and assist handling between every device in the bank. - Page 61 Application templates To minimize commissioning time, the CMF160 features up to 8 pre-configured templates. Simply selecting the required template configures the CMF160's function blocks and display automatically. Customization of the pre-configured templates is also possible, providing the flexibility to create versatile solutions. Single PV indication This template provides indication of a single process value.

- Page 62 ControlMaster CMF160 Universal process indicator, fieldmount Single totalizer This template provides totalization only. In this example, the CMF160 is counting the number of products passing a specific point on a production line: Single level with volume The single level with volume template adds level specific functions to the single PV indication template. The volume contained within a vessel can be calculated and indicated and products of varying specific gravity accounted for.

- Page 63 Technical specification Acknowledgement Via front panel keys or digital signals Operation Display Real-time alarms* Color, VGA TFT, liquid crystal display (LCD) Number: with built-in backlight — 2 Language Programmable: English, German, French, Italian and Spanish — Time Operator keypad — Day 4 tactile membrane keys —...

- Page 64 ControlMaster CMF160 Universal process indicator, fieldmount Custom linearizer* Digital filter Number: Programmable 0 to 60 s — 2 Elements: Display range — 20 breakpoints –9999 to 99999 Bank control* Update rate Number of outputs: 125 ms — 6 Wear levelling: Common mode noise rejection >...

- Page 65 Inputs Outputs Retransmission outputs Thermocouple Maximum range °C (°F) Accuracy (% of reading) — 4 (2 standard, 2 optional) –18 to 1800 0.1 % or ±2 °C (3.6 °F) Isolation: (0 to 3270) (above 200 °C [392 °F])* — Galvanically isolated from the rest of the circuitry, –100 to 900 0.1 % or ±0.5 °C (0.9 °F) 500 V for 1 minute...

- Page 66 ControlMaster CMF160 Universal process indicator, fieldmount Digital I/O Communications Number: Note. Only one communications option can be — 6 (standard) fitted per indicator. Type: — User-programmable as input or output IrDA service port (standard) — Minimum input pulse duration – 125 ms Baud rate: Input: —...

- Page 67 Electrical Emissions & immunity Supply ranges Meets requirements of IEC 61326 for an Industrial Environment 100 V to 240 V AC ±10 % (90 V min. to 264 V max.) 50 / 60 Hz Power consumption Environmental 25 W max. Operating temperature range Power interruption protection 0 to 55 °C (32 to 131 °F)

-

Page 68: Electrical Connections

ControlMaster CMF160 Universal process indicator, fieldmount Electrical connections Analog input I/O module Analog input I/O module 1 (shown fitted) 2 (module not fitted) OUT 3 OUT 4 RELAY RELAY Optional I/O module 3 option communications module I/O MODULE 2 I/O MODULE 3 I/O MODULE 3 card (shown fitted) –... -

Page 69: Overall Dimensions

Overall dimensions Dimensions in mm (in.) Transmitter Wall mount option 213 (8.38) 200 (7.87) Fixing centers (7.64) (2.44) Ø6.4 (2.40) (0.25) Cable gland kit (optional) Cable gland kit (optional) Pipe mount option Panel mounting 98 (3.85) 66 (2.6) (1.4) (3.6) Pipe-mount Panel cut-out dimensions* kit (optional) -

Page 70: Ordering Information

Ethernet RS 485 MODBUS Approval Standard CE cULus approval UL Class 1 Div. 2 Power supply 90 to 264 V AC Branding ABB Standard Unbranded front panel and start-up screen HMI language English German Spanish French Italian Expansion 1 None... - Page 71 ControlMaster CMF160 universal process indicator, fieldmount CMF160 AN AN AN Mounting hardware Wall Wall and panel Cable glands None (blanking plugs) Standard cable gland pack Ethernet cable gland pack Expansion 2 None Calibration certificate Certificate of calibration Printed instruction manual English German Spanish...

-

Page 72: Standard Accessories

We reserve all rights in this document and in the subject matter and illustrations contained therein. Any reproduction, disclosure to third parties or utilization of its contents in whole or in parts – is forbidden without prior written consent of ABB. Copyright© 2015 ABB... - Page 73 Data sheet DS/C160–EN Rev. I C160 Wall-/Pipe Mounted Universal Process Indicator C160 – reliable process indicator, wherever it’s needed High visibility LED display Totalizer and math functions — the clearest view of your process status — 6-digit totals and max./min. values 0.1% measurement accuracy Universal process input with transmitter power supply —...

- Page 74 Wall-/Pipe Mounted Universal Process Indicator C160 DS/C160–EN Rev. I C160 The C160 Universal Wall-mounting Indicator is a highly versatile, 5-digit industrial display indicator, with the capability to measure and indicate temperature, pressure, flow, level and other process variables. The standard C160 provides a retransmission output and two alarm relays, with the option to add RS485 communications to suit your application.

- Page 75 Wall-/Pipe Mounted Universal Process Indicator C160 DS/C160–EN Rev. I Display and Alarm The C160’s two built-in 5A relays can be used to annunciate high or low process alarms. Active alarms are indicated by flashing LEDs to the right of the main display. Isolated Retransmission The C160 has, as standard, a 4 to 20mA output for retransmission of the process variable to a chart recorder or data...

- Page 76 Wall-/Pipe Mounted Universal Process Indicator C160 DS/C160–EN Rev. I Specification Broken sensor protection Summary Upscale drive on thermocouple and RTD Downscale drive on milliamps and voltage Fully user-configurable universal indicator Cold junction compensation IP66/NEMA4X all-round protection Automatic CJC incorporated as standard Large 5-digit display Stability <0.05°C/°C change in ambient temperature...

- Page 77 Wall-/Pipe Mounted Universal Process Indicator C160 DS/C160–EN Rev. I Physical Environmental Size Operating limits 160mm (6.3 in.) wide x 250mm (9.84 in.) high x –10 to 55°C (32 to 131°F) 68mm (2.68 in.) deep 5 to 95% RH non-condensing Weight Temperature stability 2kg (4.5 lb) approx.

- Page 78 Wall-/Pipe Mounted Universal Process Indicator C160 DS/C160–EN Rev. I Overall Dimensions Dimensions in mm (in.) (1.65) 68 (2.68) 160 (6.3) 68 (2.68) (8.43) (9.13) (9.13) (9.84) (8.43) 69 (2.72) 200 (7.9) Allowance for Cable Bends Fixing 61 (2.375) O.D. 3 Fixing Holes Centers Vertical or Horizontal Post 6.5 (0.25) Dia.

- Page 79 Wall-/Pipe Mounted Universal Process Indicator C160 DS/C160–EN Rev. I Ordering Information - l l X X X X X X X i g i l a t i g i l a t i g i l a t t i f h t i t i f h t i...

- Page 80 Howard Road notice. With regard to purchase orders, the agreed St. Neots particulars shall prevail. ABB does not accept any Cambridgeshire PE19 8EU responsibility whatsoever for potential errors or possible lack of information in this document.

- Page 81 Data sheet DS/L160–EN Rev. F L160 Wall-/Pipe-Mount Level Indicator L160 – the flexible level system that meets your needs High visibility 5-digit LED display Max./Min. and Average levels — clear multi-functional indication — as standard the L160 can store these values Analog and 2-relay outputs as standard Wide range of sensor inputs —...

- Page 82 The L160 Universal Wall-/Post-mount Level Indicator is a highly versatile unit, accepting inputs from a wide range of level sensors offered by ABB and third party suppliers. As standard the L160 has a 5-digit indicator with IP66 all- round protection. It includes two alarm relays, 4 to 20mA...

- Page 83 Wall-/Pipe-Mount Level Indicator L160 DS/L160–EN Rev. F Custom Linearization As standard the L160 has a 20-breakpoint linearizer suitable for volume calculation. (Factory setup using PC configurator). Low Alarm Pump 1 Pump 2 Multiple Alarm Control Option The L160 accommodates up to three relays to indicate a range of alarm states, i.e.

- Page 84 Wall-/Pipe-Mount Level Indicator L160 DS/L160–EN Rev. F Specification Operation Outputs – Standard Build Retransmission Display High-intensity, 7-segment, 1 x 5-digit LED display Analog, configurable in the range 4 to 20mA Max. load 15V (750Ω at 20mA) Three alarm LED indicators Display range –9999 to +99999 Isolation...

- Page 85 Wall-/Pipe-Mount Level Indicator L160 DS/L160–EN Rev. F Environmental Electrical Operating limits Voltage (supply) –10 to 55°C (14 to 131°F) 85 to 265V AC 50/60Hz 5 to 95% RH non-condensing 24V DC optional Temperature stability Power consumption < 0.02% of reading or 2μV/°C (1μV/°F) <6VA (85 to 265V AC) <5W (24V DC) Enclosure...

- Page 86 Wall-/Pipe-Mount Level Indicator L160 DS/L160–EN Rev. F Overall Dimensions Dimensions in mm (in.) (1.65) 68 (2.68) 160 (6.3) 68 (2.68) (8.43) (9.13) (9.13) (9.84) (8.43) 69 (2.72) 200 (7.9) Allowance for Cable Bends Fixing 61 (2.375) O.D. 3 Fixing Holes Centers Vertical or Horizontal Post 6.5 (0.25) Dia.

- Page 87 Wall-/Pipe-Mount Level Indicator L160 DS/L160–EN Rev. F Ordering Information - l l X X X X i g i l a t i g i l a t l a i g i f g i f e r i l a i n i t t i k...

- Page 88 Howard Road notice. With regard to purchase orders, the agreed St. Neots particulars shall prevail. ABB does not accept any Cambridgeshire PE19 8EU responsibility whatsoever for potential errors or possible lack of information in this document.