Toro STX-26 Operator's Manual

Stump grinder

Hide thumbs

Also See for STX-26:

- Operator's manual (44 pages) ,

- Service bulletin (4 pages) ,

- Operator's manual (44 pages)

Summary of Contents for Toro STX-26

- Page 1 Form No. 3422-813 Rev A STX-26 Stump Grinder Model No. 23208—Serial No. 402000000 and Up Model No. 23208G—Serial No. 402000000 and Up *3422-813* A Register at www.Toro.com. Original Instructions (EN)

-

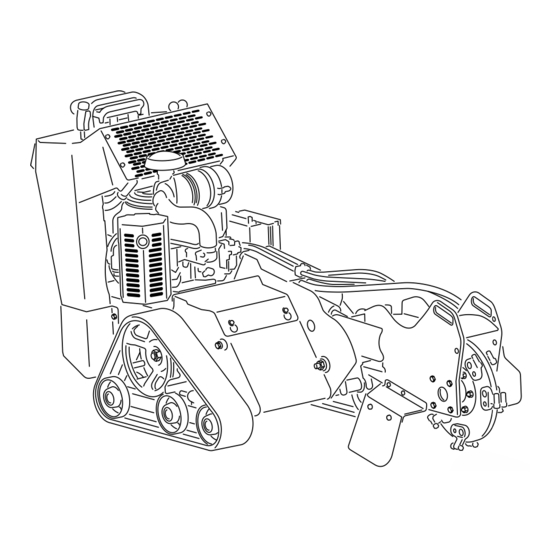

Page 2: Figure 1

Replacements may be ordered through Whenever you need service, genuine Toro parts, or the engine manufacturer. additional information, contact an Authorized Service Dealer or Toro Customer Service and have the model WARNING and serial numbers of your product ready. Figure... -

Page 3: Table Of Contents

(Figure 2), which signals a hazard that may cause Drive System Maintenance ........31 serious injury or death if you do not follow the Servicing the Tracks ......... 31 recommended precautions. Belt Maintenance ..........34 Replacing the Pump-Drive Belt ......34 Controls System Maintenance ...... -

Page 4: Safety

Safety • Evaluate the terrain to determine what accessories and attachments you need to properly and safely perform the job. Use only the accessories Improper use or maintenance by the operator or owner and attachments that are approved by the can result in injury. - Page 5 • Ensure that all the drives are in neutral and the and good judgment when performing this parking brake is engaged (if applicable) before evaluation. Changes in the terrain, such as starting the engine. Start the engine only from the moisture, can quickly affect the operation of operator's position.

-

Page 6: Safety And Instructional Decals

Shut off the engine, remove the key, and inspect the machine if you strike an object. Make any necessary repairs before starting. • Use only genuine Toro replacement parts. decal93-6686 93-6686 • Keep your body and hands away from pinhole 1. - Page 7 decal93-7814 93-7814 1. Entanglement hazard, belt—stay away from moving parts; keep all guards and shields in place. decal93-9084 decal119-4560 93-9084 119-4560 1. Lift point/Tie-down point 1. Ignition key 2. Engine—start 3. Engine—run 4. Engine—stop 5. Fast 6. Engine speed 7. Slow 8.

- Page 8 decal133-8056 133-8056 decal119-4561 119-4561 1. Push forward to lower the stump grinder. 2. Move right to move the stump grinder to the right. 3. Pull back to raise the stump grinder. 4. Move left to move the stump grinder to the left. 5.

- Page 9 decal119-4606 119-4606 1. Warning—read the Operator's Manual. 5. Explosion and electric shock hazard—do not dig in areas with buried utility lines; contact local power organizations before digging. 2. Cutting/dismemberment hazard; grinder—keep bystanders 6. Tipping/crushing hazard—lower the cutter head when a safe distance away from the machine; do not operate the operating on slopes.

-

Page 10: Setup

Setup Loose Parts Use the chart below to verify that all parts have been shipped. Procedure Description Qty. Grinder control lever Install the grinder control lever. Jam nut – No parts required Check the fluid levels. – No parts required Charge the battery. -

Page 11: Product Overview

Control Panel Product Overview g025098 Figure 5 1. Key switch 5. Traction control g013171 Figure 4 2. Throttle lever 6. Reference bar 3. Choke lever 7. Grinder 1. Reverse 3. Engine 5. Tie-down/lift 7. Chip control/hydraulic-lift lever safety point shield 4. - Page 12 Reference Bar • To turn right, rotate the traction control clockwise (Figure When driving the machine, use the reference bar as a handle and a leverage point for controlling the machine. To ensure smooth, controlled operation, do not take both hands off the reference bar while operating the machine.

- Page 13 Grinder Control/Hydraulic-Lift • To raise the grinder, pull the lever rearward (Figure 12). Lever Operate the grinder using the grinder control lever as follows: • To start the grinder (Figure 11), squeeze the trigger and then press the red button on the top of the lever.

-

Page 14: Specifications

Contact buy more than a 30-day supply of fuel. your Authorized Service Dealer or authorized Toro distributor or go to www.Toro.com for a list of all • Do not operate without entire exhaust approved attachments and accessories. - Page 15 Recommended Fuel DANGER • For best results, use only clean, fresh (less than In certain conditions during fueling, static 30 days old), unleaded gasoline with an octane electricity can be released, causing a spark rating of 87 or higher ((R+M)/2 rating method). that can ignite the fuel vapors.

-

Page 16: Performing Daily Maintenance

Filling the Fuel Tank Starting the Engine Park the machine on a level surface, engage Move the throttle lever midway between the the parking brake (if applicable), and lower the and F positions (Figure 16). hydraulic lift. Shut off the engine, remove the key, and allow the engine to cool. -

Page 17: Driving The Machine

Driving the Machine Grinding a Stump Use the traction controls to move the machine. The DANGER farther you move the traction controls in any direction, the faster the machine moves in that direction. This machine is capable of amputating hands Release the traction controls to stop the machine. -

Page 18: Moving A Non-Functioning Machine

Moving a Non-Functioning Machine Important: Do not tow or pull the machine without first opening the tow valves, or you will damage the hydraulic system. Engage the parking brake and lower the hydraulic lift. Shut off the engine and remove the key. Remove the bottom shield. -

Page 19: Lifting The Machine

Operating Tips 20). Refer to your local ordinances for trailer and tie-down requirements. • Clean the area of trash, branches, and rocks before operating to prevent equipment damage. • Always use full throttle (maximum engine speed) when grinding. • Cut the edges of the stump for more efficient grinding. -

Page 20: Maintenance

Maintenance Note: Determine the left and right sides of the machine from the normal operating position. Recommended Maintenance Schedule(s) Maintenance Service Maintenance Procedure Interval • Change the engine oil. After the first 8 hours • Check and adjust the track tension. After the first 50 hours •... -

Page 21: Pre-Maintenance Procedures

Pre-Maintenance To install the cover plate before operating the machine, slide the plate into place and secure it Procedures with the 3 bolts you loosened previously (Figure 22). Important: The fasteners on the covers of this machine are designed to remain on the cover after Removing the Bottom removal. -

Page 22: Lubrication

Lubrication Greasing the Machine Service Interval: Before each use or daily (Grease immediately after every washing.) Grease Type: General-purpose grease Park the machine on a level surface and lower the hydraulic lift. Shut off the engine and remove the key. Clean the grease fittings with a rag. -

Page 23: Engine Maintenance

Engine Maintenance Servicing the Primary Filter Inspect the primary filter for damage by looking into the filter while shining a bright light on the outside of Servicing the Air Cleaner the filter. Service Interval: Every 250 hours—Replace the Note: Holes in the filter appear as bright spots. If primary air filter and check the the filter is dirty, bent, or damaged, replace it. -

Page 24: Servicing The Engine Oil

Servicing the Engine Oil Service Interval: After the first 8 hours—Change the engine oil. Before each use or daily—Check the engine-oil level. g242254 Every 100 hours—Change the engine oil. Every 200 hours—Change the engine-oil filter. Engine-Oil Specifications Note: Change the oil more frequently when the operating conditions are extremely dusty or sandy. - Page 25 Changing the Engine Oil Note: Dispose of the used oil at a recycling center. Start the engine and let it run for 5 minutes. Note: This warms the oil so that it drains better. Park the machine on a level surface, engage the parking brake (if applicable), and lower the hydraulic lift.

-

Page 26: Servicing The Spark Plug(S)

Changing the Engine-Oil Filter Servicing the Spark Plug(s) Drain the oil from the engine; refer to Changing Service Interval: Every 100 hours the Engine Oil (page 25). Make sure that the air gap between the center and Change the engine-oil filter (Figure 31). -

Page 27: Fuel System Maintenance

Checking the Spark Plug(s) Fuel System Important: Do not clean the spark plug(s). Maintenance Always replace the spark plug(s) when it has: a black coating, worn electrodes, an oily film, or cracks. Draining the Fuel Tank If you see light brown or gray on the insulator, the engine is operating properly. -

Page 28: Replacing The Fuel Filter

Replacing the Fuel Filter Electrical System Maintenance Service Interval: Every 200 hours Park the machine on a level surface, engage the parking brake, and lower the hydraulic lift. Servicing the Battery Shut off the engine and remove the key. Service Interval: Every 25 hours—Check the battery electrolyte level. - Page 29 Charge the battery at a rate of 3 to 4 A for 4 to 8 hours (Figure 38). Do not overcharge the battery. g003792 Figure 38 1. Positive battery post 3. Red (+) charger lead 2. Negative battery post 4. Black (-) charger lead When the battery is fully charged, unplug g008335 the charger from the electrical outlet, then...

- Page 30 If the electrolyte is low, add the required amount Coat the battery posts and cable connectors with of distilled water; refer to Adding Water to the Grafo 112X (skin-over) grease (Toro Part No. Battery (page 30). 505-47) or petroleum jelly to prevent corrosion.

-

Page 31: Replacing The Fuses

Replacing the Fuses Drive System Maintenance There are 4 fuses in the electrical system. They are under the control panel on the left side (Figure 40). Start circuit 30 A Servicing the Tracks Charge circuit 25 A Cooler fan circuit 20 A Headlight (optional) 15 A... - Page 32 Checking and Adjusting the Track is applied to the track span. Adjust the torque on the tensioning bolt as needed. Tension Tighten the jam nut. Service Interval: After the first 50 hours Tighten the clamp bolts and torque to 102 N∙m Every 100 hours (75 ft-lb).

- Page 33 Checking and Greasing the Road Wheels Service Interval: Every 250 hours Park the machine on a level surface, engage the parking brake, and lower the hydraulic lift. Shut off the engine and remove the key. Remove the tracks; refer to Replacing the Tracks (page 32).

-

Page 34: Belt Maintenance

Belt Maintenance Torque the pump bolts to 68 N∙m (50 ft-lb). Install the bottom shield. Replacing the Pump-Drive Belt If the pump drive belt begins to squeal or is cracked, worn, or frayed, replace it. Contact your Authorized Service Dealer for a replacement belt. Park the machine on a level surface, engage the parking brake, and lower the hydraulic lift. -

Page 35: Controls System Maintenance

Controls System Maintenance Adjusting the Traction-Control Alignment The factory adjusts the traction controls before g004191 Figure 49 shipping the machine. However, after many hours of use, you may need to adjust the traction-control 1. Traction control 2. Stem, bolt, and nut alignment, the neutral position of the traction control, and the tracking of the traction control in the full Adjust the traction control so that it rests flush... - Page 36 Adjusting the Traction-Control Neutral Position If the machine creeps forward or backward when the traction control is in neutral and the machine is warm, you may need to adjust the return-to-neutral mechanism on the pumps; contact your Authorized Service Dealer. Adjusting the Traction-Control Forward Position If the machine does not drive straight when you hold...

-

Page 37: Hydraulic System Maintenance

Toro Premium All Season Hydraulic Fluid (refer to your Authorized Toro Dealer for more information) • If either of the above Toro fluids are not available, you may use another Universal Tractor Hydraulic Fluid (UTHF), but they must be only conventional, petrolium-based products. The... -

Page 38: Changing The Hydraulic Fluid

g007839 Figure 54 1. Filler-neck cap 2. Hydraulic-fluid filter If the level is low, add fluid until it is visible in the glass bubble. Install the cap and filter on the filler neck and torque bolt on top to 13 to 15.5 N∙m (110 to 140 in-lb). -

Page 39: Grinder Maintenance

Grinder Maintenance Replacing the Teeth Service Interval: Before each use or daily—Check the condition of the teeth; rotate or replace any that are worn or damaged and torque the nuts for all teeth. Due to the high amount of wear placed on the teeth, you need to rotate and replace them periodically (Figure 56). -

Page 40: Cleaning

Cleaning Storage Park the machine on a level surface, engage the Removing Debris from the parking brake, and lower the hydraulic lift. Machine Shut off the engine, remove the key, and wait for the engine to cool. Service Interval: After each use Remove dirt and grime from the external parts of the entire machine, especially the engine. - Page 41 With the spark plug removed from the engine, pour 2 tablespoons of engine oil into the spark-plug hole. Place a rag over the spark-plug hole to catch any oil spray, then use the starter or recoil handle to crank the engine and distribute the oil inside the cylinder.

-

Page 42: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The starter does not crank. 1. The battery is discharged. 1. Charge the battery or replace it. 2. The electrical connections are 2. Check the electrical connections for corroded or loose. good contact. 3. The relay or switch is damaged. 3. -

Page 43: Schematics

Schematics g013418 Electrical Schematic (Rev. A) - Page 44 g025169 Hydraulic Schematic (Rev. A)

- Page 45 Notes:...

- Page 46 Notes:...

- Page 47 The Way Toro Uses Information Toro may use your personal information to process warranty claims, to contact you in the event of a product recall and for any other purpose which we tell you about. Toro may share your information with Toro's affiliates, dealers or other business partners in connection with any of these activities. We will not sell your personal information to any other company.

- Page 48 While the exposure from Toro products may be negligible or well within the “no significant risk” range, out of an abundance of caution, Toro has elected to provide the Prop 65 warnings. Moreover, if Toro does not provide these warnings, it could be sued by the State of California or by private parties seeking to enforce Prop 65 and subject to substantial penalties.