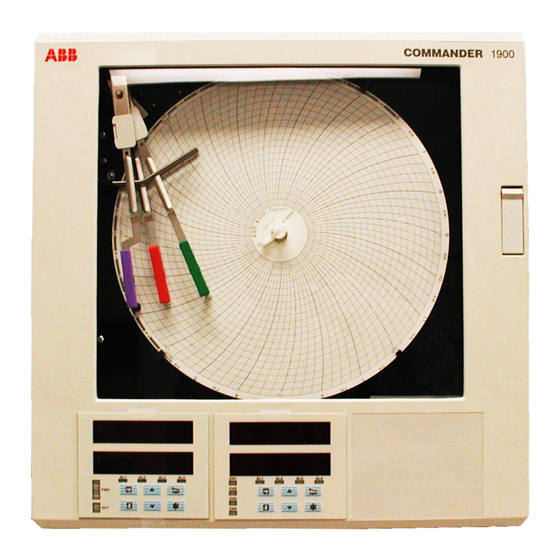

ABB COMMANDER 1900 Series Programming Manual

Circular chart recorders

Hide thumbs

Also See for COMMANDER 1900 Series:

- Programming manual (57 pages) ,

- User manual (36 pages) ,

- Operating manual (44 pages)

Summary of Contents for ABB COMMANDER 1900 Series

- Page 1 COMMANDER 1900 Series Programming Guide Circular Chart Recorders Recorder Versions ABB Automation...

- Page 2 St Neots, U.K. – Cert. No. Q5907 environmental applications. Stonehouse, U.K. – Cert. No. FM 21106 As a part of ABB, a world leader in process automation technology, we offer customers application expertise, service and support worldwide. EN 29001 (ISO 9001) We are committed to teamwork, high quality manufacturing, advanced technology and unrivalled service and support.

-

Page 3: Table Of Contents

CONTENTS 1 INTRODUCTION Section Page The COMMANDER 1900 series of documentation is shown in Fig. 1.1. The , including the specification Standard Manuals sheet, are supplied with all instruments. The INTRODUCTION ............1 Supplementary supplied depend on the specification of the Manuals instrument. -

Page 4: General Programming

2 GENERAL PROGRAMMING 3 BASIC CONFIGURATION LEVEL The programming procedures are used to make changes to 3.1 Set Up Input (Process Variable) ......4 the operating parameter values and for scale adjustment – • Input types see Fig. 3.2. • Linearization •... - Page 5 OPrtOr LEVEL Operator Level bASIC CONFIG Basic Config Set Up Inputs Set Up Pen Range Setup Chart Set Up Alarms Set Up Relay Output* Set Up Digital Output Set Up Analog Output Digital Inputs Access Page Scale Adjust AdVNCd Section 3.1 Page 4 Section 3.2 Page 8 Section 3.3 Page 9 Section 3.4 Page 12...

- Page 6 …3 BASIC CONFIGURATION LEVEL 3.1 Set Up Input (Process Variable) Information. • Universal inputs – mV, mA, V, THC, RTD and resistance. • Internal cold junction compensation. • Linearization – of temperature sensors to allow use of non-linearizing transmitters or any electrical input. •...

-

Page 7: Set Up Input (Process Variable)

3 BASIC CONFIGURATION LEVEL… …3.1 Set Up Input (Process Variable) SEt UP Page Header – Set Up Input (Process Variable) INPUt To advance to press the switch. Set Up Pen Range Page SELECt Select Channel PV–4 Select the channel to be programmed: PV–... - Page 8 …3 BASIC CONFIGURATION LEVEL …3.1 Set Up Input (Process Variable) Input Range High rNG–HI Set the maximum electrical input value required (in electrical units). 20. 0 Note. The value set must be within the limits detailed in the table below. I n p u t T y p e Input Type...

- Page 9 3 BASIC CONFIGURATION LEVEL… …3.1 Set Up Input (Process Variable) Decimal Point dECPt Set the decimal point position required for the engineering range high and engineering both 1000 range low values. Engineering Range Low ENG–LO Set the minimum engineering (display) value required, Note.

-

Page 10: Set Up Pen Range/Event Source

…3 BASIC CONFIGURATION LEVEL 3.2 Set Up Pen Range/Event Source Information. • Trend pens – have an independent chart range allowing a selected part of the engineering (display) range to be used for extra resolution on the chart. • Three position event pen function – can be driven by digital inputs, alarms, logic equation results and real time events (when timer option is fitted). -

Page 11: Set Up Chart

3 BASIC CONFIGURATION LEVEL… 3.3 Set Up Chart Information. • Programmable chart duration – between 1 and 167 hours or 7 and 32 days. • Chart stop function – the chart can be stopped by an alarm, digital input, logic equation result or a real time event (if timer option is fitted). - Page 12 …3 BASIC CONFIGURATION LEVEL 3.4 Set Up Alarms Information. • Four alarms per channel – identified A1 to D1 (for channel 1) up to A4 to D4 (for channel 4). • Three operator acknowledge options. • Global alarm acknowledgment – by digital input, alarm, logic equation result or real time event (if option fitted). •...

- Page 13 3 BASIC CONFIGURATION LEVEL… …3.4 Set Up Alarms The maximum time it takes to detect an alarm condition is present (T), in seconds, is calculated as follows: 1800 T = 10.81 + 10.1 10.1 Trip Value The time it takes for the alarm state to be cleared once the alarm condition has been removed is also equal to T.

-

Page 14: Set Up Alarms

…3 BASIC CONFIGURATION LEVEL …3.4 Set Up Alarms SEt UP Page Header – Set Up Alarms ALArMS To advance to page press the switch. Set Up Relay Output ACKtYP Alarm Acknowledge Type LAtCH Alarms may be acknowledged while they are displayed. Select the alarm acknowledge type: NOrMAL NONE... -

Page 15: Alarm Type

3 BASIC CONFIGURATION LEVEL… …3.4 Set Up Alarms tYPE Alarm Type S–rAtE Select the alarm type required for the alarm selected. F–rAtE HI–PrC – high process SELECt LO–PrC LO–PrC – low process HI–PrC F–rtE – fast rate (rate of change of process variable) S–rtE –... - Page 16 …3 BASIC CONFIGURATION LEVEL 3.5 Set Up Relay Output Information. • Relay Output – omitted on 1901J (non-upgradeable version). • Relays – can be energized by alarms, logic equation results, digital inputs, real time events (timer option ) and totalizer wrap signal (totalizer option).

-

Page 17: Set Up Relay Output

3 BASIC CONFIGURATION LEVEL… …3.5 Set Up Relay Output POLrtY Polarity The polarity selection is used to invert the effect of the digital source state on the relay state as POStVE shown in the following table: NEGtVE Source State Polarity Relay State Positive Energized... - Page 18 …3 BASIC CONFIGURATION LEVEL 3.6 Set Up Digital Output Information. • This page is not displayed if there are no digital outputs fitted. • Up to 24 digital outputs are available – depending on the module types fitted. • Digital outputs – can be energized by alarms, logic equations results, digital inputs, real time events (timer option) and totalizer wrap signal (totalizer option).

-

Page 19: Set Up Digital Output

3 BASIC CONFIGURATION LEVEL… …3.6 Set Up Digital Output dIGtAL Page Header – Set Up Digital Outputs OUtPtS to advance to page press the switch. Set Up Analog Output SELECt Select Digital Output OUt 1. 1 Select the output to be programmed – the selections in this frame relate to the number of fitted digital output modules and their relative module positions. - Page 20 …3 BASIC CONFIGURATION LEVEL 3.7 Set Up Analog Output Information. • Analog Output – omitted on 1901J (non-upgradeable version). • Fitted analog outputs – assignable to retransmit any process variable. • Selectable retransmission range – allows maximum resolution on range of interest. •...

-

Page 21: Set Up Analog Output

3 BASIC CONFIGURATION LEVEL… …3.7 Set Up Analog Output SEt UP Page Header – Set Up Analog Output ANALOG To advance to press the switch. Digital Inputs Page SELECt Select Analog Output OP–1 Select the analog output to be programmed. The selections in this frame relate to the number of fitted modules with analog output. -

Page 22: Digital Inputs

…3 BASIC CONFIGURATION LEVEL 3.8 Digital Inputs Information. • Digital Input – omitted on 1901J (non-upgradeable version). • Up to 30 digital inputs are available – depending on the module types fitted. • Volt-free contacts or TTL levels. • Polarity – sets the logic state (unchanged or inverted) for the module position(s). Polarity Select Digital Input Logic State... -

Page 23: Access Page

3 BASIC CONFIGURATION LEVEL… 3.9 Access Page Information. • Configurable password protection – of PROGRAMMING LEVELS • Internal security link – enable/disable password protection. ACCESS Page Header – Access Page. PAGE To advance to press the switch. Scale Adjust Page C–PASS Configuration Password ––––... - Page 24 …3 BASIC CONFIGURATION LEVEL 3.10 Scale Adjust Information. • Analog Inputs – do not require re-calibrating when the input type or range is changed. • Process variable adjust reset – removes any previously programmed offset or scale adjustment settings. • System offsets errors – can be removed using process variable scale offset adjustment. •...

-

Page 25: Scale Adjust

3 BASIC CONFIGURATION LEVEL …3.10 Scale Adjust Page Header – Scale Adjust SCALE AdJUSt To advance to frame use the switch. BASIC CONFIGURATION LEVEL Select Process Variable/Pen SELECt Select linearity check, process variable or pen required: LINCHK LINCHK dONE – the pens automatically draw a test pattern to check pen linearity. - Page 26 …3 BASIC CONFIGURATION LEVEL …3.10 Scale Adjust SELECt SEtPEN Calibrate Pen At 100% Drives the pen automatically to the full scale position on the chart. At 100 Use the switches to set pen to 100% on the chart. SEtPEN Calibrate Pen At 0% Drives the pen automatically to the zero position on the chart.

-

Page 27: Advanced Configuration Level

4 ADVANCED CONFIGURATION LEVEL Set Up Function Keys ............................... 25 Set Up Logic ..................................26 Set Up Pen Functions ............................... 28 OPrtOr LEVEL Operator Level bASIC CONFIG Basic Config AdVNCd CONFIG Set Up Functions Keys Set Up Logic Set Up Pen Functions Advanced Config Section 4.1 Page 25 Section 4.2 Page 26... - Page 28 …4 ADVANCED CONFIGURATION LEVEL 4.2 Set Up Logic Information. • 4 logic equations • 7 elements per equation • OR/AND operators • Can combine internal and external digital signals – i.e. alarms, digital inputs, other logic equation results and real time events (timer option).

-

Page 29: Set Up Logic

4 ADVANCED CONFIGURATION LEVEL… …4.2 Set Up Logic SEt UP Page Header – Set Up Logic LOGIC To advance to press the switch. Set Up Pen Functions Page SELECt Select Equation EQN1 Select equation to be constructed. EQN2 In the remaining frames press the switch to view the equation selected. -

Page 30: Set Up Pen Functions

…4 ADVANCED CONFIGURATION LEVEL 4.3 Set Up Pen Functions Information. • Any fitted pen can be assigned to a trend or an event function. Page Header – Pen Functions FUNCtN To advance to frame press the switch. Advanced Configuration PEN–1 Pen 1 trENd Select pen function required:... - Page 31 Main Input, Standard Input & Analog + Relay 4 Relays Module 8 Digital Inputs/Outputs Module Common Common Analog Output Input 1 Output 1 – Relay 1 Input 2 Output 2 Input 3 Output 3 Analog Input Input 4 Output 4 Relay 2 Input 5 Output 5...

- Page 32 PRODUCTS & CUSTOMER SUPPORT A Comprehensive Instrumentation Range Customer Support Analytical Instrumentation ABB Instrumentation provides a comprehensive after sales service via a Worldwide Service Organization. Contact one of • Transmitters the following offices for details on your nearest Service and...

- Page 33 The Company’s policy is one of continuous product improvement and the right is reserved to modify the information contained herein without notice. © ABB 1998 Printed in UK (10.98) ABB Kent-Taylor Ltd. ABB Instrumentation Inc. ABB Kent-Taylor SpA St. Neots...