Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Prusa Research Original Prusa i3 MK2S KIT 1.75mm

- Page 2 Read carefully! This part of the text has the uppermost importance - either for user safety of for a proper printer service. This symbol indicates text related to a printer kit only. Handbook version 2.02 from January 4, 2018 © Prusa Research s.r.o.

-

Page 3: About The Author

About the author rd Josef Prusa (born Feb 23 , 1990) became interested in the 3D printing phenomenon before joining the Prague’s University of Economics in 2009 - at first it was a hobby, a new technology open to changes and improvements. The hobby soon became a passion and Josef grew into one of the leading developers of Adrien Bowyer’s international, open source, RepRap project. -

Page 4: Table Of Contents

Table of contents About the author Table of contents 2 Product details 3 Introduction 3.1 Glossary 3.2 Disclaimer 3.3 Safety instructions 3.4 Licenses 4 Original Prusa i3 MK2S printer 5 Original Prusa i3 MK2S printer kit 6 First steps 6.1 Printer unpacking and proper handling 6.2 Printer assembly 6.3 Setup before printing 6.3.1 Calibration flow and wizard... - Page 5 7.2.8 Print speed versus print quality 7.2.9 USB cable and Pronterface 7.3 Printer addons 7.3.1 Different nozzles 7.3.1.1 Hardened steel nozzle 7.3.1.2 0.25mm nozzle 8 Advanced calibration 8.1 PID tuning for Hotend (Optional) 8.2 PINDA probe calibration/ Temp. calibration (Experimental/Optional) 8.3 View XYZ calibration details (Optional) 8.4 Linear Advance (Experimental) 9 Printer drivers...

-

Page 6: Product Details

2 Product details Title: Original Prusa i3 MK2S / Original Prusa i3 MK2S (kit), Filament: 1.75 mm Manufacturer: Prusa Research s.r.o., Partyzánská 188/7A, Prague, 170 00, Czech Republic Contacts: phone +420 222 263 718, e-mail: i nfo@prusa3d.com EEE group: 3 (IT and/or telecommunication equipment), Device use: indoor only Power supply: 90-135 VAC, 2 A / 180-264 VAC, 1 A (50-60 Hz) Working temperature range: 18 °C (PLA)-38 °C, indoor use only... -

Page 7: Disclaimer

3.2 Disclaimer Failure to read the Manual may lead to personal injury, inferior results or damage to the 3D printer. Always ensure that anyone who operates the 3D printer knows and understands the contents of the Manual. We can not control the conditions in which you assemble the Original Prusa i3. -

Page 8: Original Prusa I3 Mk2S Printer

4 Original Prusa i3 MK2S printer Unlike the printer kit, it’s completely assembled and almost ready to print. After plugging in and running the necessary calibration you, can print a 3D object in a matter of minutes after unpacking the printer. Keep in mind you can use our support email when you purchased the assembled printer. -

Page 9: Original Prusa I3 Mk2S Printer Kit

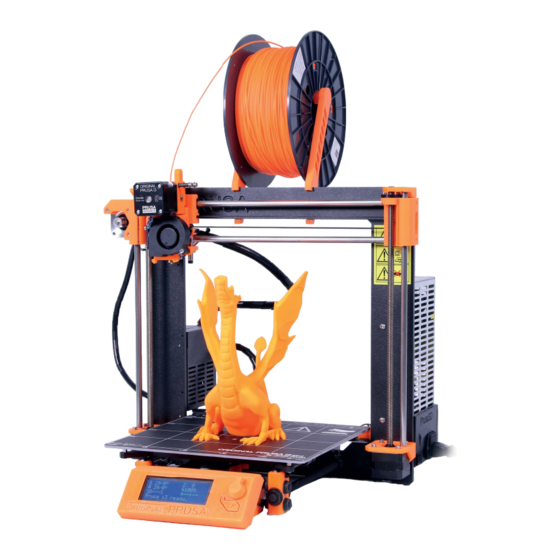

5 Original Prusa i3 MK2S printer kit Original Prusa i3 MK2S kit is pictured in pict. 2. Detailed information and assembly description can be found in chapter 6 .2 Printer assembly . We offer the support for users who purchased the printer kit through our official forum. If you need help do not hesitate to visit our forum at ... -

Page 10: First Steps

6 First steps 6.1 Printer unpacking and proper handling Holding the upper frame, take the printer and pull it out from the box. Be careful when handling the printer not to damage the electronics and thus the proper printer functionality. Anytime you move the printer, always hold the upper frame with hotbed upright pointing away from you as pictured in pict. -

Page 11: Printer Assembly

6.2 Printer assembly With Original Prusa i3 MK2S printer kit we suggest to follow the guidelines and assemble the kit according to the the online manual at m anual.prusa3d.com . (Online manual is available in several languages on the website). The construction of the printer should not take more than one working day. - Page 12 Wizard is available since firmware version 3.1.0 onward. With your first start-up of your freshly assembled printer, it will guide you through all the tests and calibrations you need to do to get started printing. Wizard can be also started manually from LCD menu C alibration -> Wizard . Do not forget to read chapter ...

-

Page 13: Pei Print Surface Preparation

There are few special occasions where you will need to redo the calibration or part of it. ● Firmware update - Complete guide is in the chapter 1 2.8 Updating printer firmware 6.3.9. First layer calibration needs to be rerun otherwise the printer will show an error message. -

Page 14: Increasing The Adhesion

6.3.3 Increasing the adhesion In some special occasions, like a tall object with a very small contact area with the print surface, you might need to increase the adhesion. Fortunately PEI is a very chemically resistant polymer and you can temporary apply other adhesion solutions without damaging it. -

Page 15: Selftest Error Messages And Resolution (Kit Only)

6.3.4.1 Selftest error messages and resolution (kit only) Fan - Wiring error: Check proper wiring of print and hotend fan cables. Ensure that both are properly connected to the Rambo electronics, and that they are not swapped. Heater/Thermistor - Not connected: Check proper wiring of hot end power cables and thermistor cables. - Page 16 Place a sheet of a regular office paper (for example the checklist shipped with every order) and hold it under the nozzle during the first round (first 4 points being checked) of calibration. If the nozzle catches on the paper during the process, power off the printer and lower the P.I.N.D.A.

-

Page 17: Calibrate Xyz Error Messages And Resolution (Kit Only)

6.3.5.1 Calibrate XYZ e r ror messages and resolution ( kit only) 1) XYZ calibration failed. Bed calibration point was not found. Calibration routine did not find a bed sensor point. The printer stops close to the bed point, which it failed to detect. Please verify, that the printer is assembled correctly, that all axes move freely, the pulleys do not slip and the print nozzle is clean. - Page 18 cannot reach the right front bed calibration point. Move the right Y threaded rod in the Z frame away from you, so the PINDA probe reaches the right front bed calibration point reliably. Y ou can find out how to fix this in the next chapter 6 .3.5.2 Y axis ...

-

Page 19: Y Axis Alignment (Kit Only)

aligned during the Z calibration over time, it is possible, that a pulley is slipping or something on the machine frame got loose. 3) Bed leveling failed. Sensor triggered too high. Waiting for reset. Similar to case 2). This time the PINDA sensor triggered more than 1 mm above the reference height. -

Page 20: Mesh Bed Leveling

At the start of the Z calibration procedure the printer prompts you by a following message: "Calibrating Z. Move Z carriage up to the end stoppers. Click when done.” After that, the printer asks you to confirm this step: " Are left and right Z carriages all up?" Please make sure you really move the Z carriage up to the end stoppers until you hear a rattling sound as the Z stepper motors skip steps. -

Page 21: Loading The Filament Into The Extruder

6.3.8 Loading the filament into the extruder ● You need to preheat the nozzle before inserting the filament (and the bed too if you like to print right away). The temperature depends on the material used. Detailed information about nozzle and bed temperatures are described at chapter Materials... -

Page 22: Unloading The Filament

chapter 1 0.6 Printing in color with ColorPrint to find out how to make more intricate color models. 6.3.8.1 Unloading the filament Similar procedure to the loading operation. P reheat the nozzle for material you used last time (pre assembled printers are shipped with PLA). Wait for temperatures to stabilize and use ... - Page 23 Pict. 8 - How to tune the nozzle height live during the test print. Note: -0.640 mm is only for illustration. Your setting will be different! Observe the line which is being extruded on the print surface. Go to the LCD menu and choose the ...

-

Page 24: Bed Level Correction (Kit Only)

6.3.9.4 Bed level correction (kit only) Bed level correction is an advanced feature that was introduced in the firmware 3.0.6 and it is designed to allow advanced users to correct for the slightest imperfections in the first layer. This feature can be found in C alibration - B ed level correction. For example if the first layer seems to be ever so slightly more squished on the right side, you can virtually raise the nozzle by ... - Page 25 Pict. 11 - Probe response diagram. Now you are done! ...

-

Page 26: Printing

7 Printing ● Make sure that the nozzle and the bed are heated to the desired temperature. If you forget to preheat the printing nozzle and the bed before printing, the printer will automatically check the temperatures of the nozzle and the bed; printing will start when desired temperature is reached - it can take several minutes. -

Page 27: Printer Control

If your prints are stuck too well and don’t want to separate, try using a d ental floss . Slide a dental floss under the corner of the object which you previously separated by the spatula a in saw like motion gently separate the object from the print surface. Dental floss is generally covered in wax so the print surface needs to be ... -

Page 28: Print Statistics

7.2.2 Print statistics The printer tracks printing statistics. When you access this option during a print, you will see statistics for the running print. If you do so while the printer is idle, you will see the lifetime statistics. Both filament usage and print time are tracked. Pict. -

Page 29: Sd Card Sorting

● All data which resets everything including all calibration data and whole EEPROM is cleaned. After this reset, user is expected to go through the calibration flow again, except setting the probe height. If you experience random glitches after firmware update or after printer upgrade, use the A ll data... -

Page 30: Lcd Layout

7.2.7 LCD layout Items not mentioned below are not used for the common print setup - you should not change any of the unmentioned items unless you are absolutely sure what you are doing. ❏ Info screen ❏ Live adjust Z ( during the printing process only) ❏... - Page 31 ❏ Move Y ❏ Move Z ❏ Extruder ❏ Disable steppers ❏ Mode - Hi power / Silent ❏ Live adjust Z ❏ Select language ❏ SD card - Normal / FlashAir ❏ Sort - Time / Alphabet / None ❏...

-

Page 32: Print Speed Versus Print Quality

7.2.8 Print speed versus print quality Printing a small object takes a few minutes, but printing larger models is time consuming - there are prints taking tens of hours. The overall printing time can be changed in different ways. First way to alter the printing speed is changing layer height in Slic3r - upper right windows shows Print settings option. - Page 33 ● Connect the printer to the computer with the USB cable. Pict. 18 - You can find USB port here ● Choose connection port in Pronterface (download available with the printer drivers, ) : Mac users use / usbmodem port, PC Windows see the chapter ...

-

Page 34: Printer Addons

Pict. 19 - Pronterface 1. Load file button is used to load the desired model.. Model must be in * . gcode f ile format. 2. Choose the port printer is connected to computer. (mostly / usbmodem for Mac, COM1, COM2, etc for Windows PC). -

Page 35: Hardened Steel Nozzle

7.3.1.1 Hardened steel nozzle Hardened steel nozzles are a must for highly abrasive materials. Regular brass nozzles will degrade very quickly and lose their properties. Most of the abrasive materials are composites, plastics with something mixed in. Some examples are ColorFabb XT CF20, ColorFabb Bronzefill, ColorFabb Brassfill and some glow in the dark filaments. -

Page 36: Pinda Probe Calibration/ Temp. Calibration (Experimental/Optional)

8.2 PINDA probe calibration/ Temp. calibration (Experimental/Optional) It is still an experimental feature available since firmware version 3.0.12. Each user has the option to turn this feature on and off, as it may not help out in all of the cases. Once you decide to use this feature, be aware that there is a shorter calibration run before each of your prints compensating for different temperatures (this adds about 2 minutes to the standard preheat process). - Page 37 Pict. 20 - Distance of the front calibration point from the axis start. Ideal value is between 2 and 3 mm but everything larger than 0.5 mm is good enough. Pict.21 - Example in the picture - moving the frame forward on the Y axis (increasing the 100 mm distance from the build manual) will increase the Y distance from min.

-

Page 38: Linear Advance (Experimental)

Pict. 22: moving one side of the frame forward (increasing the measured value) on the Y axis and other side backward (decreasing the measured value) according to the values from the first screen will improve the skew. 8.4 Linear Advance (Experimental) Linear Advance is the new feature from the firmware version 3.1.0. - Page 39 The K values (the parameter affecting how much Linear Advance affects the print) we measured and tested are as follows: PLA: M 900 K30 ● ● ABS: M 900 K30 ● PET: M 900 K45 Multi material printer: M 900 K200 for all materials ●...

-

Page 40: Printer Drivers

9 Printer drivers Latest drivers and information can be found at h ttp://www.prusa3d.com/drivers/ Driver package contains following settings and programs: PrusaControl - preparing the 3D models to .gcode format for printing. Slic3r Prusa Edition - preparing the 3D models to .gcode format for printing. Pronterface ... -

Page 41: Prusacontrol

Pict. 24 - Fusion 360 10.3 PrusaControl A 3D printer can print a lmost a nything. Whether you’ve downloaded 3D models from the Internet or created your own models, you will need to c onvert the .obj or .stl format into a .gcode file... - Page 42 Pict. 25 - Prusa Control interface 1. Undo/Redo buttons return changes. 2. Scale button allows you to scale with the mouse while the model is selected. 3. Rotate button allows you to rotate with the mouse while the model is selected (outer circle step are 0,1°, inner circle step is 45°.) 4.

-

Page 43: Slic3R Prusa Edition

10.4 Slic3r Prusa Edition PrusaControl is build on top of the S lic3r Prusa Edition and hides all the unnecessary clutter from having all settings exposed. If you choose to create your own specific print settings or tweak material settings heavily, you can use Slic3r PE directly. Pict. -

Page 44: Bundled 3D Models

10.5 Bundled 3D models We asked a couple of known 3D designers and prepared some printable object for you to print. They are ideal for the first prints on your new printer. STL and GCODE files are available after installing the driver’s package in “3D Objects” folder or bundled on your SD card. - Page 45 Pict. 29 - Adding color change in PrusaControl ● First of all you need to prepare regular g code with common print and filament settings. Save the file. ● Then go to w ww.prusaprinters.org and choose C olor Print in the header menu. ●...

- Page 46 Pict. 30 - Web version of Colorprint interface at prusaprinters.org/colorprint Insert the filament which you want to start with into your printer and start printing the file. When the color change is triggered from the gcode the printer will follow simple procedure: ●...

-

Page 47: Printing Of Non-Standard Models

is loaded properly, you can choose the “Yes” option and the printing will continue with a new color. 3. “Color not clear” Filament was loaded but the color is still mixed with the previous filament. Press the button with this option and the printer will extrude more filament from the nozzle. -

Page 48: Large Object Printing

Enforce support option ( 5) is used mostly with small models or models with small base to prevent the object from breaking or tearing out from the bed. Pict. 31 - Print with support menu 10.7.2 Large object printing Another special printing case is when printing objects larger than the heatbed. - Page 49 If you need to print an object that doesn’t fit the printer, you have to cut the object using Slic3r. Right-click and choose the C ut… option in menu. You can cut the object horizontally - if you need to perform a cut in a different axis, use the F lip... o ption in the same menu. Pict.

-

Page 50: Materials

11 Materials Temperatures and the heatbed treatment before print according to a specific material. 11.1 ABS ABS is very strong and versatile material with g reat thermal resistance . It’s suitable for both indoor and outdoor use. ABS is a thermoplastic polymer, that means that just like PLA, it can be melted and crystallized multiple times without degrading too much. - Page 51 11.2 PLA PLA is the most commonly used filament. It’s b iodegradable , e asy to print , and very strong m aterial. The perfect choice for printing l arge o bjects thanks to its low thermal expansion (little to no warping) and for printing ...

- Page 52 11.3 PET/PETG PETG is a very tough material with good thermal resistance. It’s universal but suitable especially for mechanical parts and both indoor and outdoor use. PETG has almost n o warping , so printing large objects isn’t a problem. We use PETG to print parts for our printers! PETG is one of our favorite materials for 3D printing.

- Page 53 11.4 HIPS HIPS is high impact polystyrene, and as for behavior, it's similar to ABS, so it's easy to print. It's a universal and stable material with excellent heat resistance, and it produces very smooth layers. HIPS is also very malleable, and it can be dissolved using limonene. HIPS is mostly suited for printable mechanical components.

- Page 54 11.6 Nylon (Taulman Bridge) Nylon is very tough material suitable for mechanical parts. ADVANTAGES DISADVANTAGES Durable Demanding storage (it’s hygroscopic) Chemically resistant Flexible, but strong Chemical resistance ● Nozzle temperature: 2 40 °C ● Bed temperature: 8 0 - 9 0 °C. ●...

- Page 55 11.8 Composite materials Composite materials (woodfill, copperfill, bronzefill, glow-in-the-dark, carbon or aramid composites and many others) consist of main plastic base and second material in the form of dust. These materials tend (with the exception of wood composites) to be very abrasive, therefore hardened nozzle is strongly suggested for long-term printing.

- Page 56 ● Bed temperature: 1 00 - 110 °C (bigger object -> higher temp.) ● Heatbed: Make sure the surface of the heatbed is clean. Usage of brim is suggested (see Prusa Knowledgebase). 11.10 nGen Developed by Eastman Chemical Company and colorFabb, nGen offers increased resistance to heat as well as dimensional stability.

-

Page 57: Dialing In New Materials

11.12 Dialing in new materials Each manufacturer produces slightly different material even though, they are under the same group. For example Prusa PLA and ColorFabb PLA will have slightly different output when printed. To achieve the best possible output you should experiment with the n ozzle temperature , fan speed... -

Page 58: Faq - Printer Maintenance And Print Issues

12 FAQ - Printer maintenance and print issues 12.1 Regular maintenance 12.1.1 Bearings Every couple hundred hours, the smooth rods should be cleaned with a paper towel. Then apply a little bit of general purpose machine oil on the smooth rods and move the axis back and forth a couple of times. -

Page 59: Print Surface Preparation

12.2 Print surface preparation Print surface preparation is described in 6 .3.2 PEI print surface preparation chapter. 12.3 Clogged / jammed extruder Material clogged in the extruder can cause problems with the printing or with the loading of a new filament. -

Page 60: Nozzle Cleaning

12.4 Nozzle cleaning Use a wire brush to clean the nozzle from outside. Heat the nozzle before you do so. If filament is not extruded from a nozzle (or in very small volume), first check the extruder fan is working properly and that the temperature is set correctly (PLA 210 °C; ABS 255 °C, HIPS 220 °C, PET 240 °C). - Page 61 Pict. 35 - Nozzle change ...

-

Page 62: Printing Problems

12.6 Printing problems 12.6.1 Layers break and split when printing from ABS material ABS material has a higher thermal expansion than other materials. We suggest other materials as PET, HIPS or PLA when you print larger models. 12.6.2 Models contain either too much or not enough of the filament You can manage the filament flow during the print. -

Page 63: Faq - Common Issues When Assembling The Printer Kit

13 FAQ - common issues when assembling the printer kit 13.1 Nozzle/print surface gap is greater in the middle than at the corners The reason of this issue isn’t the bent printer surface or bed but a distorted Y-axis. We suggest to remove the whole Y-axis out of the printer. -

Page 64: Printer Stops Printing Soon After Start

13.2 Printer stops printing soon after start Extruder is likely overheated. Make sure the nozzle fan is working properly. If not, please inspect its connection according to the assembly manual. Pict. 37 - Proper wiring of the connectors 13.3 Printer can’t read SD card First, make sure that the ... -

Page 65: Loose X- And/Or Y-Axis Belts

13.4 Loose X- and/or Y-axis belts Check if both belts are properly tightened, loose belts would cause a printer malfunction and prevent proper printing. The easiest way to check is printing a round object - if any of the belts are not tightened properly the result is an irregular shape instead of a perfect circle. Y-axis belt is located under the heatbed, X-axis belt moves the extruder. -

Page 66: Detached Cables To The Heatbed

13.5 Detached cables to the heatbed Do not forget to use a spiral wrap on heatbed cables and attach the cables properly so they won’t restrict movement during printing. Pict. 40 - Cables to be wrapped in a spiral wrap... - Page 67 Print and share! Do not forget to tag your prints with #prusai3mk2 while sharing so we can find, pin and showcase them with our http://www.prusa3d.com/original-prusa-i3-prints/ Happy Printing :) ...

Need help?

Do you have a question about the Original Prusa i3 MK2S KIT 1.75mm and is the answer not in the manual?

Questions and answers