Table of Contents

Advertisement

Table of Contents

.......................................................................................................................

.....................................................................................................

.................................................................................

.........................................................................................................

.............................................................................

......................................................................................

.............................................................................

...........................................................................................

............................................................................................................

...................................................................................

..........................................................................

..............................................................................

..........................................................................

..........................................................................

..........................................................................

........................................................................................

..............................................................................

............................................................................

..........................................................................

.............................................................................

...............................................................................

................................................................

........................................................................

...............................................................

..................................................

..................................................................

......................................................

..............................................

.............................................

.....................................................

.........................................................................

..................................................................

.....................................................

....................................................................

...................................................................

...................................................................

................................................................

......................................................................

.......................................................

....................................................

.....................................................................

.............................................................

...............................................................

......................................................................

......................................................................

.......................................................................

.......................................................................

.......................................................................

......................................................................

........................................................................

7

8

8

8

9

9

10

10

11

11

12

13

15

16

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

32

33

33

1

Advertisement

Table of Contents

Summary of Contents for Prusa Research i3 MK3S+

-

Page 1: Table Of Contents

Table of Contents 1. Introduction ....................................... Step 1 - All the required tools are included ..................... Step 2 - Labels guide ................. Step 3 - Use labels for reference ......................Step 4 - Spare bag ................ Step 5 - View high resolution images ................ - Page 2 ....................Step 38 - Haribo time! ..................Step 39 - Y-axis is finished! 3. X-axis assembly .................................... Step 1 - Tools necessary for this chapter ............Step 2 - X-axis: x-end idler and motor holder ............Step 3 - X-axis: x-end idler and motor holder ..............

- Page 3 ................. Step 25 - Hotend fan assembly ................. Step 26 - Hotend fan assembly ............... Step 27 - Extruder-idler parts preparation ..................Step 28 - Bearing assembly ................Step 29 - Extruder-idler assembly ................ Step 30 - Filament alignment check ................

- Page 4 7. Heatbed & PSU assembly ................................Step 1 - Tools necessary for this chapter ..............Step 2 - Heatbed cable assembly (part 1) ............... Step 3 - Heatbed cable assembly (part 2) ............... Step 4 - Heatbed cable assembly (part 3) .................

- Page 5 ................ Step 27 - PSU and HB - final check ................... Step 28 - Cable management ..........Step 29 - Connecting the extruder cable bundle ..............Step 30 - Wrapping the cable bundle ........... Step 31 - Connecting the extruder cable bundle ..............

-

Page 7: Introduction

1. Introduction Original Prusa i3 MK3S+ kit assembly... -

Page 8: Step 1 All The Required Tools Are Included

1. Introduction STEP 1 All the required tools are included The kit includes: Needle-nose pliers (1x) Philips screwdriver (1x) Allen key (6x) The printer's package contains a lubricant, which is intended for maintenance. No need to use it now the bearings are lubricated. There is a dedicated online manual on how to clean the printer and apply the lubricant. -

Page 9: Step 3 Use Labels For Reference

1. Introduction STEP 3 Use labels for reference Most of the labels are scaled 1:1 and can be used to identify the part :-) For the most common screws, nuts and PTFE tubes. You can also use the enclosed letter, which contains Prusa Cheatsheet on the other side. You can help.prusa3d.com/cheatsheet from our site. -

Page 10: Step 5 View High Resolution Images

Most of the 3D printed parts on Original Prusa i3 MK3S+ are marked with their version. Dx series (e.g. D1) - those parts are printed on Prusa Research farm and are distributed with the kit. Rx series (e.g. R6) - those parts are available for download at prusa3d.com/printable-parts. -

Page 11: Step 7 We Are Here For You

1. Introduction STEP 7 We are here for you! Lost in the instructions, missing screw or cracked printed part? Let us know! You can contact us using following channels: Using comments under each step. Using our 24/7 live chat at shop.prusa3d.com Writing an email to info@prusa3d.com... -

Page 12: Step 9 Important: Electronics Protection

1. Introduction STEP 9 Important: Electronics protection WARNING: Make sure to protect the electronics against electrostatic discharge (ESD). Always unpack the electronics right before you need them! Here are some tips to prevent damage to the electronics: Keep the electronics inside the ESD bag right until you are asked to install them. -

Page 13: Step 10 Reward Yourself

1. Introduction STEP 10 Reward yourself Building the MK3S+ printer is a challenge unlike any other and you should treat yourself for every milestone you reach. That is why a bag of Haribo Bears is included! The biggest issue from the previous builds (MK3S, MK2S) which we had to address was inadequate bear consumption. -

Page 14: Step 11 - How To Successfully Finish The Assembly

1. Introduction STEP 11 How to successfully finish the assembly To successfully finish the assembly please follow all these: Always read all the instructions at current step first, it will help you to understand, what you need to do. Don't cut or trim unless you are told to!!! Don't follow pictures only! It is not enough, the written instructions are as brief as they could be. -

Page 15: Y-Axis Assembly

2. Y-axis assembly Original Prusa i3 MK3S+ kit assembly... -

Page 16: Step 1 Tools Necessary For This Chapter

2. Y-axis assembly STEP 1 Tools necessary for this chapter Needle-nose pliers for zip tie trimming. 3mm Allen key for M5 screws 2.5mm Allen key for M3 screws 2mm Allen key for nut alignment STEP 2 YZ frame - preparing the components Prepare the following parts to build the YZ frame: Aluminum extrusions (4x) Aluminum frame (1x) -

Page 17: Step 3 Yz Frame - Mounting The Longer Extrusions

2. Y-axis assembly STEP 3 YZ frame - mounting the longer extrusions Take the LONGER aluminum extrusions and place them next to the frame. Make sure the engraved PRUSA logo (top left) and the safety sticker (right) on the frame ARE VISIBLE! Note: screws are inserted from the opposite side of the frame. -

Page 18: Step 5 Yz Frame - Final Check

2. Y-axis assembly STEP 5 YZ frame - final check Before we proceed further, let's make a final check. IT IS VERY IMPORTANT to have extrusions on the correct side of the frame. Long extrusions - must be on the side of the frame with the Prusa logo and the safety sticker, also ensure longer extrusions are closer... -

Page 19: Step 7 Y-Axis: Front Plate Assembly

2. Y-axis assembly STEP 7 Y-axis: front plate assembly Rotate the frame with longer extrusions towards you. Place the front plate on the extrusions and secure it with M5x16r screws, DON'T TIGHTEN them yet! Now, tighten the screws fully, but ON A DIAGONAL, see the second picture. As soon as you finish the first, tighten the second pair. -

Page 20: Step 9 Y-Axis: Rear Plate Assembly

2. Y-axis assembly STEP 9 Y-axis: rear plate assembly Ensure the frame with shorter extrusions is rotated towards you. Place the rear plate on the extrusions and secure it with M5x16r screws, DON'T TIGHTEN them yet! Now, tighten the screws fully, but ON A DIAGONAL, see the second picture. As soon as you finish the first, tighten the second pair. -

Page 21: Step 11 - Mounting Antivibration Feet (Optional)

2. Y-axis assembly STEP 11 Mounting antivibration feet (optional) Note this step is optional for now. We recommend mounting the feet now to protect the surface on your table (workbench). However, you need to lift the frame up before each turn. There will be extra step at the end of the assembly to remind you of the antivibration feet. -

Page 22: Step 13 Preparing Y-Belt-Idler (Part 2)

2. Y-axis assembly STEP 13 Preparing Y-belt-idler (part 2) Take the Y-belt-idler and insert two M3n nuts from the top. Turn the idler to the other side and insert the M3nN nyloc nut. The rubber inside the nut must be facing towards you. BE CAREFUL, don't over tighten the screw, you can break the part! Make sure all three nuts are all the way in. -

Page 23: Step 15 Mounting The Y-Belt-Idler

2. Y-axis assembly STEP 15 Mounting the Y-belt-idler Rotate the frame with longer extrusions towards you. Take the Y-belt-idler and place it on the front plate. Note there is a mark (circle) on the printed part facing Secure the Y-belt-idler with two M3x10 screws. -

Page 24: Step 17 Preparing Y-Motor-Holder

2. Y-axis assembly STEP 17 Preparing Y-motor-holder Take the Y-motor-holder and insert two M3n nuts. In case you can't press the nuts in, don't use excessive force. Use an M3 screw from the other side and tighten it. Place the Y-motor-holder on the motor, ensure the correct orientation as in the picture (use the motor cable). -

Page 25: Step 19 Y-Axis: Y-Carriage

2. Y-axis assembly STEP 19 Y-axis: Y-carriage For the following steps, please prepare: Y-carriage (1x) Linear bearing (3x) Bearing clip (3x) M3nN nyloc nut (6x) M3x12 screw (6x) The printer's package contains a lubricant, which is intended for maintenance. No need to use it now the bearings are lubricated. There is a dedicated online manual on how to clean the printer and apply the lubricant. -

Page 26: Step 21 Installing Bearings On The Y-Carriage

2. Y-axis assembly STEP 21 Installing bearings on the Y-carriage Insert linear bearing in the cutout. Place the bearing clip over the bearing. Insert two M3x12 screws into the holes in the bearing clip. Hold by your fingers the heads of both screws and turn the Y-carriage. Place the nyloc nuts on both screws. -

Page 27: Step 23 Y-Axis: Smooth Rods Holders

2. Y-axis assembly STEP 23 Y-axis: smooth rods holders For the following steps, please prepare: Y-rod-holder (4x) M3x10 screw (12x) M3nS nut (12x) STEP 24 Preparing Y-rod-holder Take one Y-rod-holder and insert two M3nS nuts. Make sure you've pressed the nuts all the way in. You can use pliers, BUT be careful, you can damage the printed part. -

Page 28: Step 25 Mounting The Y-Rod-Holder Parts

2. Y-axis assembly STEP 25 Mounting the Y-rod-holder parts Place the Y-carriage on a flat surface (table) with the bearings facing up. Push the Y-rod-holder on the rod. Align the front surface of the plastic part with the flat surface of the rod. Check the correct position of the Y-rod-holder. -

Page 29: Step 27 Aligning The Smooth Rods

2. Y-axis assembly STEP 27 Aligning the smooth rods IMPORTANT: proper alignment of the smooth rods is crucial to reduce noise and overall friction. Ensure all M3x10 screws on Y-holders are slightly loosened, so the printed parts are able to move. Move the Y-carriage back and forth across the entire length of the smooth rods to align them. -

Page 30: Step 29 Y-Axis: Assembling The Belt

2. Y-axis assembly STEP 29 Y-axis: Assembling the belt For the following steps, please prepare: Y-belt-holder (1x) smaller of two Y-belt-tensioner (1x) bigger of two Y-axis belt 650 mm (1x) M3x30 screw (1x) M3x10 screw (4x) M3nN nyloc nut (1x) M3n nut (2x) STEP 30 Y-axis: Assembling the belt... -

Page 31: Step 32 - Y-Axis: Assembling The Belt

2. Y-axis assembly STEP 31 Y-axis: Assembling the belt Bend one end of the belt around M3x10 screw. Push it in the holder as in the picture. Use an Allen key to push the belt in. Make sure the bent part and the end are within the width of the printed part. Teeth on the belt must be facing up! Tighten the screw until you reach the nut, don't over tighten the screw, you will deform the belt. - Page 32 2. Y-axis assembly STEP 33 Y-axis: Assembling the belt Take the Y-belt-tensioner (bigger of the two printed parts). Insert M3n nut, all the way in. Use the screw pulling technique. Bend second end of the belt around the screw and push it in the holder as in the picture.

-

Page 33: Step 35 Aligning The Y-Axis Belt

2. Y-axis assembly STEP 35 Aligning the Y-axis belt Make sure the belt is placed in the "axis" of the printer. Both top and bottom part of the belt should be parallel (above each other). To adjust the belt position, release screws on the pulley and slightly move with it, until you reach the best position. -

Page 34: Step 37 Testing The Y-Axis Belt

2. Y-axis assembly STEP 37 Testing the Y-axis belt Use the technique described below to test if the belt is properly stretched. Use pliers to hold the Y-axis motor shaft. Move the Y-carriage with your hand towards the Y-axis motor. Don't use excessive force. - Page 35 2. Y-axis assembly STEP 39 Y-axis is finished! Y-axis is done, great job! Check the final look, compare it to the picture. Note that you should feel some resistance while moving with the Y- carriage. It is due to the tightened belt and also the motor has some resistance.

-

Page 36: X-Axis Assembly

3. X-axis assembly Original Prusa i3 MK3S+ kit assembly... -

Page 37: Step 1 Tools Necessary For This Chapter

3. X-axis assembly STEP 1 Tools necessary for this chapter 2.5mm Allen key for M3 screws 2mm Allen key for nut alignment STEP 2 X-axis: x-end idler and motor holder For the following steps, please prepare: X-end-motor (1x) X-end-idler (1x) Linear bearing (4x) The list continues in the next step... -

Page 38: Step 4 X-Axis: Inserting Linear Bearings

3. X-axis assembly STEP 3 X-axis: x-end idler and motor holder M3x30 screw (1x) M3x18 screw (1x) M3nN nyloc nut (1x) M3nS nut (1x) 623h bearing with housing (1x) STEP 4 X-axis: inserting linear bearings Insert linear bearings into the printed parts (X-end-motor and X-end-idler) as shown in the picture. -

Page 39: Step 5 X-End-Motor: Tensioner Assembly

3. X-axis assembly STEP 5 X-end-motor: tensioner assembly Insert the square nut all the way in. Insert the M3x30 screw. For now, we need the screw just to hold in place. Do not tighten the screw fully. Leave a 2 mm (0.079 inch) gap between the screw head and the plastic part. -

Page 40: Step 7 X-Axis: Smooth Rods Preassembly

3. X-axis assembly STEP 7 X-axis: smooth rods preassembly Take remaining smooth rods and compare their length. For X-axis you need longest rods (370 mm). Linear bearing (3x) Permanent marker (1x) not included in the kit Several paper towels to wipe oil and grease from the bearing surface. STEP 8 Marking the bearings Wipe grease from the outer surface... -

Page 41: Step 10 Assembling The X-Axis Motor Pulley (Part 1)

3. X-axis assembly STEP 9 X-axis: assembly NOW, PLEASE BE VERY CAREFUL! Gently insert the rod straight into the bearings, do not apply too much force and do not tilt the rod! In case you manage to push out balls from the bearings, please count them. One or two balls are ok, if there are more of them, please consider ordering new bearings. -

Page 42: Step 11 Assembling The X-Axis Motor Pulley (Part 2)

3. X-axis assembly STEP 11 Assembling the X-axis motor pulley (part 2) There is a flat part on the motor shaft, rotate it upwards. Slide the Pulley on, note the CORRECT orientation. Compare it with the second picture! One of the screws must be facing directly against the pad (flat part) on the shaft. Slightly tighten both screws. -

Page 43: Step 13 Haribo Time

3. X-axis assembly STEP 13 Haribo time! This is an easy easy chapter, have a 10% dose of bears ;) STEP 14 X-axis is finished! X-axis is done! Check the final look, compare it to the picture. Checked everything? It's time for: 4. Z-axis assembly. -

Page 44: Z-Axis Assembly

4. Z-axis assembly Original Prusa i3 MK3S+ kit assembly... -

Page 45: Step 1 Tools Necessary For This Chapter

4. Z-axis assembly STEP 1 Tools necessary for this chapter Needle-nose pliers for tension check. 2.5mm Allen key for M3 screws STEP 2 Z-axis: assembling motor holders WARNING: Printed parts aren't the same! There is a left and right oriented piece. See the markings on the parts. -

Page 46: Step 3 Placing The Z-Screw Covers

4. Z-axis assembly STEP 3 Placing the Z-screw covers For the following steps, please prepare: Z-axis motor (2x) Note each Z-axis motor has different cable length. The shorter one must be on the left side, longer on the right side. Z-screw-cover (2x) Remove the trapezoidal nuts from the motors. -

Page 47: Step 5 X-Axis: Trapezoidal Nuts (Part 1)

4. Z-axis assembly STEP 5 X-axis: trapezoidal nuts (part 1) For the following step, please prepare: Trapezoidal nut (2x) M3x18 screw (4x) M3n nut (4x) Turn the X-axis upside down and insert nuts into traps on both X-ends. In case you can't press the nuts in, don't use excessive force. First, check that there isn't any obstacle in the nut trap. -

Page 48: Step 7 Assembling The X-Axis And Smooth Rods

4. Z-axis assembly STEP 7 Assembling the X-axis and smooth rods Besides the X-axis, please prepare for the following step: Smooth rod 320 mm (2x) WARNING: be very careful while installing the X-axis on the trapezoidal lead screws. The process should be smooth, otherwise you might damage the thread inside the plastic nut. -

Page 49: Step 9 Placing The Z-Axis-Top Parts (Part 2)

4. Z-axis assembly STEP 9 Placing the Z-axis-top parts (part 2) Place the Z-axis-top-left part on the rods and align it with the frame. Ensure the holes in the printed part are fully aligned with the holes on the frame. Use two M3x10 screws to tighten the Z-axis-top-left part. -

Page 50: Step 11 - Z-Axis Is Finished

4. Z-axis assembly STEP 11 Z-axis is finished! Z-axis is done! Check the final look, compare it to the picture. Checked everything? It's time for: 5. E-axis assembly. Original Prusa i3 MK3S+ kit assembly... -

Page 51: E-Axis Assembly

5. E-axis assembly Original Prusa i3 MK3S+ kit assembly... -

Page 52: Step 1 Tools Necessary For This Chapter

5. E-axis assembly STEP 1 Tools necessary for this chapter Needle-nose pliers for zip tie trimming. 2.5mm Allen key for M3 screws 2mm Allen key for nut alignment 1.5mm Allen key for tightening the pulley STEP 2 Few tips before we start This is the most important and hardest chapter, take your time, don't rush. -

Page 53: Step 3 Extruder-Body Parts Preparation

5. E-axis assembly STEP 3 Extruder-body parts preparation For the following steps, please prepare: Extruder-body (1x) Adapter-printer (1x) FS-lever (1x) Look for these parts in E-AXIS and MK3S/MK2.5S EXTRUDER bags. The list continues in the next step. STEP 4 Extruder-body parts preparation For the following steps, please prepare: M3x18 screw (1x) -

Page 54: Step 5 Extruder-Body Assembly

5. E-axis assembly STEP 5 Extruder-body assembly Take the M3nS nut and insert it in the Extruder-body. Make sure the nut is all the way in. Ensure correct alignment of the nuts using the Allen key. Secure the nut using an M3x10 screw. Tighten the screw just slightly, later on we need to add the SuperPINDA. -

Page 55: Step 6 Fs-Lever Assembly

5. E-axis assembly STEP 6 FS-lever assembly Insert the FS-lever in the body. Secure the part with a M3x18. Tighten it, but ensure the lever can move freely. WARNING: make sure the following procedure is done right, otherwise the filament sensor won't work!!! Insert the bigger magnet (20x6x2) in the Extruder-body, it will stick out: Incorrect setup: magnets are attracting each other, thus the lever is pulled to the left. - Page 56 5. E-axis assembly STEP 7 Steel ball assembly Take the printed part Adapter-printer and insert the steel ball in. Roll with the ball to all sides to ensure smooth movement. In case of any rough surface, remove the ball and clean the inside of the printed part.

-

Page 57: Step 8 Extruder Motor Parts Preparation

5. E-axis assembly STEP 8 Extruder motor parts preparation For the following steps, please prepare: Extruder motor (1x) Extruder-motor-plate (1x) M3x10 screw (2x) ATTENTION: there is a set of the Bondtech gears. Make sure you have all the parts and you are using correct ones. Use now: Bondtech gear with a set screw. -

Page 58: Step 9 Bondtech Gear Assembly

5. E-axis assembly STEP 9 Bondtech gear assembly Take the Extruder-motor-plate and secure it using two M3x10 screws. Use the cable as a guide to properly orient the part. Resist the temptation to place a screw in the third hole! Leave it for later ;) Rotate the shaft as in the picture. -

Page 59: Step 11 - Extruder-Cover Part Preparation

5. E-axis assembly STEP 11 Extruder-cover part preparation For this step, please prepare: Extruder-cover (1x) M3nS nut (1x) Slide the nut all the way in. Ensure correct alignment using the Allen key. Leave the hole on the "arm" empty for now. We will use it later, while assembling a print fan. -

Page 60: Step 13 Hotend Assembly

5. E-axis assembly STEP 13 Hotend assembly Take two M3x10 screws and insert them in the holes. Doing this now makes the assembly slightly easier, but both holes are shallow and the screws might fall out. If this happens, you can continue without them and put them back later on (you will be notified later). -

Page 61: Step 15 X-Carriage Parts Preparation

5. E-axis assembly STEP 15 X-carriage parts preparation For the following steps, please prepare: X-carriage (1x) M3n nut (2x) M3nS nut (4x) IR-sensor cable (1x) STEP 16 X-carriage assembly For the following nut insertion USE A SCREW. THAT'S AN ORDER!!! Seriously, use a screw to pull the nuts in, both have to be properly seated in the X-carriage. -

Page 62: Step 17 Assembling The Ir-Sensor Cable

5. E-axis assembly STEP 17 Assembling the IR-sensor cable Take the IR-sensor cable and locate the end with the smaller connector. Place cable in the X-carriage, use the small printed overhangs to keep the cable inside. The distance between the connector and the X-carriage should be around 15 mm (0.6 inch). - Page 63 5. E-axis assembly STEP 19 Assembling the X-carriage Following cable management is CRUCIAL for the extruder TO WORK PROPERLY! Read the instructions carefully. Before you assemble the X-carriage, check the nuts in the Extruder body are still in place. The upper nut sometimes falls out. Grab the X-carriage and place it onto the back of the extruder assembly as shown in the picture.

-

Page 64: Step 20 Ir-Sensor Parts Preparation

5. E-axis assembly STEP 20 IR-sensor parts preparation For the following steps, please prepare: Prusa IR-sensor (1x) M2x8 screw (1x) M3x40 screw (1x) BE CAREFUL with the filament sensor, do not touch the PCB nor the chips on it. Hold the PCB from sides. STEP 21 IR-sensor assembly Place the IR-sensor on the top of the Extruder-body and secure it with the M2x8. -

Page 65: Step 22 Ir-Sensor Assembly

5. E-axis assembly STEP 22 IR-sensor assembly Finish the sensor assembly by inserting an M3x40 screw. Make sure all the gaps are gone. STEP 23 Hotend fan parts preparation For the following steps, please prepare: Hotend fan (1x) M3x14 screw (3x) Make sure you are using the correct screws. -

Page 66: Step 25 Hotend Fan Assembly

5. E-axis assembly STEP 24 Hotend fan cable adjustment For easier fan installation, remove temporarily the black twist tie from the cable bundle and release at least one loop. Then tie the bundle back, see the picture. Before you move to the next step, take an Allen key and GENTLY PUSH the motor cable to the channel to create space for the fan cable. -

Page 67: Step 27 Extruder-Idler Parts Preparation

5. E-axis assembly STEP 26 Hotend fan assembly Use the three M3x14 screws to fix the fan in place. Don't over tighten them, you can break the fan's plastic casing. Also make sure the fan can rotate freely. Note that the screws are "self- tapping"... -

Page 68: Step 28 Bearing Assembly

5. E-axis assembly STEP 28 Bearing assembly Insert both bearings in the pulley. Be aware that bearings can slip out during assembly. STEP 29 Extruder-idler assembly Take M3n nut and place it in the Extruder-idler. Use the screw pulling technique. Insert the pulley in idler as shown in the picture. -

Page 69: Step 30 Filament Alignment Check

5. E-axis assembly STEP 30 Filament alignment check Let's use this opportunity to check once more the proper alignment of the filament and the Bondtech gear. Push the filament from the top, through the Bondtech into the PTFE tube. Check the alignment and if needed, adjust the position. -

Page 70: Step 32 Fs-Cover Parts Preparation

5. E-axis assembly STEP 32 FS-cover parts preparation For the following steps, please prepare: FS-cover (1x) M3x10 screw (1x) STEP 33 FS-cover assembly Place the FS-cover on the extruder and align it according to the picture. Insert the M3x10 screw (mind the correct hole) and tighten it. -

Page 71: Step 34 Pretensioning The Extruder-Idler

5. E-axis assembly STEP 34 Pretensioning the Extruder-idler Use the M3x40 screw with the spring to introduce tension to the Extruder-idler. Hold the Extruder-idler on the other side, until the screw reaches the nut. Since there is only one screw, you need to introduce a large force. The head of the screw, should be aligned or slightly below the surface. -

Page 72: Step 36 Print-Fan-Support Assembly

5. E-axis assembly STEP 36 Print-fan-support assembly Take the M3n nut and insert it all the way to the support. It is crucial! Use the screw pulling technique. Place the support on the extruder and ensure the inclined part is facing "down" (towards the nozzle) Secure the support using an M3x10 screw. -

Page 73: Step 38 Fan-Shroud Assembly

5. E-axis assembly STEP 38 Fan-shroud assembly Insert M3nS nut in the Fan-shroud, all the way in. Ensure correct alignment using the Allen key. See the protrusion on the Fan-shroud and the groove in the extruder. Slide the Fan-shroud into the extruder. Make sure that both protrusions on the Fan- shroud fit in the grooves on the extruder (see the picture). -

Page 74: Step 40 Print Fan Assembly

5. E-axis assembly STEP 40 Print fan assembly First, slide the fan in the Fan-shroud and make sure it is aligned properly. Second, fix the fan in place using one M3x20 screw. Tighten carefully, or you will damage the fan's casing. Turn the extruder around and insert the M3n nut. -

Page 75: Step 42 Superpinda Sensor Assembly

5. E-axis assembly STEP 42 SuperPINDA sensor assembly Insert SuperPINDA sensor in the holder. Exact position doesn't matter, we will adjust it later. Tighten the M3x10 screw, but just slightly. Create a loop on the cable from the sensor. Push the cable in the channel together with the fan cable. -

Page 76: Step 44 Extruder Preparation And Mounting

5. E-axis assembly STEP 44 Extruder preparation and mounting Insert the zip ties in the X-carriage like in the picture. Lower the X-axis at about 1/3 from the top. Turn the printer like in the picture with X-axis motor and shorter extrusions facing towards you. -

Page 77: Step 46 X-Axis Belt Parts Preparation

5. E-axis assembly STEP 46 X-axis belt parts preparation For the following steps, please prepare: X-axis belt (850 mm) STEP 47 X-axis belt assembly Insert the flat part of the X-axis belt into the X-carriage as in the picture. Use a screwdriver or the smallest Allen key to push the belt in. -

Page 78: Step 49 - X-Axis Belt Assembly

5. E-axis assembly STEP 49 X-axis belt assembly Before you continue to guide the belt through the X-axis, please release two M3 screws on the X-end. Rotate the X-axis motor as indicated towards the frame. Insert the flat part of the X-GT2 belt into the X-carriage as in the second picture. Use a screwdriver or the smallest Allen key to push the belt in. -

Page 79: Step 50 Tensioning The X-Axis Belt

5. E-axis assembly STEP 50 Tensioning the X-axis belt Using right hand rotate the motor to its original position and hold it (tension is applied to the belt). Using two fingers on your left hand push the belt together. Very small force should be needed for bending the belt, BUT the belt shouldn't be bent by its own weight before being pressed with your fingers, it must be straight. -

Page 80: Step 52 Testing The X-Axis Belt

5. E-axis assembly STEP 52 Testing the X-axis belt Use the technique described below to test if the belt is properly stretched. Use pliers to hold the X-axis motor shaft. Move the extruder towards the X- axis motor. Don't use excessive force. -

Page 81: Step 54 Fine Tuning The X-Axis Belt

5. E-axis assembly STEP 54 Fine tuning the x-axis belt In this step, we will finish tensioning the belt. Please read the instructions first, your belt might have proper tension already, then there is no need for additional screw adjustment. First, slightly release all the screws holding the motor, otherwise, the "tensioner"... -

Page 82: Step 56 Nylon Guide Assembly

5. E-axis assembly STEP 56 Nylon guide assembly Locate the hole for the NYLON filament. Using the smallest Allen key ensure there are no obstacles inside. Using the pliers insert the NYLON filament with the pointed end into the slot and twist it. -

Page 83: Step 58 Cable-Holder Assembly

5. E-axis assembly STEP 58 Cable-holder assembly Prepare the M3x40 screw and cable-holder from the previous step. Drive the screw all the way through the printed part. Note there is a recess (slot) for the screw's head on one side of the printed part. STEP 59 X-carriage-back assembly Take the M3n nut and place it in the printed part (all the way in). -

Page 84: Step 61 - X-Carriage-Back Assembly

5. E-axis assembly STEP 60 Mounting the X-carriage-back Push the cables from the Extruder THROUGH the X-carriage-back. Start with IR- sensor cable, then the extruder motor and hotend fan. Next, add the print fan and SuperPINDA sensor cables. Cables from hotend are NOT GOING through the X-carriage-back! Carefully insert the nylon filament and then slide the X-carriage-back towards the X-axis. -

Page 85: Step 63 Tightening The Textile Sleeve

5. E-axis assembly STEP 62 Textile sleeve parts preparation For the following steps, please prepare: Zip tie (5x) Textile sleeve 13 x 490 mm (1x) There are three textile sleeves in the package, use the largest one (both diameter and length). STEP 63 Tightening the textile sleeve Open one end of the textile sleeve and slide it on the cable bundle leading from the... -

Page 86: Step 64 Tightening The Hotend Cables

5. E-axis assembly STEP 64 Tightening the hotend cables Use two zip ties and push them through the upper slots on the cable-holder. ATTENTION! Before tightening the zip ties add the cables from the hotend. Use the channel in the printed part to arrange them properly. Once the hotend cables are included, tighten the zip ties and cut remaining parts. - Page 87 5. E-axis assembly STEP 66 E-axis is finished! Are we there yet? Almost! Check the final look, compare it to the picture. Checked everything? Let's move to: 6. LCD assembly. Original Prusa i3 MK3S+ kit assembly...

-

Page 88: Lcd Assembly

6. LCD assembly Original Prusa i3 MK3S+ kit assembly... -

Page 89: Step 1 Tools Necessary For This Chapter

6. LCD assembly STEP 1 Tools necessary for this chapter 2.5mm Allen key for M3 screws 2mm Allen key for nut alignment Bag with fasteners for the LCD is usually taped to the LCD. STEP 2 Preparing the LCD parts For the following steps, please prepare: LCD-cover (1x) -

Page 90: Step 4 Assembling The Lcd Supports

6. LCD assembly STEP 4 Assembling the LCD supports Prepare the LCD controller and LCD-support printed part as shown in the picture. Slide the LCD-support parts on the LCD-controller. Repeat the steps above for the second support. Ensure the correct orientation of parts and the LCD controller. The exact position will be adjusted later, no need to worry at this moment. -

Page 91: Step 6 Securing The Lcd Controller

6. LCD assembly STEP 6 Securing the LCD controller Using the 2.5mm Allen key and two M3x10 screws, secure the LCD controller in place. STEP 7 Preparing the supports for assembly Place four M3nS nuts in the prepared slots, all the way in. Check the proper alignment with Allen key. -

Page 92: Step 8 Mounting The Lcd Display Onto The Printer

6. LCD assembly STEP 8 Mounting the LCD display onto the printer ATTENTION!!! In case you haven't assembled the anti-vibration feet yet, the front part of the printer will be resting on the mounted LCD. Apply the feet now or be very careful as you might damage the LCD holder. -

Page 93: Step 10 Haribo Time

6. LCD assembly STEP 10 Haribo time! Compared to the previous chapter, this was extremely easy, right? Have 10 %, not more. STEP 11 LCD is done! That was fast! Wasn't it? Check the final look, compare it to the picture. You can now remove the protective foil from the LCD panel. -

Page 94: Heatbed & Psu Assembly

7. Heatbed & PSU assembly Original Prusa i3 MK3S+ kit assembly... -

Page 95: Step 1 Tools Necessary For This Chapter

7. Heatbed & PSU assembly STEP 1 Tools necessary for this chapter Needle-nose pliers for the heatbed assembly 2.5mm Allen key for M3 screws 2mm Allen key for heatbed alignment STEP 2 Heatbed cable assembly (part 1) For the following step please prepare: Heatbed MK52 24V (1x) Power cable (1x) M3x10 screw (2x) -

Page 96: Step 3 Heatbed Cable Assembly (Part 2)

7. Heatbed & PSU assembly STEP 3 Heatbed cable assembly (part 2) Place the black wire above the pin with "GND" sign. Make sure you are using the rounded connector. Place the washer above the rounded cable connector. Press the M3x10 screw through all parts. Hold the screw and carefully turn the heatbed upside down. -

Page 97: Step 5 Preparing The Heatbed

7. Heatbed & PSU assembly STEP 5 Preparing the heatbed For the following steps, please prepare: Heatbed MK52 (1x) Textile sleeve 5 x 300 mm (1x) M3nN nyloc nut (1x) M3n nut (2x) M3x10 screw (3x) Heatbed-cable-cover-clip (1x) Heatbed-cable-cover (1x) STEP 6 Preparing the heatbed-cable-cover Take the smaller part and insert... -

Page 98: Step 9 Proper Cable Management

7. Heatbed & PSU assembly STEP 8 Mounting the heatbed-cable-cover Hold the screw with your thumb and flip the heatbed upside down. Use M3nN nyloc nut and tighten the screw. Use pliers and Allen key to tighten the nut with the screw. STEP 9 Proper cable management Do not stretch the black thermistor cable, leave some slack under the heatbed, so... -

Page 99: Step 10 Wrapping The Heatbed Cables

7. Heatbed & PSU assembly STEP 10 Wrapping the heatbed cables Use the textile sleeve and wrap the cables from the heatbed. Start by wrapping a few centimeters of the sleeve behind the heatbed cover. When the first "wrap" is ready, slide it inside the heatbed cover. Ensure it is at least 5-6 mm. -

Page 100: Step 12 Finalizing The Wrap

7. Heatbed & PSU assembly STEP 12 Finalizing the wrap Now, finish wrapping the cable into the textile sleeve. When done, slightly twist the sleeve (not the cables inside). The sleeve will evenly wrap all around the cable bundle. STEP 13 Preparing the heatbed screws and spacers For the following steps, please prepare:... -

Page 101: Step 15 Mounting The Heatbed (Part 2)

7. Heatbed & PSU assembly STEP 15 Mounting the heatbed (part 2) Push the Allen key through the middle hole on the Heatbed and place it above the spacer. Use the Allen key to align all parts. After the alignment insert the M3x12b screw instead. Tighten the screw just slightly. -

Page 102: Step 17 Mounting The Heatbed (Part 4)

7. Heatbed & PSU assembly STEP 17 Mounting the heatbed (part 4) Using pliers insert spacers and screw into the remaining holes. DON'T fully tighten the screws. After all screws are in place, tighten them in the following order: Center screw First four screws (edges) Last four screws (corners) Original Prusa i3 MK3S+ kit assembly... -

Page 103: Step 18 Preparing The Psu Parts

7. Heatbed & PSU assembly STEP 18 Preparing the PSU parts For the following steps, please prepare: 24V power supply (1x) Power panic cable (1x) PSU-cable (2x) M4x10r screw with dome head (2x) M3x10 screw (2x) The PSU is designed to work worldwide and automatically switch to the local voltage. -

Page 104: Step 21 Connecting The Power Cables (Critical)

7. Heatbed & PSU assembly STEP 20 Assembling the PSU FOLLOW THE INSTRUCTIONS, there is a risk of DEFORMING THE FRAME! Insert M4 screws in both holes in the frame. Adjust the position of the PSU, there are holes in the casing, which must align with the holes in the frame. -

Page 105: Step 22 Connecting The Power Cables

7. Heatbed & PSU assembly STEP 22 Connecting the power cables Release the screw on the FIRST (positive) slot from the left. Take the first power cable and choose the RED wire, slide it all the way in. Make sure the steel washer is above the "fork" connector. Tighten the screw firmly, but keep in mind some parts are made from plastic. -

Page 106: Step 24 Connecting The Power Panic

7. Heatbed & PSU assembly STEP 24 Connecting the power panic Take the Power panic cable and connect it to the PSU. Both ends of the cable are the same, use any. Gently bend the Power panic cable and place it close to the power cables (PSU- cable). -

Page 107: Step 26 Heatbed And Psu Are Done

7. Heatbed & PSU assembly STEP 26 Heatbed and PSU are done! You're getting closer! Just one more chapter and the assembly is done! Check the final look, compare it to the picture. Don't place the steel sheet on the heatbed yet. -

Page 108: Electronics Assembly

8. Electronics assembly Original Prusa i3 MK3S+ kit assembly... -

Page 109: Step 1 Tools Necessary For This Chapter

8. Electronics assembly STEP 1 Tools necessary for this chapter Needle-nose pliers for zip tie trimming. 2.5mm Allen key for M3 screws 1.5mm Allen key for nut alignment Philips screwdriver to tighten PSU and HB cables WARNING: Make sure to protect the electronics against electrostatic discharge (ESD). -

Page 110: Step 3 Preparing The Einsy-Door (Part 2)

8. Electronics assembly STEP 3 Preparing the Einsy-door (part 2) Insert M3nS nut all the way in. You can use the small screw driver to push it down if needed. Check the proper alignment with the Allen key. If this nut is loose in the slot then it can easily fall out and then possibly short some electrical contacts on the Einsy board whenever you open your Einsy case. -

Page 111: Step 5 Preparing The Lower Hinge

8. Electronics assembly STEP 5 Preparing the lower hinge Take the Einsy-hinge-bottom and push M3x10 screw through. Note there is a cutout for the screw's head in the printed part. Locate the hole for the lower hinge. Place the hinge on the frame and tighten the screw. The hinge must be facing upwards. -

Page 112: Step 7 Wrapping X-Axis Cable

8. Electronics assembly STEP 7 Wrapping X-axis cable For the following step, please prepare: Textile sleeve 5 x 300 mm (1x) Zip tie (1x) Wrap the sleeve around the X-axis motor cable. The sleeve is shorter, than the motor cable. Secure the sleeve using a zip tie, you have to tighten the zip tie firmly and it is only a temporary fix until the Einsy case is assembled, but you can leave the zip tie in place afterwards... -

Page 113: Step 9 Preparing The Einsy-Base (Part 2)

8. Electronics assembly STEP 9 Preparing the Einsy-base (part 2) Take the four M3nS nuts you've prepared earlier and insert them in the Einsy case the following way: Two nuts inside the heatbed holder (note one slot is from the inside of the cover) Two nuts inside the extruder cable holder. -

Page 114: Step 11 Mounting The Einsy-Base (Part 1)

8. Electronics assembly STEP 11 Mounting the Einsy-base (part 1) Holes with blue arrows will be used to mount the Einsy-base. Insert M3x10 screws in the holes and tighten them just slightly. 3-4 turns are enough for now. STEP 12 Mounting the Einsy-base (part 2) Before mounting the base on the frame, take the cable from X-axis motor (see the yellow label) and plug it in the EINSY. -

Page 115: Step 13 Mounting The Einsy-Base (Part 3)

8. Electronics assembly STEP 13 Mounting the Einsy-base (part 3) Slide the Einsy-base on the prepared M3x10 screws and align it with the edge of the Z-axis frame. Using 2.5mm Allen key tighten both screws. See second and third picture. STEP 14 Cable management (part 1) In the following steps, we will manage all the cables on the printer. -

Page 116: Step 15 Cable Management (Part 2)

8. Electronics assembly STEP 15 Cable management (part 2) Continue upwards and using another zip tie create the next loop. Insert Z-axis cable and all cables from the PSU. Make sure all the cables are below smooth rods and not interfering with the Y-carriage. Push the cable gently in the zip tie and tighten it so it is snug and holding the wires. -

Page 117: Step 17 Cable Management (Part 4)

8. Electronics assembly STEP 17 Cable management (part 4) Take the LCD cables and gently push them in the aluminum extrusion. Leave some slack, do not stretch the cables too much. Use the whole length of the extrusion. Bend the cable bundle down for now. Carefully fold the LCD cables around the frame. -

Page 118: Step 19 Cable Management (Part 6)

8. Electronics assembly STEP 19 Cable management (part 6) Slide the zip tie through the circular holes in the frame to create a loop. This time place the LCD cables carefully in the zip tie. Insert the Z-axis left motor cable and all cables from the bundle. Don't tighten the zip tie! Wait for the next step. -

Page 119: Step 22 Connecting The Heatbed Cable Bundle

8. Electronics assembly STEP 22 Connecting the heatbed cable bundle Insert the heatbed cable bundle including the textile sleeve in the Einsy-base. Make sure the sleeve is inside the holder, see the picture. Use the Heatbed-cable-clip and two M3x10 screws to fix the cable bundle in place. Note the correct orientation of the clip, try closing the door. -

Page 120: Step 23 Psu And Hb Power Cables

8. Electronics assembly STEP 23 PSU and HB power cables IMPORTANT: it is CRUCIAL to connect the PSU and HB cables in correct order to the EINSY board. POSITIVE WIRE must be connected to POSITIVE SLOT. There are TWO VERSIONS of the cables with different coloring system: Version A: both wires on each pair are black, POSITIVE WIRE is marked with a RED LINE Version B: on each pair, there is a red and black wire. -

Page 121: Step 25 - Psu And Hb Power Cables

8. Electronics assembly STEP 24 PSU and HB power cables PROPER ORIENTATION of the POWER CABLE is IMPORTANT!!! CORRECT: Bent part of the connector is facing up. Push it below the square washer, all the way in. INCORRECT: Bent part of the connector is facing down. This will cause issues and might end up damaging the board! STEP 25 PSU and HB power cables... -

Page 122: Step 26 Preparing The Psu Cover

8. Electronics assembly STEP 26 Preparing the PSU cover For the following step please prepare: PSU-cover-Delta (1x) M3x10 screw (2x) STEP 27 PSU and HB - final check Now it is time for the final check of the power cables. Make sure you've connected the correct polarity and tightened the screws properly. -

Page 123: Step 28 Cable Management

8. Electronics assembly STEP 28 Cable management Merge all cables leading from below the printer to the electronics. Guide the LCD cables along with the frame behind this cable bundle. Tie all the cables together. Do not overtighten the zip-tie, you can damage the cables! Cut the remaining part of the zip-tie. -

Page 124: Step 30 Wrapping The Cable Bundle

8. Electronics assembly STEP 30 Wrapping the cable bundle Before we proceed further, we need to twist the textile sleeve. This will prevent the cables inside to slip out during the printing. Using your fingers gently twist the sleeve (not the cables) and create several wraps. -

Page 125: Step 32 Connecting The Lcd Cables

8. Electronics assembly STEP 32 Connecting the LCD cables Guide both LCD cables like in the picture. Push the cables behind the nylon filament. Take the LCD cables and see the marking on both cables. Connect the LCD cable with TWO stripes to the left connector (P2) Connect the LCD cable with ONE stripe to the right connector (P1) STEP 33 Connecting the motor cables... -

Page 126: Step 34 Preparing The Zip Ties

8. Electronics assembly STEP 34 Preparing the zip ties Slightly bend the tip on two zip ties. There are two perforations in the right corner of the Einsy base. We will use them for securing the cable bundle. Push the zip tie through the upper perforation. Push the zip tie through the lower perforation. -

Page 127: Step 36 Hotend Cable Guiding (Part 2)

8. Electronics assembly STEP 36 Hotend cable guiding (part 2) Connect the heatbed thermistor cable (labelled H) to the Einsy board. Leave a slack on the cable. Connect the hotend heater cable to the Einsy board. Guide the cable like in the picture. -

Page 128: Step 38 Finalizing The Einsy-Case

8. Electronics assembly STEP 38 Finalizing the Einsy-case For this step, please prepare: M3x40 screw (1x) Close the Einsy-door. Make sure that no wire is pinched! Tighten the M3x40 screw. STEP 39 Mounting antivibration feet If you've assembled the feet in the second chapter, you can skip this step. Antivibration feet (4x) Turn the frame on its side, insert feet and turn 90 degrees to lock them in place. -

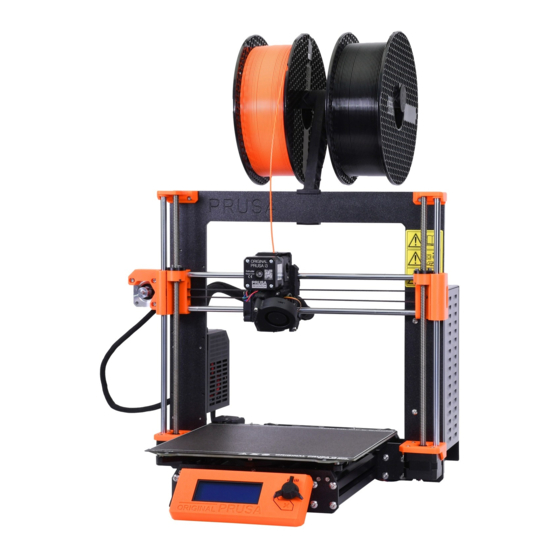

Page 129: Step 40 Assembling The Double Spool Holder (Part 1)

8. Electronics assembly STEP 40 Assembling the double spool holder (part 1) For the following steps, please prepare: Centre part (1x) Side arm (2x) STEP 41 Assembling the double spool holder (part 2) Don't use excessive force during the assembly, or you might damage the spool holder locking system. -

Page 130: Step 42 Mounting The Double Spool Holder

8. Electronics assembly STEP 42 Mounting the double spool holder To properly mount the spool holder, let the "tooth" sit on the frame (in the middle) and then press in the direction of the arrows (push backwards, while slightly pressing downwards). Don't try to assemble spool holder by pushing it only from the top. -

Page 131: Step 44 Haribo Time

8. Electronics assembly STEP 44 Haribo time! Phew! That was a lot of work to do. Eat 15 % of the bears. STEP 45 Hooray! Congratulations, you've just assembled the Original Prusa i3 MK3S+ 3D printer! You're almost there... Just finish the chapter 9. -

Page 132: Preflight Check

9. Preflight check Original Prusa i3 MK3S+ kit assembly... -

Page 133: Step 1 Superpinda Adjustment (Part 1)

9. Preflight check STEP 1 SuperPINDA adjustment (part 1) Ensure the printer is turned off and not plugged in. While moving with the extruder, the X-axis motor works as a generator. You will create a small amount of electricity and the LCD might flicker. Move with the extruder reasonably slowly and in the future always use the printer's controls. -

Page 134: Step 3 Superpinda Adjustment (Part 3)

9. Preflight check STEP 3 SuperPINDA adjustment (part 3) Move the extruder to the centre of the X-axis. Take a zip tie from the package and place it under the SuperPINDA sensor. Use the middle part of the zip tie, not the tip. Release the screw holding the SuperPINDA sensor and gently press it against the zip tie. -

Page 135: Step 5 Printable 3D Models

9. Preflight check STEP 5 Printable 3D models Read the chapter Printing in 3D Printing Handbook. Congratulations! You should be ready to print by now ;-) You can start by printing some of our test objects bundled on the included SD card - you can check them out here prusa3d.com/printable-3d-models STEP 6... -

Page 136: Step 8 Haribo Time

9. Preflight check STEP 8 Haribo time! That's it, the assembly is over. Calibrate the printer according to the Handbook and you are ready to print! Eat the remaining bunch of bears. We hope, you've enjoyed the build. Don't forget to leave feedback and see you in the next one :) - Page 137 Notes:...

- Page 139 Notes:...

- Page 141 Notes:...

- Page 143 Notes:...

Need help?

Do you have a question about the i3 MK3S+ and is the answer not in the manual?

Questions and answers