Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

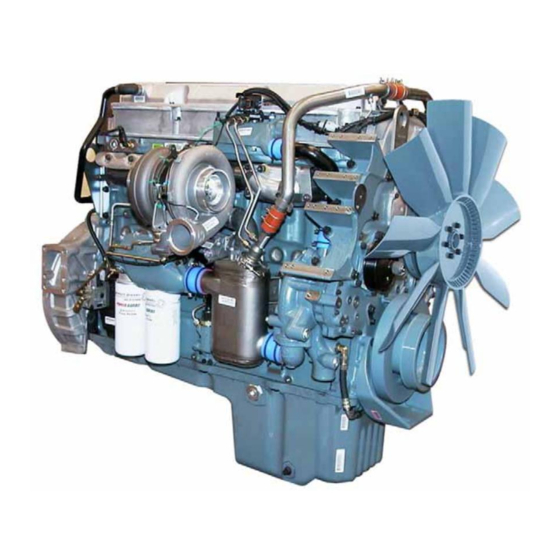

Summary of Contents for Detroit Diesel Series 60 EGR

- Page 2 This manual is to be used in conjunction with the DDEC III/IV Single ECM Troubleshooting Guide and the DDEC V Single ECU Troubleshooting Guide. Series 60®, Detroit Diesel®, DDC®, DDEC® and the spinning arrows design are registered trademarks of Detroit Diesel Corporation. Diagnostic Link® is a registered trademarks of the...

- Page 3 This manual is designed with that thought in mind. This Series 60 EGR Technician’s Guide will provide you with concentrated information that will allow you to excel in EGR technology.

- Page 4 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 5: Table Of Contents

APPENDIX C: ENGINE DIAGNOSTIC QUESTIONNAIRE ............APPENDIX D: SERVICE INFORMATION LETTERS ..............APPENDIX E: DDEC IV ECM OVERVIEW AND VEHICLE INTERFACE HARNESS ....All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 6 TABLE OF CONTENTS All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 7 SERIES 60 EGR TECHNICIAN'S MANUAL INTRODUCTION The Series 60 EGR Technician's Guide is intended to be used by a qualified service technician familiar with Detroit Diesel electronically controlled (DDEC) diesel engines and to provide a better understanding of the EGR system to improve the diagnosing of a Series 60® EGR system.

- Page 8 Verify that alternator grounds are clean and making good contact. Disconnect the alternator belt to test. Wiggle wires and harnesses to try to make the problem active, or re-occur. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 9 Develop your own Driver Questionnaire (see Figure 1-1). NOTE: A full page copy of the questionnaire can be found in Appendix C. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 10: Introduction

INTRODUCTION Figure 1-1 Drivers Questionnaire All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 11: All Information Subject To Change Without Notice. (Rev. June 2005) 7Se60 0506 Copyright © 2005 Detroit Diesel Corporation

9. Did the problem occur at a specific vehicle speed? If so, at what vehicle speed? 10. Does the problem occur at specific engine RPM? If so, at what engine RPM? All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 12 9. If the problem occurs at a specific engine rpm, unplug the oil, coolant, and air temperature sensors, and note any changes to the problem. Gather this data and contact DDC Customer Support Center at 313-592-5800. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 13: Ddec Iv Components

(NOx) emissions. Figure 2-1 illustrates how the components of a EGR system function. Figure 2-1 EGR System All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 14 6. S Pipe 9. High Flow Water Pump 3. VNT Turbocharger 7. EGR Valve 4. Delta Pressure Sensor Figure 2-2 Pre-2004 Right Side View All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 15 4. Intake Manifold Air Temperature Sensor 2. EGR Mixer 5. Barometric Pressure Sensor 3. Intake Manifold 6. Turbo Boost Pressure Sensor Figure 2-3 Pre-2004 Left Side View All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 16 DDEC IV COMPONENTS An enhancement program has been launched to upgrade production 2004 DDEC IV EGR engines. For detailed information, please visit the Detroit Diesel Technical Information Web Page at http://192.135.85.10/public/sp/spnav.asp and browse for 18SP597. Figure 2-4 illustrates some of the enhancements such as tube and shell EGR cooler, redesigned delivery pipe, EGR valve, and venturi tube.

- Page 17 DDEC IV ECM engine management benifits are: Excellent engine performance Optimum fuel economy Emission levels that meet current laws without after treatment Engine diagnostics Simple programming All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 18 12V or 24V power supply DDEC IV ECM: PWM#2 (Y1) EGR and PWM#4 (X2) VNT Figure 2-5 EGR Valve and VNT Control System All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 19 Regulated exhaust restriction is at the maximum. EGR flow is at maximum while operating in EGR mode Figure 2-6 Maximum Regulated Air Pressure to the VNT All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 20 Exhaust gas restriction is moderate EGR flow is increased while operating in EGR Mode Figure 2-7 Regulated Air Pressure to the VNT All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 21 Exhaust gas restriction is minimal EGR flow is minimal while operating in EGR Mode Figure 2-8 No Air Pressure to the VNT All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 22 VNT actuator is spring loaded. If air pressure is lost the actuator will open the VNT vanes resulting in low/no boost. Figure 2-9 Variable Nozzle Turbocharger 2-10 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 23 ECM relative to turbo boost pressure. Return voltage increases as boost pressure increases. Operating values are 0.10-5.0 V during normal engine operation. Figure 2-10 Turbocharger Boost Sensor 2-11 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 24: Egr Valve

The EGR actuator is spring loaded. If air pressure is lost the actuator will close the EGR valve resulting in no EGR flow. Figure 2-11 Pre-2004 EGR Valve 2-12 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 25 Enhanced EGR Valve EGR Valve Actuator The EGR valve actuator (see Figure 2-13) regulates EGR butterfly valve. Figure 2-13 EGR Valve Actuator 2-13 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 26 2-15 for a view of the current EGR cooler. 1. Pre-2004 EGR Cooler 2. Enhanced EGR Cooler Figure 2-14 Pre-2004 EGR Cooler and Enhanced EGR Cooler 2-14 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 27 EGR/charge air mixer. The gases are then mixed with incoming air from the charge air cooler before being sent to the intake manifold. 2-15 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 28 Return sensor voltage increases as pressure differential increases during engine operation (operating values are 0.23-4.77 V). 1. Thermostat Housing 2. Delta P Sensor Figure 2-16 Delta P Sensor 2-16 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 29 EGR mass flow rate. See Figure 2-19 for pre-2004 venturi tube and see Figure 2-20 for enhanced venturi tube. Figure 2-17 Pre-2004 Delivery Pipe 2-17 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 30 DDEC IV COMPONENTS Figure 2-18 Enhanced Delivery Pipe 2-18 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 31 SERIES 60 EGR TECHNICIAN'S MANUAL Figure 2-19 Pre-2004 Venturi Tube 2-19 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 32 DDEC IV COMPONENTS Figure 2-20 Enhanced Venturi Tube 2-20 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 33 Sensor return voltage decreases as exhaust gas temperature increases (sensor operating values are 0.10-5.0 V). See Figure 2-21 to view the sensor with connector. Figure 2-21 EGR Tempertaure Sensor 2-21 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 34 See Figure 2-22 for a view of the pre-2004 EGR mixer and see Figure 2-23 for a view of the enhanced EGR mixer. Figure 2-22 Pre-2004 EGR Mixer 2-22 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 35 TCI sensor increases as atmospheric humidity increases and return voltage decreases as air inlet temperature increases. The TCI operating values during normal engine operation are 0.23-4.93 V. 2-23 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 36 The EGR engine uses a high flow water pump to improve the coolant flow for added heat dissipation. NOTE: The high flow water pump is not interchangeable between EGR and non-EGR engines. 2-24 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 37: Operational Modes

SERIES 60 EGR TECHNICIAN'S MANUAL OPERATIONAL MODES New terminology has been introduced as a result of the Series 60 EGR engine. Boost Mode — Boost Mode is when the engine is generating power with NO EGR flowing. The EGR valve position is closed and the vanes in the turbocharger adjust to achieve a desired boost level. - Page 38 VNT vane position controlled by intake manifold boost pressure and limited by the turbocharger speed Red = Exhaust Gas Yellow= Vehicle Air (VPODs) Blue= No EGR Flow Figure 3-1 Boost Mode EGR Valve Closed All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 39 Once the EGR butterfly valve opens, the EGR gases flow through the EGR cooler and into the delivery pipe. Red = Exhaust Gas Yellow= Vehicle Air (VPODs) Orange= Cooled Exhaust Gas Green= Coolant Flow Figure 3-2 EGR Mode All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 40 Figure 3-3, to initiate the valve opening event by providing air pressure to the EGR actuator. Figure 3-3 Transition from Boost Mode to EGR Mode All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 41 Exhaust gas enters the EGR cooler at high temperatures and is cooled by the engine coolant system to increase the density of the gas. Figure 3-4 Coolant Flow through the EGR Cooler All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 42 The delta pressure measurement, in conjunction with the EGR temperature determines the EGR flow rate. Figure 3-5 EGR Measurement All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 43 The VNT is controlled via the DDEC PWM #4, see Figure 3-6, which regulates the air pressure to change the VNT vane position. Figure 3-6 EGR Valve and VNT Control System All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 44 EGR flow rate. See Figure 3-7. Red = Exhaust Gas Yellow= Vehicle Air (VPODs) Orange= Cooled Exhaust Gas Green= Coolant Flow Figure 3-7 VNT Control Flow All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 45: Ddec Iv Diagnostic Codes

All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 46 DDEC IV DIAGNOSTIC CODES DDEC IV CODE DESCRIPTIONS To read codes, use the Detroit Diesel Diagnostic Link (DDDL). The DDDL will display active and inactive fault codes which are listed in the following color coded chart. Blue = Logic Codes...

- Page 47 Turbo Compressor Out Temperature High TCO Temperature Derate Turbo Compressor Out Temperature Sensor Input Voltage High A/D Conversion Fail Nonvolatile Checksum Incorrect All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 48 PWM #2 Short to Battery (+) PWM #2 Open Circuit PWM #3 Above Normal Range PWM #3 Below Normal Range PWM #3 Short to Battery (+) All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 49 EGR temperature circuit failed high — EGR temperature smart sensor not responding EGR Temperature Smart Sensor not Responding EGR Temperature Smart Sensor Failed All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 50 Leaking or low vehicle air supply to the VPODs Plugged Delta P ports Plugged EGR cooler VPOD mechanical failure VNT vanes stuck in an open position All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 51 Response: The CEL will illuminate and a fault message will be generated. Possible Causes: Defective Delta P sensor EGR valve mechanical failure (open) Plugged Delta P lines All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 52 Defective or leaking VPOD Delta P sensor system measurement incorrect Mechanical failure, EGR valve Mechanical failure, turbocharger actuator Mechanical failure, VNT vane set All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 53 Mechanical failure, EGR valve Mechanical failure, turbocharger actuator Mechanical failure, turbocharger failure Mechanical failure, VNT vane set Restricted air intake including air filter All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 54 Response: Red Stop Lamp (RSL) will illuminate and fault message will be generated. Probable Causes: Restricted air filter EGR valve stuck open High exhaust back pressure 4-10 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 55 Failure Modes: PID 110, FMI 3 - Voltage High and FMI 4 - Voltage Low Response: The CEL will be illuminated and the temperature will be set to a fixed value. 4-11 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 56 Both CEL and SEL will illuminate. The Series 60 pressure limit parameters and listed below. See Figure 4-1. Figure 4-1 Oil Pressure Shutdown 4-12 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 57 250° F (121° C) — 2004 243° F (117° C) 244° F (117° C) 253° F (122° C) Table 4-1 Temperature Limits 4-13 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 58 DDEC IV DIAGNOSTIC CODES THIS PAGE INTENTIONALLY LEFT BLANK 4-14 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 59: Ddec Iv Testing

Prior to performing any DDEC IV troubleshooting or testing procedures, please ensure that the engine’s EGR system has been modified. Please refer to: Service Information Letter 04 TS-32. For detailed information, please visit the Detroit Diesel Technical Service Letter Web Page at http://192.135.85.10/cust/sletr/revised_2004.asp and browse for Technical Service Letter “04 TS-32”. - Page 60 Exhaust Gas Recirculation System Basic Checks Poor performance, high exhaust temperatures, high soot levels, SID 147 codes, and black exhaust smoke checks. For detailed information, please visit the Detroit Diesel Technical Service Letter Web Page at http://192.135.85.10/cust/sletr/revised_2004.asp and browse for Technical Service Letter 05 TS-01.

- Page 61 7. Test drive the vehicle with DDDL and perform a snapshot. Analyze the snapshot. 8. Perform “Test B” in the “Testing Procedure” section. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 62 [a] If seats are damaged, replace as necessary. NOTE: The fuel injector may need to be replaced also. [b] If the seats are not damaged, testing is complete. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 63 4. Inspect the VPOD air supply for leaks. If the VPOD air supply has leaks, repair the leak. 5. Perform Test B in the “Testing Procedures” section. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 64 [b] If the engine mount clearance is greater than 0.060 in., testing is complete. Engine Backfire, Engine Misfire, Intermittent Exhaust Smoke For engine backfire, engine misfire, and intermittent exhaust smoke reprogram the ECM. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 65 7. Visually inspect the EGR cooler for restrictions. If the EGR cooler is restricted, replace the EGR cooler. 8. Visually check the delivery pipe for restrictions. Clean the pipe as necessary to remove restrictions. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 66 Visually inspect the VNT and EGR valve for proper rod travel (full travel to stops). [a] If the VNT is not functioning properly, verify VNT vanes are moving freely. For detailed information, please visit the Detroit Diesel Technical Service Letter Web Page at http://192.135.85.10/cust/sletr/revised_2004.asp and browse for Technical Service Letter “04 TS-16”.

- Page 67 If any corrections are made as a result of these checks, test the unit again before proceeding further: Basic checks for all Series 60 EGR engines require the following tools: 1,000 Ohm resistor (low watt) DDR suite 8 or DDDL version 4.2 or higher...

- Page 68 VPOD. 4. Test: activating 11% duty cycle: Pressure = 106-134 kPa (15.4-19.4 psi). Go to steps 5[a] and 5[b]. 5-10 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 69 VPOD Wiring” section. [b] If the VPOD P/N and voltage are not correct, contact the DDC Customer Support Center at 313-592-5800. 5-11 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 70 [b] If the PWM voltage measurements are incorrect, and the wiring checks are okay, try a test ECM programmed for EGR, or contact the DDC Customer Support Center at 313-592-5800. 5-12 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 71 2. Start and run the engine. 3. Perform a road test if this is necessary to duplicate original complaint. [a] If symptoms/codes are gone, repairs are complete. [b] If any codes display, review this section again; contact Detroit Diesel Customer Support Center at 313-592-5800. 5-13 All information subject to change without notice.

- Page 72 DDEC IV TESTING THIS PAGE INTENTIONALLY LEFT BLANK 5-14 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 73: Dddl/Snapshots

3. Upon choosing the New option a Record Snapshot box will appear in the upper left section of your screen. 4. The Record Time will be counting from the second you clicked on the New option. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 74 Yes option. To discard the data recorded by the snapshot click on the NO option. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 75 8. If you choose the Yes option the Save As dialog box will appear on your screen. A suggested file name will appear outlined in blue in the File Name box. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 76 2. A dialog box will appear listing all the available snapshot files. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 77 SERIES 60 EGR TECHNICIAN'S MANUAL NOTE: The default folder that snapshot files are saved in is C:\Detroit Diesel\Diagnostic and have a file extension of .ddl. 3. Highlight the file you wish to open with one click of the left mouse button. The selected file name will now appear in the File Name box.

- Page 78 8. Move to a specific time in the replay by dragging the replay slider button. As you drag the slider, the time shown in the time box changes to reflect the position of the slider. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 79 Samples of windows that may be activated include: Normal Instrumentation Window Diagnostic Instrumentation Window All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 80 DDDL/SNAPSHOTS Graph Window User Window All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 81 SERIES 60 EGR TECHNICIAN'S MANUAL Fault Codes Window All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 82 DDDL/SNAPSHOTS THIS PAGE INTENTIONALLY LEFT BLANK 6-10 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 83: Snapshot Examples

It is important to understand what Normal looks like During normal engine operation, all parameters should have smooth transitions. Review the snapshots in this section for examples of normal engine operation. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 84 SNAPSHOT EXAMPLES EGR Flow at Idle Detroit Diesel EGR Engines will flow EGR @ idle, as certain conditions are met. MY-2002 EGR engines will flow EGR for a short duration if DDEC determines a quick rise (snap-acceleration) in engine rpm’s over time. Engine parameters programmed determine the duration of EGR flow.

- Page 85 This inactive code is stored to allow technicians the ability to assure the driver there is not any fault of failure and this operation is normal to the EGR system. All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 86 SNAPSHOT EXAMPLES EGR Flow Troubleshooting Tips All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 87 SERIES 60 EGR TECHNICIAN'S MANUAL Examples Figure 7-1 Engine at Idle with EGR Flowing All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 88 SNAPSHOT EXAMPLES Figure 7-2 Idle — Cold Engine — No EGR Demand — No EGR Flow All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 89 SERIES 60 EGR TECHNICIAN'S MANUAL Figure 7-3 Throttling Without Load — EGR is On and Of All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 90 SNAPSHOT EXAMPLES Figure 7-4 1500 — No Load — EGR Off All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 91 SERIES 60 EGR TECHNICIAN'S MANUAL Figure 7-5 Start Up — EGR Valve Stuck Open All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 92 SNAPSHOT EXAMPLES Figure 7-6 Code 147 14 — EGR Flow Too Low 7-10 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 93 SERIES 60 EGR TECHNICIAN'S MANUAL Figure 7-7 146 2 EGR Leak — Boost Power 7-11 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 94 SNAPSHOT EXAMPLES Figure 7-8 Leaking Charge Air Cooler 7-12 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 95 SERIES 60 EGR TECHNICIAN'S MANUAL Figure 7-9 One of the Delta P Ports Plugged in the Delivery Pipe 7-13 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 96 SNAPSHOT EXAMPLES Figure 7-10 Normal Operation — Eaton Autoshift Transmission 7-14 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 97 SERIES 60 EGR TECHNICIAN'S MANUAL Figure 7-11 Normal EGR Flow with Request 7-15 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 98 SNAPSHOT EXAMPLES Figure 7-12 Normal — EGR Off 7-16 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 99 SERIES 60 EGR TECHNICIAN'S MANUAL Figure 7-13 Plugged Delta P Port 7-17 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 100 SNAPSHOT EXAMPLES THIS PAGE INTENTIONALLY LEFT BLANK 7-18 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 101: Ddec V Components

Improved Exhaust Manifold Sealing (Fey Rings) Exhaust Gas Delivery Pipe Flexible Bellow connecting the Upper Hot Pipe to the EGR Valve Single VPOD All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 102 (NOx) emissions. Figure 8-1 graphically illustrates how the EGR components function to accomplish reduced NOx emissions. Figure 8-1 EGR Component Overview All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 103 The VPOD also interfaces with other engine system components as illustrated in Figure 8-2. Figure 8-2 EGR Valve and VNT Control System All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 104 3. Venturi to Delta P Sensor Line 7. Tube and Shell EGR Cooler 4. Delta P Sensor 8. VNT Actuator Figure 8-3 Right Side Component Engine View All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 105 2. EGR Delivery Pipe 4. Intake Manifold Pressure Sensor 6. Charge Air Mixer (IMP Sensor) Figure 8-4 Left Side Component Engine View All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 106 3. Turbocharger Speed Sensor 7. EGR Tube and Shell Cooler (TSS) 4. Delta P Sensor Figure 8-5 Front Right Side Component Engine View All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 107 2. Check Valve and Regulator Fitting for Return Fuel 5. Injector Harness Connector 3. Breather Tube Figure 8-6 Lower Rear Left Side Engine Components All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 108 See Figure 8-7 a detailed view of the Delta P Sensor. 1.Thermostat Housing 2. Delta P Sensor Figure 8-7 Delta P Sensor Location All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 109 2. VNT Actuator Air Line 5. EGR Valve 3. VNT Actuator 6. EGR Valve Hydraulic Actuator Figure 8-8 VNT and Related Components Location All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 110 3. Turbocharger Compressor Outlet Temperature Sensor (TCOT) 2. Turbocharger Oil Inlet Line 4. Variable Nozzle Turbocharger (VNT) Figure 8-9 VNT and Related Components 8-10 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 111 1. Fey Ring Grooves with Fey Rings 3. Exhaust Manifold Assembly 2. EGR Valve to Bellow Connector Figure 8-10 Fey Ring Exhaust Manifold 8-11 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 112 When the EGR valve is open, some of the exhaust gas is directed into the EGR cooler, through the delivery pipe, and into the intake manifold. 8-12 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 113 3. EGR Control Valve Body 6. EGR Control Valve Oil Supply Line Figure 8-12 Top Right Side View of EGR Components 8-13 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 114 See Figure 8-13 for a detailed right side view of the EGR components. 1. EGR Control Valve Hydraulic Actuator 2. Delivery Pipe Connection Figure 8-13 Front Right Side View of EGR Components 8-14 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 115 2. Venturi Tube 5. EGR Control Valve Oil Return Line 3. High Volume Water Pump Figure 8-14 EGR Cooler and Related Components 8-15 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 116 The Accelerator Pedal Assembly (AP) eliminates the need for any throttle linkage eliminating throttle delay. 8-16 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 117 As return voltage decreases the air inlet temperature voltage increases. The TCI operating values during normal engine operation are 0.10-5.0 V. 8-17 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 118 DDEC V uses this information along with temperature and density of the exhaust gases to determine precise EGR Mass Flow Rate. Figure 8-16 Venturi Tube 8-18 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 119 The cooled exhaust gases are then mixed with incoming air from the charge air cooler before being sent to the intake manifold. Figure 8-17 EGR Cooler 8-19 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 120 CAC. The compressed intake charge air flowing through the CAC core transfers the heat to the tubes and fins where it is dissipated to the outside air. 8-20 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 121 VNT actuator is spring loaded. If air pressure is lost the actuator will open the VNT vanes resulting in low/no boost. 8-21 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 122 DDEC V COMPONENTS Figure 8-20 VNT Actuator 8-22 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 123 DDEC V ECU: PWM#3 (E1) EGR and PWM#4 (E4) VNT NOTE: VNT is fully open at 7% and closed at 90% Figure 8-21 EGR Valve and VNT Control System 8-23 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 124 The EGR valve operating values are 0-12 V or 0-24 V depending on vehicle electrical system. Figure 8-22 Hydraulic Actuator with Solenoid 8-24 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 125 The sensor return voltage decreases as exhaust gas temperature increases (sensor operating values are 0.10-5.0 V). See Figure 8-23 to view the sensor with connector. Figure 8-23 EGR Tempertaure Sensor 8-25 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 126 Return sensor voltage increases as pressure differential increases during engine operation (operating values are 0.23-4.77 V). 1. Thermostat Housing 2. Delta P Sensor Figure 8-24 Delta P Sensor 8-26 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 127 ECU relative to turbo boost pressure. Return voltage increases as boost pressure increases. Operating values are 0.10-5.0 V during normal engine operation. Figure 8-25 Turbocharger Boost Sensor 8-27 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 128 DDEC V COMPONENTS THIS PAGE INTENTIONALLY LEFT BLANK 8-28 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 129 SERIES 60 EGR TECHNICIAN'S MANUAL DDEC V CODES To read DDEC V codes, use the Detroit Diesel Diagnostic Link (DDDL). The DDDL will display active and inactive fault codes which are listed in Table 9-1. NOTE: Some vehicle dashboard displays will show SAE faults.

- Page 130 AWL Open Circuit Turbo Boost Pressure Sensor Input Voltage High Turbo Boost Pressure Sensor Input Voltage Low Oil Pressure Sensor Input Voltage Low All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 131 Turbo Boost Pressure High Air Inlet Pressure High Fuel Pressure Low Air Inlet Pressure Low TCI Temperature Below Range Turbo Compressor Temperature Out Low All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 132 Injector #4 Circuit Short To Ground Injector #5 Circuit Short To Ground Injector #6 Circuit Short To Ground Aux. Output #1 Short to Battery (+) - V4 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 133 PWM #2 (V46) Below Normal Range PWM #2 (V46) Short to Battery (+) PWM #2 (46) Open Circuit PWM #1 (V46) Mechanical System Failre All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 134 Oil Filter Restriction High Injector Vreg Voltage Failed High ECU Battery Voltage High Vehicle Sensor Supply Voltage High Injector Vslope Voltage Failed High All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 135 Oil Level Sensor Input Voltage High Exhaust Temperature Sensor Input Voltage High Engine Oil Life Sensor Circuit Failed High EGR Delta Pressure Circuit Failed High All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 136 External RAM Failed Internal RAM Failed Module Forced To Boot Mode Boot Code Checksum INcorrect Table 9-1 Flash Codes, SAE Codes, Descriptions All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 137 [a] If resistance is less than 100 , the two wires are shorted to each other. [b] If the resistance is greater than 100 , try a test ECU or contact Detroit Diesel Customer Support Center at 313-592–5800. Figure 9-1 EGR Valve Coil Wiring All information subject to change without notice.

- Page 138 12 L — 02–23–04 14 L — 03–08–04 NOTE: There is an update program for the DDEC V troubleshooting in 6.0 DDDL. 9-10 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 139 EGR valve electric current is too low (FMI 5) or EGR valve electric current is too high (FMI 6) The CEL (AWL) will be illuminated and the engine will operate in boost mode. 9-11 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 140 DDEC V CODES THIS PAGE INTENTIONALLY LEFT BLANK 9-12 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 141: Ddec V Testing

SERIES 60 EGR TECHNICIAN'S MANUAL DDEC V TESTING PROBABLE COMPLAINTS The following probable complaints are based on conditions identified by the Detroit Diesel Customer Support Center. Flash Code 13 Flash Code 16 Flash Code 39 Flash Code 61 Black Smoke Black Fuel Engine Misfire, Engine Backfire, Intermittent Smoke Issues... - Page 142 2. Once troubleshooting is done, verify that troubleshooting step 1[a] or step 1[b] resolved the problem. [a] If Flash Code 13 (SID 146/FMI 6) is still logged, contact the Detroit Diesel Customer Support Center at 313-592-5800. [b] If Flash Code 13 (SID 146/FMI 6) is not logged, troubleshooting task is complete.

- Page 143 6. Once service is done, verify that the problem has been resolved. [a] If the problem has been resolved, no further testing is required. [b] If the problem has not been resolved, contact the Detroit Diesel Customer Support Center at 313-592-5800.

- Page 144 [a] If the procedures in Modification Bulletin 05M-2, Series 60 EPA 04 Fuel System have not been performed, do so now. To print a copy of 05M-2, please visit the Detroit Diesel Modification Letter Web Page at http://192.135.85.10/cust/mods/05mods/Index05.asp. [b] If the procedures in Modification Bulletin 05M-2, Series 60 EPA 04 Fuel System have been performed, contact the Detroit Diesel Customer Support Center at 313-592-5800.

- Page 145 [a] If the procedures in Modification Bulletin 05M-2, Series 60 EPA 04 Fuel System have not been performed, do so now. To print a copy of 05M-2, please visit the Detroit Diesel Modification Letter Web Page at http://192.135.85.10/cust/mods/05mods/Index05.asp. [b] If the procedures in Modification Bulletin 05M-2, Series 60 EPA 04 Fuel System have been performed, contact the Detroit Diesel Customer Support Center at 313-592-5800.

- Page 146 6. Verify that the VNT turbocharger is operating correctly. Refer to the “Turbocharger” section of the Series 60 Service Manual, (6SE483) for removal, inspection, and replacement steps. 10-6 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 147 2. Verify that the engine hardware has been campaigned or modified to the latest version. [a] If you are uncertain or unable to determine if the engine has been campaigned or modified to the latest version, please contact the Detroit Diesel Customer Support Center at 313-592-5800.

- Page 148 [b] If no damage was found, proceed to step 3. 3. Verify repairs have resolved the cab odor problem. [a] If cab odor problems have not been resolved, please contact the Detroit Diesel Customer Support Center at 313-592-5800. [b] If the cab odor problems have been resolved, the troubleshooting task has been completed.

- Page 149 5. Perform TEST F. Once the test has been perfromed, proceed to step 6. 6. Verify that the troubleshooting task has resolved the problem. [a] If the problem has not been resolved, please contact the Detroit Diesel Customer Support Center at 313-592-5800.

- Page 150 6. Using DDDL, activate the EGR Valve (PWM #2) to 90%. 7. Monitor the boost pressure for pressure drops when the EGR valve opens. 10-10 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 151 EGR cooler. 10. Visually check the delivery pipe for restrictions. Clean the pipe as necessary to remove restrictions. 11. Verify repairs. 10-11 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 152 2. Activate the VPOD outputs to 50% duty cycle using the DDDL. Visually inspect the VNT and EGR valve for proper rod travel. [a] If the VNT is not functioning properly, please visit the Detroit Diesel Technical Service Letter Web Page at http://192.135.85.10/cust/sletr/revised_2004.asp and browse for Technical Service Letter 04 TS 16 or Detroit Diesel Special Publications Web Page at http://192.135.85.10/public/sp/spnav.asp and browse for Special...

- Page 153 DDDL version 4.2 or higher or DDR suite 8 Volt Ohm Meter (VOM) Pressure gage 1379 kPa (0-200 psi) Pressure gage 690 kPa (0-100 psi) 10-13 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 154 Perform the following steps to check the Delta P Sensor. 1. Turn ignition On. 2. Connect either a Detroit Diesel Diagnostic Link® (DDDL) or a Diagnostic Data Reader (DDR) to read the Delta P counts. 3. Record the Delta P counts.

- Page 155 2. Install gage at the outlet of the VNT air line. See Figure 10-2. NOTE: The gage should be accurate to within 1.4 kPa (0.2 psi). 10-15 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 156 fitting is not properly seated, the EGR actuator will not function properly. 5. Connect VPOD air supply line to the EGR actuator. Perform a VPOD Input Pressure Test. 10-16 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 157 [b] If the VPOD part number and voltage and the ECU voltage were not correct, match the VPOD component to the ECU voltage and perform a VPOD Wiring Test. 10-17 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 158 [a] If the PWM voltage measurement is correct, go to step 7. [b] If the PWM voltage measurement is incorrect and the wiring checks were correct, try a test ECU programmed for EGR or contact the Detroit Diesel Customer Support Center at 313-592-5800.

- Page 159 ECU to protect other engine components. 5. If the issue is not related to the EGR system components, or if technical support is required, contact the Detroit Diesel Customer Support Center at 313-592-5800. 6. Perform a Final Test.

- Page 160 [a] If the difference is greater than 4.1 kPa (0.6 psi), replace the Barometric Pressure Sensor. [b] If the difference is less than 4.1 kPa (0.6 psi), contact the Detroit Diesel Customer Support Center at 313-592-5800. 3. Verify repair.

- Page 161 2. Fill the exhaust side of the cooler with hot tap water. Allow the water to overflow until the loose carbon has floated away allowing for a clear viewing of any bubbles. See Figure 10-4. 10-21 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 162 4. Disconnect the regulated air supply from the regulator and watch for bubbles on the exhaust side of the cooler. See Figure 10-5. [a] If bubbles were observed, replace the cooler. [b] If no bubbles were observed, contact the Detroit Diesel Customer Support Center for further information (313-592-5800). Figure 10-5...

- Page 163 Bulletin 01–81 (see Figure 10-6, see Figure 10-7, and see Figure 10-8). Figure 10-6 Freightliner Service Bulletin 01–81 (Page One of Three) 10-23 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 164 DDEC V TESTING Figure 10-7 Freightliner Service Bulletin 01–81 (Page Two of Three) 10-24 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 165 SERIES 60 EGR TECHNICIAN'S MANUAL Figure 10-8 Freightliner Service Bulletin 01–81 (Page Three of Three) 10-25 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 166 DDEC V TESTING THIS PAGE INTENTIONALLY LEFT BLANK 10-26 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 167: Appendix A: List Of Acronyms

Turbo Speed Sensor (TSS) Turbo Speed Sensor (TSS) Vehicle Speed Sensor (VSS) Vehicle Speed Sensor (VSS) Table A-1 DDEC IV to DDEC V All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 168 APPENDIX A: LIST OF ACRONYMS All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 169: Appendix B: Ddec Iv Wiring Schematics

APPENDIX B: DDEC IV WIRING SCHEMATICS DDEC IV Vehicle Harness DDEC IV Engine Wiring Diagram DDEC V Engine Harness DDEC V Vehicle Interface Harness All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 170 APPENDIX B: DDEC IV WIRING SCHEMATICS All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 175: Appendix C: Engine Diagnostic Questionnaire

SERIES 60 EGR TECHNICIAN'S MANUAL APPENDIX C: ENGINE DIAGNOSTIC QUESTIONNAIRE Engine Diagnostic Questionnaire All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 176 APPENDIX C: ENGINE DIAGNOSTIC QUESTIONNAIRE All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

-

Page 178: Appendix D: Service Information Letters

Technical Service Letter 04 TS-17 Technical Service Letter 04 TS-16 Technical Service Letter 04 TS-16 Technical Service Letter 04 TS-16 Technical Service Letter 04 TS-16 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... -

Page 190: Appendix E: Ddec Iv Ecm Overview And Vehicle Interface Harness

Engine Harness Connector Pin Locations - see Figure E-3 Vehicle Interface Harness Connector - see Figure E-4 Vehicle Interface Harness Connector Pin Locations - see Figure E-5 All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION... - Page 191 APPENDIX E: DDEC IV ECM OVERVIEW AND VEHICLE INTERFACE HARNESS Figure E-1 DDEC IV ECM Front Side View All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 192 SERIES 60 EGR TECHNICIAN'S MANUAL Figure E-2 ECM Engine Harness Connector View All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 193 APPENDIX E: DDEC IV ECM OVERVIEW AND VEHICLE INTERFACE HARNESS Figure E-3 Engine Harness Connector Pin Locations All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 194 SERIES 60 EGR TECHNICIAN'S MANUAL Figure E-4 Vehicle Interface Harness Connector All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

- Page 195 APPENDIX E: DDEC IV ECM OVERVIEW AND VEHICLE INTERFACE HARNESS Figure E-5 Vehicle Interface Harness Connector Pin Locations All information subject to change without notice. (Rev. June 2005) 7SE60 0506 Copyright © 2005 DETROIT DIESEL CORPORATION...

Need help?

Do you have a question about the Series 60 EGR and is the answer not in the manual?

Questions and answers