Detroit Diesel MBE 4000 Service Manual

Hide thumbs

Also See for MBE 4000:

- Application and installation manual (224 pages) ,

- Service information (40 pages) ,

- Installation instructions manual (7 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Service Information

Advertisement

Chapters

Table of Contents

Summary of Contents for Detroit Diesel MBE 4000

- Page 1 www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 2 www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 3 (compare Examples 1 and 2). ENGINE EXHAUST Consider the following before servicing engines: All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 4 If operating an engine in an enclosed area, vent the exhaust to the outside. Do not modify or tamper with the exhaust system or emission control system. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 5: Table Of Contents

EGR CAMSHAFT ..................1-181 ADDITIONAL INFORMATION ..............1-183 FUEL SYSTEM INJECTOR UNIT PUMP ................EGR INJECTOR UNIT PUMP ..............2-11 FUEL INJECTOR LINE ................2-13 All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 6 EGR EXHAUST MANIFOLD ..............7-14 EGR COOLER AND COOLER SUPPORT BRACKET ......7-26 EGR CONTROL VALVE, GAS OUTLET PIPE, AND GAS MIXER ..7-43 All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 7 PREPARING ENGINE FOR STORAGE ........... 14-3 MECHANICAL TROUBLESHOOTING 15.1 TROUBLESHOOTING THE ELECTRONIC ENGINE CONTROL SYSTEM ....................15-3 15.2 GENERAL TROUBLESHOOTING ............15-4 INDEX ....................Index-1 All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 8 MBE 4000 SERVICE MANUAL www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 9: General Information

www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru GENERAL INFORMATION Section Page SCOPE AND USE OF THIS MANUAL ............GENERAL DESCRIPTION ................. ELECTRONIC ENGINE CONTROL SYSTEM ..........ENGINE BRAKING POWER ............... GENERAL SPECIFICATIONS AND ENGINE VIEWS ........ ENGINE MODEL AND SERIAL NUMBER ..........EXHAUST GAS RECIRCULATION (EGR) SYSTEM ........SAFETY INSTRUCTIONS AND PRECAUTIONS ........ - Page 10 MBE 4000 SERVICE MANUAL www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 11: Scope And Use Of This Manual

Basic maintenance and overhaul procedures are common to all MBE 4000 engines, and apply to all engine models. This manual is divided into numbered sections. Section one covers the engine (less major assemblies). -

Page 12: Electronic Engine Control System

J1587 and J1939 datalinks, where it can be read by minidiag2, Nexiq™ ® Diagnostic Data Reader (DDR), or Detroit Diesel Diagnostic Link (DDDL) PC software. The DDEC-ECU monitors both the engine and the datalink. When a malfunction or other problem is detected, the system selects an appropriate response;... - Page 13 Figure 1 DDEC-ECU Control Unit Location NOTE: To obtain a replacement DDEC-ECU, all the data given on the DDEC-ECU label are required. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 14 Other electronic control units (for example, the antilock brake system) The DDEC-ECU control unit (data such as oil pressure and coolant temperature) All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

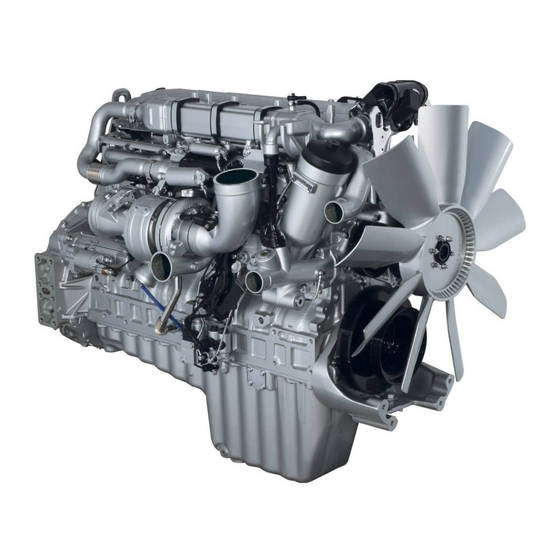

Page 15: Engine Braking Power

For a general view of the MBE 4000 engine, showing major components, see Figure 3 for the left-hand side, and see Figure 4 for the right-hand side. For a general view of the MBE 4000 engine, showing ports and fluid lines, see Figure 5 for the left-hand side and see Figure 6 for the right-hand side. - Page 16 5. Engine Trim Cover 13. Fuel Pump 6. Crankcase Breather 14. Air Conditioner Compressor 7. Air Compressor Figure 3 Left Side, Major Engine Components All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 17 4. Exhaust Manifold 12. Oil Dipstick 5. Cylinder Head Cover 13. Turbocharger 6. Fan 7. Belt Tensioner Figure 4 Right Side, Major Engine Components All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 18 3. Charge Air Inlet 7. Electronic Engine Harness Connector 4. Open Breather Tube 8. Fuel Feed Line Figure 5 Left Side, Ports and Lines All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 19 3. Constant-Throttle Inlet 7. Oil Fill Cap 4. Exhaust Brake Valve Outlet 8. Coolant Pump Inlet Pipe Figure 6 Right Side, Ports and Lines All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 20 2. TDC Sensor (on camshaft) 6. Fuel Temperature Sensor 3. Crank Angle Position Sensor 7. Oil Pressure/Temperature Sensor 4. Coolant Temperature Sensor Figure 7 Sensor Locations All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 21 MBE 4000 SERVICE MANUAL www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru The general specifications for the MBE 4000 engine are listed in Table 1. Description 6–Cylinder Engines Engine Type Vertical, inline cylinder block with turbocharger and charge-air cooler Cooling System Liquid Circuit Combustion Principle 4–Stroke direct-injection diesel...

-

Page 22: Engine Model And Serial Number

OM 460 LA is the production code. The engine serial number contains the type reference followed by a sequential manufacturing number. See Figure 9. Figure 8 Location of Engine Type Plate All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 23 DDEC-ECU label. The ten-digit number is derived from the fourteen-digit number. See Figure 10. Figure 10 Engine Serial Number All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 24: Exhaust Gas Recirculation (Egr) System

Reed Valves EGR Charge Air Mixer The MBE 4000 engines for on-highway EPA 2004 regulation applications use a cooled EGR system. Part of the exhaust gasses from the front three cylinders are routed from the exhaust manifold through the EGR cooler, past control and reed valves, and are mixed with the intake manifold charge air. - Page 25 MBE 4000 SERVICE MANUAL www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru For an general view of the MBE 4000 engine with an EGR system, See Figure 12 for a right side view and see Figure 13 for a left side view. 1. Oil Filter 8. EGR Cooler ®...

- Page 26 7. Crankcase Breather (Hengst filter) 4. EGR Modulated Control Valve 8. EGR Mixer Figure 13 EGR Engine with EGR Components and Revised Parts (Left View) All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 27 EGR modulated control valve and the mixer and then back to the cylinder. EGR Control Valves There are two EGR valves on the MBE 4000 EGR engine — the EGR shutoff valve and the EGR modulated control valve. The EGR shutoff valve is a pneumatically driven butterfly valve, located at the inlet of the EGR cooler.

-

Page 28: Safety Instructions And Precautions

SAFETY INSTRUCTIONS AND PRECAUTIONS The following safety measures are essential when working on the MBE 4000 engine. To reduce the chance of personal injury and/or property damage, the following instructions must be carefully observed: Proper service and repair are important to the service technician and the safe, reliable operation of the engine. - Page 29 To avoid injury when removing or installing a heavy engine component, ensure the component is properly supported and securely attached to an adequate lifting device to prevent the component from falling. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 30 After servicing or adjusting the engine: Reinstall all safety devices, guards or shields Ensure that all tools and servicing equipment are removed from the engine All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 31 MBE 4000 SERVICE MANUAL www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru Welding Wear welding goggles and gloves when welding or using an acetylene torch. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 32 Use proper shielding around hydraulic lines when welding to prevent hydraulic line damage. Ensure that a metal shield separates the acetylene and oxygen that must be chained to a cart. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 33 Check for frayed cords prior to using the tool. Be sure all electric tools are grounded. Defective electrical equipment can cause severe injury. Improper use of electrical equipment can cause severe injury. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 34 If injured by escaping fluid, see a doctor at once. Serious infection or reaction can result without immediate medical treatment. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru...

- Page 35 This will reduce the likelihood of a dangerous spark. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 36 Apply baking soda or lime to help neutralize the acid. Flush your eyes with water. Get medical attention immediately. Always disconnect the battery cable before working on the electrical system. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 37 Disconnect the batteries or disable an air starter when working on the engine to prevent accidental starting. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 38 PERSONAL INJURY To avoid injury, use care when working around moving belts and rotating parts on the engine. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 39 This is extremely corrosive and, if touched by bare skin, may cause severe burns, sometimes with symptoms delayed for several hours. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru...

-

Page 40: English To Metric Conversion

To get equivalent number of: Pound-inch (lb·in.) 0.11298 Newton-meters (N·m) Pound-foot (lb·ft) 1.3558 Newton-meters (N·m) Multiply Power To get equivalent number of: All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... -

Page 41: Decimal And Metric Equivalents

Kilometers/hour (km/hr) Table 2 English to Metric Conversion Table DECIMAL AND METRIC EQUIVALENTS Listed in Table 3 are the decimal and metric equivalents. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 42 0.46875 11.90625 31/32 0.96875 24.60625 31/64 0.484375 12.30312 63/64 0.984375 25.00312 0.500 12.70000 1.00 25.40000 Table 3 Conversion Chart-Customary and Metric Units All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 43: Torque Specifications

Listed in Table 4, listed in Table 5, listed in Table 6, listed in Table 7, and listed in Table 8 are the torque specifications for the MBE 4000 engine. Torque Values for U.S. Customary Thread Fasteners with Lubricated* or Plated Threads†... - Page 44 † Use these torque values if either the bolt or nut is lubricated or plated (zinc-phosphate conversion-coated, cadmium-plated, or waxed). Table 5 Torque Specifications Table Two All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 45 † Use one of the previous tables if either the male or female threads (bolt and nut) are plated or lubricated. Coat all plated and unplated fasteners with oil before installation. Table 6 Torque Specifications Table Three All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 46 † Use one of the previous tables if either the male or female threads (bolt and nut) are plated or lubricated. Coat all plated and unplated fasteners with oil before installation. Table 7 Torque Specifications Table Four All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 47 † Use one of the previous tables if either the male or female threads (bolt and nut) are plated or lubricated. Coat all plated and unplated fasteners with oil before installation. Table 8 Torque Specifications Table Five All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 48 MBE 4000 SERVICE MANUAL www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 49: Engine

www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru ENGINE Section Page CYLINDER HEAD COVER ..............CYLINDER HEAD ..................CYLINDER BLOCK .................. 1-24 EGR CYLINDER HEAD AND BLOCK ............. 1-40 EGR FRONT AND REAR LIFTER BRACKETS ........1-43 ENGINE BRAKE ..................1-45 FRONT RADIAL SEAL ................1-51 REAR RADIAL SEAL ................ - Page 50 1.23 EGR CAMSHAFT ..................1-181 ADDITIONAL INFORMATION ..............1-183 All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 51: Cylinder Head Cover

4. Cylinder Head Figure 1-1 Cylinder Head Cover 1.1.1 Removal of Cylinder Head Cover Perform the following steps to remove the cylinder head cover: All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 52 2. Place the cylinder head cover in position on the cylinder head. 3. Install the cylinder head cover bolts. Tighten the bolts 20 N·m (15 lb·ft). All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru...

-

Page 53: Cylinder Head

CYLINDER HEAD The MBE 4000 engine has individual heads for each cylinder. To remove one head, follow these instructions, step by step. To remove all the heads, repeat each step in these instructions, as applicable, for all six cylinders. - Page 54 6. Fuel Return Line 13. Exhaust Manifold Mounting Bolt 7. Cylinder Head Bolt 14. Guide Pin Figure 1-3 Exploded View of Cylinder Head All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 55 4. Remove the engine trim cover to gain access to the fuel injector lines. 5. Remove the charge-air intake manifold. Refer to section 6.1.1. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru...

- Page 56 7. Remove the high-pressure injector line from the head and unit pump. 8. To prevent any dirt from entering, cover the openings in the unit pump and the transfer tube. All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 57 When all the bolts are loose, remove the bolts from the cylinder head. See Figure 1-5. Figure 1-5 Loosening the Head Bolts All information subject to change without notice. 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 58 2. Position the cylinder head on the head gasket. Make sure the head is seated onto the guide pins. All information subject to change without notice. 1-10 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 59 Maximum shaft length 212.0 mm (8.35 inches) Table 1-3 Cylinder Head Bolt Lengths 4. Lubricate the cylinder head bolts with engine oil. All information subject to change without notice. 1-11 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 60 6. Replace the seal rings and connect the fuel return line to the cylinder head. 7. Replace the seal rings and install the constant-throttle line on the cylinder head. All information subject to change without notice. 1-12 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 61 19. Check that the coolant drain plug is tight and not leaking. 20. Fill the radiator with coolant. Refer to section 4.1.1. 21. Install the cylinder head cover. Refer to section 1.1.2. All information subject to change without notice. 1-13 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 62 2. Remove the nozzle holder. Refer to section 2.4.1. 3. Remove the intake and exhaust valves. Refer to section 1.19.5. 4. Remove the constant-throttle valve. Refer to section 1.6.1. All information subject to change without notice. 1-14 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 63 Deviation of Head Mating Surface When New 113.85-114.15 (4.482-4.494) Overall Height of Cylinder Head After Machining 113.5 (4.46) Table 1-6 Cylinder Head Specifications All information subject to change without notice. 1-15 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 64 [e] Repeat this procedure at each spot marked by an arrow (each corner of the cylinder head). All information subject to change without notice. 1-16 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 65 4. Install the intake and exhaust valves. Refer to section 1.19.6. 5. Install the nozzle holder. Refer to section 2.4.2. 6. Install the cylinder head. Refer to section 1.2.2. All information subject to change without notice. 1-17 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 66 3. Adjust the valve lash. Refer to section 1.19.3. NOTE: To do this procedure, coolant temperature must be between 155 and 205 F (70 to 95 C). All information subject to change without notice. 1-18 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 67 4. Turn on the ignition keyswitch and run the engine until it reaches operating temperature. 5. Shut down the engine. All information subject to change without notice. 1-19 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 68 4. High-Pressure Fuel Line 9. Retaining Bolt 5. Seal Ring 10. Constant Throttle Valve Cover Figure 1-11 Removing the Injector Nozzle All information subject to change without notice. 1-20 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 69 [c] Tighten the bolt attaching the hold-down to the cylinder head. NOTE: Follow the equipment manufacturer's operating instructions to connect the compression tester. All information subject to change without notice. 1-21 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 70 Pressure in kPa (psi) Minimum Compression Pressure Valve 2800 (406) Permissible Difference Between Individual Cylinders 400 (58) Table 1-7 Compression Testing All information subject to change without notice. 1-22 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 71 7. Install the cylinder head cover. Refer to section 1.1.2. 8. Repeat this procedure for each cylinder. 9. Remove the chocks from the tires. All information subject to change without notice. 1-23 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 72: Cylinder Block

If the same liner is used again, it must be installed at an offset of 90 degrees from its last position. 1. Cylinder Block 2. Cylinder Liner Figure 1-14 Mark the Cylinder Liner All information subject to change without notice. 1-24 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 73 5. Threaded end of Spindle 2. Hold-down bolt 6. Hold-down bolt 3. Washer 7. Cylinder Liner 4. Spindle Nut Figure 1-15 Cylinder Liner Removal All information subject to change without notice. 1-25 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 74 See Figure 1-16. 1. Block 3. Cylinder Liner Collar 2. Cylinder Liner 4. Collar Seat Insert Figure 1-16 Cylinder Liner Collar Seat All information subject to change without notice. 1-26 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 75 7. Check the condition of the cylinder liner collar. Make sure that the height of the collar is within the specifications given. Discard the liner if the collar is not within specifications listed in Table 1-8. All information subject to change without notice. 1-27 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 76 Table 1-9. NOTE: The cylinder liner collar and collar seat must remain completely free of oil. All information subject to change without notice. 1-28 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 77 [b] Cylinder liners with tolerance code B require a piston of either code BA or BC. [c] Cylinder liners with tolerance code C require a piston of code BC. All information subject to change without notice. 1-29 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 78 If installing a new liner, use the first reference mark. If installing the old liner, use the second reference mark, offset 90 degrees from the first one. All information subject to change without notice. 1-30 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 79 [c] If the O-rings are damaged, replace them. [d] Check the out-of-round again until it meets specifications. 8. Install the piston. Refer to section 1.17.2. All information subject to change without notice. 1-31 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 80 Minor fading of the honing pattern at the top ring inversion area is not sufficient cause to reject the liner. Figure 1-21 Intact Honing Pattern All information subject to change without notice. 1-32 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 81 3. Do an external visual check of the cylinder liner for signs of cavitation and corrosion. Discard the liner if any damage is noted. All information subject to change without notice. 1-33 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 82 A to Axis B Table 1-10 Cylinder Liner Measurements NOTE: This measurement serves as a baseline against which to measure the actual wear. All information subject to change without notice. 1-34 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 83 [b] Make the second measurement 90 degrees away, along the side-to-side axis. [c] When finished, set the dial gauge to zero. All information subject to change without notice. 1-35 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 84 2. Clean the contact surfaces of the cylinder block, the cylinder liner, and the measuring plate. All information subject to change without notice. 1-36 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 85 See Figure 1-26. 1. Cylinder Head Bolts Figure 1-26 Measuring Plate Installation 4. Tighten the cylinder head bolts 50 N·m (37 lb·ft). All information subject to change without notice. 1-37 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 86 Support the dial gauge. See Figure 1-27. 1. Dial Gauge 3. Feeler 2. Slot (4 qty.) Figure 1-27 Dial Gauge Installation All information subject to change without notice. 1-38 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 87 7. Remove the bolts, spacers and measuring plate (J 46071 or 402 589 00 21 00), as installed. 8. Install the cylinder head. Refer to section 1.2.2. All information subject to change without notice. 1-39 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 88: Egr Cylinder Head And Block

EGR CYLINDER HEAD AND BLOCK There are several minor changes in the cylinder liner, block and engine lifter brackets between the MBE 4000 EGR engine and the non-EGR engine. 1.4.1 EGR Cylinder Head Installation Be aware of the following notice when installing the cylinder head on an EGR engine:... - Page 89 EGR engine is in the area previously hardened in the non-EGR cylinder liner. Its purpose is to inhibit coke formation. All information subject to change without notice. 1-41 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 90 EGR cooler.See Figure 1-31. 1. Opening near the air compressor housing 2. Flange for attaching coolant inlet pipe Figure 1-31 EGR Cylinder Block Changes All information subject to change without notice. 1-42 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 91: Egr Front And Rear Lifter Brackets

See Figure 1-32. 1. Front Lifter Bracket Mounting Bolts 2. Front Lifter Bracket Figure 1-32 Removal / Installation of Front Lifter Bracket All information subject to change without notice. 1-43 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 92 3. Install the rear lifter bracket using two mounting bolts. See Figure 1-33. 4. Torque the two bolts to 200 N·m (147.5 lb·ft). All information subject to change without notice. 1-44 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 93: Engine Brake

Remove the constant-throttle valve as follows: 1. Remove the cylinder head. Refer to section 1.2.1. 2. Remove the injector nozzle. Refer to section 2.4.1. All information subject to change without notice. 1-45 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 94 Insert a spacer beneath the valve head to prevent the valve from opening while doing the rest of the removal procedures. See Figure 1-35. All information subject to change without notice. 1-46 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 95 4. Piston Seal 10. Valve 5. Collets 11. Spacer 6. Spring Retainer Figure 1-35 Constant-Throttle Valve (cutaway view, with spacer installed) All information subject to change without notice. 1-47 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 96 6. Inspect the piston and piston seal for damage and signs of wear. If necessary, replace the piston and piston seal. All information subject to change without notice. 1-48 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 97 NOTE: Always replace the valve stem seal whenever the constant-throttle valve is removed. 11. Repeat this procedure for each constant-throttle valve. All information subject to change without notice. 1-49 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 98 10. Install the injector nozzle. Refer to section 2.4.2. 11. Install the cylinder head. Refer to section 1.2.1. 12. Repeat this procedure for each constant-throttle valve. All information subject to change without notice. 1-50 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 99: Front Radial Seal

6. Check the seal for wear at the places where it contacts the crankshaft. NOTE: When drilling holes for screws, make sure to coat the drill bit with grease to catch the shavings. All information subject to change without notice. 1-51 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 100 5. Install the three drive belts. Refer to section 8.1.1. 6. Install the support angle bracket fairing. Install the bumper beam. All information subject to change without notice. 1-52 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 101 7. Check the engine oil pressure at idle. Engine oil pressure at idle should be at least 50 kPa (7 psi). 8. Close the hood, and remove the chocks from the tires. All information subject to change without notice. 1-53 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 102: Rear Radial Seal

1. Remove the flywheel. Refer to section 1.12.1. See Figure 1-39. 1. Flywheel 3. Flywheel Housing 2. Rear Radial Seal 4. End of Crankshaft Figure 1-39 Rear Radial Seal Location All information subject to change without notice. 1-54 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 103 2. Place the receptacle,(J 45393 or 457 589 02 15 00), on the end of the crankshaft. Put the new radial seal in place on the rear seal installer, (J 45393 or 457 589 02 15 00). All information subject to change without notice. 1-55 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 104 3. Check the sealing lip on the radial seal to make sure it is positioned correctly. 4. Install the flywheel. Refer to section 1.12.2. All information subject to change without notice. 1-56 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 105: Crankshaft Assembly

7. Main Bearing Cap (center) 4. Lower Bearing Shell(s) 8. Main Bearing Cap Bolt Figure 1-42 Crankshaft, Main Bearings, and Main Bearing Caps All information subject to change without notice. 1-57 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 106 5. Remove the flywheel and flywheel housing. Refer to section 1.12.1. 6. Remove the front cover housing. Refer to section 1.10.1. 7. Remove the pistons. Refer to section 1.17.1. All information subject to change without notice. 1-58 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 107 2. Crankshaft Gear Figure 1-43 Aligning the Marked Gear Teeth 9. Remove the crankshaft gear from the crankshaft. Refer to section 1.9.3. All information subject to change without notice. 1-59 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 108 Removal Order, Main Bearing Cap Bolts 11. Loosen the main bearing caps with a plastic hammer, if necessary. Remove the main bearing caps. All information subject to change without notice. 1-60 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 109 Then lift the crankshaft out of the block. See Figure 1-45. 1. Crankshaft 3. Hoisting Chain 2. Flexible Straps 4. Engine Stand Figure 1-45 Attaching the Hoist All information subject to change without notice. 1-61 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 110 Clean the crankshaft, bearings, and bearing seats with a chamois. 2. Lubricate the bearing surfaces with a light coating of clean engine oil. All information subject to change without notice. 1-62 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 111 See Figure 1-44. NOTE: Make sure the numbers on the bearing caps are in ascending order, starting from the front of the engine. All information subject to change without notice. 1-63 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 112 14. Install the flywheel and flywheel housing. Refer to section 1.12.2. 15. Install the front cover housing. Refer to section 1.10.2. All information subject to change without notice. 1-64 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 113 If it doesn't, either replace the crankshaft, or have it re-hardened. [a] Place a hard base underneath the bearing journal to be tested. All information subject to change without notice. 1-65 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 114 If, for any one journal, the two measurements differ by more than 0.02 mm (0.0008 inch), replace the crankshaft. Refer to section 1.9.1. All information subject to change without notice. 1-66 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 115 Undersize - 0.75 (0.030) 103.230-103.250 (4.0642-4.0650) 93.230-93.250 (3.6705-3.6712) Undersize - 1.00 (0.040) 102.980-103.000 (4.0543-4.0551) 92.980-93.000 (3.6606-3.6614) Table 1-14 Crankshaft Journal Diameters All information subject to change without notice. 1-67 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 116 Undersize - 0.50 (0.020) 46.24-46.31 (1.820-1.823) 46.500-46.562 (1.8307-1.8331) Undersize - 1.00 (0.040) 46.74-46.81 (1.840-1.843) 47.000-47.062 (1.8504-1.8528) Table 1-16 Bearing Shell and Bearing Journal Width All information subject to change without notice. 1-68 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 117 11. Measure the fillet radius of the main journals and the connecting-rod journals as listed in Table 1-13. See Figure 1-49. Figure 1-49 Measuring the Fillet Radius All information subject to change without notice. 1-69 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 118 [a] When the main bearing caps have been installed, measure the radial play (radial runout) of the crankshaft. Refer to section 1.9.2.2. All information subject to change without notice. 1-70 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 119 1. Crankcase Race 3. Cylinder Block 2. Upper Bearing Shell 4. Bearing Shells Locking Lug Figure 1-51 Installing the Upper Bearing Shell All information subject to change without notice. 1-71 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 120 Installing the Lower Bearing Shell NOTE: The guide pins on the bearing cap ensure correct seating of the cap on the crankcase race. All information subject to change without notice. 1-72 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 121 Installing the Bearing Caps NOTE: Make sure the numbers on the bearing caps are in ascending order, starting from the front of the engine. All information subject to change without notice. 1-73 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 122 [a] Measure vertically from the top to the bottom of the bore. (see Figure 1-55, A.) [b] Measure 30 degrees counterclockwise from the separation point of the bearing shells. (see Figure 1-55, B.) All information subject to change without notice. 1-74 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 123 New bearing shells are supplied ready for installation. Do not machine them or remove any material from them. Refer to section 1.9.2. All information subject to change without notice. 1-75 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 124 Crankshaft Radial Play [a] For the main bearing shell, note the inside diameter of the bearing shell. Example: = 4.0875 inches. All information subject to change without notice. 1-76 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 125 2. Check the width of the center main bearing journal. If damage or cracks are present, replace the crankshaft. See Figure 1-57. Figure 1-57 Measuring the Width of the Center Journal All information subject to change without notice. 1-77 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 126 = 1.8120 inches. [b] For the center main bearing shell, note the width (thickness) of the bearing shell. Example: W =1.8030 inches. All information subject to change without notice. 1-78 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 127 [a] Set up a dial gauge and a dial gauge holder on the front end of the crankshaft. Set the dial gauge to 5 mm (0.2 inch) preload. All information subject to change without notice. 1-79 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 128 3. Crankshaft Gear 2. Guide Pin Figure 1-60 Removing the Crankshaft Gear 5. Remove the crankshaft from the engine. Refer to section 1.9.1. All information subject to change without notice. 1-80 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 129 7. Press the gear onto the end of the crankshaft. Make sure the chamfer on the gear is facing outward. See Figure 1-60. 8. Install the crankshaft. Refer to section 1.9.2. 9. Install the engine. All information subject to change without notice. 1-81 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 130: Front Cover Housing

2. Tilt the hood. 3. Remove the front engine mounting bolts attaching the front cover housing to the front crossmember. All information subject to change without notice. 1-82 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 131 Tighten the front engine mounting bolts 325 N·m (240 lb·ft). 10. Close the hood, and remove the chocks from the tires. All information subject to change without notice. 1-83 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 132: Crankshaft Vibration Damper

3. Oil Deflector 2. Mounting Bolt 4. End of Crankshaft Figure 1-62 Vibration Damper Removal 5. Remove the oil deflector from the crankshaft. All information subject to change without notice. 1-84 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 133 Tighten the inspection cover bolts 25 N·m (18 lb·ft). 5. Install the drive belts on their pulleys, as removed. Refer to section 8.1. All information subject to change without notice. 1-85 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 134: Flywheel

(J 46167 or 407 589 00 63 00). Insert the pin and make sure the tool is blocked. Refer to section 1.15.2. All information subject to change without notice. 1-86 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 135 See Figure 1-64. 1. Flywheel Mounting Bolt (10 qty.) 2. Flywheel Figure 1-64 Flywheel (exploded view) All information subject to change without notice. 1-87 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 136 See Figure 1-65. 1. Bolt used as a handle 2. Flywheel Mounting Bolt Figure 1-65 Flywheel Removal All information subject to change without notice. 1-88 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 137 [b] Using the two bolts as handles, dislodge the flywheel from the crankshaft flange and remove it from the flywheel housing. [c] After removing the flywheel, remove the bolts from the clutch bolt holes. All information subject to change without notice. 1-89 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 138 Refer to section 1.13.1. 1.12.2 Flywheel Installation Install the flywheel as follows: 1. Grease the ring gear with a suitable heavy-duty grease. All information subject to change without notice. 1-90 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 139 Verify the alignment of the crankshaft dowel with the guide hole in the flywheel. 4. With a light coating of engine oil, lubricate the threads of the ten multipoint socket-head flywheel bolts. All information subject to change without notice. 1-91 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 140 1. Remove the flywheel. Refer to section 1.12.1. 2. Thoroughly clean the flywheel and check it for cracks, scoring, burned areas, or rough spots. All information subject to change without notice. 1-92 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 141 If the width of the flywheel between the friction surface and the mounting flange is less than 60 mm (2.4 inches), replace the flywheel. All information subject to change without notice. 1-93 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 142 See Figure 1-70for the locations on the flywheel to coordinate with the specifications in the table. Figure 1-69 Machining the Flywheel Friction Surface All information subject to change without notice. 1-94 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 143 2. Check the radial and lateral deviation from true of the flywheel. The deviation from true must not exceed 0.2 mm (0.008 inch). 3. Install the flywheel. Refer to section 1.12.2. All information subject to change without notice. 1-95 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 144: Ring Gear

Ring Gear Replacement Replace the flywheel ring gear as follows: 1. Remove the flywheel from the crankshaft flange. Refer to section 1.12.1. All information subject to change without notice. 1-96 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 145 2. Heat the ring gear on the flywheel with a torch and press the gear off. See Figure 1-72. Figure 1-72 Heating the Ring Gear All information subject to change without notice. 1-97 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 146 (A) from the flywheel shoulder diameter (B). [d] Make sure that the amount of interference fit lies between 0.295 and 0.645 mm (0.0116 and 0.0254 inch). All information subject to change without notice. 1-98 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 147 With the ring gear pressed onto the flywheel, make sure the radial run-out of the ring gear does not exceed 0.5 mm (0.02 inch). 8. Install the flywheel on the crankshaft flange. Refer to section 1.12.2. All information subject to change without notice. 1-99 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 148: Pilot Bearing

Pilot Bearing Removal 1.14.2 Pilot Bearing Installation Install the pilot bearing as follows: 1. Lubricate the new bearing with longlife grease. All information subject to change without notice. 1-100 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 149 3. Flywheel 2. Pilot Bearing Figure 1-76 Pilot Bearing Installation 3. Install the clutch on the flywheel. 4. Install the transmission. All information subject to change without notice. 1-101 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 150: Engine Cranking Tool

Engine Cranking Tool Installation 2. Remove the pin from the engine cranking tool (J 46167 or 407 589 00 63 00). All information subject to change without notice. 1-102 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 151 The engine cranking tool must be removed from the timing case before starting the engine. Failure to do so could damage the flywheel ring gear. All information subject to change without notice. 1-103 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 152: Flywheel Housing

3. Camshaft (TDC) Sensor 8. Starter 4. Flywheel Housing 9. Rear Radial Seal 5. Gasket Figure 1-78 Flywheel Housing Assembly (exploded view) All information subject to change without notice. 1-104 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 153 11. Install the camshaft (TDC) sensor. Refer to section 1.22.3. 12. Install the crank angle position sensor. Refer to section 2.6.3. 13. Install the engine. All information subject to change without notice. 1-105 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 154: Piston, Piston Ring, And Connecting Rod

1. Remove the engine from the vehicle. NOTE: The MBE 4000 engine has individual heads for each cylinder. To remove one piston, do these procedures step by step. To remove all the pistons, repeat each step in these instructions, as applicable, for all six pistons. - Page 155 6. Be sure the connecting rods and the bearing caps are marked so that they can be matched for installation. See Figure 1-80. 1. Bearing Cap 2. Connecting Rod Figure 1-80 Checking Rod and Bearing Cap Markings All information subject to change without notice. 1-107 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 156 7. Remove and inspect the oil spray nozzles. See Figure 1-81. Refer to section 3.2.1. Replace them if damaged. 1. Oil Spray Nozzle 2. Cylinder Liner Figure 1-81 Location of Oil Spray Nozzle All information subject to change without notice. 1-108 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 157 13. Remove the wrist-pin snap rings. Push the wrist pin out and remove the piston from the connecting rod. 1.17.2 Piston Installation Install the piston assembly as follows: All information subject to change without notice. 1-109 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 158 [a] Lubricate the wrist pin with a light coating of clean engine oil. [b] Insert the wrist pin into the wrist pin bore. [c] Secure the wrist pin with the two snap rings. All information subject to change without notice. 1-110 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 159 4. Offset the ring gaps alternately by 120 degrees. 5. Position a ring compressor loosely over the piston. Tighten the ring compressor on the piston. All information subject to change without notice. 1-111 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 160 [b] Lubricate the bearing surface with a light coating of clean engine oil. 7. Lubricate the cylinder liners with a light coating of clean engine oil. All information subject to change without notice. 1-112 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 161 [a] Be sure that the locking lug in the bearing shell is fully seated in the groove of the cap. [b] Lubricate the bearing surface with a light coating of clean engine oil. All information subject to change without notice. 1-113 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 162 If it is necessary to turn the crankshaft and the flywheel has been removed, install the flywheel guide studs in the crankshaft gear. All information subject to change without notice. 1-114 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 163 Refer to section 3.1.2. 19. Install the oil pan. Refer to section 3.1.2. 20. Install each cylinder head, as removed. Refer to section 1.2.2. All information subject to change without notice. 1-115 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 164 3. Double Chamfered Oil Control Ring with Garter Spring (Groove III) 2. Taper Face Ring with Internal Angle (Groove II) 4. Piston Figure 1-89 Piston Rings All information subject to change without notice. 1-116 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 165 Check the end gap of the upper two piston rings first. The garter spring must be removed from the third (lowest) piston ring before you can measure its end gap. All information subject to change without notice. 1-117 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 166 [b] Remove the spring garter from the third (lowest) ring, then measure its gap in the same way as the other two rings. All information subject to change without notice. 1-118 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 167 Install the rings in the reverse order of their removal; from the bottom to the top of the piston. All information subject to change without notice. 1-119 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 168 7. Install the piston. Refer to section 1.17.2. 1.17.3.1 Piston Inspection Inspect the piston as follows: 1. Remove the piston. Refer to section 1.17.1. All information subject to change without notice. 1-120 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 169 3. Inspect the cylinder liner and piston for damage and signs of wear. Replace any piston with damage to the snap ring grooves, cracks in the piston wall, or signs of seizing and/or erosion. All information subject to change without notice. 1-121 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 170 6. Check the connecting rod for any unusual condition. Refer to section 1.17.3.2. 7. Measure the diameters of the bearing shell bore and crankshaft journals. Refer to section 1.17.3.3 for instructions. All information subject to change without notice. 1-122 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 171 2. Inspect the connecting rod for blue discoloration (indicates bearing damage), scoring, notches, and cracks. If any of these conditions are found, replace the connecting rod. All information subject to change without notice. 1-123 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 172 Checking the connecting rod for a twisted or bent condition in the next step requires machine shop equipment such as a caliper gauge with a round scale. All information subject to change without notice. 1-124 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 173 [a] On each side of the connecting rod, measure the length of the connecting rod (Dimension A in see Figure 1-98) : the distance from the center bearing bore (big-end All information subject to change without notice. 1-125 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 174 1. Remove the piston. Refer to section 1.17.1. 2. Using a chamois cloth, clean the bearing bores in both the connecting rod and the bearing cap. All information subject to change without notice. 1-126 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 175 108 N·m (80 lb·ft) 68.5 mm (2.70 in) Stage 2 additional 90 degrees Table 1-29 Tightening Stages, Connecting Rod Stretch Bolts All information subject to change without notice. 1-127 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 176 [a] Measure the bearing journal in the vertical plane and note the reading. [b] Measure the bearing journal in the horizontal plane and note the reading. All information subject to change without notice. 1-128 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 177 8. Place the connecting rod in a vise with protective jaws. To prevent the rod from twisting excessively, position the rod in the vise as close as possible to the big-end bore. All information subject to change without notice. 1-129 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 178 10. Using a quick-release caliper (internal measurement 80-120 mm), dial gauge, and holder, measure the inside diameter of the bearing bore (with the shells installed) at three points. All information subject to change without notice. 1-130 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 179 To obtain a correct value for connecting-rod radial play, the diameters of each bearing bore and its corresponding journal must belong to the same repair stage (both must be "standard," "undersize 0.1 mm," etc.). All information subject to change without notice. 1-131 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 180 In the above example, both measurements belonged to repair stage "undersize 0.1 mm." 12. Remove the bearing cap from the connecting rod. 13. Install the piston. Refer to section 1.17.2. All information subject to change without notice. 1-132 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 181 2. Check the bushing bore in the connecting rod. If surface material is missing from the bushing bore, replace the connecting rod. All information subject to change without notice. 1-133 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 182 7. Measure the inside diameter of the bushing. If the measurement is shorter than 52.05 mm (2.049 in.), machine the inside contact surface of the bushing until the measurement is correct. All information subject to change without notice. 1-134 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 183: Egr Piston, Piston Ring, And Connecting Rod

1. Cylinder Liner 3. Installed Piston 2. Carbon Scraper Ring 4. Installed Carbon Scraper Ring Figure 1-104 Removing Carbon Scraper Ring All information subject to change without notice. 1-135 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 184 There are NO arrows on the top of the EGR piston to direct the installation. The piston can be installed in any direction and it will be correct. All information subject to change without notice. 1-136 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 185 5. Check carbon scraper ring for correct fit after installation. 6. Follow remaining steps for piston installation in a non-EGR engine . Refer to section 1.17.2. All information subject to change without notice. 1-137 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 186: Valves

3. Select the first cylinder. Using the engine cranking tool (J 46167 or 407 589 00 63 00), turn the flywheel until the piston in that cylinder is at ignition TDC (top dead center). All information subject to change without notice. 1-138 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 187 4. Adjust the valve lash. See Figure 1-106. Refer to section 1.19.3. 1. Rocker Arm 3. Valve Spring Retainer 2. Valve Bridge Figure 1-106 Valve Lash and Valve Lift All information subject to change without notice. 1-139 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 188 15 mm (0.60 inch) to provide adequate travel for checking the intake valve lift. [b] Set the scale on the dial gauge to "0" (zero). All information subject to change without notice. 1-140 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 189 3. Exhaust Rocker Arm Figure 1-108 Checking Valve Lift, Exhaust Valves [a] Turn the flywheel in a counterclockwise direction until both valves are closed. All information subject to change without notice. 1-141 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 190 Each Cylinder in Firing Order); By type of valve, depending on crankshaft position (see Method Two—Adjust All Valves Using Two Crankshaft Positions). All information subject to change without notice. 1-142 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 191 MBE 4000 SERVICE MANUAL www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru See Figure 1-109 for the cylinder and valve layout on MBE 4000 engines. Figure 1-109 Cylinder and Valve Layout 1.19.2.1 Method One — Adjust Each Cylinder in Firing Order Method one allows you to adjust each cylinder in the order in which fuel is injected. The crankshaft must be repositioned after each cylinder is adjusted as listed in Table 1-35.

- Page 192 2. Cylinder Head Cover 4. Cylinder Head Figure 1-110 Cylinder Head Cover, (exploded view) 2. Remove the inspection cover on the flywheel housing. All information subject to change without notice. 1-144 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 193 6. For each valve, measure the valve lash with a feeler gauge between the rocker arm and valve bridge. It should be possible to pull the feeler gauge through with no more than light resistance. All information subject to change without notice. 1-145 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 194 2. Cylinder Head Cover 4. Cylinder Head Figure 1-112 Cylinder Head Cover, (exploded view) 2. Remove the inspection cover on the flywheel housing. All information subject to change without notice. 1-146 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 195 3. Fit the engine cranking tool (J 46167 or 407 589 00 63 00) into the inspection hole on the flywheel housing. See Figure 1-113 . 1. Inspection Cover 2. Cranking Device Figure 1-113 Placement of the Cranking Tool All information subject to change without notice. 1-147 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 196 6. Using the cranking tool, turn the crankshaft until cylinder #6 is at the ignition TDC position (all valves are closed) and cylinder #1 is at the valve overlap position (all valves are open). All information subject to change without notice. 1-148 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 197 If the value measured is outside the range given in the "Check For" column listed in Table 1-36, adjust the valve lash. 1.19.3 Valve Lash Adjusting Adjust the valve lash as follows: All information subject to change without notice. 1-149 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 198 Measuring Valve Standback Measure the valve standback as follows: 1. Remove the cylinder head from the engine. Refer to section 1.2.1. All information subject to change without notice. 1-150 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 199 Setting the Dial Gauge Preload NOTE: Before doing this procedure, make sure the valve head is making contact with the valve seat. All information subject to change without notice. 1-151 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 200 0.7 mm (0.03 inch), or more than 1.1 mm (0.04 inch), the valve standback is not within specifications. All information subject to change without notice. 1-152 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 201 Remove the intake and exhaust valves as follows: NOTE: The MBE 4000 engine has individual heads for each cylinder. To replace the valves on one head, follow these instructions, step by step. To replace all the valves, repeat these instructions for all six cylinder heads.

- Page 202 4. Attach the valve spring adaptor and remover, (J 46173), to the cylinder head. See Figure1-118. 1. Valve 2. Cylinder Head Figure 1-118 Valve Removal All information subject to change without notice. 1-154 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 203 7. Turn over the cylinder head and remove the valves. NOTE: Mark the valves in order for ease of installation. All information subject to change without notice. 1-155 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 204 8. With the cylinder head again in the upright position, remove and discard the valve stem seals. See Figure 1-120. 1. Valve Stem Seal 3. Cylinder Head 2. Valve Guide Figure 1-120 Valve Stem Seals All information subject to change without notice. 1-156 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 205 12. Check the following critical valve dimensions, and repair as necessary. See Figure 1-122 to determine the dimensions given in the table. Listed in Table 1-42 are the dimensions. Valve stem diameter (A) All information subject to change without notice. 1-157 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 206 Table 1-42 Valve Removal/Installation Specifications in mm (inches) 13. Check the condition of the valve seat insert. Repair the valves if necessary. All information subject to change without notice. 1-158 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 207 1. Remove the cylinder head from the engine. Refer to section 1.2.1. NOTE: Use care during removal to not damage the valve guides and valve stems. All information subject to change without notice. 1-159 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 208 8. Install the collets, spring retainer, valve spring and spring base, as removed. 9. Repeat the procedure for the other valves. 10. Install the cylinder head. Refer to section 1.2.2. All information subject to change without notice. 1-160 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 209: Egr Valves

EGR valves. Valve stem diameter (A) Valve seat diameter at the contact surface of the cylinder head (B) Valve head diameter (C) All information subject to change without notice. 1-161 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 210 Valve length (G) 145.0 (5.71) 145.0 (5.71) 145.0 (5.71) Table 1-44 Valve Removal/Installation Specifications in mm (in.) for non-EGR and EGR engines All information subject to change without notice. 1-162 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 211 7. Install the valve stem sealing ring in the valve guide and then install the valve in the head. Repeat procedure for all remaining valves. All information subject to change without notice. 1-163 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 212 14. Install the keeper, spring retainer, valve spring and spring seat, as removed. 15. Repeat the procedure for the other valves. All information subject to change without notice. 1-164 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 213 (G) Relative position (H) to 4.00-4.15 (0.157-0.163) 3.80-3.95 (0.15-0.16) 4.00-4.15 (0.157-0.163) diameter G Table 1-45 Valve Seat Specifications for EGR Engine All information subject to change without notice. 1-165 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 214: Rocker Arm

3. Inspect the rocker arm assembly for wear. If necessary, disassemble the rocker arm assembly and replace any worn parts. Refer to section 1.21.2. All information subject to change without notice. 1-166 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 215 5. Intake Rocker Arm 2. Washer 6. Locknut 3. Exhaust Rocker Arm 7. Adjusting Screw 4. Rocker Support Figure 1-129 Rocker Arm Components All information subject to change without notice. 1-167 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 216 1. Install a valve bridge on each set of valves, both intake and exhaust. 2. Lubricate each pushrod with a light coating of engine oil. All information subject to change without notice. 1-168 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 217 [c] Tighten each mounting bolt 60 N·m (44 lb·ft). Final angular tightening: 90 degrees. 5. Adjust the valve lash. 6. Install the cylinder head cover on each cylinder head. Refer to section 1.1.2. All information subject to change without notice. 1-169 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 218: Camshaft And Camshaft Sensor

3. Remove the unit pumps. Refer to section 2.1.1. 4. Remove the vibration damper. Refer to section 1.11.1. 5. Remove the fan support. All information subject to change without notice. 1-170 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 219 6. Remove the eight mounting bolts attaching the camshaft front cover to the cylinder block. See Figure 1-130. Figure 1-130 Removing the Camshaft Front Cover All information subject to change without notice. 1-171 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 220 9. Turn the engine on the stand until it is upside down. 10. Remove the oil pan. Refer to section 3.1.1. 11. Remove the flywheel housing. Refer to section 1.16.1. All information subject to change without notice. 1-172 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 221 Attaching the Camshaft Guide Tool 13. From the gear end (rear of the engine), carefully remove the camshaft from the block. See Figure 1-132. All information subject to change without notice. 1-173 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 222 [a] Measure the outside diameter of each tappet. [b] Measure the diameter of the tappet housing in the cylinder block. 16. Inspect the camshaft. Refer to section 1.22.2.1. All information subject to change without notice. 1-174 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 223 [d] Carefully insert the camshaft into the block. 4. Install the flywheel housing. Refer to section 1.16.2. 5. Install the oil pan. Refer to section 3.1.2. All information subject to change without notice. 1-175 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 224 NOTE: To get a correct hardness reading, it is critical to place a hard base below the cam or bearing journal. All information subject to change without notice. 1-176 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 225 A hard base should be placed below the cam or bearing journal to be inspected. See Figure 1-135. 1. Camshaft Figure 1-135 Inspecting Cam Hardness All information subject to change without notice. 1-177 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 226 6. Measure the cam rise of the exhaust valve cams. See Figure 1-136, Ref. E. 7. Measure the cam rise of the unit pump valve cams. See Figure 1-136, Ref. U. All information subject to change without notice. 1-178 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 227 Cam Gear to Crank Gear 0.074–0.176 (0.0029–0.0069) Gear Back Lash Cam Gear to Air Compressor Gear 0.082–0.168 (0.0032–0.0066) Table 1-50 Camshaft Specifications All information subject to change without notice. 1-179 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 228 3. Install a new sensor in the flywheel housing. 4. Connect the electrical connector. NOTE: Be sure that the correct electrical connector is connected to the sensor. All information subject to change without notice. 1-180 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 229 The holes in the camshaft journal must be lined up with the holes in the camshaft bushing. 1. Bushing Groove Figure 1-138 Camshaft Bushing Installation All information subject to change without notice. 1-181 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 230 1.23 EGR CAMSHAFT www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru All information subject to change without notice. 1-182 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

- Page 231 Piston, Piston Ring and Connecting Rod ............1-191 Valves ......................1-193 Rocker Arm ....................1-196 Camshaft and Camshaft Sensor ..............1-197 Sensor and Fittings ..................1-198 All information subject to change without notice. 1-183 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 232: Specifications

The torque specifications for the cylinder head cover are listed in Table 1-51. Description Torque Value Cylinder Head Cover Bolts 20 N·m (15 lb·ft) Table 1-51 Cylinder Head Cover Torque Values All information subject to change without notice. 1-184 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... -

Page 233: Cylinder Head

Engine at Idle Speed 50 kPa (7 psi) Engine at Max. rpm 250 kPa (36 psi) Table 1-56 Oil Pressure Readings All information subject to change without notice. 1-185 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 234 Table 1-59 Compression Pressure Test Data Description N·m (lb·ft) Tensioning Arm Bolts 50 (37) Table 1-60 Tensioning Arm Bolt Torque Values All information subject to change without notice. 1-186 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 235: Cylinder Block

Cylinder Liner Protrusion From Block 0.245–0.315 (0.0096–0.0124) Difference Between the Four Measuring Points Max.: 0.02 (0.0007) Table 1-64 Specifications for Measuring Cylinder Liner Protrusion All information subject to change without notice. 1-187 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... -

Page 236: Crankshaft Assembly

Undersize - 0.50 (0.020) 46.24-46.31 (1.820-1.823) 46.500-46.562 (1.8307-1.8331) Undersize - 1.00 (0.040) 46.74-46.81 (1.840-1.843) 47.000-47.062 (1.8504-1.8528) Table 1-67 Bearing Shell and Bearing Journal Width All information subject to change without notice. 1-188 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 237 71.20 mm (2.803 in.) Stage 1 150 (111) (2.754 - 2.756 in.) Stage 2 Additional 90 Table 1-71 Torque Values for Crankshaft Counterweight Bolts All information subject to change without notice. 1-189 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 238: Flywheel And Flywheel Housing

Flywheel Housing Mounting Bolts (to cylinder block) 70 (52) Vibration Damper Mounting Bolts (to crankshaft) 200 (148) Table 1-74 Torque Values for Flywheel and Flywheel Housing All information subject to change without notice. 1-190 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... -

Page 239: Piston, Piston Ring And Connecting Rod

Piston Compression Height 79.50-79.55 (3.130-3.132) Wrist Pin Bore Diameter 52.03-52.04 (2.0484-2.0488) Wrist Pin Diameter 51.992-51.998 (2.0469-2.0472) Table 1-78 Piston Inspection Specifications All information subject to change without notice. 1-191 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru... - Page 240 Undersize - 0.75 (0.030) 93.304-93.346 (3.6764-6.6750) Undersize - 1.00 (0.040) 93.054-93.096 (3.6635-3.6652) Table 1-82 Bearing Bore Inside Diameter with Bearing Shells Installed All information subject to change without notice. 1-192 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION www.rtrucks.ru www.rtrucks.ru www.rtrucks.ru...

-

Page 241: Valves