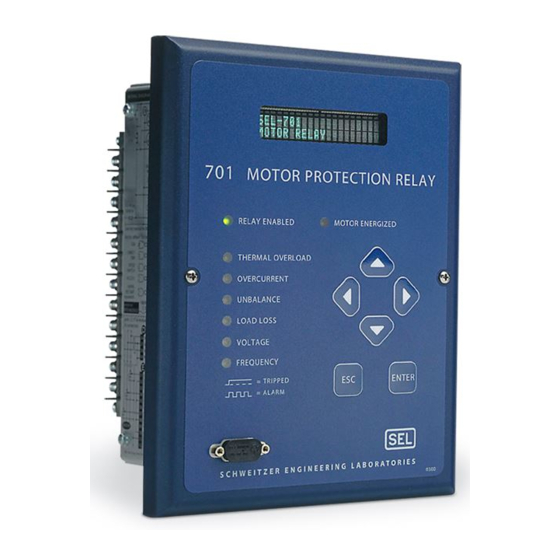

Schweitzer Engineering Laboratories SEL-701 Manuals

Manuals and User Guides for Schweitzer Engineering Laboratories SEL-701. We have 1 Schweitzer Engineering Laboratories SEL-701 manual available for free PDF download: Instruction Manual

Schweitzer Engineering Laboratories SEL-701 Instruction Manual (468 pages)

Motor Protection Relay

Brand: Schweitzer Engineering Laboratories

|

Category: Relays

|

Size: 4.04 MB

Table of Contents

-

Introduction17

-

-

Introduction23

-

Table 1.125

-

Table 1.226

-

-

-

-

Table 2.155

-

-

Introduction65

-

General Data68

-

Table 4.168

-

-

-

-

Table 5.1123

-

-

Introduction145

-

You will Need146

-

Table 6.3150

-

Command Summary152

-

Table156

-

-

-

-

-

Introduction199

-

Measured Values200

-

Table 8.1200

-

Table 8.2201

-

-

-

Load Profiling205

-

-

-

Introduction213

-

Event Reports219

-

Event Commands220

-

Table 9.2220

-

-

-

Table 9.6225

-

-

-

Self-Testing235

-

Ogic247

-

-

Stop/Trip Logic267

-

-

-

CASCII Command366

-

CSTATUS Command370

-

CHISTORY Command371

-

CEVENT Command372

-

CME E Command374

-

CME M Command375

-

-

Introduction377

-

-

Glossary443

-

Index453

Advertisement

Advertisement

Related Products

- Schweitzer Engineering Laboratories SEL-700G Series

- Schweitzer Engineering Laboratories SEL-700G0

- Schweitzer Engineering Laboratories SEL-700G1

- Schweitzer Engineering Laboratories SEL-700GT

- Schweitzer Engineering Laboratories SEL-700GW

- Schweitzer Engineering Laboratories SEL-751

- Schweitzer Engineering Laboratories SEL-787-3

- Schweitzer Engineering Laboratories SEL-787-4

- Schweitzer Engineering Laboratories SEL-787-2X

- Schweitzer Engineering Laboratories SEL-787-21