Table of Contents

Advertisement

2WSA

Operator's

Manual

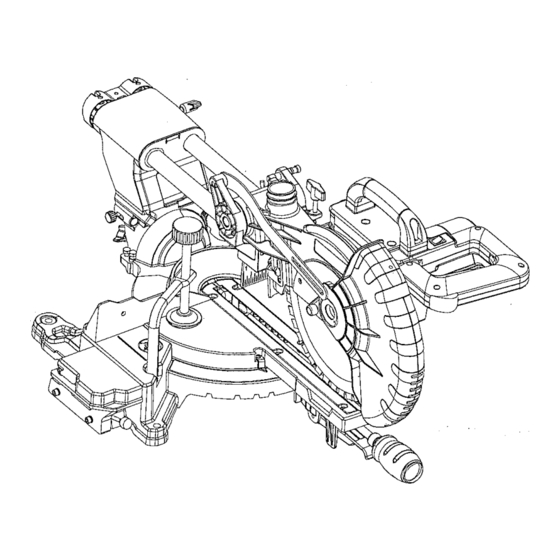

10 in. SLiDiNG COMPOUND

MITER SAW WiTH LASER TRAC ®

Model No. 137.212371

CAUTION:

Before using this Miter Saw,

read this manual and follow

all its Safety Rules and

Operating Instructions

0

Safety Instructions

•

Installation

0

Operation

0

Maintenance

0

Parts List

Customer

Help

Line

For Technical

Support

t-800-843-t

682

Sears

Parts

&

Repair

Center

t-800-488-t

222

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Visit our Craftsman

website: www,sears.com/craftsman

Part No. __'_

Printed in China

P/N

2WSA

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Craftsman 137.212371

- Page 1 Safety Rules and Parts List Operating Instructions Sears Parts & Customer Help Line For Technical Support Repair Center t-800-843-t t-800-488-t Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA Visit our Craftsman website: www,sears.com/craftsman Printed in China Part No. __'_ 2WSA...

- Page 2 Operation ....................Maintenance ....................Troubleshooting Guide ................Parts List ............:........... Repair Protection Agreement..:............... CRAFTSMAN FULL WARRANTY If this Craftman product fails due to a manufacturer's defect inmaterial or workmanship with one year from the date of purchase, return it to any Sears store or other Craftman outlet in the United States for free replacement.

-

Page 3: Miter Saw

MOTOR Power Source ..............120V AC, 60Hz, 15 Amp Arbor Shaft Size ............5/8 in. Speed ................4800 RPM (No load) Brake ................Electric Double Insulated ............. MITER SAW Rotating Table: 'MiterDetent Stops ............0°, 15°, 22,5°, 31.6°, 45° R & L Bevel Positive Stops ............ -

Page 4: Symbols

WARNING ICONS Your power tool and its Operator's Manual may contain "WARNING ICONS" (a picture symbol intended to alert you to, and/or instruct you how to avoid, a potentially hazardous condition). Understanding and heeding these symbols will help you operate your tool better and safer. Shown below are some of the symbols you may see. -

Page 5: Power Tool Safety

GENERAL SAFETY INSTRUCTIONS KEEP CHILDREN AWAY. All BEFORE USING THIS POWER TOOL visitors and bystanders should be kept a safe distance from work area. Safety is a combination of common sense, staying alert and knowing how MAKE WORKSHOP CHILD PROOF to use your power tool. - Page 6 12.ALWAYS W EAREYE 17.USE RECOMMENDED ACCESSORIES. Consult tool can throw foreign this Operator's Manual for PROTECTION. Any power recommended accessories. The use objects into the eyes and could cause permanent of improper accessories may cause eye damage. ALWAYS wear Safety risk of injury to yourself or others.

-

Page 7: Maintain Tools With Care

22.MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance. Follow instructions for lubricating and changing accessories. 23.WARNING: Dust generated from certain materials can be hazardous to your health. Always operate saw in well-ventilated area and provide for proper dust removal. - Page 8 SPECIFIC SAFETY INSTRUCTIONS ALWAYS MAKE SURE all handles FOR THIS COMPOUND MITER SAW are tight before cutting, even if the table is positioned in one of the IMPORTANT: DO NOT USE positive stops. THIN KERF BLADES. They can 10.MAKE SURE both the blade and deflect and contact the blade guard the collar are clean and the arbor and cause possible injury to the...

- Page 9 20.MAKE SURE thebladehascome 25.NEVER use solvents to clean plastic toa complete s topbeforeremoving parts. Solvents could possibly or securing theworkpiece, changing dissolve or otherwise damage the material. theworkpiece a ngleor changing t he angleoftheblade. 26.SHUT OFF the power before servicing or adjusting the tool. .NEVER cut metals or masonry products with this tool.

-

Page 10: Product Specifications

POWER SUPPLY AND MOTOR way. If the plug does not fit fully in the SPECIFICATIONS outlet, reverse the plug. If it still does The AC motor used in this saw is not fit, contact a qualified electrician to a universal, nonreversible type. install the proper outlet. -

Page 11: Guidelines For Extension Cords

4. FUSES may "blow" or circuit Use a separate electrical circuit breakers may trip frequently if: for your tools. This circuit must not be less than a #14 wire with a 15 A a. MOTOR is overloaded - overloading can occur if you feed time lag fuse. -

Page 12: Recommended Accessories

RECOMMENDED ACCESSORIES should be taken while mounting, using, and storing carbide tipped [,_WARNING blades to prevent accidental ® Use only accessories damage. Slight shocks, such as recommended for this miter striking the tip while handling, saw. Follow instructions that can seriously damage the blade. accompany accessories. - Page 13 Supplied Notsupplied Blade Wrench Adjustable Wrench Phillips Screwdriver Hex Wrench ..Slotted Screwdriver Combination-Square-- COMBINATION SQUARE MUST BE TRUE _ ..Should not gap or overlap when square is flipped over (see dotted figure)..Draw light lineon Straight edge or a 3/4 in. board, this edge must be perfectly straight.

- Page 14 UNPACKING YOUR MITER SAW Separate all parts from the packing material. Check each one with the illustration to make certain all [_WARNING items are accounted for, before To avoid injury from unexpected discarding any packing material. starting or electrical shock, do not plug the power cord into a source [AWARNING I of power during unpacking and...

- Page 15 Carrying Handle Upper Blade Guard LaserON/OFF Switch Bevel D etent P in SwitchHandle Bevel L ocking Handle Hold-Down C lamp ON/OFF Trigger S witch, Mounting Hole Blade Laser Guide Base Miter Handle Hold Down Latch Dust Exhaust Port \Slide Carriage Safety Lock Slide Carriage Lock Knob...

- Page 16 AMPERAGE (AMPS) - A measure eyes. Eye protection should meet the of the flow of electric current. Higher requirements of ANSI Z.87.1 (USA) or CSA Z94.3-M88 (Canada). ratings generally means the tool is suited for heavier use. FACE SHIELD - An impact resistant ARBOR LOCK - Allows the user to shield that helps to protect your face from chips, sparks, small debris.

- Page 17 -i!f :!ii_i L :k;! :ii ' ::!::'; :!?_::! :_"-"T :??':_ : ¸ ¸ " :L • • KICKBACK- Sudden and unintended POSITIVE STOP LOCKING LEVER - movement of the tool or workpiece. It is Locks the miter saw at a preset positive typically caused by binding or pinching stop for the desired miter angle.

-

Page 18: Assembly

Estimated Assembly Time: 5-10 SAW BLADE WRENCH (FIG. C) minutes 1. For convenient storage and prevention of loss, there is a slot (1) ,_WARNING in the rear of the carrying handle (2) for storing the blade wrench (3) To avoid injury, do not connect when not in use. - Page 19 Locking [AWARNING1 Whentransporting or storing themiter When using stop block on the right saw,thecutting headshould always be locked inthedownposition. side, hold-down clamp must also be 1. Push thecuttinghead downtoits in right side. Using hold-down clamp on the left side during this operation lowest p osition.

-

Page 20: Mounting The Miter Saw

® Donotstartthesliding compound ® To avoid back injury, lift the saw mitersawwithout c hecking for by using the designated carrying interference between the bladeand handles located on the top of the tableinsert. D amage couldresult t o machine. When lifting, bend at theblade, t ableinsert o r turntable if your knees, not from your back. - Page 21 For portable use, place the saw on a 3/4 in. thick piece of plywood. Bolt Fig. K the base of the miter saw securely to the plywood using the mounting holes on the base. Use C-clamps to clamp this mounting board to a stable work surface at the worksite.

- Page 22 the blade into the lower table Installing Blade (Fig. K, L, M) and check for any contact with Unplug the miter saw before changing/ the base or the miter table by installing the blade. spinning the blade manually. 1. Install a 10 in. blade with a 5/8 in. arbor, making sure the rotation arrow THE LASER GUIDE (FIG.

- Page 23 o Laser beam is calibrated and set up ® Laser Aperture Label: AVOID EXPOSURE: Laser to project to the left of the blade. radiation is emitted from this (Fig. N-l) aperture. (Fig. N-2) ® If you have any problem or question on the laser guide, please call the AVOID EXPOSURE Service Center.

-

Page 24: Bevel Stop Adjustment

BEVEL STOP ADJUSTMENT Fig. 0 ,_WARNING To avoid injury from an accidental start, make sure the switch is in the OFF position and the plug is not connected to the power source outlet. 90 ° Bevel adjustment (Fig. O) 1. Loosen bevel lock handle (1) and tilt the cutting arm completely to the right. -

Page 25: Miter Angle Adjustment

4. Tiltthecutting armtotheleftto45° Follow the process below for quickest bevel a ndrecheck f oralignment. and most accurate adjustments. 5. Repeat steps1 through 4 untilthe bladeis at45° to themiter table. 1. Unlock the miter table by turning the 6. Tighten bevel l ockhandle (7) miter handle (1) counterclockwise. -

Page 26: Adjusting Fence Squareness

ADJUSTING FENCE SQUARENESS Fig. T (FIG. S) 1. Loosen the four fence locking bolts (1). 2. LOWER THE CUTTING ARM AND LOCK IN POSITION. 3. Using a square (3), lay the heel of the square against the blade and the ruler against the fence (2) as shown. -

Page 27: Electrical Requirements And Safety

SAFETY INSTRUCTIONS FOR BASIC ® Tighten the arbor bolt. SAW OPERATIONS ® Tighten the cover plate screw. ® Check for damaged parts, check for: BEFORE USING THE MITER SAW e Alignment of moving parts [,_WARNING ® Damaged blade teeth To avoid mistakes that could cause ®... -

Page 28: Plan Your Work

• :, <:_-:::_--,, i_:_¸ : _:_Lt" • ,: _._ _ : accessories may cause risk of [ &WARNINGJ injury. This machine is NOT designed ® Choose the correct 10 in. blade for cutting masonry, masonry products the material and the type of cutting or ferrous metals (steel, iron and you plan to do. - Page 29 DONOTOVERREACH ® When cutting odd shaped workpieces, Keepgoodfooting andbalance. Keep plan your work so it will not bind in the yourfaceandbodytooneside,outof blade and cause injury. Molding, for thelineofa possible kickback. NEVER example, must lie flat or be held by standinthelineoftheblade. a fixture Or jig that will not let it move when cut.

-

Page 30: Troubleshooting

BODY AND HAND POSITION (FIG. U) Fig. U cutting area. Proper Never place hands near the positioning of your body and hands when operating the miter saw will make cutting easier and safer. Keep children away. Keep all visitors at a safe distance from the miter saw. -

Page 31: Before Leaving The Saw

Themitersawis equipped w ithan Fig. W automatic b ladebrake. W henthe trigger s witchis released, theelectric bladebrakewillstopthebladewithin approximately 6 seconds. _WARNING To avoid injury, after completing a cut and releasing the trigger switch, allow the blade brake to activate and stop the blade before raising the BEFORE LEAVING THE SAW cutting head. - Page 32 Fig. X 3. Rotate the cutting head until the bevel detent pin stops the bevel angle at 33.9 ° on the bevel scale. 4. Tighten the bevel lock handle before making a cut. Fig. Z BEVEL CUT (FIG. Y) 1. When a bevel cut is required, loosen the bevel lock handle (1) by turning it clockwise.

- Page 33 SLIDE CUTTING WIDE BOARDS UP Fig. BB TO 12 in. WIDE (FIG. BB) ,_WARNING To avoid injury: o Never pull the cutting head assembly and spinning blade toward you during the cut. The blade may try to climb up on the top of the workpiece, causing the cutting assembly and spinning blade to kick back, forcefully.

-

Page 34: Cutting Bowed Material

CUTTING BOWED MATERIAL AUXILIARY WOOD FENCE (FIG. FF) When making multiple or repetitive cuts (FIG. DD) that result in cut-off pieces of one inch A bowed workpiece must be positioned or less, it is possible for the saw blade against the fence and secured with to catch the cut-off piece and throw it a clamping devise before cutting as out of the saw or into the blade guard... -

Page 35: Cutting Crown Molding

1. Always makesuremoldings r est When setting the bevel and miter firmlyagainst fenceandtable.Use angles for compound miters, remember hold-down o r C-clamps, whenever that the settings are interdependent - possible, andplace tapeonthearea changing one changes the other, as beingclamped to avoidmarks. well. -

Page 36: Type Of Cut

BEVEL MITER TYPE OF CUT SETTING SETTING Inside corner-Left side 33.9 ° 31.6 ° Right 1. Position top of molding against fence. 2. Miter table set at RIGHT 31,6 °. 3. LEFT side is finished piece. Inside corner-Right side 33.9 ° 31.6 °... -

Page 37: Crown Molding

CROWN MOLDING CHART Compound Miter Saw Miter and Bevel Angle Settings Wall to Crown Molding Angle 52/38= Crown Molding 45/45' Crown Molding 52/38 = CroWn Molding 45/45=Crown Molding Angle Between _ter Setting Beve! Setting Miter 5elting Bevel Se_ng Angle Between Miter Setting Bevel Setting Miter Setting... -

Page 38: Maintenance

MAINTENANCE Fig. JJ DANGER] Never put lubricants on the blade while it is spinning, [,_WARNJNG ® To avoid fire or toxic reaction, never use gasoline, naphtha acetone, lacquer thinner or similar highly volatile solvents to clean the miter saw. ® To avoid injury from unexpected LOWER BLADE GUARD starting or electrical shock, Do not use the saw without the lower... - Page 39 LUBRICATION ( FIG. K K) Fig, KK All the motorbearings in this toolare Link lubricated with a sufficient a mountof high-grade lubricant f or the life of the unitunder normal o perating conditions; Link therefore, no further lubrication is required. Chop Lubricate t hefollowing a s necessary: Central pivot...

-

Page 40: I'roubleshooting

I,AWARNINGJ To avoid injury from accidental starting, always turn switch OFF and unplug the tool before moving, replacing the blade or making adjustments. I'ROUBLESHOOTING GUIDE - MOTOR SUGGESTED CORRECTIVE PROBLEM PROBLEM CAUSE ACTION Brake does not Motor brushes not sealed 1. -

Page 41: Eye Protection

_.WARNING To avoid injury from accidental starting, always turn switch OFF and unplug the tool before moving, replacing the blade or making adjustments. TROUBLESHOOTING GUIDE - SAW OPERATION : SUGGESTED CORRECTIVE _ PROBLEM CAUSE PROBLEM ACTION Blade hits table. 1. Misalignment. 1. -

Page 42: Parts List

MODEL NO. 137.212371 I,AWARNING When servicing use only CRAFTSMAN replacement parts. Use of any other parts many create a HAZARD or cause product damage. Any attempt to repair or replace electrical parts on this Miter Saw may create a HAZARD unless repair is done by a qualified service technician. - Page 43 10 IN. SLIDING COMPOUND MITER SAW MODEL NO. 137,212371 SCHEMATIC "T"...

- Page 44 MODEL NO. 137.212371 10 IN. SLIDING COMPOUND MITER SAW PARTS LIST FOR SAW SCHEMATIC I.D. Description Size Q_ I.D. Description Size 07WD SLIDE PLATE KNOB 2C8T 084W WARNING LABEL 2CD2 COMPRESSION SPRING 091S COMPRESSION SPRING 2DWJ TABLE INSERT 0CPD CENTER BOLT 2DWK TABLE INSERT 2DWL...

- Page 45 10 IN. SLIDING COMPOUND MITER SAW MODEL NO. 137.212371 SCHEMATIC 2VEP OJE7 2WEB 2VN6 OJM f _OK7X 2W9C 26LU 2VN3 DJ7G 2KHE 2VH6 2VNI OJBG OJ4M OKDU OKD82 2WUV OKD76...

- Page 46 10 IN. SLIDING COMPOUND MITER SAW MODEL NO. 137.212371 PARTS LIST AND SCHEMATIC FOR MOTOR I.D. Description Size OHX9 NEEDLE BEARING OJCD SPRING PIN OJX2 HEX.-SOC SETSCREW M5xO.8-6 0K43 CR.RE. PAN HD. SCREW & WASHER M5"0.8-16 0K44 CR.RE. PAN HD. SCREW & WASHER M5"0.8-12 OKBC CR.RE.

-

Page 47: Repair Protection Agreement

Congratulations on making a smart purchase. Your new Craftsman® product is designed and manufactured for years of dependable operation. But like all products, it may require repair from time to time. That's when having a Repair Protection Agreement can save you money and aggravation. - Page 49 Your Home For expert troubleshooting and home solutionsadvice: manage www.managemyhome.com For repair- in your home - of all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it! For the replacement parts, accessories owner's manuals that you need to do-it-yourself.

Need help?

Do you have a question about the 137.212371 and is the answer not in the manual?

Questions and answers