Table of Contents

Advertisement

Quick Links

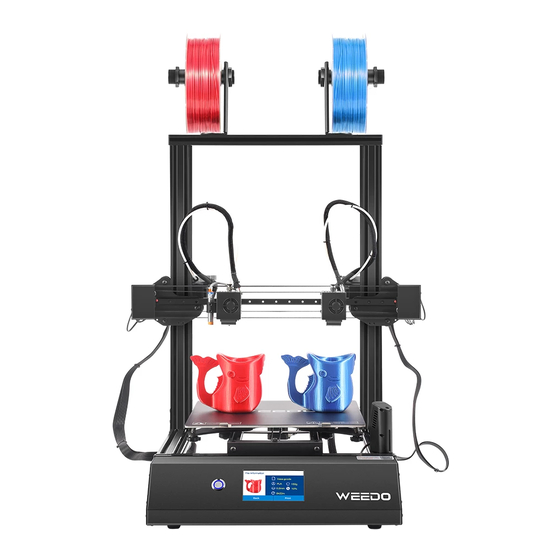

X40/X40V2 3D Printer

Quick Start Guide

INTRODUCTION

Thank you for purchasing this X40/X40V2 3D Printer! This printer uses the FFF (Fused Filament Fabrication) method of

printing. It features a metal frame, open structure design and heated build platform. It can print 1.75mm ABS, PLA,

Metal fill, Wood fill, and other filament types with melting points below 250°C (Default hot end). The machine with

independent dual extruders can print at a speed up to150mm/s and 300x300x400mm printing area. It can print from

sliced g-code files stored on a micro SD™ card or from our App (Poloprint Pro). It supports auto-leveling, automatic

shut-down, with a 4.3-inch touch screen, a removable and a heated build plate.

CUSTOMER SERVICE

The WEEDO Customer Service department is dedicated to ensuring that your ordering, purchasing, and delivery

experience is second to none. If you have any problem with your order, please give us an opportunity to make it right.

You can contact a WEEDO Customer Service representative through the Live Chat link on our website

www.weedo.ltd

or via email at support@weedo3d.com. Check the website for support times and links. You can also search our

product wiki

website: www.weedo3dprinter.com.

Advertisement

Table of Contents

Summary of Contents for WEEDO X40

- Page 1 Quick Start Guide INTRODUCTION Thank you for purchasing this X40/X40V2 3D Printer! This printer uses the FFF (Fused Filament Fabrication) method of printing. It features a metal frame, open structure design and heated build platform. It can print 1.75mm ABS, PLA, Metal fill, Wood fill, and other filament types with melting points below 250°C (Default hot end).

- Page 2 NOTES The temperature of the nozzle parts Children are not allowed Pay attention to the voltage and platform can reach 250°C .It is Please check whether the input voltage forbidden to touch while the printer value of the switching power supply meets is printing or cooling.

-

Page 3: Parts List

PARTS LIST... -

Page 4: Left View

OVERVIEW Left view 12 13 Right view 11. Filament Holder 1. Left X End Stop Sensor 6. Wi-Fi Camera Module 12. Power Interface 2. Proximity 7. Build Platform 13. Power switch 3. Left Extruder 8. Nozzle brush 14. TF slot 4. - Page 5 Step 1: Open the accessory box and get the frame base 1. Cut the tie on the frame base. 2. Tear off the tape and make sure the platform does not move. 3. Check that the four Leveling Nuts are not falling off. Tighten them. 1x 3D printer Frame...

- Page 6 Step 2: Install the Z/X Gantry onto the base 3. Screw the M5X25 into the hole with an L-shaped 2. Take a foam on the 4.0mm wrench. right side of the base. Tips: If it's deformed,you can align the Gantry with the base so that the screw goes into the screw hole.

- Page 7 Step 3: Install T-shaped fixtures on both sides of the printer 1. Install screws and T-nuts 2. Insert the long side of on T-shaped fixtures by the 2.5mm L-shaped hand. wrench into the screw cap. No.2Bag: 1x 2.5 mm L Wrench No.3Bag: 3.

- Page 8 Step 4: Connect the Y and Z Motor Cable and Extruder Cable 1. Connect the Y Motor Cable on the back of the host, check the Y end 2. Plug the motor cable and sprinkler stop sensor is installed properly. cable on both sides of the printer respectively.

- Page 9 Step 5: Install the WIFICAM module 1. Insert the M3X45 screw into the WIFICAM module with the long edge of the L-shaped wrench. Tips: Hide the cables so the platform 2. Screw the T-nut on the won't scratch them M3X45 screw by hand. No.2Bag: 1x WIFICAM 3.

- Page 10 4x M4*6Screw 4x T-Nut Tips: The filament holder installation location shown below is recommended by WEEDO X40 users. If your machine has limited space, you can also install the holder on the aluminum profile bar at the top of the printer.

- Page 11 Step 7: Install the Nozzle Brush 1. Install the Nozzle brush module to the printer. No.6Bag: 2x Brush Module 4x M3*6Screw 1x 2.0mm L Wrench 2. In the installation progress, the brush module can be adjust up and down, make sure the brass nozzle is about 1mm under the white Teflon sheet, Teflon sheet can wipe the nozzle slightly.

-

Page 12: Step 8: Check Before Power On

Step 8: Check before Power On 1. Press and hold the black plastic edge on the connector. 2. Insert the Teflon tube to the bottom, the insert distance is about 3.5 CM. Tips: Be sure to insert the Teflon tube into the bottom,so it does not fall off. -

Page 13: Step 9:Load The Filament

Step 9:Load the filament 2. For better printing,cut a 1. Hang the filaments on 3. Straighten the 45-degree slope at the end the filament holder. end of the filament. of filament with pliers. 4. Press the handle of extruder 5. Pull filament into the wire tube. to pull filament pass through. - Page 14 Step 10: Check the tightness of the belt and the Voltage 1. Press the belt with your hand, and the belt has a certain degree of elasticity. 2. There is a voltage switch button on the back of the printer chassis. Use the wrench to toggle the switch to the RIGHT local voltage Before powered on.

- Page 15 Step 11: Check the Z/X Gantry Assembly is horizontal 1. Place two positioning blocks on the left and right sides of aluminum profiles. 2. Use two fingers to turn the left and right coupling on the Z motor at the same time. 3.

- Page 16 Step 12: Check the Left hot end and Right hot end at the same height 1. Install the positioning block on the linear guide. 2. Move the left and right extruder to the positioning block, and check whether the installation height of the hot end is the same.

-

Page 17: Printer Calibration

Printer calibration Step 1: Turn On The printer 1. Plug the power cord into the socket. 3. Click the metal switch on 2. Press the switch from the front panel. 4.Select the language you need. Tips: Please unplug the 3D Printer if it will not be in use for a while. -

Page 18: Step 2: Bed Leveling

Step 2: Bed Leveling 1. After the self-test is completed, you will enter the main interface.Perform the bed leveling, 2. Click on ‘Maintenance’--‘Next’--‘Level Bed’. 3. Prepare an A4 paper. The nozzle will test 4 points on the platform. Down 4. At each point, adjust the nut to allow the distance between the nozzle and the platform is the thickness of A4 paper. - Page 19 Step 3: Z-Offset 1. Set the gap between the nozzle and the platform. Prepare an A4 paper. 2. Click on ‘Maintenance’---‘Next’--‘Z Offset’. 3. Click the ‘Up’ or ‘Down’ button in the Z Offset interface, then the nozzle will move in the direction accordingly. Ensure that the gap between the nozzle and the platform is a distance of the thickness of A4 paper.

-

Page 20: Printing Test

Printing test 1. The card has a test model that we prepared for you before delivery. 2. Please select the file in the TF card for printing. No.7Bag: 1x TF card Tips: Please make sure that the metal of the TF card faces up to prevent damage to the machine motherboard. Don't let it fall. - Page 21 XY Offset Setting Required in replacing the nozzle or two-color modules that are not aligned Step 1: Nozzle Coarse tune 1. Loading two-color filament in the left and right nozzle, which is easy to observe. 2. Set XY Coarse X to 3(353), Y to 3(0) 3.

- Page 22 Step 2: Nozzle Fine Tuning 1. Print the Gcode NozzleFintTune.gcode and set the XY Fine Tune 2. Find the small offset in X (the horizontal direction) and Y(the vertical direction), in the example printing the X Y smallest offset is both 3.

- Page 23 Question 1: What if the nozzles clog? Error Diagnosis:Check the feedrate, temperature,and tube insertion. Solution: Dredge the nozzle,Please remove the fan above the nozzle,and then heat the nozzle to 230℃ and carefully pull out filament with pliers. Set the parameters of TPU, and insert the Heat Break. Reinsert or replace Hotend. If the problem still cannot be solved, You can search website: www.weedo3dprinter.com.

- Page 24 Question 5: What if the machine is deformed or falling off for transportation? Error Diagnosis:Examine the problem area Solution: Replace the parts. Question 6: What if model does not stick to platform or difficult to remove? Solution: If the gap between the nozzle and the platform is too large, the model will not stick to the platform. If the nozzle clearance is too small, the model will adhere too tightly to the platform.Please use Z Probe Offset to adjust the gap between the nozzle and the platform,or stick it on platform with a glue stick.

Need help?

Do you have a question about the X40 and is the answer not in the manual?

Questions and answers