Advertisement

Advertisement

Table of Contents

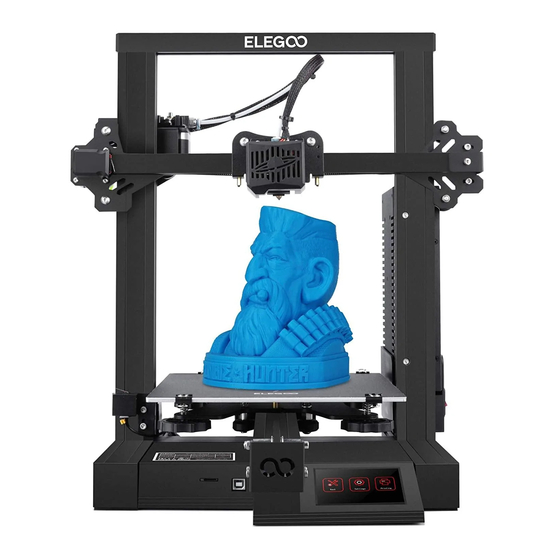

Summary of Contents for Elegoo Neptune 2

- Page 1 User Manual for Neptune 2 3D Printer...

- Page 2 For questions or problems not covered in this manual, please contact us at this email address: 3dp@elegoo.com. ELEGOO team is always ready to provide you with quality service. To give you a better experience of our products, you can also gain knowledge of the operation of the equipment in the following ways:...

- Page 3 Cautions 1. Do not place the printer in vibrating or other unstable environments, as the shaking of the machine will affect the print quality. 2. Do not touch the nozzle and heatbed when the printer is working to prevent high-temperature scald and personal injury.

-

Page 4: Table Of Contents

Contents Machine Parameters ---------------------------------------------------- Machine Structure Diagram -------------------------------------------- Packing List ---------------------------------------------------------------- Machine Installation ------------------------------------------------------ Operation Screen Introduction ---------------------------------------- Platform Leveling --------------------------------------------------------- Model Test ------------------------------------------------------------------ Software Installation ----------------------------------------------------- Online Print ---------------------------------------------------------------- Troubleshooting Guide ------------------------------------------------- Circuit wiring --------------------------------------------------------------... -

Page 5: Machine Parameters

Machine Parameters Print Parameters Software Parameters Print Principle:FDM(Fused Deposition Modeling) Slicer Software:Cura Build Volume:220X220X250(mm³) Input Format:STL、OBJ Print Precision:±0.1mm Output Format:Gcode Nozzle Diameter:0.4mm Connection Type:TF Card、USB Wire Print Speed:30~180mm/s(60mm/s is recommanded) Power Supply Parameters Temperature Parameters Power Input:100-120V/200-240V Power Output:24V Ambient Enviroment Temperature:5°C~40°C Physical Parameters Maximum Temperature of... -

Page 6: Machine Structure Diagram

Machine Structure Diagram Filament tube Filament holder PTFE tube X-axis limit Power switch X-axis supply X-axis stepper Nozzle kit slave kit Build Z-axis limit Platform Power Switch switch Z-axis Y-axis limit stepper Y-axis switch slave kit Extruder stepper Touch screen Y-axis stepper leveling nut... -

Page 7: Packing List

Packing List Spanner (HM5*25)4pcs (HM5*45)4pcs (PM4*18)4pcs (KM4*20)2pcs (HM4*20)2pcs (HM4*18)2pcs (SW M4)2pcs ELEGOO Neptune 2 3D Printer Tools... -

Page 8: Machine Installation

Machine Installation (HM4*20)2pcs+(SW M4) 2pcs The TF card of the machine comes with an installation instruction video. The end with long holes distance The end The end with with holes short holes of the distance aluminum profile should face down (HM5*45)4pcs... - Page 9 Installation height is about 5mm (HM4*18)2pcs (KM4*20)2pcs...

- Page 10 (PM4*18)2pcs The end with long holes distance The end with long holes distance The end with short holes distance...

- Page 11 (PM4*18)2pcs Belt chute Tighten the synchronous belt Mounting the and lock the screws synchronous belt around the bearing...

- Page 12 (HM5*25)4pcs...

-

Page 14: Operation Screen Introduction

Operation Screen Introduction Main Menu Tool:Click to enter the tool interface, the machine can be tested to preheating, leveling, moving, extruding, etc. Settings:Click to enter the settings interface to set the language and fan or query the firmware version as required. Printing:Click to enter the printing interface, select the print file, and then start printing. - Page 15 Operation Screen Introduction Settings Interface Fan:Control side fan operation. About:Check the firmware version. Language:Click to change languages: Japanese, German, English, Russian, Spanish, French, Chinese. Motoroff:Turn off the stepper that is running or free a locked stepper. Continue:Continue printing at a certain layer position of the model. Printing Interface File:Select the model file and comfirm to start printing.

- Page 16 Description of Special Function: Continue: l This function allows you to resume printing if you want to continue printing after the model has been interrupted by a misoperation. l First click 【Tool】-【Home】, observe if the model will collide by setting the X/Y/Z axis to zero in sequence.

- Page 17 Continue:If you want to continue printing because of a sudden power outage or accidentally turn off the power of the machine, this function does not need to be set manually. When the printer is reconnected to the power supply and turned on, just click resume to continue. Filaments Detection:This function is designed to effectively prevent the model from being scrapped after running out of filaments during the printing...

-

Page 18: Platform Leveling

Platform Leveling l In the process of printing, we need to level the platform in order to make the base of the model stick to the build platform and not falling off. l The best distance between the nozzle and the platform is 0.1mm- 0.2mm, and you need to prepare an A4 paper to assist in leveling. - Page 19 Supplymentary Introduction of Leveling Special Case 1: ①:When the machine returns to zero, the nozzle is far lower than the platform. (Even if the four leveling nuts below the platform are tightened, the nozzle is still pressing against the platform.) ②:When the machine returns to zero, the nozzle is far higher than the platform.

-

Page 20: Model Test

Model Test Extrusion inspection Push the filaments to the bottom of the print head. Click【Tool】- 【Extrude】 , and then click 【In】, the nozzle temperature will be automatically heated to 200°C. After the nozzle is preheated to 200°C, click [In], and the filaments can be spun out normally from the nozzle. -

Page 21: Software Installation

The software installation steps are as follows: Open the TF card of the machine to select the path \ Software and Software Drivers folder \ ELEGOO Software folder \ Double-click the ELEGOO-Cura-4.7.0-win64 application to install it. - Page 22 Other operation tips: Instructions for Use ① Scroll the middle mouse wheel to zoom the viewpoint, and hold down the middle wheel to move the platform position. ② Press and hold the right mouse button to move the mouse to change the viewpoint. ③...

-

Page 23: Online Print

Online Print l Connect the printer and computer with USB cable, double-click to open the slicing software, select the corresponding model and then click on the monitor, if the interface shows a blank then it proves that the connection is not successful, you need to install the driver. l The driver installation method is as follows: Open the profile of the TF card to select the path \ Software and Software Driver Folder \ Software Driver Folder \ CH340G USB Driver Folder \ Double- click the [DRVSETUP64] file to run it and click to install it. - Page 24 After the driver installation is complete, reconnect the USB cable, open the ELEGOO slicing software, and then click on the monitor, if it display the printer model and other information, the computer has been successfully connected. l After importing the model, set the print temperature, layer thickness and other relevant information, and then click on the 【slice】, select the USB online printing.

-

Page 25: Troubleshooting Guide

Troubleshooting Guide A stepper of the X/Y/Z axis is not moving or making a noise when zeroed ① The stepper cable is loose. Please recheck the wiring connection. ② The corresponding limit switch does not trigger properly, please check whether there is any interference in the movement of the corresponding shaft and whether the limit switch wire is loose. -

Page 26: Circuit Wiring

Circuit wiring X axis Y axis Z axis E axis E1 axis stepper stepper stepper stepper stepper Laser fan Laser signal Model fan X- axis limit switch Y- axis limit switch Main board fan/print head fan Z- axis limit switch Heating head interface Filament detector BL -TOUCH... - Page 27 After-sales service registration card 售后服务登记卡 Place of purchase Date of purchase : : 购买地点 购买日期 Printer : : 机器 序列号 Fault description : 故障描述 Contact Phone number 联系人: 电话号码: Address 地址:...

- Page 28 ELEGOO website:www.elegoo.com...

Need help?

Do you have a question about the Neptune 2 and is the answer not in the manual?

Questions and answers