Wood-mizer LT10 Safety, Setup, Operation & Maintenance Manual

Sawmill

Hide thumbs

Also See for LT10:

- Safety, setup, operation & maintenance manual (65 pages) ,

- User manual (94 pages) ,

- User manual (110 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Wood-mizer LT10

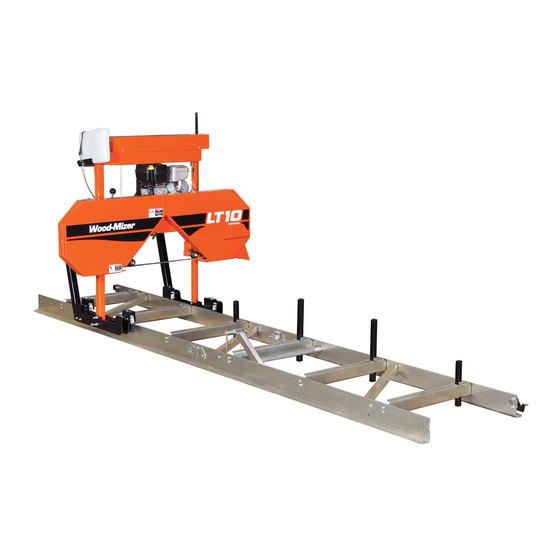

- Page 1 ® Wood-Mizer Sawmill Safety, Setup, Operation & Maintenance Manual LT10S3 E7,5S rev. A1.00 Safety is our #1 concern! Read and understand all safety information and instructions before operating, setting up or maintaining this machine. December 2006 Form #794...

-

Page 2: Table Of Contents

1.12 Components......................1-10 1.13 Electrical Information....................1-11 SECTION 2 SAWMILL ASSEMBLY Mounting Parts of LT10 Sawmills with Electric Motors .......... 2-1 Unpacking the Sawmill ..................... 2-6 Bed Frame Assembly ....................2-8 Saw Head Assembly....................2-15 SECTION 3 SETUP & OPERATION Sawmill Setup...................... - Page 3 Table of Contents Page-Section SECTION 5 TROUBLESHOOTING GUIDE Sawing Problems ....................... 5-1 SECTION 6 SAWMILL ALIGNMENT Pre-Alignment Procedures..................6-1 Preparing The Sawmill For Alignment ..............6-1 Blade Installation and Alignment................6-2 Blade Wheel Alignment .................... 6-4 Blade Guide Arm Alignment..................6-9 Aligning The Blade Guides ..................

- Page 4 Sawmill and Customer Identification Each Wood-Mizer LT10 sawmill is identified with a revision and VIN numbers. E7,5 LT10 Type Motor/Engine Basic Sawmill I.D. Revision Number Minor ”Revision” Major “Revision” Code Code VIN N EVISION AND UMBERS When you pick up your mill, you will receive a customer number. The VIN number, revision, and your customer number expedite our service to you.

-

Page 5: Safety

It is always the owner's responsibility to comply with all applicable federal, state and local laws, rules and regulations regarding the ownership, operation and towing of your Wood-Mizer sawmill. All Wood-Mizer mill owners are encouraged to become thoroughly familiar with these applicable laws and comply with them fully while using the mill. -

Page 6: Blade Handling

Safety Blade Handling Blade Handling DANGER! Always disengage the blade and shut off the sawmill engine before changing the blade. Failure to do so will result in serious injury. WARNING! Always wear gloves and eye protection when handling bandsaw blades. Changing blades is safest when done by one person! Keep all other persons away from area when coiling, carrying or changing a blade. - Page 7 Safety Sawmill Operation persons are out of the path of the blade before starting the engine or motor. Failure to do so may result in serious injury. WARNING! Secure all loose clothing and jewelry before operating the sawmill. Failure to do so will result in serious injury or death.

-

Page 8: Sawmill Maintenance

Safety Sawmill Maintenance Sawmill Maintenance CAUTION! Reinstall the track wiper so that it lightly touches the track bar. If the wiper presses too firmly against the bar, it can cause the power feed to bind. CAUTION! Never use grease on the mast rails as it will collect sawdust. - Page 9 Safety Sawmill Maintenance Pictograph decals used to warn the user about danger in the LT10: Carefully read operator’s manual before handling the machine. Observe instructions and safety rules when operating Stay clear of hot surfaces Do not open or remove safety shields while...

-

Page 10: Belt Sizes

Safety Belt Sizes Belt Sizes See Table 1-1. Belt sizes for the LT10 are shown. Description Belt Size Wood-Mizer Part # Motor Drive Belt E7,5 014819 Blade Pulley Belts P04185 TABLE 0-0 To insure proper blade tracking, use Goodyear, Dayco Super II, or Browning belts only. -

Page 11: Cutting Capacity

Safety Cutting Capacity Cutting Capacity See Table 1-3. The log size capacities of the LT10 sawmills are listed below. Max. Diameter Max. Length LT10 with three bed 71 cm 5,4 m sections LT10 with two bed 71 cm 3,5 m... - Page 12 Safety Engine/Motor Specifications Conveying Speed When 10m 20 m/s Long Hose is Used TABLE 0-0 15doc052207 Safety...

-

Page 13: Overall Dimensions

Safety Overall Dimensions 1.11 Overall Dimensions See Figure 1-1. The overall dimensions of the LT10 sawmills are shown below. 2234 2043 1950 4660 1950 6610 FIG. 1-1 Safety 15doc052207... -

Page 14: Components

Safety Components 1.12 Components See Figure 1-2. The major components of the Wood-Mizer LT10 are shown below. Water Tank Blade Drive Motor Blade Tension Handle Blade Guide Arm Handle Up/Down Crank Handle Sawmill Frame Electric Box Clamp FIG. 1-2 1-10... -

Page 15: Electrical Information

Safety Electrical Information 1.13 Electrical Information See Figure 1-3. The electrical symbol diagram of the LT10 equipped with the 5,5kW electric motor is shown below FIG. 1-3 Safety 15doc052207 1-11... - Page 16 Blade Drive Motor AZ17-11ZRK SCHMERSAL 094232 Safety Switch EVN2000C HONEYWELL 089816 Limit Switch TABLE 0-0 See Table 1-7. LT10 Site preparation 3-Phase V Switch, Fuse Recommended wire section 400 VAC 16 A 1,5 mm to 15m length TABLE 0-0 DANGER! It is recommended to use 30mA GFI (Ground Fault Interrupter.

-

Page 17: Sawmill Assembly

SAWMILL ASSEMBLY Mounting Parts of LT10 Sawmills with Electric Motors SECTION 2 SAWMILL ASSEMBLY Mounting Parts of LT10 Sawmills with Electric Motors 2.1.1 Parts specifications Table 1: Sawmill Frame Assembly Fig. Wood-Mizer No. Description Qty. 097466-1 Plate, frame supporting left... - Page 18 Table 1: 094530 Log Clamp 097369-1 Bed Extension, LT10-zinc 097473-1 Stop, Saw Head LT10-zinc 086035-1 Wedge Weldment, Log Taper LT10 zinc 092567-1 Upper Sprocket Cover, ptd. Saw Head Assembly 086323 Plate, Left Track Wiper 086322 Plate, Right Track Wiper 093859 Operator’s Guard...

- Page 19 SAWMILL ASSEMBLY Specifications of Fasteners Table 1: 092379-1 Guard, Blade Guide Roller 086132-1 Power Cord Bracket 097567-1 Latch, Saw Head LT10 094246-1 Sawdust Chute 097248-1 Mast Side Bracket.LT10-ptd Frame with 3-bed sections 2.1.2 Specifications of Fasteners Table 2: Wood-Mizer No.

- Page 20 SAWMILL ASSEMBLY Specifications of Fasteners Table 2: F81001-7 M6x12 Bolt F81054-1 Flat Washer 8.4 F81032-2 M8 Nut F81002-5 M8x25 Bolt F81002-4 M8x20 Bolt F81055-2 Washer, 10.2 Split Lock F81003-11 M10x25 Bolt F81003-1 M10x20 Bolt F81055-1 Flat Washer 10.5 F81037-1 M20 Nut F81032-1 M8 Nut F81002-20...

- Page 21 SAWMILL ASSEMBLY Tools Necessary for Assembling the Sawmill 2.1.3 Tools Necessary for Assembling the Sawmill Table 3: Required tools Flat Wrench #8 1pcs Flat Wrench #10 2pcs Flat Wrench #13 2pcs Flat Wrench #17 2pcs Flat Wrench #19 2pcs Ratchet Wrench #30 1pcs Hammer 1pcs...

-

Page 22: Unpacking The Sawmill

SAWMILL ASSEMBLY Unpacking the Sawmill Unpacking the Sawmill FIG. 2-1 1. Cut the bands holding the components together. 2. Remove frame parts from the pallet. 3. Remove up/down crank from the saw head, slide on the up/down handle and secure with the pin (Part No F81045-1). - Page 23 SAWMILL ASSEMBLY Unpacking the Sawmill Locking Pin F81045-1 FIG. 2-1 4. Using the up/down crank raise the saw head. Open the box with sawmill’s equipment. SAWMILL ASSEMBLY 15doc052207...

-

Page 24: Bed Frame Assembly

SAWMILL ASSEMBLY Bed Frame Assembly Bed Frame Assembly IMPORTANT! With all screw joints without spring lock washer or lock nylon nut, use the "LOCTITE 243" (blue, of average durability, for screw joints). 1. Mount 094513-1 outrigger legs to the frame supporting plates and to bed extension. See Figure 2-2. - Page 25 SAWMILL ASSEMBLY Bed Frame Assembly 2. Mount the bed rails with frame supporting plates as shown on the figure below. Use the frame mounting squares (097182-1) to screw them together, See Figure 2-3. M8x25 Bolt 097181-1 M8x25 Bolt 8.4 Washer 097182-1 M8 Nut M8x25 Bolt...

- Page 26 SAWMILL ASSEMBLY Bed Frame Assembly 3. Lay the frame sections end-to-end so they facing each other the correct side. Slide the sections together and using the outrigger adjusting nuts, adjust the segments position. The adjacent segments should be on the same height. See Figure 2-4.

- Page 27 SAWMILL ASSEMBLY Bed Frame Assembly 4. Fasten the segments together using the 097185-1 segments connectors, blocks and mounting bolts. See Figure 2-5. Nut, M8 Hex Nylon Zinc Lock M8x100 Bolt 8.4 Washer 097464-1 Nut, M8 Hex Nylon M8x25 Bolt Zinc Lock 097185-1 8.4 Washer FIG.

- Page 28 SAWMILL ASSEMBLY Bed Frame Assembly 5. Assemble the log clamp to the bed rail on each bed segment, using the hex head bolts and nylon lock nuts. See Figure 2-6. Step 1 Step 2 M8x25 Bolts M8x25 Bolts 8.4 Washers Nuts, M8 Hex Nylon 8.4 Washer Zinc Lock...

- Page 29 SAWMILL ASSEMBLY Bed Frame Assembly 6. Mount the bed extension (Part No 097369-1) and saw head stops (Part No 097473-1). See Figure 2-7. Nut, M8 Hex Nylon Zinc Lock 097185-1 8.4 Washer M8x100 Bolt 097369-1 097464-1 M8 Nut 8.4 Washer M8x25 Bolt 097473-1 FIG.

- Page 30 SAWMILL ASSEMBLY Bed Frame Assembly 7. Each bed segment has got two side supports (Part No 097470 – long and 097472 – short). Install the log side supports as shown on the Figure 2-8. Each side support can be adjusted in two positions, depends of the cutting height. See Figure 2-8.

-

Page 31: Saw Head Assembly

SAWMILL ASSEMBLY Saw Head Assembly Saw Head Assembly 1. Using a forklift truck or a winch with lifting capacity of minimum 500 kg, carefully lift the saw head and set it aside. Attach the winch hook to the bracket on the saw head. WARNING! When removing the saw head, use extreme care and keep all persons at a safe distance. - Page 32 SAWMILL ASSEMBLY Saw Head Assembly 2. Install a track wiper with a felt strip and saw head latch (Part No 097567-1) to each track roller housing as shown below. See Figure 2-10. M8x12 Bolt Track Wiper (086322) M8x12 Bolt Track Wiper (086322) M8 Nut 8.4 Washer...

- Page 33 SAWMILL ASSEMBLY Saw Head Assembly See Figure 2-11. M8x16 Bolt 8.4 Washer 094246-1 FIG. 2-11 SAWMILL ASSEMBLY 15doc052207 2-17...

- Page 34 SAWMILL ASSEMBLY Saw Head Assembly 4. Install the operator guard. See Figure 2-12. M8x16 Bolt M8x25 Bolt Nut, M8 Hex Nylon Zinc Washer M10x50 Bolt Guard (093859) 10.5 Washer M8x20 Bolt FIG. 2-12 2-18 15doc052207 SAWMILL ASSEMBLY...

- Page 35 SAWMILL ASSEMBLY Saw Head Assembly 5. Install the blade guides. See Figure 2-13. Blade Guide (094682) Blade Guide (094683) M10x1x25 Bolt Nut, M10x1 Screw, Thin (8) M10x1x20 (7) FIG. 2-13 SAWMILL ASSEMBLY 15doc052207 2-19...

- Page 36 SAWMILL ASSEMBLY Saw Head Assembly 6. Install the power cord bracket. See Figure 2-14. Holder, Plastic Cable Screw, M4x16 Tie (F81082-1) Power Cord Bracket 086132-1 M4 Nut 4.3 Washer FIG. 2-14 2-20 15doc052207 SAWMILL ASSEMBLY...

-

Page 37: Setup & Operation

Setup & Operation Sawmill Setup SECTION 3 SETUP & OPERATION Sawmill Setup NOTE: The following setup procedure should be performed whenever the sawmill is moved or reassembled. If sawing problems occur and misalignment is suspected, Section SECTION 6 for complete alignment instructions. 1. - Page 38 Setup & Operation Sawmill Setup 5. The blade guide rollers should not touch and deflect the blade and the blade guide arm should be adjusted all the way out, away from the other blade guide. 6. Measure the distance from the bed rail to the bottom of the blade near the inside (fixed) blade guide.

- Page 39 Setup & Operation Sawmill Setup 8. Make sure the entire face of each slide pad makes contact with the mast. Use the adjustment nuts shown below to adjust the slide pads if necessary. Slide Pad Adjustment Nuts FIG. 3-3 Setup & Operation 15doc052207...

- Page 40 Setup & Operation Sawmill Setup 9. Check the vertical alignment of each blade wheel using the blade guide alignment tool. Attach the tool to the blade near the outer blade guide. Be sure the tool does not rest on a tooth or burr, and is lying flat on the blade. See Figure 3-4.

- Page 41 Setup & Operation Sawmill Setup See Figure 3-5. To tilt the idle-side blade wheel up, loosen the bottom adjustment screw 1/2 turn. Loosen the nut on the top adjustment screw and tighten the screw. Tighten the top and bottom nuts. To tilt the wheel down, loosen the top adjustment screw 1/2 turn.

- Page 42 Setup & Operation Sawmill Setup See Figure 3-6. To tilt the drive-side blade wheel down, loosen the top adjustment screw, loosen the nut on the bottom adjustment screw and tighten the bottom screw. Tighten the top and bottom nuts. To tilt the wheel up, loosen the bottom adjustment screw, loosen the nut on the top adjustment screw and tighten the top screw.

- Page 43 Setup & Operation Sawmill Setup 10. Adjust the spacing between each blade guide roller flange and the back of the blade. Section 6.9 11. Adjust the horizontal angle of the blade guides. See Section 6.10 12. Adjust the blade deflection (See Section 6.7) and the vertical angle of the blade guides (See Section...

- Page 44 Setup & Operation Sawmill Setup head stops moving at its lower travel limit, i.e. at the height of 25 mm above the bed. Loosen the nut and adjust the stop bolt FIG. 3-8 16. Adjust the side bracket. See Section 6.13 WARNING! Adjust the side bracket before first operating the sawmill.

-

Page 45: Replacing The Blade

Setup & Operation Replacing The Blade Replacing The Blade DANGER! Always disengage the blade and shut off the sawmill motor before changing the blade. Disconnect the power supply using the main switch. Failure to do so will result in serious injury. WARNING! Always wear gloves and eye protection when handling bandsaw blades. -

Page 46: Tensioning The Blade

Setup & Operation Tensioning The Blade Tensioning The Blade See Figure 3-9. Turn the blade tension handle clockwise to compress the rubber spring and tension the blade. Check the blade tension occasionally when adjusting the cant control or while cutting. As the blade and belts heat up and stretch, the blade tension will change. -

Page 47: Tracking The Blade

Setup & Operation Tracking The Blade Tracking The Blade 1. Make sure the blade housing cover is closed and all persons are clear of the blade. 2. Start the motor for a moment until the blade positions itself on the wheels. WARNING! Do not spin the blade wheels by hand. - Page 48 Setup & Operation Tracking The Blade control bolt. Cant Control Bolt 15B017 FIG. 3-11 If the blade is too far out, back the blade onto the wheel by turning the cant control counterclockwise. If the blade is too far in, turn the cant control clockwise until the gullet of the blade is the correct distance from the front edge of the wheel.

-

Page 49: Loading, Turning, And Clamping Logs

Setup & Operation Loading, Turning, And Clamping Logs Loading, Turning, And Clamping Logs To Load Logs 1. Move the cutting head to the front end of the frame. CAUTION! Before loading a log, be sure the cutting head is moved far enough forward so the log does not hit it. Failure to do so may result in machine damage. - Page 50 Setup & Operation Loading, Turning, And Clamping Logs evenly support the length of the log. See Figure 3-13. FIG. 3-13 6. Position the log at the foot of the ramps. 7. Use a cant hook to roll the log up the ramps and onto the sawmill bed. Position the log against the side supports.

- Page 51 Setup & Operation Loading, Turning, And Clamping Logs To Clamp Logs: 1. Position the clamps against the log, far enough down so they are below your cuts on a given side of the log. Using the clamp handles move the log firmly against the side supports.

- Page 52 Setup & Operation Loading, Turning, And Clamping Logs To Level A Tapered Log: Use shims or the optional wedge to raise either end of a tapered log, if desired. Shim one end of the log until the heart of the log measures the same distance from the bed rails at each end of the log.

-

Page 53: Up/Down Operation

Setup & Operation Up/Down Operation Up/Down Operation 1. Install a blade, if needed, and check for correct blade tension. (See Section 3.3). Set the cutting head to the desired height. (The blade height scale shows the height of the blade above the bed rails.) See Figure 3-15. -

Page 54: Blade Guide Arm Operation

Setup & Operation Blade Guide Arm Operation the up/down system may result. Blade Guide Arm Operation 1. Look down the length of the log to see its maximum width. The outer blade guide roller should be adjusted to clear the widest section of the log by less than 1" (25.4 mm). 2. -

Page 55: Blade Drive Operation

Setup & Operation Blade Drive Operation Blade Drive Operation IMPORTANT! When starting the machine for the first time, check that main motor rotation direction is as indicated by the arrow located on the motor body (fan guard). If the rotation direction is incorrect, invert the phases in the phase inverter located in the power socket (electric box). - Page 56 Setup & Operation Blade Drive Operation Switch, Switch, Emergency Start-Stop Main Switch Safety Handle FIG. 3-16 3-20 15doc052207 Setup & Operation...

-

Page 57: Feed Operation

3.10 Cutting The Log The following steps guide you through normal operation of the Wood-Mizer sawmill. 1. Once the log is placed where you want it and clamped firmly, position the blade close to the end of the log. - Page 58 Setup & Operation Cutting The Log blade before returning the cutting head for the next cut. 8. Repeat until the first side of the log is cut as desired. Set aside the usable flitches (boards with bark on one or both sides).You can edge them on the mill later. 9.

-

Page 59: Edging

Setup & Operation Edging 3.11 Edging The following steps guide you through edging boards on the Wood-Mizer sawmill. 1. Raise the side supports to 1/2 the height of the flitches, or the boards that need to be edged. 2. Stack the flitches on edge against the side supports. -

Page 60: Blade Height Scale

Setup & Operation Blade Height Scale 3.12 Blade Height Scale See Figure 3-17. The blade height scale is mounted on the vertical mast. It includes: a blade height indicator centimeter scale (or quarter inch scale) Scale Blade Height Indicator 150028C FIG. - Page 61 Setup & Operation Blade Height Scale See Table 3-1. The quarter scale contains of four sets of marks. Each set represents a specific lumber thickness. Saw kerf and shrinkage allowance are included, but actual board thickness will vary slightly depending on blade thickness and tooth set. To choose which scale to use, determine what finished thickness you want to end up with.

-

Page 62: Water Lube Operation

Setup & Operation Water Lube Operation 3.13 Water Lube Operation The Water Lube System keeps the blade clean. Water flows from a 5 liter bottle through a hose to the blade guide where the blade enters the log. A valve in the bottle cap controls the amount of water flow. - Page 63 Setup & Operation Water Lube Operation See Figure 3-19. Open the valve on the water bottle to start water flow on the blade. To close turn valve clockwise; to open turn valve counterclockwise. FIG. 3-19 Not all types of wood require the use of the Water Lube System. When it is needed, use just enough water to keep the blade clean.

-

Page 64: Transporting The Sawmill

Setup & Operation Transporting the Sawmill 3.14 Transporting the Sawmill The assembled sawmill cannot be transported. To transport the sawmill, the vertical mast and the saw head have to be removed from the frame, and secured. WARNING! Keep all persons out of the path while loading and unloading the sawmill. - Page 65 Wood-Mizer LT10 Short Interval Maintenance Schedule PROCEDURE MANUAL REFERENCE EVERY BLADE CHANGE SEE SECTION 4.2 Check Blade Guide Roller Performance SEE SECTION 4.2 Remove Excess Sawdust From Blade Wheel Housings And Sawdust Chute EVERY 8 HOURS SEE SECTION 4.3 Clean And Lubricate Track SEE SECTION 4.3...

- Page 66 30doc022007...

- Page 67 30doc022007...

- Page 68 WOOD-MIZER LT10 MAINTENANCE LOG PROCEDURE MANUAL TOTAL HOURS OF OPERATION REFERENCE FILL IN THE DATE AND THE MACHINE HOURS AS YOU PERFORM EACH PROCEDURE. A SHADED BOX INDICATES MAINTENANCE IS NOT NEEDED AT THIS TIME. 50 HRS 100 HRS 150 HRS...

- Page 69 WOOD-MIZER LT10 MAINTENANCE LOG PROCEDURE MANUAL TOTAL HOURS OF OPERATION REFERENCE FILL IN THE DATE AND THE MACHINE HOURS AS YOU PERFORM EACH PROCEDURE. A SHADED BOX INDICATES MAINTENANCE IS NOT NEEDED AT THIS TIME. 1050 HRS 1100 HRS 1150 HRS...

- Page 70 WOOD-MIZER LT10 MAINTENANCE LOG PROCEDURE MANUAL TOTAL HOURS OF OPERATION REFERENCE FILL IN THE DATE AND THE MACHINE HOURS AS YOU PERFORM EACH PROCEDURE. A SHADED BOX INDICATES MAINTENANCE IS NOT NEEDED AT THIS TIME. 2050 HRS 2100 HRS 2150 HRS...

-

Page 71: Maintenance

Maintenance Wear Life SECTION 4 MAINTENANCE This section lists the maintenance procedures that need to be performed on the LT10 sawmills. The Short Interval Maintenance Schedule lists procedures that need to be performed every 4, 8 or 25 hours.The Maintenance Log lists procedures that need to be performed every 50, 100, 200, or 1000 hours. -

Page 72: Carriage Track & Rollers

Maintenance Carriage Track & Rollers Carriage Track & Rollers See Figure 4-1. 1. Clean the track bar to remove any sawdust and sap buildup every eight hours of operation. 2. Remove sawdust from the track roller housings. Remove the track roller housing covers and brush any sawdust buildup from the housings. -

Page 73: Miscellaneous Lubrication

Maintenance Miscellaneous Lubrication Miscellaneous Lubrication 1. Lubricate the tensioner screw and up/down crank handle shaft with a rolling bearing grease (e.g. ŁT4S or Shell Extreme Pressure Grease) as needed. See Figure 4-2. Grease the blade tensioner thread FIG. 4-2 Blade Wheel Belts 1. -

Page 74: Up/Down System

Maintenance Up/Down System Up/Down System 1. Adjust the up/down chain tension as needed. Measure chain tension, with the saw head all the way to the top of the vertical mast. Secure the saw head with a chain at the top or shim it underneath. -

Page 75: Miscellaneous Maintenance

Maintenance Miscellaneous Maintenance Miscellaneous Maintenance 1. Check the drive belt tension after the first 20 hours, and every 50 hours thereafter. See Section 6.13 for more informations. 2. Check the mill alignment every setup. See Section 6, Alignment) 3. Make sure all safety warning decals are readable. Remove sawdust and dirt. Replace any damaged or unreadable decals immediately. -

Page 76: Troubleshooting Guide

Troubleshooting Guide Sawing Problems SECTION 5 TROUBLESHOOTING GUIDE Sawing Problems PROBLEM CAUSE SOLUTION Blades Dull Quickly Dirty logs Clean or debark logs, especially on entry side of the When grinding teeth, heating Grind just enough metal too much and causing teeth to to restore sharpness to the soften teeth. - Page 77 Troubleshooting Guide Sawing Problems PROBLEM CAUSE SOLUTION Boards Thick Or Thin On Stress in log which causes log After log has been squared, Ends Or Middle Of Board to not lay flat on the bed take equal cuts off opposing sides.

- Page 78 Troubleshooting Guide Sawing Problems 15doc022007 Troubleshooting Guide...

-

Page 79: Sawmill Alignment

Sawmill Alignment Pre-Alignment Procedures SECTION 6 SAWMILL ALIGNMENT Pre-Alignment Procedures Periodically check the sawmill alignment and adjust if necessary. This chapter explains how to align the entire sawmill. Care should be taken in performing these steps. Sawmill alignment determines the accuracy and squareness of your cuts. The sawmill alignment steps are: 1. -

Page 80: Blade Installation And Alignment

Sawmill Alignment Blade Installation and Alignment Blade Installation and Alignment Install a blade and apply the appropriate tension as shown in See Section 3.3. 1. Close the blade housing cover and make sure all persons are clear of the open side of the saw head. - Page 81 Sawmill Alignment Blade Installation and Alignment 150060 3.0 mm ± 1.0 mm 1 1/4" Blade FIG. 6-1 To adjust where the blade travels on the idle-side and drive-side blade wheel, see next section in this manual. Sawmill Alignment 15doc052207...

-

Page 82: Blade Wheel Alignment

Sawmill Alignment Blade Wheel Alignment Blade Wheel Alignment The blade wheels should be adjusted so they are level in the vertical and horizontal planes. If the blade wheels are tilted up or down, the blade will want to travel in the tilted direction. - Page 83 Sawmill Alignment Blade Wheel Alignment See Figure 6-3. Use the vertical adjustment screws to adjust the drive-side blade wheel. To tilt the wheel down, loosen the top adjustment screw half turn. Loosen the jam nut on the bottom adjustment screw and tighten the screw. Tighten the top and bottom jam nuts. To tilt the wheel up, loosen the bottom adjustment screw half turn.

- Page 84 Sawmill Alignment Blade Wheel Alignment To tilt the wheel up, loosen the bottom nut and adjustment screw half turn. Loosen the jam nut on the top adjustment screw and tighten the screw. Tighten the top and bottom jam nuts. To tilt the wheel down, loosen the top adjustment screw half turn. Loosen the jam nut on the bottom adjustment screw and tighten the screw.

- Page 85 Sawmill Alignment Blade Wheel Alignment 9. Check the position of the blade on the idle-side blade wheel. See Figure 6-5. The horizontal tilt of the blade wheel should be adjusted so that the gullet of an 1-1/4" blade is 1/8" (3 mm) out from the front edge of the wheel (±1/32 [0.75 mm]). 3.0 mm ±...

- Page 86 Sawmill Alignment Blade Wheel Alignment 10. Check the position of the blade on the drive-side blade wheel. The blade should be positioned on the wheel as described for the idle-side blade wheel. Adjust the drive-side blade wheel if necessary. See Figure 6-7. Use the horizontal adjustment screw to adjust the drive-side blade wheel.

-

Page 87: Blade Guide Arm Alignment

Sawmill Alignment Blade Guide Arm Alignment RYS. 6-8 Blade Guide Arm Alignment Before aligning the blade guide arm, track the blade on the blade wheels as described in See Section 3.4. Move the cutting head so the blade is positioned over the first bed rail. Level the blade to the bed rail as shown in See Section 3.1. - Page 88 Sawmill Alignment Blade Guide Arm Alignment See Figure 6-9. Adjust front top and bottom Adjust rear top and bottom screws with arm open screws with arm closed FIG. 6-9 2. Use the arm adjustment screws, marked with blue arrows in the figure above, to adjust the arm up until the slide pad touches the saw head brace tube.

- Page 89 Sawmill Alignment Blade Guide Arm Alignment Horizontal Alignment See Figure 6-10. 1. With the blade guide arm still all the way in toward the other blade guide, tighten all the side screws until they touch the arm. Back the screws off 1/4 turn and tighten the jam nuts.

-

Page 90: Aligning The Blade Guides

Aligning The Blade Guides Aligning The Blade Guides Each Wood-Mizer sawmill has two blade guide assemblies that help the blade maintain a straight cut. The two blade guide assemblies are positioned on the saw head to guide the blade on each side of the material being cut. -

Page 91: Blade Deflection

Sawmill Alignment Blade Deflection Blade Deflection Perform the following steps to achieve proper blade deflection with the blade guides: 1. Raise the carriage until the blade is 15" (375 mm) above a bed rail. Measure the actual distance with a tape from the top of the rail to the bottom of the blade. See Figure 6-11. -

Page 92: Blade Guide Vertical Tilt Adjustment

Sawmill Alignment Blade Guide Vertical Tilt Adjustment Blade Guide Vertical Tilt Adjustment Check that the blade guide does not tilt the blade up or down. A Blade Guide Alignment Tool (BGAT) is provided to help you measure the vertical tilt of the blade. 1. - Page 93 Sawmill Alignment Blade Guide Vertical Tilt Adjustment See Figure 6-13. Loosen jam nuts and turn screws to tilt roller up or down SM0070 FIG. 6-13 7. Move the carriage forward so the back end of the tool is over the bed rail. 8.

-

Page 94: Blade Guide Flange Spacing

Sawmill Alignment Blade Guide Flange Spacing Blade Guide Flange Spacing HINT: When adjusting blade guide flange spacing, loosen the top set screw and one side set screw only. This will insure horizontal and vertical tilt adjustments are maintained when the set screws are retightened. 1. -

Page 95: Horizontal Tilt Adjustment

Sawmill Alignment Horizontal Tilt Adjustment 6.10 Horizontal Tilt Adjustment 1. Move the blade guide arm half way in. See Figure 6-15. FIG. 6-15 2. Place Blade Guide Alignment Tool against the face of the outer blade guide roller, as shown above. 3. -

Page 96: Blade Height Scale Adjustment

Sawmill Alignment Blade Height Scale Adjustment 6.11 Blade Height Scale Adjustment Standard scale After the entire sawmill has been aligned and all adjustments made, check that the blade height scale indicates the true distance from the blade to the bed rails. See Figure 6-16. - Page 97 Sawmill Alignment Blade Height Scale Adjustment Quarter inch scale (option) 1. The maximum distance between the scale and the scale indicator should be 5 mm. If it is different, loosen the indicator bracket mounting bolts and move the bracket in the horizontal plane until the correct distance is obtained.

-

Page 98: Motor Drive Belt Adjustment

Sawmill Alignment Motor Drive Belt Adjustment 6.12 Motor Drive Belt Adjustment See Figure 6-18. Loosen the motor mounting bolts. Using the adjustment bolts shown below, adjust the drive belt until it has 7/16" (11 mm) deflection with a 8 lbs (3.6 kG) deflection force - in the case of E11 motor or 7/16"... -

Page 99: Mast Side Bracket Adjustment

Sawmill Alignment Mast Side Bracket Adjustment 6.13 Mast Side Bracket Adjustment To prevent saw head mast from tilting, the side bracket should be adjusted properly. Use the adjustment bolt, and adjust it so the distance between bolt head and bed rail is about 1mm. -

Page 100: Safety Handle Linkage Adjustment

Sawmill Alignment Safety Handle Linkage Adjustment 6.14 Safety Handle Linkage Adjustment See Figure 6-19. Use the adjustment nuts to adjust linkage tension so the blade stops during 8 seconds after the safety handle is released. Adjustment Nuts FIG. 6-19 6-22 15doc052207 Sawmill Alignment...

Need help?

Do you have a question about the LT10 and is the answer not in the manual?

Questions and answers