Wood-mizer LT10 Safety, Setup, Operation & Maintenance Manual

Sawmill

Hide thumbs

Also See for LT10:

- Safety, setup, operation & maintenance manual (100 pages) ,

- User manual (94 pages) ,

- User manual (110 pages)

Table of Contents

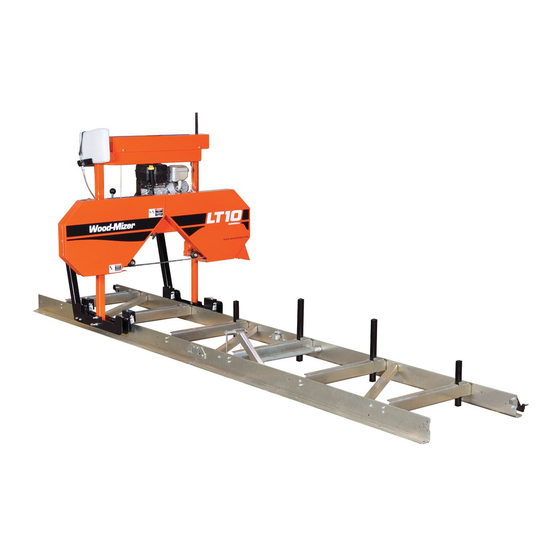

Summary of Contents for Wood-mizer LT10

- Page 1 ® Wood-Mizer Sawmill Safety, Setup, Operation & Maintenance Manual LT10 rev. B4.09 Safety is our #1 concern! Read and understand all safety information and instructions before oper- ating, setting up or maintaining this machine. Form #1230...

- Page 2 Printed in the United States of America, all rights reserved. No part of this manual may be reproduced in any form by any photographic, electronic, mechanical or other means or used in any information storage and retrieval system without written permission from Wood-Mizer 8180 West 10th Street Indianapolis, Indiana 46214...

-

Page 3: Table Of Contents

Table of Contents Section-Page SECTION 1 INTRODUCTION About This Manual.................1-1 Getting Service ..................1-2 General Contact Information..........1-2 Wood-Mizer Locations............1-3 Specifications ..................1-4 LT10 Dimensions ..............1-5 Customer and Sawmill Identification.............1-6 Warranty ....................1-8 SECTION 2 SAFETY Safety Symbols..................2-1 Safety Instructions ..................2-2 SECTION 3 SETUP Required Tools ..................3-1... - Page 4 Table of Contents Section-Page Up/Down Assist..................5-5 SECTION 6 TROUBLESHOOTING Sawing Problems ..................6-1 SECTION 7 ALIGNMENT Blade Tracking ..................7-1 Blade Guide Adjustment ................7-3 Blade Guide Vertical Tilt Adjustment ........7-3 Blade Guide Horizontal Tilt Adjustment.......7-4 Blade Guide Flange Spacing ..........7-6 INDEX WMdoc072619 Table of Contents...

-

Page 5: Introduction

The information and instructions given in this manual do not amend or extend the limited warranties for the equipment given at the time of purchase. For general information regarding Wood-Mizer and our “Forest to Final Form” products, please refer to the All Products Catalog in your support package. -

Page 6: Getting Service

Getting Service Getting Service Wood-Mizer is committed to providing you with the latest technology, best quality and strongest customer service available on the market today. We continually evaluate our customers’ needs to ensure we’re meeting current wood-processing demands. Your com- ments and suggestions are welcome. -

Page 7: Wood-Mizer Locations

Brazil Headquarters Europe Headquarters Serving Brazil Serving Europe, Africa, West Asia Wood-Mizer do Brasil Wood-Mizer Industries Sp z o.o. Rua Dom Pedro 1, No: 205 Bairro: Sao Jose Nagorna 114 Ivoti/RS CEP:93.900-000 62-600 Kolo, Poland Tel: +55 51 9894-6461/ +55 21 8030-3338/ +55 51 Phone: +48.63.26.26.000... -

Page 8: Specifications

Introduction Specifications Specifications Model: LT10 Rev. B3.02+ Dimensions: Metric Length: 14'-4" 4.36m Width: 5'-5" 16.5m Height (Ground To Mast): 5'-5 1/2" 16.6m Height (Max Head Position): 6'-5" 1.95m Bed Height (Ground To Bed): 11'-1/4" 3.36m Blade Length: 144" 3.65m Weights:... -

Page 9: Lt10 Dimensions

Introduction LT10 Dimensions LT10 Dimensions Introduction 10doc072619... -

Page 10: Customer And Sawmill Identification

Customer and Sawmill Identification Each Wood-Mizer LT10 sawmill is identified with a model number, revision, and serial number (see the figure below). MFG BY/ FABRIQUÉ PAR: WOOD-MIZER PRODUCTS, INC. 8180 W. 10t h St . Indianapolis, IN 46214-2400 U.S.A. 317/ 271-1542 800/ 553-0182 Model No.:... - Page 11 Introduction Customer and Sawmill Identification The serial number tag can be found at the following location. Serial Number 100003-1D SERIAL NUMBER TAG LOCATION. Introduction 10doc072619...

-

Page 12: Warranty

Wood-Mizer Limited Product Warranty Wood-Mizer LLC (“Warrantor”), an Indiana corporation with its principal place of business at 8180 West Tenth Street, Indianapolis, IN 46214-2400 USA, warrants to the purchaser (“Purchaser”) that for the time periods specifically stated herein and subject to the terms, conditions and limitations stated herein, the equipment... - Page 13 Introduction Warranty misuse, negligence, alterations, damage due to overload, abnormal conditions, excessive operation, acci- dent, or lack of performance of normal maintenance services. Several components which are used in the manufacture of the equipment but not manufactured by Warrantor, such as cant hooks, power plants, laser sights, batteries, tires, and trailer axles have warranties provided by the original equipment manufacturer (written copies available upon request).

- Page 14 This warranty cannot be amended, except in writing, which refers to this warranty that is signed by both Warrantor and Purchaser. © 2018 Wood-Mizer LLC – 8180 West 10 Street, Indianapolis, IN 46214...

-

Page 15: Safety

Safety Safety Symbols SECTION 2 SAFETY Safety Symbols The following symbols and signal words call your attention to instructions concerning your personal safety. Be sure to observe and follow these instructions. DANGER! indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. -

Page 16: Safety Instructions

Wood-Mizer sawmill. All Wood-Mizer mill owners are encour- aged to become thoroughly familiar with these applicable laws and com- ply with them fully while using the mill. - Page 17 Safety Safety Instructions WARNING! Always wear gloves and eye protection when handling bandsaw blades. Changing blades is safest when done by one person! Keep all other persons away from area when coiling, carrying or chang- ing a blade. Failure to do so may result in serious injury.

- Page 18 Safety Safety Instructions CAUTIONS FOR SAWMILL SETUP WARNING! Do not set up the mill on ground with more than a 10 degree incline. If setup on an incline is necessary, put blocks under one side of the mill or dig out areas to keep mill level. Setting up the mill on an incline could cause it to tip over, resulting in serious personal injury.

- Page 19 Safety Safety Instructions of your engine are especially hot during and following operation. Con- tact with hot engine components can cause serious burns. Therefore, never touch or perform service functions on a hot engine. Allow the engine to cool sufficiently before beginning any service function. DANGER! Always keep hands away from moving bandsaw blade.

- Page 20 Safety Safety Instructions KEEP SAFETY LABELS IN GOOD CONDITION IMPORTANT! Always be sure that all safety decals are clean and readable. Replace all damaged safety decals to prevent personal injury or damage to the equipment. Contact your local distributor, or call your Customer Service Representative to order more decals.

-

Page 21: Setup

Setup Required Tools SECTION 3 SETUP Required Tools The following materials and tools are required to assemble and setup the sawmill for operation: Two each wrenches: 7/16”, 3/8”, 1/2”, 9/16” & 3/4” (9/16” ratchet/socket required). Rubber Mallet. Phillips Head Screwdriver. ... - Page 22 Setup Bed Assembly Bed Rail (3) 100032-1B Track Rail (2) Bed Stop 3/8-16 x 1" Hex Head Bolt 3/8-16 Hex Decal (2) Nylon Lock Nut Catch Rail Plate (2) FIG. 3-1 10doc072619 Setup...

- Page 23 Setup Bed Assembly See Figure 3-2. 3. Connect the bed sections using two connecting plates, two clamp plates and hardware as shown. 5. 4. Be sure the track rails of each bed section are aligned before tightening the bolts. 5. Install the three cross brace plates to the bed sections as shown. Cross Brace Plate (3) 3/8-16 x 1”...

- Page 24 Setup Bed Assembly See Figure 3-3. 6. Run a string along one side of the track rail. 7. Place equal size objects between the string and track rail at each end of the bed (wrench sockets work well for this). 8.

-

Page 25: Mast Assembly

Setup Mast Assembly See Figure 3-4. 11. Assemble the clamp to a bed rail near the center of the bed assembly with the provided hardware to secure the clamp to the bed rail. Clamp Assembly Hex Head Bolt Flat Washer Spacer Flat Washer Lock Nut... - Page 26 Setup Mast Assembly See Figure 3-5. 100038-3 Push Handle 5/16-18 x 1” Hex Head Bolt (2) Lower Roller Assembly FRONT VIEW 5/16-18 Hex Nylon Lock Nut (4) 5/16-18 x 3 1/4” Hex Head Bolt (2) 5/16” Flat Washer (4) Mast Latch Plate (2) Catch Rail Plate Mast Latch Plate Catch Rail Plate...

-

Page 27: Engine Assembly

Setup Engine Assembly See Figure 3-6. 4. Use a large square on the track rail to position the mast upright to true vertical. 5. When square, tighten the roller mounting bolts. 6. Repeat on the other side of the mast. 7. - Page 28 Setup Engine Assembly See Figure 3-7. Smooth for mounting Threaded for dismounting (Larger) (Smaller) sm0411 FIG. 3-7 See Figure 3-8. Remove the engine from the box. Install the provided pulley and the bushing to the engine as shown below. G10 Engine G7 Engine Pulley Pulley...

- Page 29 Setup Engine Assembly See Figure 3-9. Adjust and secure the pulley and the bushing to the engine shaft as shown below. G10 Engine G7 Engine Pulley Pulley Pulley flush with end of shaft 3 3/4” 100034-2 FIG. 3-9 See Figure 3-10. Place the engine on the mount plate, positioning the engine pulley through the hole in the saw head housing.

-

Page 30: Water Lube Installation

Setup Water Lube Installation 100005-9C Place engine in position with drive pulley through hole in saw head Hex Nut (4) Flat Washer (4) Split Lock Washer (4) Hex Head Bolt (4) FIG. 3-10 IMPORTANT! Fill the engine with the provided engine oil. Check to make sure the engine oil level is correct. -

Page 31: Carriage Lock Bolts

Carriage Lock Bolts Two bolts with washers and lock nuts are supplied to secure the saw carriage to the bed frame during transport of the assembled LT10. 1. Align the lower roller assembly slotted holes with an unused hole in the bed. -

Page 32: Feed Cable Assembly

Setup Feed Cable Assembly See Figure 3-13. 100003-3 3/8" Flat Washer (2) 3/8-16 Hex Nylon Lock Nut 3/8-16 x 4 ½" Hex Head Bolt FIG. 3-13 Feed Cable Assembly This feed cable assembly helps stabilize the saw head for safer and more accurate oper- ation. - Page 33 Setup Feed Cable Assembly 1. Use the provided fasteners to securely install the pulley brackets and pulleys to the front end of the sawmill bed. Cable Pulley Pulley Bracket Cable Pulley 3/8-16 x 1" Hex Head Bolt (2) Cable Pulley 100042-8 FIG.

- Page 34 Setup Feed Cable Assembly See Figure 3-15. 2. Use the provided fasteners to securely install the pulley brackets and pulleys to the rear end of the sawmill bed 100042-9 Cable Pulley Cable Pulley 3/8-16 x 1" Hex Head Bolt (2) Pulley Bracket Cable...

- Page 35 Setup Feed Cable Assembly 4. Route the saw head feed cables as shown. See Figure 3-17. TOP VIEW Pulley Pulley Feed Cable Feed Cable Feed Cable Saw Head Bolt Push Handle Pulley Pulley 100042-4B FIG. 3-17 Setup 10doc072619 3-15...

- Page 36 Setup Feed Cable Assembly See Figure 3-18. Use the pulleys on the pulley tensioner brackets to tighten the feed cables evenly so the lower roller assemblies align with the bed rail as shown below. Tighten the pulley nuts when the alignment procedure is complete. Track Roller Cover 100042-10 FIG.

-

Page 37: Blade Installation

Setup Blade Installation Blade Installation DANGER! Always disengage the blade and shut off the sawmill engine before changing the blade. Failure to do so will result in serious injury. WARNING! Always wear gloves and eye protection when handling bandsaw blades. Changing blades is safest when done by one person! Keep all other persons away from area when coiling, carrying or changing a blade. -

Page 38: 3.10 Blade Tension

Setup Blade Tension See Figure 3-20. 150060 1/8” (3.0 mm) ± 1/32” (0.75 mm) 1 1/4” Blade FIG. 3-20 6. Close and latch the blade housing covers. 7. Tension the blade. 3.10 Blade Tension WARNING! Use both hands to operate the blade tensioner handle. Failure to do so may result in injury. - Page 39 Setup Blade Tension If not, release the blade tension and turn the tension adjustment pin to compress or decompress the rubber spring as needed. Re-tension the blade and recheck the alignment of the rubber spring washer with the indi- cator gauge.

-

Page 40: 3.11 Blade Height Indicator Adjustment

Setup Blade Height Indicator Adjustment 3.11 Blade Height Indicator Adjustment 1. Unpack and assemble the blade height indicator as shown below: See Figure 3-22. 100010-16 Washer Hex head bolt FIG. 3-22 2. Position the saw head so that the blade is over a bed rail. 3. - Page 41 Setup Blade Height Indicator Adjustment See Figure 3-23. 100005B Hex Nuts (2) Phillips Pan Head Screws (2) Blade Height Indicator FIG. 3-23 Setup 10doc072619 3-21...

-

Page 42: Operation

Operation Loading, Turning And Clamping Logs SECTION 4 OPERATION Loading, Turning And Clamping Logs 1. Move the saw carriage to the front end of the frame. See Figure 4-1. Move mast/saw head Insert side supports to front of bed in bed rails Roll log onto Adjust clamp to loading side of bed and adjust... - Page 43 Operation Loading, Turning And Clamping Logs CAUTION! Roll or lower log onto the sawmill bed. Do not drop it from any height. Failure to do so may result in machine damage. NOTE: Use boards for ramps to load the log on the sawmill bed. Use a cant hook to roll the log up the ramps onto the sawmill bed and into cutting position against the side supports.

-

Page 44: Up/Down Adjustment

Operation Up/Down Adjustment Up/Down Adjustment 1. Check for correct blade tension before cutting. (See Section 3.9). 2. Position the blade for the first cut by raising or lowering the saw head on the mast. See Figure 4-3. 3. Pull the up/down lock handle up to release the lock. 4. -

Page 45: Water Lube Operation

Operation Water Lube Operation WARNING! Always wear eye, ear, respiration, and foot protection when operating the sawmill. Failure to do so may result in serious injury. 1. Clear loose objects from the area around the blade, engine, and drive belt. 2. - Page 46 15 seconds. This will clean the blade of sap buildup. Wipe the blade dry with a rag before storing or sharpening. For further lubrication benefits, add 3 oz. (0.9 liter) of Wood-Mizer Lube Additive to 1.25 gallons (4.7 liters) of water. Wood-Mizer Lube Additive enables some previously impossi- ble timbers to be cut by significantly reducing resin buildup on the blade.

-

Page 47: Feed Operation

Operation Feed Operation Feed Operation 1. Push the feed handle forward to start the blade into the log. See Figure 4-6. 100003-5B Push feed handle to feed blade into log FIG. 4-6 HINT: To get a straight cut in the first part of the board, feed the blade into the log at a slow speed. -

Page 48: Cutting The Log

Cutting The Log The following steps guide you through normal operation of the Wood-Mizer sawmill. 1. Clamp the log firmly in position. 2. Move the blade close to the end of the log. -

Page 49: Edging

Edging The following steps guide you through edging boards on the Wood-Mizer sawmill. 1. Stack the flitches on edge against the side supports. 2. Clamp the flitches against the side supports halfway up the flitch height. (Wider flitches should be placed to the clamp side. - Page 50 Sawmill Operation Edging 4. Loosen the clamp and turn the edged boards over to edge the other side. 5. Repeat steps 1-4. 6. Loosen the clamp and remove the boards that have good clean edges on both sides. Clamp the remaining flitches and repeat steps 1-5. 10doc072619 Sawmill Operation...

-

Page 51: Maintenance

Maintenance Blade Guides SECTION 5 MAINTENANCE Blade Guides WARNING! Before performing service near moving parts such as blades, pulleys, motors, belts and chains, first turn the engine switch to the OFF position. If the engine switch is turned on and moving parts activated, serious injury may result. -

Page 52: Vertical Mast Rails

Maintenance Vertical Mast Rails CAUTION! Keep track rails free of rust. Formation of rust on the track rail in the areas contacting the track rollers can cause rapid deteriora- tion of the track rail's surface. Lubricate the rails by wiping them with Dexron III ATF transmission fluid. Lubrication will help protect the rails from corrosive elements such as acid rain and/or moisture from nearby bodies of saltwater (if applicable). -

Page 53: Miscellaneous

See Table 5-1. See the table below for drive belt tension specifications for your model sawmill. Measure the belt tension with a gauge. NOTE: Wood-Mizer offers a belt tension gauge (Part No. 016309) that will let you accurately measure the belt tension. - Page 54 Maintenance Drive Belt Adjustment 3. To adjust the belt tension, use the turnbuckle underneath the engine. Loosen the turn- buckle jam nuts and turn the turnbuckle to tighten or loosen the belt. Tighten the turn- buckle jam nuts. See Figure 5-2. 5/16”...

-

Page 55: Up/Down Assist

Maintenance Up/Down Assist Up/Down Assist The up/down system is equipped with a gas spring assist mechanism to provide improved speed and performance. The saw head must be raised and blocked and tension released from the assist assembly before performing any maintenance to assist components. WARNING! Release pressure from the up/down assist prior to per- forming any service to the assembly. - Page 56 If the machine is turned on and moving parts activated, serious injury may result. See Figure 5-5. The LT10 up/down cable routing is shown below. Up/Down Assist Cover Up/Down Cable...

-

Page 57: Troubleshooting

Troubleshooting Sawing Problems SECTION 6 TROUBLESHOOTING Sawing Problems PROBLEM CAUSE SOLUTION Blades Dull Quickly Dirty logs Clean or debark logs, especially on entry side of the cut When grinding teeth, heating Grind just enough metal to restore too much and causing teeth to sharpness to the teeth. - Page 58 Troubleshooting Sawing Problems PROBLEM CAUSE SOLUTION Boards Thick Or Thin On Stress in log which causes log After log has been squared, take equal Ends Or Middle Of Board. to not lay flat on the bed. cuts off opposing sides. Take a board off the top.

-

Page 59: Alignment

Alignment Blade Tracking SECTION 7 ALIGNMENT The Wood-Mizer sawmill is factory aligned. The blade tracking and blade guide adjust- ment instructions should be performed as necessary to solve sawing problems related to blade performance. Blade Tracking 1. Make sure the blade housing covers are closed and all persons are clear of the area around the blade. - Page 60 Alignment Blade Tracking See Figure 7-2. To adjust where the blade travels on the blade wheels, use the cant con- trol. NOTE: Do not loosen the locking nuts at the other end of the cant control bolt. 100005-12B Cant Control Turn cant control counterclockwise to move blade in on wheel;...

-

Page 61: Blade Guide Adjustment

Alignment Blade Guide Adjustment Blade Guide Adjustment After the blade is tensioned and tracked on the blade wheels, check alignment of the blade guide rollers. To check the blade guides, disengage the up/down lock and move the saw head up or down so it is positioned approximately at the center of the vertical mast. Engage the up/down lock handle. -

Page 62: Blade Guide Horizontal Tilt Adjustment

Alignment Blade Guide Horizontal Tilt Adjustment See Figure 7-4. Loosen the jam nuts on the top and bottom vertical tilt adjustment screws. To tilt the roller up, loosen the bottom screw and tighten top screw. To tilt the roller down, loosen the top screw and tighten the bottom screw. Tighten the jam nuts and recheck the tilt of the blade. - Page 63 Alignment Blade Guide Horizontal Tilt Adjustment See Figure 7-5. 100005-15 Blade Guide Alignment Tool FIG. 7-5 9. Measure between the back edge of the blade and the tool at the end closest to the inner blade guide ("B"). 10. Measure between the back edge of the blade and the other end of the tool ("A"). The roller should be tilted slightly to the left (’A’...

-

Page 64: Blade Guide Flange Spacing

Alignment Blade Guide Flange Spacing Blade Guide Flange Spacing Each blade guide must be adjusted so the roller flange is the correct distance from the back edge of the blade. If the flange is too close to or too far from the blade, the sawmill will not cut accurately. - Page 65 INDEX setup bed assembly blade guide adjustment maintenance blade height indicator 3-20 blade guides blade installation 3-17 drive belt blade tension 3-18 mast rails blade tracking miscellaneous carriage lock bolts 3-11 sawdust removal engine assembly track, rollers & scrapers feed cable installation 3-12 up/down assist mast assembly...

Need help?

Do you have a question about the LT10 and is the answer not in the manual?

Questions and answers