Beta Marine Beta 10 Operator's Maintenance Manual

Heat exchanger and keel cooled. small diesel engine range

Hide thumbs

Also See for Beta 10:

- Operator's maintenance manual (80 pages) ,

- Operator's maintenance manual (100 pages) ,

- Installation manual (132 pages)

Table of Contents

Advertisement

Operator's

Maintenance

Manual

Heat

Exchanger

and Keel Cooled

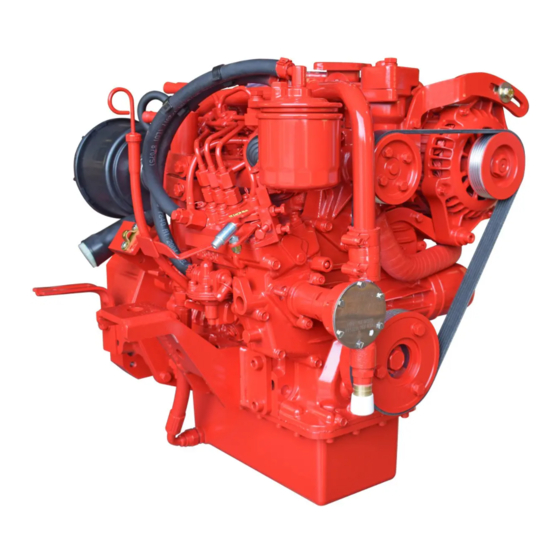

Small Diesel Engine Range: Beta 10,

BZ482, Beta 16, BD722 & Beta 25

CALIFORNIA –

Proposition 65 Warning: Diesel engine exhaust and some of its constituents are known to

the state of California to cause cancer, birth defects and other reproductive harm.

Advertisement

Table of Contents

Summary of Contents for Beta Marine Beta 10

- Page 1 Manual Heat Exchanger and Keel Cooled Small Diesel Engine Range: Beta 10, BZ482, Beta 16, BD722 & Beta 25 CALIFORNIA – Proposition 65 Warning: Diesel engine exhaust and some of its constituents are known to the state of California to cause cancer, birth defects and other reproductive harm.

- Page 2 Engine Details IMPORTANT – Please fill in details at moment of purchase – it really will help you! (and it will really help us specify the correct spare parts for you). Engine Type: Power: Speed: BETA WOC NO: Engine Serial No: Gearbox Type: Serial No: Ratio...

-

Page 3: Table Of Contents

Contents INTRODUCTION Engine Identification Initial Receipt of the engine Engine Storage SAFETY PRECAUTIONS TECHNICAL SPECIFICATIONS SECTION 1: GUIDELINES FOR OPERATION OF ENGINE Important checks prior to initial use Initial Start-up and Bleeding The Fuel System Starting/Stopping SECTION 2: MAINTENANCE AND SERVICE GUIDELINES Maintenance Schedule: Lubrication –... -

Page 4: Introduction

OPERATION AND MAINTENANCE MANUAL FOR THE FOLLOWING BETA MARINE ENGINES BASED ON KUBOTA MINI SERIES Beta 10, BZ482, Beta 16 (BZ602), BD722 & Beta 25 (BD902) This manual has been compiled to All information and carried out at the place of... -

Page 5: Safety Precautions

J A Growcoot, C.E.O, injury if personnel or clothing clean and free of leaks. Beta Marine Limited come in contact with the belts or E OIL pulleys, when the engine is running. -

Page 7: Section 1: Guidelines For Operation Of Engine

SECTION 1 GUIDELINES FOR OPERATION OF ENGINE IMPORTANT CHECKS PRIOR the ‘ON’ position). low revs. Warranty will not be accepted on gearboxes returned TO INITIAL USE 4. Ensure Morse speed and gearbox in the warranty period for failure cables are fitted correctly and that 1. -

Page 8: Starting/Stopping

NORMAL STARTING (ALL BETA PANELS WITH SILVER KEYSWITCH) With the engine out of gear, set speed *(Note: this will only illuminate if 2nd Release key (when engine has started) control lever to 1/3 throttle. Turn key alternator is fitted) to RUN position. Ensure alarm buzzer anti-clockwise to HEAT* (A) position is not sounding and that warning OIL PRESSURE and green POWER... -

Page 9: Maintenance Schedule

SECTION 2 MAINTENANCE SCHEDULE DAILY OR EVERY 8 HOURS AFTER FIRST 50 HOURS EVERY 750 HOURS RUNNING • Change engine lubricating oil. • As every 250 hours plus the following:- • Check engine oil level. • Change oil filter. • Check gearbox oil level. •... -

Page 10: Lubrication - Checking And Changing Oil

LUBRICATION Engine oil: Engine oil should be MIL- 1. To check the oil level, draw out IMPORTANT L-2104C or have properties of API the dipstick, wipe it clean, re- classification CC/CD/CE grades. The insert it, and draw it out again. When using an oil of different make following table gives grades of oil Check to see that the oil level lies... -

Page 11: Fuel System - Pumps, Filter, Fuel/Water Separator

CHECKING GEARBOX OIL LEVEL (1) The gearbox is fitted with a (3) New engines are normally box or sucked out with a hand dipstick and oil filler plug, see fig supplied with the gearbox pump via the filler plug. topped up with lubricant but (5) A guide to the type of oil to be Check the level before (2) Each engine is supplied with a... -

Page 12: Cooling - Fresh Water System, Keel Cooling, Heat Exchanger

COOLING The Mini Series range of engines are KEEL COOLING is an option. In this a. Baffle continuously welded to normally fresh water cooled. This system the freshwater is pumped outer skin and close fitting on water circulates through the engine through the engine and then through inner skin and on to a heat exchanger where it... - Page 13 Fig. 2l Fig. 2m Repeat (h) if coolant level is more than 1 inch IMPORTANT below the base of the filler neck when the engine has cooled Removal of the pressure cap when down. Note: When draining fresh water the engine is hot can cause severe system, ensure the engine has cooled injury from scalding hot water under (j) Run engine on 2/3 full load for...

-

Page 14: Sea Water Pump, Heat Exchanger

SEA WATER PUMP AND COOLING SYSTEM - (Heat exchanger-cooled engines) (2) Withdraw the rubber impeller CAUTION from its drive shaft as shown. See diagram 2i. Before working on the sea water system ensure that the sea cock is (3) Check impeller for cracks in the in the off position. -

Page 15: Belt Tensioning

BELT TENSION 40 AMP ALTERNATOR (2) The belt tension is adjusted by Check that the depression of the WARNING swinging the alternator outboard belt at position shown is as it pivots on its power support approximately ” or 12 mm Belt tension must only be checked bolt. -

Page 16: Electrical

MAINTENANCE - ELECTRICAL (1) The panel must be protected top up if required. For low WARNING from rain and sea water, see maintenance and ‘gel’ batteries installation. Sea water entering see manufacturers instructions. Under NO circumstances should the the key switch will eventually battery be disconnected or switched (3) Loose spade terminal cause corrosion and could result... -

Page 17: Troubleshooting

TROUBLE SHOOTING Beta diesels are very reliable if installed and serviced correctly, but problems can occur and the following list gives the most common ones and their solution. PROBLEM ENGINE DOES NOT START BUT STARTER MOTOR TURNS OVER OK Possible Cause Solution No fuel: Turn fuel cock on and fill tank. - Page 18 PROBLEM: ERRATIC RUNNING Possible Cause Solution Air in fuel supply: Check supply system for leaks and fix. Fuel lift pump faulty: Replace. Clogged fuel filter: Replace. Fuel return not fed back to the fuel Re-route pipe or clean. tank, or blocked pipe: Air filter blocked: Replace.

- Page 19 PROBLEM: LOW POWER OUTPUT Possible Cause Solution Blocked fuel filter: Replace. Blocked air filter: Replace. Air in fuel system: Check system. Governor spring incorrectly mounted: Dealer to adjust. Single lever control not operating Disconnect speed control cable and move the lever by hand. Adjust cable. correctly: The electrical load is too large on start Disconnect or reduce the load.

- Page 20 PROBLEM: LOW OIL PRESSURE WARNING LIGHT comes on when engine speed reduced to tick over: Possible Cause Solution Faulty switch sender: Replace. Engine running too hot: Check cooling water flow (see section 2 Cooling). Oil relief valve stuck partially open Remove and clean.

- Page 21 GENERAL -HEAT EXCHANGE ONLY: The most common cause of exhaust outlet for 10 seconds and pipe to the heat exchanger or in the overheating is insufficient seawater measure the amount of water end of the exchanger. This must be flow due to a blocked intake (weed collected.

- Page 22 PROBLEM: TRANSMISSION NOISE Possible Cause Solution Check gearbox oil level: Top up. “Singing” propeller: Check with supplier. Drive plate rattle at tickover: Check engine rpm (must be 850 rpm minimum in gear). Worn drive plate: Change. Propellor shaft hitting the gearbox Move shaft back to give at least 5mm clearance (type 12/16 couplings only) half coupling PROBLEM: VIBRATION...

- Page 23 All Beta panels have the following warning lamps: (A, AB, ABV, ABVW, diagnosis of electrical faults, based on B and C Deluxe) the Beta 10-90hp range of engines. If your engine was built before July Starter battery charge warning lamp 2005, contact Beta Marine for the relevant electrical trouble shooting •...

- Page 24 ELECTRICAL FAULT FINDING –LED PANELS PROBLEM POSSIBLE CAUSE & SOLUTION • Battery isolation switch in off position –switch on • Starter battery discharged – charge No warning lamps or buzzer functioning, • Engine fuse blown –check fuse (above starter motor or flywheel housing) & replace engine will not start or stop if necessary.

- Page 25 ELECTRICAL FAULT FINDING – C DELUXE & WATER TEMPERATURE FUNCTION ON B PANELS In addition to the fault finding detailed on the previous table, the following is specific for the C Deluxe type deluxe panel (Also applicable for the B panel with Murphy water temperature gauge) PROBLEM POSSIBLE CAUSE &...

- Page 26 ELECTRICAL – CORRECT OPERATION OF KEYLESS PANELS These panels control the engine with • Green lamp for panel power on • Green lamp for panel power on three water resistant push buttons should function should still function instead of a keyswitch, which are less •...

- Page 27 BETA PART NUMBERS FOR REPLACEMENT ITEMS: Description Part number 40 amp blade fuse (all panels) 200-00959 Alarm board –all panels from June 05 200-04655 Oil pressure switch ”BSP (not C panels) 600-62670 Oil pressure sender (C panels only) 200-94350 Oil pressure switch gauge (C panels only) 200-96190 Temperature switch with single terminal (on some Beta 16 &...

-

Page 28: Torque Settings

Spanner torque settings Tightening Torques for general use bolts and nuts kgf . m ft . lbs N . m ITEM Size x Pitch M6 (7T) : 6mm (0.24in) – 1.0~1.15 7.2~8.3 9.8~11.3 M8 (7T) : 8mm (0.31) – 2.4~2.8 17.4~20.3 23.5~27.5 M10 (7T) : 10mm (0.39in) -

Page 29: Engine Mounting

The installation details contained herewith are basic guidelines to assist installation, due to great diversity of marine craft it is impossible to give definitive instructions. Therefore Beta Marine can accept no responsibility for any damage or injury incurred during the installation of a Beta Marine Engine whilst following these guidelines. -

Page 30: Exhausts & Bends

EXHAUSTS Exhausts Beta 10 BZ482 / Beta 16 BD722 / Beta 25 Standard 50mm 50mm 50mm (a) A correctly installed engine as described in this handbook will meet Option 1 ” is available in SS ” ” ” the exhaust emission requirements of... -

Page 31: Fuel Supply

DRY EXHAUST SYSTEM The exhaust system installed in a (1) Ensure that rain water cannot (3) A dry exhaust system will give off canal boat or work boat with a dry enter the exhaust port and run considerable heat and suitable exhaust should be back down the system, flooding ventilation must be provided. -

Page 32: Cooling

7. Fuel lines and hoses must be pump must be fitted (ask your corrected immediately. secured and separated or dealer or Beta Marine). protected from any source of 5. A fuel/water separator must be significant heat. The filling, 2. It is very important that the installed. -

Page 33: Calorifier System

KEEL COOLED 1. The supply pipe to the keel the water over the cool outer surface. IDEAL KEEL COOLING TANK cooler should be 22mm bore (3) Air bleed valves should be fitted and the return 22mm bore. Air bleed valves both ends. -

Page 34: Electrical Installations

ELECTRICAL INSTALLATIONS Beta has 4 panels: A -standard provide various lengths of 6. All cables must be adequately extension looms for runs of over clipped and protected from AB or ABV 3m, but this kit includes a start abrasion. or ABVW relay to overcome the voltage 7. - Page 35 1.0 to 1.4 SUGGESTED MINIMUM ENGINE STARTER BATTERY SIZE: Engine (cc) Typical Battery Capacity Typical C.C.A. (A) (AH) at a 20hr Rate Cold Cranking Amperage Beta 10/BZ482/Beta 16 35~ 40 350~ 405 BD722/Beta 25 65~ 75 450~ 540 KEYSWITCH TERMINATIONS...

- Page 64 Emission durability. IN RESPECT TO THE RECREATIONAL CRAFT DIRECTIVE 94/25/EC AND AMENDMENT 2003/44/EC ANNEX 1, B3. The engine must be installed, maintained and operated within the parameters detailed in the Operator’s Maintenance Manual. Maintenance must use approved materials, parts and consumables.

-

Page 65: Component Identification At Rear Of Manual

QUICK REFERENCE PARTS LISTING Heat Exchanger & Keel Cooled Beta 10, BZ482, Beta 16, BD722, & Beta 25 In all cases please quote Beta Marine WOC “K” number and Engine Type Description Part Number Qty per Engine Alarm board 200-04655... - Page 66 QUICK REFERENCE PARTS LISTING Heat Exchanger & Keel Cooled Beta 10, BZ482, Beta 16, BD722, & Beta 25 In all cases please quote Beta Marine WOC “K” number and Engine Type Part Number Qty per Engine Description Wasting Zinc Anode 209-61840 Heat Exchanger “O”...

-

Page 67: Maintenance Record

Service Record Service Date Responsible Commissioned First 25 hours First 50 hours Every 150 hours with Shallow sump Every Year / Every 250 hours if sooner Every 750 hours... - Page 68 Sail Drives 13.5 to 50bhp Heat Exchanger Cooled 10 to 90bhp Beta Marine Generating Sets Keel Cooled 10 to 90bhp 3.7 to 40kVA Beta Marine Limited Davy Way, Waterwells, Quedgeley, Gloucester GL2 2AD, U.K. Beta Marine Generating Sets Tel: 01452 723492...

Need help?

Do you have a question about the Beta 10 and is the answer not in the manual?

Questions and answers