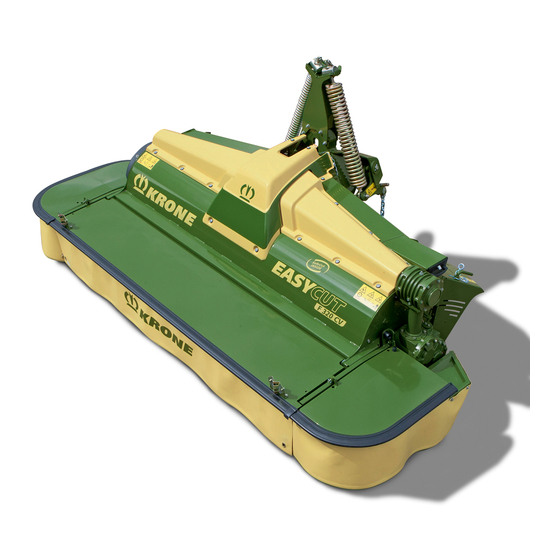

Krone EasyCut F 320 CV Original Operating Instructions

Disc mower

Hide thumbs

Also See for EasyCut F 320 CV:

- Supplement to operating instructions (12 pages) ,

- Original operating instructions (118 pages)

Summary of Contents for Krone EasyCut F 320 CV

- Page 1 Disc Mower EasyCut F 320 CV (from serial no.: 861 914) Order no.: 150 000 163 01 en 12.12.2012...

- Page 2 Pos : 2 /BA/Vor wort/Sehr geehrter Kunde @ 0\mod_1195626300326_78.doc x @ 905 @ @ 1 Dear customer, Dear customer, You have now received the operating instructions for the KRONE product which you have purchased. These operating instructions contain important information for the proper use and safe operation of the machine.

-

Page 3: Table Of Contents

Table of Contents Pos : 4 /Ü berschriften/Ü bers chriften 1/F-J/Inhalts verzeic hnis @ 31\mod_1251969952727_78.doc x @ 302165 @ 1 @ 1 Table of Contents Pos : 5 /BA/Inhalts verz eichnis Spr ac henneutr al @ 10\mod_1221574899104_0.doc x @ 135495 @ @ 1 Table of Contents ...........................3 Foreword ..............................6 Introduction.............................7... - Page 4 Table of Contents Lighting ............................35 Clamp and Buffer..........................37 Operation...............................38 Before mowing ..........................38 Tensioning the Guard Cloth......................39 Moving the guards into the working position ................... 39 Detaching the machine ........................40 Removing the retaing chain (s)......................40 Settings ..............................41 Adjusting the Compensation Springs ....................

- Page 5 Table of Contents 11.3 Intermediate PTO shaft........................71 11.4 Lubrication Chart ..........................71 Placing in Storage ..........................72 Before the Start of the New Season ....................73 13.1 Special Safety Instructions ......................73 13.2 Test run............................73 13.3 Friction Clutch ..........................75 Special equipment..........................76 14.1 Special Safety Instructions ......................

-

Page 6: Foreword

Pos : 7.2 /BA/Vor wort/Eas yC ut/Verehrter Kunde Eas yC ut @ 3\mod_1204546394934_78.doc x @ 70529 @ @ 1 Dear Customer! By purchasing the disc mower, you have acquired a quality product made by KRONE. We are grateful for the confidence you have invested in us in buying this machine. -

Page 7: Introduction

Pos : 9.4 /BA/Ei nleitung/Gültigkeit/Eas yC ut /Eas yC ut F 320 C V @ 101\mod_1330610863651_78.doc x @ 897695 @ 2 @ 1 Validity These operating instructions apply to the disc mowers of series: EasyCut F 320 CV Pos : 9.5 /Ü bers chriften/Ü bersc hriften 3/A- E/Ans pr echpartner @ 0\mod_1195569394286_78.doc x @ 839 @ 3 @ 1 3.2.1 Contact Pos : 9.6 /Adr ess en/Adresse Mas chi nenfabrik KR ONE Spell e @ 0\mod_1195568531083_78.doc x @ 734 @ @ 1... -

Page 8: Identification Plate

Authentic KRONE spare parts and accessories authorised by the manufacturer help to ensure safety. The use of spare parts, accessories and other devices which are not manufactured, tested or approved by KRONE will result in the revoking of the liability for damages resulting thereof. -

Page 9: Intended Use

Introduction Pos : 9.12.1 /Übersc hriften/Übersc hriften 2/A-E/Besti mmungsgemäß er Gebrauch (alt) @ 0\mod_1196401545090_78.doc x @ 7728 @ 2 @ 1 Intended Use Pos : 9.12.2 /BA/Einl eitung/Besti mmungsgemäßer Gebrauc h/Eas yCut/Bes timmungsgemäß er Gebrauc h (Ei nz ahl) @ 3\mod_1204548357809_78.doc x @ 70671 @ @ 1 The disc mower is built exclusively for customary use in agricultural work (intended use). - Page 10 Introduction Pos : 11 /BA/Di es e Seite is t bewusst fr eigelass en worden. @ 1\mod_1201783680373_78.doc x @ 54443 @ @ 1 This page has been left blank deliberately!! Pos : 12 /BA/---------------Seitenumbruc h---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ @ 1...

-

Page 11: Safety

Safety Pos : 13.1 /Übersc hriften/Übersc hriften 1/P-T/Sicher heit @ 0\mod_1195566748646_78.doc x @ 635 @ 1 @ 1 Safety Pos : 13.2 /BA/Sicher heit/Überar bei tete Warnhinweis eKennz eic hnung von Hi nwei sen i n der Betriebsanl eitung Einführungstext (2012-07-27 09:59:06) @ 0\mod_1195637804826_78.doc x @ 1098 @ 2 @ 1 Identifying Symbols in the Operating Instructions The safety instructions contained in this manual which could result in personal injury if not followed are identified by the general danger sign:... -

Page 12: Personnel Qualification And Training

Safety Pos : 13.6.1 /BA/Sicherheit/Personalqualifi kati on und-Sc hul ung @ 0\mod_1195639383185_78.doc x @ 1136 @ 3 @ 1 4.2.1 Personnel Qualification and Training The machine may be used, maintained and repaired only by persons who are familiar with it and have been instructed about the dangers connected with it. -

Page 13: Safety Instructions And Accident Prevention Regulations

Safety Pos : 13.6.5 /BA/Sicherheit/Sic her hei ts- und U nfall ver hütungs-Vorschriften Swadro_Ladewag en_Eas yC ut @ 73\mod_1308298589597_78.doc x @ 655493 @ 2 @ 1 Safety Instructions and Accident Prevention Regulations Please follow all generally applicable safety and accident prevention regulations in addition to the safety instructions contained in these operating instructions! The attached warning and safety signs provide important information for safe operation. -

Page 14: Attached Devices

Safety Parts operated by external power (e.g. hydraulically) can cause crushing and shearing injuries! Before leaving the tractor, lower the implement onto the ground, apply the parking brake, switch off the engine and remove the ignition key! Pos : 13.6.6 /BA/Sicherheit/Angebaute Ger äte/Ger äte angebaut Eas yC ut @ 3\mod_1204552588996_78.doc x @ 70752 @ 2 @ 1 Attached devices Use extreme caution when attaching or detaching implements onto or from the tractor! Couple the respective application devices to the appropriate couplings (e.g. -

Page 15: Pto Operation

Safety Pos : 13.6.8 /BA/Sicherheit/Zapfwellenbetri eb Traktor @ 0\mod_1199699899350_78.doc x @ 33264 @ 2 @ 1 PTO operation 1 Use only PTO shafts specified by the manufacturer! 2 The guard tube and guard cone of the PTO shaft and the PTO guard must be attached and in good working condition (on the implement side, too)! 3... -

Page 16: Hydraulic System

Safety Pos : 13.6.11 /BA/Sic herheit/H ydrauli kanl age @ 2\mod_1203503691986_78.doc x @ 66225 @ 2 @ 1 Hydraulic system 1 The hydraulic system is pressurised! 2 When connecting hydraulic cylinders and motors, make sure the hydraulic hoses are connected as specified! 3... -

Page 17: Maintenance

Replacement parts must at least comply with the technical requirements set by the manufacturer of the implements! This is guaranteed by original KRONE spare parts! Only use nitrogen for filling pneumatic accumulators - risk of explosion! -

Page 18: Unauthorised Conversion/Modification And Spare Parts Production

Safety Pos : 13.6.18 /BA/Sic herheit/Eigenmäc htiger U mbau und Ers atz teil hers tell ung @ 1\mod_1201937705539_78.doc x @ 55745 @ 2 @ 1 Unauthorised Conversion/Modification and Spare Parts Production Conversions or modifications of the machine are permitted only with prior consultation with the manufacturer. -

Page 19: Introduction

Safety Pos : 13.8 /BA/Sicher heit/Eas yC ut/Sic her hei t Ei nführ ung Eas yC ut @ 3\mod_1204553763950_78.doc x @ 70812 @ 2 @ 1 4.11 Introduction The disc mower is equipped with all safety devices (protective devices). However, it is not possible to eliminate all potential hazards on this machine as this would impair its full functional capability. -

Page 20: Position Of The Adhesive Safety Stickers On The Machine

Safety Pos : 13.11 /Ü bersc hriften/Ü berschriften 2/K-O/Lage der Sic her hei tsaufkl eber an der M asc hine @ 0\mod_1195634967326_78.doc x @ 1020 @ 2 @ 1 4.12 Position of the Adhesive Safety Stickers on the Machine Pos : 13.12 /BA/Sic herheit/Aufkleber/Eas yC ut/Sic her heitsaufkl eber Eas yC ut F 320 CV @ 101\mod_1330611409756_78.doc x @ 897857 @ @ 1 Fig. -

Page 21: Re-Ordering The Adhesive Safety And Information Labels

Safety O.K. 1000 O.K. 1000 When the machine is Order No. 939 running, keep your distance. 106-3 (1x) Order No. 942 197-1 (2x) 1000 Lebensgefahr! Danger to life! Danger de mort! Levensgevaarlijk! Livsfara! ¡Peligro de muerte! 942 197-1 942 459-0 Order No. - Page 22 Safety Pos : 16 /BA/Di es e Seite is t bewusst fr eigelass en worden. @ 1\mod_1201783680373_78.doc x @ 54443 @ @ 1 This page has been left blank deliberately!! Pos : 17 /BA/---------------Seitenumbruc h---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ @ 1...

-

Page 23: Commissioning

Commissioning Pos : 18.1 /Übersc hriften/Übersc hriften 1/A-E/Ers tinbetriebnahme @ 0\mod_1196314201498_78.doc x @ 5855 @ 1 @ 1 Commissioning Pos : 18.2 /Übersc hriften/Übersc hriften 2/P-T/Spezi elle Sic her heitshi nweis e @ 0\mod_1196660495760_78.doc x @ 9134 @ 2 @ 1 Special Safety Instructions Pos : 18.3 /BA/Sicher heit/Gefahr enhi nweis e/Eins tell arbeiten / Eins tell ungenGefahr - Eins tellar beiten g ezog ene M asc hinen @ 0\mod_1199717011038_78.doc x @ 33980 @ @ 1 Danger! - Unexpected movements of the machine... -

Page 24: Installation Of Weiste Triangle

Commissioning Pos : 18.9 /BA/Inbetriebnahme/Ersti nbetri ebnahme/Eas yCut/Anbau Weiste-Dreiec k @ 3\mod_1204640890345_78.doc x @ 71160 @ 2 @ 1 Installation of Weiste triangle AFL 245-0-007 Fig. 3 Pos : 18.10 /BA/Sic herheit/Gefahrenhinweise/Mähwer ke/Warnung Anbau des Kuppeldr eiec ks ( Weis te Drei ec k) @ 3\mod_1204638378407_78.doc x @ 71102 @ @ 1 Warning - Installation of the triangle linkage (Weiste triangle) Effect: Danger to life or serious injuries. -

Page 25: Installation Of The Lighting System

Commissioning Pos : 18.15 /BA/Inbetri ebnahme/Erstinbetriebnahme/Eas yC ut/Anbau Bel euc htungsanlage EC F 320 C V @ 101\mod_1330612441935_78.doc x @ 898001 @ 2 @ 1 Installation of the Lighting System EC-433-0 Fig. 5 Observe the country regulations and provisions concerning lighting and warning panels. Install lighting and warning panels, if necessary. - Page 26 Commissioning Pos : 20 /BA/Di es e Seite is t bewusst fr eigelass en worden. @ 1\mod_1201783680373_78.doc x @ 54443 @ @ 1 This page has been left blank deliberately!! Pos : 21 /BA/---------------Seitenumbruc h---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ @ 1...

-

Page 27: Start-Up

Start-up Pos : 22.1 /Übersc hriften/Übersc hriften 1/F-J/Inbetri ebnahme @ 0\mod_1196327075811_78.doc x @ 6375 @ 1 @ 1 Start-up Pos : 22.2 /Übersc hriften/Übersc hriften 2/U-Z/Vorberei tungen am Traktor @ 2\mod_1202363643678_78.doc x @ 58694 @ 2 @ 1 Preparations on tractor Pos : 22.3 /BA/Sicher heit/Gefahr enhi nweis e/M ähwer ke/Gefahr - Unbeabsic htigtes Abkuppeln Frontmähwer ke @ 3\mod_1204641660735_78.doc x @ 71218 @ @ 1 Danger! - Inadvertent uncoupling of the machine during road travel or work. -

Page 28: Mounting Onto The Tractor

Start-up Pos : 22.8 /Übersc hriften/Übersc hriften 2/A-E/Anbau an den Traktor @ 0\mod_1199717845194_78.doc x @ 34039 @ 2 @ 1 Mounting onto the Tractor Pos : 22.9 /BA/Inbetriebnahme/Eas yC ut/Vorbereitung am Tr aktor Bild EC F 320 CV @ 101\mod_1330612646893_78.doc x @ 898143 @ @ 1 Fig. -

Page 29: Lower Suspension Arm

Start-up Pos : 22.15.1 /Ü berschriften/Ü berschriften 3/U-Z/U nterlenkeradapter @ 79\mod_1314688743340_78.doc x @ 697532 @ 3 @ 1 6.2.1 Lower suspension arm Pos : 22.15.2 /BA/Inbetri ebnahme/Eas yCut/U nterlenker adapter /Unterlenkeradapter fi xieren Bild @ 79\mod_1314690338900_78.doc x @ 697669 @ @ 1 EC-387-0 Fig. -

Page 30: Mounting And Adjusting The Relief Springs

Start-up Pos : 22.17 /Ü bersc hriften/Ü berschriften 2/A-E/Anbau und Eins tell ung der Entlastungsfeder n Ü S @ 89\mod_1321958243040_78.doc x @ 756797 @ 2 @ 1 Mounting and Adjusting the Relief Springs Pos : 22.18 /BA/Ers tinbetriebnahme/Eas yC ut/Eas yCut 32 CV Float/Anbau und Eins tell ung der Entl astungsfeder n Schritt 2 @ 89\mod_1321958434944_78.doc x @ 756846 @ @ 1 EC-390-0 Fig. - Page 31 Start-up Pos : 22.20 /BA/Ers tinbetriebnahme/Eas yC ut/Eas yCut 32 CV Float/Anbau und Eins tell ung der Entl astungsfeder n Schritt 3 @ 89\mod_1321958507840_78.doc x @ 756874 @ @ 1 EC-392-0 Fig. 10 • Assemble the tension jacks (1) on the top link clevis (2) and adjust them to the maximum value a = 230 mm Pos : 22.21 /BA/Ers tinbetriebnahme/Eas yC ut/Eas yCut 32 CV Float/Anbau und Eins tell ung der Entl astungsfeder n Schritt 4,5 @ 89\mod_1321958644984_78.doc x @ 756930 @ @ 1 •...

-

Page 32: Pto Shaft

Start-up Pos : 22.24 /Ü bersc hriften/Ü berschriften 2/F-J /Gelenkwelle @ 0\mod_1199781879794_78.doc x @ 34542 @ 2 @ 1 PTO shaft Pos : 22.25 /BA/Sic herheit/Gel enkwell e/Gefahr - Sic h drehende Gel enkwelle_2 @ 0\mod_1199781692950_78.doc x @ 34523 @ @ 1 Danger! - Rotating PTO shaft Effect: Danger to life or serious injuries •... -

Page 33: Install The Pto Shaft

Start-up Pos : 22.30 /Ü bersc hriften/Ü berschriften 2/F-J /Gelenkwelle montier en @ 2\mod_1202398342788_78.doc x @ 59253 @ 2 @ 1 Install the PTO shaft Pos : 22.31 /BA/Inbetri ebnahme/Eas yCut/Anbau Gel enkwell e/Anbau Gelenkwelle @ 3\mod_1204702102883_78.doc x @ 71462 @ @ 1 AFA-0-005 Fig. -

Page 34: Trial Run After First Installation

Start-up Pos : 22.36 /BA/Inbetri ebnahme/Eas yCut/Probel auf nac h Erstmontag e @ 3\mod_1205215927275_78.doc x @ 73555 @ 2 @ 1 Trial run after first installation Caution! After the first connection to the tractor, the machine must undergo a trial run. •... -

Page 35: Driving And Transport

Driving and Transport Pos : 24.1 /Übersc hriften/Übersc hriften 1/F-J/F ahr en und Trans port @ 0\mod_1196330049217_78.doc x @ 6553 @ 1 @ 1 Driving and Transport Pos : 24.2 /BA/Sicher heit/Fahren und Trans port/Mitfahr en Straß enfahrt/Gefahr Straß enfahrt, Mitfahren Eas yCut Front @ 3\mod_1204784303933_78.doc x @ 72994 @ @ 1 Danger! - Transport / road travel Effect: Danger to life, serious injuries or serious damage to the machine. - Page 36 Driving and Transport Pos : 24.7 /BA/F ahren und Tr ansport/Eas yCut/Vor baumaß Länderabhängig EC _Front @ 3\mod_1204784822668_78.doc x @ 73052 @ @ 1 A 3,5 m EC-224-0 Fig. 15 Note - Depending on the country If the front end dimension "A" exceeds 3.5 m, provide suitable means (e.g. assistant giving instructions or mirror at road junctions) to ensure road safety (data sheet for attached implements supplied by the Federal Minister for Transport).

-

Page 37: Clamp And Buffer

Driving and Transport Pos : 24.10 /BA/F ahr en und Trans por t/Eas yC ut/Feststeller und Sc hnäpper @ 78\mod_1314002912379_78.doc x @ 694482 @ 2 @ 1 Clamp and Buffer EC-385-0 Fig. 17 Check the clamp and buffer (1) for tight fit every time before transport or road travel. If the clamp and buffer show signs of damage or wear, replace them. -

Page 38: Operation

Operation Pos : 26.1 /Übersc hriften/Übersc hriften 1/A-E/Bedienung @ 0\mod_1199789505403_78.doc x @ 34825 @ 1 @ 1 Operation Pos : 26.2 /Übersc hriften/Übersc hriften 2/U-Z/Vor dem Mähei ns atz @ 3\mod_1204788384465_78.doc x @ 73168 @ 2 @ 1 Before mowing Pos : 26.3 /BA/Sicher heit/Gefahr enhi nweis e/M ähwer ke/Gefahr - Ar bei tsei ns atz / M ähen @ 73\mod_1307695972255_78.doc x @ 654926 @ @ 1 DANGER! - Using the machine for work Effect: Danger to life, injuries or damage to the machine. -

Page 39: Tensioning The Guard Cloth

Operation Pos : 26.8 /BA/Bedi enung /Eas yC ut/Sc hutz e/Schutz tuch spannen EC F 280/320 CV @ 101\mod_1330615233048_78.doc x @ 898339 @ 2 @ 1 Tensioning the Guard Cloth EC-418-0 Fig. 18 The guard cloth (1) must be tightened each time before using the mower so that it cannot be caught by the conditioner auger. -

Page 40: Detaching The Machine

Operation Pos : 26.12 /Ü bersc hriften/Ü berschriften 2/A-E/Abbau der M asc hine @ 3\mod_1204792387824_78.doc x @ 73245 @ 2 @ 1 Detaching the machine Pos : 26.13 /BA/Sic herheit/Eas yCut/Gefahr - M asc hine abs tell en_ohne H ydrauli ksc hlauch @ 3\mod_1204793072152_78.doc x @ 73283 @ @ 1 Danger! - Unexpected movements of the machine Effect: Danger to life, serious injuries •... -

Page 41: Settings

Settings Pos : 28.1 /Übersc hriften/Übersc hriften 1/A-E/Ei nstellungen @ 0\mod_1199868783862_78.doc x @ 36141 @ 1 @ 1 Settings Pos : 28.2 /BA/Sicher heit/Gefahr enhi nweis e/M ähwer ke/Gefahr - Reparatur_Wartung _Rei nigungs_3 @ 0\mod_1196660613260_78.doc x @ 9153 @ @ 1 Danger! - When performing repair, maintenance or cleaning work on the machine , or in the case of technical intervention, drive elements may start moving. -

Page 42: Adjusting The Cutting Height

Settings Pos : 28.8 /Übersc hriften/Übersc hriften 2/A-E/Ei nstellen der Sc hnitthöhe @ 0\mod_1196660879619_78.doc x @ 9191 @ 2 @ 1 Adjusting the cutting height Pos : 28.9 /BA/Eins tell ung en/Mähwer ke/Sc hni tthöhe/Sc hnitthöhe Bild EC 28/32 C V @ 3\mod_1204708273867_78.doc x @ 71808 @ @ 1 EC-083-2 Fig. -

Page 43: Adjusting The Tedder Speed

Settings Pos : 28.13 /Ü bersc hriften/Ü berschriften 2/A-E/Einstellung der Z etterdr ehz ahl @ 0\mod_1196668564463_78.doc x @ 10266 @ 2 @ 1 Adjusting the Tedder Speed Pos : 28.14 /BA/Sic herheit/Gefahrenhinweise/Ei nstellar beiten / Ei nstellungenGefahr - Ei nstellungen an der M aschi ne @ 0\mod_1196668628056_78.doc x @ 10285 @ @ 1 Danger! - Settings on the machine Effect: Danger to life, injuries or damage to the machine. -

Page 44: Adjusting The Conditioner Plate

Settings Pos : 28.18 /Ü bersc hriften/Ü berschriften 2/A-E/Einstellen des Aufber eitungs blec hs @ 0\mod_1196670615681_78.doc x @ 10399 @ 2 @ 1 Adjusting the conditioner plate Pos : 28.19 /BA/Ei nstellungen/M ähwer ke/Eins tell ung des Aufbereitungs bleches Bild 280/320 C V -1 @ 59\mod_1297428738564_78.doc x @ 558081 @ @ 1 EC-370-0 Fig. -

Page 45: Wide Spreading

Settings Pos : 28.24 /Ü bersc hriften/Ü berschriften 3/A-E/Brei tablag e @ 3\mod_1204713764351_78.doc x @ 72202 @ 3 @ 1 9.4.2 Wide spreading Pos : 28.25 /Abkürz ungen /Abkürz ung en Besc hrei bung/optional @ 102\mod_1331109267412_78.doc x @ 902782 @ @ 1 optional Pos : 28.26 /BA/Ei nstellungen/M ähwer ke/Schwadbr eite / Brei tablag e/Einstellung Breitabl age EC F 320 C V @ 102\mod_1331105706644_78.doc x @ 902725 @ @ 1 EC-434-0... -

Page 46: Maintenance

Maintenance Pos : 30.1 /Übersc hriften/Übersc hriften 1/U-Z/Wartung @ 0\mod_1199883581050_78.doc x @ 36685 @ 1 @ 1 Maintenance Pos : 30.2 /Übersc hriften/Übersc hriften 2/P-T/Spezi elle Sic her heitshi nweis e @ 0\mod_1196660495760_78.doc x @ 9134 @ 2 @ 1 10.1 Special Safety Instructions Pos : 30.3 /BA/Sicher heit/Gefahr enhi nweis e/M ähwer ke/Gefahr - Unvor herges ehene Akti onen an der Mas chi ne_1 @ 0\mod_1196782315875_78.doc x @ 14851 @ @ 1... -

Page 47: Spare Parts

Effect: Danger to life, serious injuries or loss of warranty claims as well as exclusion of liability • Use only authentic KRONE spare parts and accessories authorised by the manufacturer. The use of spare parts, accessories or additional equipment not manufactured, tested or approved by KRONE will exclude any liability for consequential damage. -

Page 48: Tightening Torques (Countersunk Screws)

Maintenance Pos : 30.13 /Ü bersc hriften/Ü berschriften 2/A-E/Anzugs drehmomente über Innens echs kant @ 45\mod_1277106415765_78.doc x @ 411230 @ 2 @ 1 10.4 Tightening Torques (Countersunk Screws) Pos : 30.14 /BA/War tung/Drehmomente / Anzugs momente/Dr ehmomente über Innens ec hs kant @ 45\mod_1277106232328_78.doc x @ 411205 @ @ 1 A = Thread size The tightening torque M is stated in Nm... -

Page 49: Filling Quantities And Lubrication Designations For Gearboxes

Maintenance Pos : 30.19 /Ü bersc hriften/Ü berschriften 2/F-J /Füll mengen und Sc hmier mittel bezeic hnungen der Getriebe @ 0\mod_1196951094046_78.doc x @ 15335 @ 2 @ 1 10.5 Filling Quantities and Lubrication Designations for Gearboxes Pos : 30.20 /BA/War tung/Mähwer ke/Hi nweis Ein Öl wec hs el am M ähhol m ist nic ht erforderlich. @ 68\mod_1304577391388_78.doc x @ 628708 @ @ 1 Note No oil change is required on the cutter bar. -

Page 50: Angular Gearbox

Maintenance Pos : 30.24.1 /Ü berschriften/Ü berschriften 2/U-Z/Wi nkelg etriebe @ 0\mod_1197005918299_78.doc x @ 15435 @ @ 1 10.6 Angular gearbox Pos : 30.24.2 /BA/Wartung/Öl kontroll e_Wechsel/M ähwer ke/Bild Wi nkelgetriebe EC F 320 C V @ 102\mod_1330962465516_78.doc x @ 901037 @ @ 1 EC-430-0 Fig. -

Page 51: Input Gearbox

Maintenance Pos : 30.26.1 /Ü berschriften/Ü berschriften 2/A-E/Eing angsgetriebe @ 0\mod_1197005979596_78.doc x @ 15454 @ @ 1 10.7 Input gearbox Pos : 30.26.2 /BA/Wartung/Öl kontroll e_Wechsel/M ähwer ke/Bild Eing angsgetriebe EC 28/32 CV CRI @ 3\mod_1204725801898_78.doc x @ 72508 @ @ 1 EC-0-040 Fig. -

Page 52: Speed Gearbox

Maintenance Pos : 30.28.1 /Ü berschriften/Ü berschriften 2/P-T/Schaltgetriebe @ 0\mod_1197010889455_78.doc x @ 15766 @ @ 1 10.8 Speed gearbox Pos : 30.28.2 /BA/Wartung/Öl kontroll e_Wechsel/M ähwer ke/Bild Sc hal tgetriebe EC F 320 CV @ 102\mod_1331292108211_78.doc x @ 905946 @ @ 1 EC-041-2 Fig. -

Page 53: Oil Level Check And Oil Change On The Cutter Bar

Maintenance Pos : 30.30.1 /Ü berschriften/Ü berschriften 2/K-O/Ölstands kontroll e und Öl wec hs el am Mähhol m @ 0\mod_1197017549815_78.doc x @ 15963 @ 3 @ 1 10.9 Oil level check and oil change on the cutter bar Pos : 30.30.2 /Ü berschriften/Ü berschriften 3/K-O/Öl wec hs el @ 0\mod_1197021941955_78.doc x @ 16139 @ @ 1 10.9.1 Oil change Pos : 30.30.3 /BA/Wartung/Mähwerke/Hi nweis Ei n Öl wec hs el am M ähhol m ist nicht erfor derlich. - Page 54 Maintenance Pos : 30.30.10 /BA/Wartung/M ähwer ke/Öl kontr olle M ähholm Eas ycut @ 3\mod_1204723206930_78.doc x @ 72428 @ @ 1 • Allow the machine to run briefly. Do not leave the driver’s cab until the cutting discs/blade drums have come to a complete stop EC-0-003 Fig.

-

Page 55: Checking The Cutter Blades And Blade Holder

Maintenance Pos : 30.32.1 /Ü berschriften/Ü berschriften 2/K-O/Kontr olle der Mähkli ngen und M ess erhalter ung @ 0\mod_1197265641329_78.doc x @ 16323 @ @ 1 10.10 Checking the Cutter Blades and Blade Holder Pos : 30.32.2 /BA/Sic herheit/Gefahrenhinweise/Mähwer ke/Gefahr - F ehlende und besc hädigte Mähkli ngen und M ähkli ngenhalterungen @ 0\mod_1197265722813_78.doc x @ 16342 @ @ 1 Warning! - Missing and damaged cutter blades and cutter blade retainers. -

Page 56: Cutter Blades

Maintenance Pos : 30.32.6 /Ü berschriften/Ü berschriften 3/K-O/M ähkli ngen @ 0\mod_1197265959110_78.doc x @ 16361 @ @ 1 10.10.1 Cutter Blades Pos : 30.32.7 /BA/Wartung/Mähwerke/Di e Bohrung der M ähklingen kann sic h durc h Versc hleiß aufweiten. @ 10\mod_1221048982715_78.doc x @ 131675 @ @ 1 The borehole on the cutter blades may spread due to wear. -

Page 57: Blade Screw Connection

Maintenance Pos : 30.32.11 /BA/Wartung/M ähwer ke/M ess erschr aub / M ess erschnellversc hlus s/M essers chr aubverschl uss Haltebolz en 14 mm @ 0\mod_1197267907375_78.doc x @ 16425 @ @ 1 10.10.2 Blade screw connection Danger! - Insufficient thickness of material on the retaining bolts. Effect: Danger to life or serious injuries. -

Page 58: Blade Quick-Fit Device

Maintenance Pos : 30.32.13 /BA/Wartung/M ähwer ke/M ess erschr aub / M ess erschnellversc hlus s/M essers chnell versc hlus s H altebolzen 14mm @ 0\mod_1197268087875_78.doc x @ 16444 @ @ 1 10.10.3 Blade Quick-Fit Device Danger! - Insufficient thickness of material on the retaining bolts. Effect: Danger to life or serious injuries. -

Page 59: Periodical Inspection Of The Leaf Springs

The abrasion limit of the leaf springs will be achieved if the application seam (1) is worn on one point. EC 225 0 Fig. 37 Note Use only original Krone spare parts to replace the leaf springs. Pos : 30.32.16 /BA/---------------Seitenumbruch---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ 3 @ 1... -

Page 60: Periodical Inspection Of The Cutting Discs / Blade Drums

In case of deformed cuttings discs or drums, the dimension of A = 48 mm must never be exceeded. EC-0-211 Fig. 38 Note The cutting discs or drums must be replaced by Original Krone spare parts only. Pos : 30.32.18 /BA/---------------Seitenumbruch---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ 3 @ 1... -

Page 61: Abrasion Limit

If cutting discs or blade drums show deformations or wear in form of abrasions (2) or similar, these components have to be replaced by Original Krone spare parts . Pos : 30.32.20 /BA/---------------Seitenumbruch---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ 2 @ 1... -

Page 62: Blade Changing On Cutting Discs

Maintenance Pos : 30.32.21 /Ü bersc hriften/Ü bersc hriften 2/K- O/Messer wec hsel an M ess ertellern @ 0\mod_1197269068562_78.doc x @ 16521 @ @ 1 10.11 Blade Changing on Cutting Discs Pos : 30.32.22 /BA/Sic her hei t/Gefahrenhi nweis e/M ähwer ke/Gefahr - Schnell roti erende M ess erteller/M ess ertrommeln_1 @ 0\mod_1197017696736_78.doc x @ 16001 @ @ 1 Danger! - Rapidly rotating cutting discs/blade drums. -

Page 63: Blade Screw Connection

Maintenance Pos : 30.32.25 /Ü bersc hriften/Ü bersc hriften 3/K- O/Messers chr aubverschl uß @ 0\mod_1197270941296_78.doc x @ 16578 @ @ 1 10.11.1 Blade Screw Connection Pos : 30.32.26 /BA/Wartung/M ähwer ke/M ess erschr aub / M ess erschnellversc hlus s/Besc hr eibung M ess er wec hs el M ess erschr aubverschl uss @ 47\mod_1285661949953_78.doc x @ 456898 @ @ 1 EC-0-250 Pic. -

Page 64: Blade Quick-Fit Device

Maintenance Pos : 30.32.28 /Ü bersc hriften/Ü bersc hriften 3/K- O/Messers chnell versc hluß @ 0\mod_1197271019859_78.doc x @ 16597 @ @ 1 10.11.2 Blade Quick-Fit Device Pos : 30.32.29 /BA/Wartung/M ähwer ke/M ess erschr aub / M ess erschnellversc hlus s/Besc hr eibung M ess er wec hs el M ess erschnellversc hlus s @ 0\mod_1197271100500_78.doc x @ 16616 @ @ 1 EC-251-0 Fig. -

Page 65: Replacing The Linings

Maintenance Pos : 30.32.31 /BA/Wartung/M ähwer ke/Stoß kanten erneuern @ 0\mod_1197271320468_78.doc x @ 16636 @ @ 1 10.12 Replacing the linings Caution! - If the linings are checked irregularly. Effect: Damage to the machine • Always check the mowing unit for damaged linings prior to start-up and replace linings, if necessary! •... -

Page 66: Rotary Hub With Shear Fuse (Optional)

Maintenance Pos : 30.34.1 /Ü berschriften/Ü berschriften 2/K-O/Kreis elnabe mit Schersic her ung ( optional) @ 4\mod_1213097920976_78.doc x @ 86356 @ @ 1 10.13 Rotary hub with shear fuse (optional) Pos : 30.34.2 /BA/Wartung/Mähwerke/Sc hersic herung/Bil d Mähhol m Aufstellung EC R 280/Bild Mähhol m Aufstellung EC R 280/320 (C V) EC F 320 C V @ 147\mod_1361180309624_78.doc x @ 1319551 @ @ 1 Fig. - Page 67 Maintenance Pos : 30.34.4 /BA/Sic herheit/Gefahrenhinweise/Mähwer ke/Gefahr - Sc hnell rotier ende Messerteller /Mess ertr ommel n_1 @ 0\mod_1197017696736_78.doc x @ 16001 @ @ 1 Danger! - Rapidly rotating cutting discs/blade drums. Effect: Danger to life or serious injuries. • Switch off the engine and remove the ignition key.

-

Page 68: After Shearing Off

Maintenance Pos : 30.34.8 /BA/Wartung/Mähwerke/Sc hersic herung/Nac h dem Absc heren Eas yCut @ 3\mod_1204205154608_78.doc x @ 69944 @ @ 1 10.13.1 After Shearing Off Caution! - Correct installation position of the bearing housing not observed. Effect: Damage to the machine •... - Page 69 • Remove the hub (1). • Remove the damaged shear pins (3). • Check the nut and hub for damage. Replace damaged parts with KRONE original replacement parts. • Fill the space above the bearing with grease (c). • Place the hub on the pinion shaft.

-

Page 70: Maintenance - Lubrication Chart

Maintenance – lubrication chart Pos : 30.36.1 /Ü berschriften/Ü berschriften 1/U-Z/Wartung - Sc hmierpl an @ 0\mod_1197359304198_78.doc x @ 18232 @ 2 @ 1 Maintenance – lubrication chart Pos : 30.36.2 /Ü berschriften/Ü berschriften 2/P-T/Speziell e Sicherheits hinweis e @ 0\mod_1196660495760_78.doc x @ 9134 @ @ 1 11.1 Special Safety Instructions Pos : 30.36.3 /BA/Sic herheit/Gefahrenhinweise/Mähwer ke/Gefahr - R epar atur_Wartung_R einigungs _4 allgemein Eas yC ut @ 11\mod_1223620198301_78.doc x @ 148349 @ 2 @ 1... -

Page 71: Intermediate Pto Shaft

Maintenance – lubrication chart Pos : 30.36.7 /Ü berschriften/Ü berschriften 2/U-Z/Z wis chengelenkwelle @ 3\mod_1204702241039_78.doc x @ 71481 @ @ 1 11.3 Intermediate PTO shaft Pos : 30.36.8 /BA/Wartung/Gelenkwelle schmi eren/Abschmi eren Z wisc heng elenkwelle Bild Eas yC ut F 320 CV @ 116\mod_1340702570926_78.doc x @ 1018197 @ @ 1 EC-440-0 Fig. -

Page 72: Placing In Storage

Perform the necessary repair tasks during the time immediately after the harvest season. Draw up a list of all replacement parts you will need. This will make it easier for your KRONE dealer to process your orders and you will be certain that your machine will be ready for use at the beginning of the next season. -

Page 73: Before The Start Of The New Season

Before the Start of the New Season Pos : 33.4 /Übersc hriften/Übersc hriften 1/U-Z/Vor Beginn der neuen Sais on @ 4\mod_1211272647559_78.doc x @ 82867 @ @ 1 Before the Start of the New Season Pos : 33.5 /Übersc hriften/Übersc hriften 2/P-T/Spezi elle Sic her heitshi nweis e @ 0\mod_1196660495760_78.doc x @ 9134 @ 2 @ 1 13.1 Special Safety Instructions Pos : 33.6 /BA/Sicher heit/Gefahr enhi nweis e/M ähwer ke/Gefahr - Reparatur_Wartung _Rei nigungs_4 allgemei n Eas yC ut @ 11\mod_1223620198301_78.doc x @ 148349 @ @ 1... - Page 74 Before the Start of the New Season Pos : 33.10 /BA/Ei nlag erung/Eas yC ut / AM M ähwer ke/Vor der Saisaon ohne Bereifung @ 3\mod_1204731533226_78.doc x @ 72767 @ @ 1 • Lubricate the machine thoroughly. Remove any condensation water which may have collected in the bearings.

-

Page 75: Friction Clutch

Manipulation of the overload protection changes the slip torque. This will lead to a loss of warranty claims! Original KRONE spare parts only may be used. Pos : 33.15 /BA/Ei nlag erung/Rei bkupplung/R eibkuppl ung entlüften @ 3\mod_1204732297351_78.doc x @ 72885 @ @ 1 EC-257-0 Fig. -

Page 76: Special Equipment

Special equipment Pos : 35.1 /Übersc hriften/Übersc hriften 1/P-T/Sonder ausstattung @ 2\mod_1202808469779_78.doc x @ 61649 @ @ 1 Special equipment Pos : 35.2 /Übersc hriften/Übersc hriften 2/P-T/Spezi elle Sic her heitshi nweis e @ 0\mod_1196660495760_78.doc x @ 9134 @ 2 @ 1 14.1 Special Safety Instructions Pos : 35.3 /BA/Sicher heit/Gefahr enhi nweis e/M ähwer ke/Gefahr - Reparatur_Wartung _Rei nigungs_4 allgemei n Eas yC ut @ 11\mod_1223620198301_78.doc x @ 148349 @ @ 1... - Page 77 index index Information Required for Questions and Orders.. 8 Input gearbox ............. 51 Abrasion Limit .............61 Install the PTO shaft .......... 33 Adjusting Skids ...........76 Installation of the Lighting System ..... 25 Adjusting the Compensation Springs ....41 Installation of Weiste triangle......24 Adjusting the conditioner plate ......44 Intended Use............

- Page 78 Safety-conscious work practices ......12 Test run.............. 46 Settings ...............41 Tightening Torques ..........47 Spare Parts ............47 Tightening Torques (Countersunk Screws) ..48 Special equipment ..........76 Tyres ..............16 Speed gearbox ...........52 Start-up ...............27 Unauthorised Conversion/Modification and Spare Parts Production ..........18 Universally-Jointed Drive Shaft......

- Page 80 . . konsequent, kompetent Maschinenfabrik Bernard Krone GmbH Heinrich-Krone-Straße 10, D-48480 Spelle Postfach 11 63, D-48478 Spelle Phone +49 (0) 59 77/935-0 +49 (0) 59 77/935-339 Internet: http://www.krone.de eMail: info.ldm@krone.de...

Need help?

Do you have a question about the EasyCut F 320 CV and is the answer not in the manual?

Questions and answers