Table of Contents

Advertisement

Quick Links

Service Manual

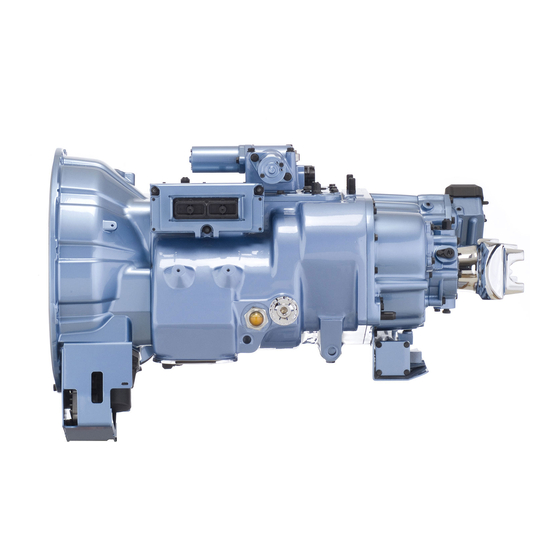

UltraShift PLUS Automated

Transmissions

TRSM0940 EN-US

July 2019

Linehaul Active Shifting (LAS)

Vocational Active Shifting (VAS)

Multipurpose Extreme Performance (MXP)

Multipurpose High Performance (MHP)

Vocational Construction Series (VCS)

Vocational High Performance (VHP)

Vocational Multipurpose Series (VMS)

Vocational Extreme Performance (VXP)

Advertisement

Table of Contents

Summary of Contents for Eaton UltraShift PLUS Series

- Page 1 Service Manual UltraShift PLUS Automated Transmissions TRSM0940 EN-US July 2019 Linehaul Active Shifting (LAS) Vocational Active Shifting (VAS) Multipurpose Extreme Performance (MXP) Multipurpose High Performance (MHP) Vocational Construction Series (VCS) Vocational High Performance (VHP) Vocational Multipurpose Series (VMS) Vocational Extreme Performance (VXP)

- Page 2 | General Information TRSM0970 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 3 FOM-16E310C-VAS FO-10E308LL-VCS FO-11E308LL-VCS FO-12E308LL-VCS FO-14E308LL-VCS FO-16E308LL-VCS FO-17E308LL-VCS FO-16E313A-VHP FO-18E313A-VHP FO-20E313A-VHP FO-10E309ALL-VMS FO-11E309ALL-VMS FO-12E309ALL-VMS FO-14E309ALL-VMS FO-16E309ALL-VMS FO-17E309ALL-VMS FO-14E313B-MHP FO-16E313B-MHP FO-18E313B-MHP FO-20E313B-MHP FO-14E318B-MXP FO-16E318B-MXP FO-18E318B-MXP FO-20E318B-MXP FO-22E318B-MXP FO-18E318A-VXP FO-20E318A-VXP FO-22E318A-VXP FO-14E318B-VXP FO-16E318B-VXP FO-18E318B-VXP FO-20E318B-VXP FO-22E318B-VXP 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 5 TRSM0970 General Information | 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 6 | General Information TRSM0970 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 7 TRSM0970 General Information | 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 8 | General Information TRSM0970 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 9 TRSM0970 General Information | 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 10 | General Information TRSM0970 2019.07.11 © 2017 Eaton. All rights reserved...

-

Page 11: Table Of Contents

Cobra Lever Removal and Installation ... .200 and Disassembly – In Chassis ....42 Eaton Push Button Shift Control Device (PBSC) VCS/VMS Auxiliary Section Removal Removal and Installation . -

Page 12: Warnings & Cautions

This symbol is used throughout this manual to call attention to procedures where carelessness or failure to follow spe- cific instructions may result in personal injury and/or com- ponent damage. Always use genuine Eaton replacement parts. 2018.12.12 © 2017 Eaton. All rights reserved... -

Page 13: How To Use This Manual

Table of Contents, turn to the page specified and follow the procedure. If you are unsure of the name of a component, reference the Transmission Overview pages. 2018.12.12 © 2017 Eaton. All rights reserved... -

Page 14: Transmission Overview

1. Input Shaft Speed Sensor 2. X-Y Shifter 3. Gear Position Sensor 4. Rail Position Sensor 5. Range Solenoid Valve 6. Air Filter/Regulator 7. Output Shaft Speed Sensor 8. Main Shaft Speed Sensor 2018.12.12 © 2017 Eaton. All rights reserved... - Page 15 TRSM0940 General Information | Transmission Overview Transmission - Side View 1. Electronic Clutch Actuator (ECA) Speed Sensor 2. Transmission Electronic Control Unit (TECU) 3. Transmission Harness 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 16 1. Release Yoke and Cross Shaft Assembly 2. Electronic Clutch Actuator (ECA) 3. Low Capacity Inertia Brake (LCIB) Driver Instruction Manual Complete operation instructions can be found in the Driver Instruction Manual TRDR1110. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 17: Serial Tag Information And Model Nomenclature

Fuller Overdrive Bill of Material or Customer Number Fuller Overdrive Multi-Torque This number may be located below the model and serial Fuller numbers. It is a reference number used by Eaton. 2018.12.12 © 2017 Eaton. All rights reserved... - Page 18 The Thru-Shaft PTO mounts on the rear of the transmis- sion. It requires a special auxiliary housing and main case Counter Shaft with internal splines. Split-Shaft The split-shaft PTO mounts between the transmission and the drive axle. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 19: Timing Procedures

4. After placing the Main Shaft assembly into the case, the Counter Shaft Bearings are installed to complete installation of the Counter Shaft assem- blies. This meshes marked Counter Shaft drive gear teeth with marked Main Drive Gear teeth. 2018.12.12 © 2017 Eaton. All rights reserved... - Page 20 “O” up to the front and mark the gear tooth. See Service Bulletin TMIB0150 for further timing instructions. Note: Timing mark may be under bearing and washer. Auxiliary Counter Shaft Marked Two Marked Teeth 180 Degrees Apart 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 21: Preventive Maintenance

1. Oil Fill Plug Check PTO opening and Rear Bearing Covers for oil 47–68 N•m (35–50 lb-ft) leakage due to faulty gaskets. 1.0625-12 Straight Thread 2. Oil Drain Plug 47–68 N•m (35–50 lb-ft) 1.0625-12 Straight Thread 2018.12.12 © 2017 Eaton. All rights reserved... -

Page 22: Assembly And Disassembly Precautions

This procedure will simplify assembly and reduce the possi- bility of losing parts. Cap Screws To prevent oil leakage and loosening, use Eaton Fuller Seal- Bearings ant, Part Number 71205, on all cap screws. Carefully wash and lubricate all usable bearings as removed and protectively wrap until ready for use. -

Page 23: And Disassembly – In Chassis

Auxiliary section with the transmission remaining in the chassis. If the transmission is removed from the truck refer to the “LAS/VAS Auxiliary Section Removal and Disassembly” on page 15. Special Tools None 2018.12.12 © 2017 Eaton. All rights reserved... -

Page 24: Las/Vas Auxiliary Section Removal

LAS/VAS Auxiliary Section Removal and Disassembly – In Chassis | Service Procedures TRSM0940 Component Identification 1. Wiring Harness 2. Auxiliary Case Bolts (x19) 3. Auxiliary Main Shaft Retaining Flange and Yoke 2018.12.12 © 2017 Eaton. All rights reserved... - Page 25 8. Slowly remove the Auxiliary Section from the Main Case and the dowel pins. 9. Once the Auxiliary Section is on the bench, go to LAS/VAS Auxiliary Section Removal and Disassembly on page 15. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 26: And Disassembly

5. Spacer 15. Bearing Cover 6. Auxiliary Main Shaft 16. Seal 7. Auxiliary Counter Shaft 17. Dust Shield 8. Spacer 18. Speed Rotor Assembly 9. Bearing 19. Output Yoke Retainer Flange 10. Race 2018.12.12 © 2017 Eaton. All rights reserved... - Page 27 2. Remove the Output Yoke from the Output Shaft, a maul or hammer may be required to apply force to the yoke for removal. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 28 Bearing Covers. Use the longer bolts to secure the cen- Note: Remove the Range Cylinder Assembly, if needed, ter of each strap as this will ensure the Auxiliary in order to remove all Auxiliary Case bolts. Counter Shafts will remain in time. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 29 4. Using prying points, separate the Auxiliary Section 5. Using an overhead crane or hoist, remove the Auxiliary from the Transmission Main Case enough to fit the Section with the Auxiliary Section Lifting Bracket. Auxiliary Section Lifting Bracket into place. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 30 4. Remove the Range Cylinder assembly. Caution: Auxiliary Counter Shafts will fall out part way through this process. 2. Remove the cap screws that fasten the Range Cover to the Range Cylinder. Remove the Range Cover. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 31 6. As the Auxiliary Main Shaft is driven out, remove the Synchronizer assembly and the Range Yoke. 7. Remove the bearing cup and outer spacer from the Auxiliary Case bore. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 32 LAS/VAS Auxiliary Section Removal and Disassembly | Service Procedures TRSM0940 Range Synchronizer Disassembly 9. Remove the splined spacer and stepped washer from the Auxiliary Reduction Gear. 1. Remove the Range Synchronizer from the Output Shaft. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 33 3. Remove the Sliding Clutch from the pins of the Syn- larger ring facing down, (place a shop towel over the chronizer Ring. assembly to avoid losing any springs) pull the High Range Synchronizer from the Blocker Ring 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 34 1. Install the Sliding Clutch on the Blocker Pins with the recessed side up. 3. Place the High Range Synchronizer Ring over the Blocker Pins of the Low Range Synchronizer, seating the springs against the pins. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 35 Blocker Pins of the Low Range Synchronizer. 5. Install the Synchronizer assembly on the splines of the Auxiliary Main Shaft with the Synchronizer seated against the Range Reduction Gear. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 36: And Installation

5. Spacer 15. Bearing Cover 6. Auxiliary Main Shaft 16. Seal 7. Auxiliary Counter Shaft 17. Dust Shield 8. Spacer 18. Speed Rotor Assembly 9. Bearing 19. Output Yoke Retainer Flange 10. Race 2018.12.12 © 2017 Eaton. All rights reserved... - Page 37 1. Place Output Shaft on bench with yoke end facing up. 4. Install the Auxiliary Reduction Gear onto the Output Shaft with the clutching teeth facing down. 2. Install the stepped washer onto the backside of the Auxiliary Reduction Gear. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 38 Output Shaft Bearing Driver. 6. Place the inner bearing (longer rollers) tapered side up 8. Slide the bearing spacer down on top of the inner bear- over the Auxiliary Main Shaft. ing. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 39 Auxiliary Counter Shaft Installation and Timing Note: The “O” may be behind the washer and bearing 1. If previously removed, install the bearings onto the rear on the rear of the Counter Shaft Gear. of each Counter Shaft. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 40 4. Move the upper and lower Counter Shafts into place on the Range Reduction Gear lining up the timing marks previously made. 7. Before installing the Main Case, remove excess RTV sealant from the mating surfaces of the Auxiliary Case and Main Case. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 41 9. Install the upper and lower Counter Shaft Rear Bearing Races into the Auxiliary Case. 11. Place the outer Auxiliary Shaft Bearing over the shaft with the tapered side down (short rollers), drive into place using the Output Shaft Bearing Driver. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 42 Range Cylinder O-ring, install the Range Cylinder. 15. If the Main Case gearing does not need to be serviced, attach the Auxiliary Section Lifting Bracket to the top of the Auxiliary Case. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 43 17. Install the Auxiliary Case assembly onto the Transmis- sion Main Case dowel pins. Using the Output Shaft, wiggle the Auxiliary Case forward until it is as far for- ward as possible. Remove the Auxiliary Section Lifting Bracket. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 44 Note: Verify the Auxiliary Counter Shafts are still timed to the Auxiliary Reduction Gear before installing. This will allow for easier installation and timing to the Auxil- iary Drive Gear. 2. Install new gasket between the Main Case and Auxiliary Case. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 45 Counter Shaft Covers and the Auxiliary Case. Use multiple positions closest to the cap screws. 5. Install the 16 cap screws that fasten the Auxiliary Sec- tion to the Transmission Main Case. Torque bolts to 35–45 lb-ft. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 46 0.003"–0.005” end-play. (If the required thickness shim does not exist, use the closest undersized shim.) 4. Install required shim into bearing bore, Install new gasket between the Main Case and Auxiliary Case. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 47: Rebuild – In Chassis

4. Range Cylinder Cover and Range Solenoid Valve 5. Range Solenoid Valve Cover 6. Range Cylinder Piston Bolt 7. Range Cylinder Piston 8. Range Cylinder Piston O-ring 9. Range Cylinder O-ring 10. Range Cylinder Bolts (x4) 11. Range Cylinder 2018.12.12 © 2017 Eaton. All rights reserved... - Page 48 Remove the cover. 2. Disconnect the air lines and mark lines that go to the Range Cylinder low and high side fitting. 3. Remove the Air Filter Regulator 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 49 8. Remove the piston from the Range Cylinder. ton. 7. Remove the Range Cylinder and piston from the Auxil- iary Case. 9. Inspect for cut O-rings, rust or debris in the cylinder, scoring, and blocked air passages. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 50 This allows for proper access to the bolt against the Auxiliary Case. Clean off any remaining that secures the Auxiliary Case to the Main Case. debris from the old gasket. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 51 4. Install the Range Piston into the cylinder and onto the yoke bar. 7. Install the Range Cylinder Cover and 4 bolts. Torque bolts 30–35 lb-ft. 5. Torque the bolt 35–45 lb-ft. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 52 10. Install the air lines to the Range Cover as marked and connect the air supply lines to the Air Filter Regulator. 11. Verify all the work is done correctly. Air-up the truck and verify operation of the Transmission Range Sys- tem. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 53 Auxiliary Section with the transmission remaining • Support jack in the chassis. If the transmission is removed from the truck refer to the “VCS/VMS Auxiliary Section Removal and Disassembly” on page 44. Component Identification 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 54: Vcs/Vms Auxiliary Section Removal

10. Slowly remove the Auxiliary Section from the main case and the dowel pins. 11. Once the Auxiliary Section is on the bench, go to “VCS/VMS Auxiliary Section Removal and Disassem- bly” on page 44. 2018.12.12 © 2017 Eaton. All rights reserved... - Page 55 Special Tools • RR1006TR – Auxiliary Section Hanger • RR1002TR – Counter Shaft Support Tools • Soft bar • Maul • Press • Hoist with lifting chain • ACM Alignment Pins (P/N XXXX) 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 56 6. Dowel Pin 17. Washer 7. Washer 18. Output Yoke Retainer Flange 8. Washer 19. Hex Flange Head Screw 9. Reduction Gear 20. Tapered Roller Bearing 10. Bushing 21. Universal Joint Yoke 11. Mainshaft Assembly 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 57 Use the longer bolts to secure the center of each strap as this will ensure the Auxiliary Countershafts will remain in time. Note: Do not use an air gun. Tighten by hand until the screws are snug. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 58 Auxiliary Case housing and insert them into the housing flange tapped holes. Tighten bolts evenly to move the Auxiliary Section away from the front box. Tighten until the gasket seal is broken. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 59 4. Prepare the Auxiliary Section to remove the Auxiliary and Reduction Pistons to the Range and Reduction Counter Shafts. For ease of disassembly, mount the shift Yoke bars. Auxiliary Section upright in a vise. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 60 9. Repeat process to remove 2nd Auxiliary Counter Shaft. 7. Support the Auxiliary Countershaft and remove the strap from the rear of the Auxiliary Case Housing 10. Remove the Auxiliary Counter Shaft Bearing Races from their bores. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 61 13. Remove the washer and dowel pin from the Auxiliary remove both the front and rear bearings from the Mainshaft shafts with a bearing separator and jaw pullers. 12. Remove the 1 ½” nut retainer that was loosened in step 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 62 Low Ranger Gear (Reduction Gear). nizer, please refer to the “How to disassemble the Synchronizer Assembly” section. 15. Remove the Low Range Gear and Coupler Assembly. 17. Remove the bushings from inside the coupler if neces- sary. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 63 Assembly. 19. Remove the splined washer from inside the Low Range 21. Using a soft bar and maul, drive the Output Shaft for- Gear (Reduction Gear) ward and through the Rear Bearing Assembly. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 64 Also remove the one piece race from it’s bore. 23. Remove the Output Shaft bearing cover. 24. Inspect the Rear Bearing Cover oil seal for damage. Remove if damage is found. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 65 2. Using the Deep Reduction Gear front as a base, press the Output Shaft through the bearing and gear. Note: If reusing the bearing set, the tapered roller bear- ings are specific to each side of the race. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 66 Set the Auxiliary Countershaft front bearings in the 3” holes. Set the assembled Auxiliary Mainshaft between the countershafts with the timing marks aligned. Special Tools • Bearing Drivers • Maul • PVC Pipe • RR1002TR Auxiliary Countershaft Support Straps 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 67 4. Range Cylinder Cover and Range Solenoid Valve 5. Range Solenoid Valve Cover 6. Range Cylinder Piston Bolt 7. Range Cylinder Piston 8. Range Cylinder Piston O-ring 9. Range Cylinder O-ring 10. Range Cylinder Bolts (x4) 11. Range Cylinder 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 68 2. Prepare the Low Range Gear for timing. Mark any tooth on the gear and repeat on the tooth directly opposite of the first marked. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 69 Torque to 180-210 lb-ft. 7. Position the Low Range Gear (Reduction Gear) on the Output Shaft with the coupler facing forward on the shaft. 8. Install the dowel pin on the shaft 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 70 11. Flip the Mainshaft so that it is sitting with the forward 12. Install the stepped washer over the Auxiliary Mainshaft section down. with the stepped side up facing the rear of the shaft. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 71 Low Range Gear and the Deep Reduction Gear. 15. Apply grease to Deep Reduction Gear rear thrust sur- face. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 72 Note: A Bearing Driver can also be used to seat the bearing, however if using a bearing driver, install the Bearing inner spacer prior to driving to avoid getting the driver stuck on the shaft. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 73 21. Install the Synchronizer Assembly on the Auxiliary Mainshaft Assembly. 19. Lay the Auxiliary Mainshaft Assembly on its side. 20. Apply light coating of transmission lubricant to the sur- face of the synchronizer assembly. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 74 Use a fixture similar to the one outlined at the begin- remaining two (2) countershaft gears. Paint these ning of the section. teeth. 3. Install the assembled Auxiliary Mainshaft Assembly between the countershafts and match the timing marks. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 75 P/N 4301348. 6. Lay the Auxiliary Case Housing front on a clean flat surface. Install the Bearing Race in the Bearing Bore. 10. Apply Eaton® sealant #71205 or equivalent to the retaining cap screws. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 76 ½” clean capsrews Note: Do not torque with an air gun. Tighten only to hand tight. 14. Apply lube to the o-rings on the Combination Cylinder and the yoke bars for the Range and Reduction. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 77 19. Position a new gasket on the Combination Cylinder Torque to 70-85 lb-ft. mounting surface. Install the Combination Cylinder Cover. Apply Eaton® Sealant #71205 or equivalent to the five (5) retaining cap screws and torque to 35-45 lb-ft. 20. Attach the Auxiliary Section lifting bracket to the top of the Auxiliary Case.

- Page 78 VCS/VMS Auxiliary Section Assembly and Installation | Service Procedures TRSM0940 23. Apply Eaton® Sealant #71205 or equivalent to the 19 retaining cap screws. Secure the Auxiliary Section to the main case. Torque to 35-45 lb-ft 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 79: And Assembly

Service Procedures | VCS/VMS Combination Cylinder Disassembly and Assembly VCS/VMS Combination Cylinder Disassembly and Assembly Special Instructions Apply Eaton® Lubricant or equivalent to Shift Cylinder Assembly and insert valve O-Rings so a film covers the entire surface of each O-Ring. - Page 80 16. Hex Screw 6. Piston 17. Hex Screw 7. O-Ring 18. Cylinder Cover Gasket 8. O-Ring 19. Pipe Plug 9. Nut 20. Range/Splitter Valve 10. O-Ring 21. Hex Flange Head Screw 11. Piston 22. O-Ring 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 81 3. Remove the 3/4” nut on the reduction yoke bar. 1. On the Combination Cover, remove the five (5) cap screws, cover, and gasket 4. Remove the cylinder housing and gasket. 2. Remove the 15/16” nut that secures the range yoke bar. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 82 7. Inspect the O-ring inside the Range Cylinder Housing, cylinder bores remove and replace if damaged. 6. Inspect the Range and Reduction Piston O-Rings for damage. Remove and replace if damage is present. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 83 2. Install the Range and Reduction Piston O-rings on the pistons’ I.D. and O.D. Lightly lubricate O-rings with VCS, VMS Eaton® silicone lubricant #71206 or equivalent. 1. Install the small O-Ring in the Range and Reduction cylinder housing bores. Lightly lubricate O-rings with Eaton®...

- Page 84 Insert the Range piston with flat side to rear. Push it as far back as far as it will go. 5. Secure the Range piston with the 15/16” retaining nut, torque to 70-85 lb-ft (94.91-115.24 N•m). 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 85 Service Procedures | VCS/VMS Combination Cylinder Disassembly and Assembly 8. Install a new gasket on the Cylinder Housing Cover mounting surface and install the Combination cylinder cover. Apply Eaton® Sealant #71205 or equivalent to the five (5) retaining cap screws and torque to 35-45 lb-ft.

- Page 86 VCS/VMS Combination Valve Removal and Installation | Service Procedures TRSM0940 VCS/VMS Combination Valve Removal and Installation Special Instructions Special Tools None None Component Identification None 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 87 4. Lift and remove the Combination valve from the hous- or it could be damaged. ing. Caution: Do not use a hammer to loosen the Combina- tion Valve or it could be damaged. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 88 MHP/MXP/VHP/VXP Auxiliary Section Removal and Disassembly Special Instructions None Special Tools • RR1006TR – Auxiliary Section Hanger • RR1002TR – Counter Shaft Support Tools • Soft bar • Maul • Press • ACM Alignment Pins (P/N XXXX) 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 89 14. Yoke-1710 Half Round 5. Rear Bearing Cover Assembly 15. Lifting Eye 6. Gasket 16. Capscrew 7. Capscrew 17. Capscrew 8. Capscrew 18. Directional Speed Sensor 9. Cover 19. Plug 10. Gasket 20. Shield 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 90 Cover. 2. Remove the Output Yoke from the Output Shaft. A maul 2. Remove the Range Cover Assembly or hammer may be required to apply force to the yoke for removal. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 91 Cylinder Cover. Note: It is helpful to mark the covers to indicate which position they are in as they will need to be reinstalled in the same location. 4. Remove the Splitter cylinder cover 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 92 Note: It may be necessary to drive the dowel pins for- shafts will remain in time. ward to help dislodge the Auxiliary Section. 7. Remove the 19 bolts that fasten the Auxiliary Section to the Transmission Main Case. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 93 Section with the auxiliary section hanger. 1. Too ease in the disassembly of the Auxiliary Section. Place in a vise. 2. Remove the 15/16” nut that fastens the Range Cylinder Assembly to the range shift Yoke bar. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 94 3. Remove the two 3/4” cap screws that secure the Range 4. Using a soft maul, drive the Range Yoke Bar towards Yoke Bar to the Range Yoke Fork. the rear of the auxiliary case. Remove the piston once relieved from cylinder bore. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 95 Counter Shafts. For ease of disassembly, mount the Auxiliary Section upright in a vise. Caution: As the counter shaft straps are remove, the Counter Shaft can fall. 7. Remove the Splitter Sliding Clutch and Splitter Yoke bar and fork. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 96 13. Repeat process to remove 2nd Auxiliary Counter Shaft. 11. Using a soft bar and maul, drive the Output Shaft for- ward far enough to partially unseat the bearing. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 97 Disassembly and Assembly – MHP, MXP, VHP, VXP” section 15. If necessary, secure the Countershafts in a vise and remove both the front and rear bearings from the shafts with a bearing separator and jaw pullers. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 98 19. Using a soft bar and maul, drive the Output Shaft for- ward and through the Rear Bearing Assembly. 22. Inspect the Rear Bearing Cover oil seal for damage. Remove if damage is found. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 99 2. Using the Auxiliary Mainshaft Assembly Gear front as a base, press the Output Shaft through the bearing and gear. Note: If reusing the bearing set, the tapered roller bear- ings are specific to each side of the race. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 100 MHP/MXP/VHP/VXP Auxiliary Section Removal and Disassembly | Service Procedures TRSM0940 3. Remove the splined spacer and stepped washer from the Auxiliary Reduction Gear 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 101 Damage to internal components will result if Auxiliary Sec- tion is not properly removed prior to Cylinder removal. During installation, apply Eaton® Lubricant or equivalent to Shift Cylinder Assembly and insert valve O-Rings so a film covers the entire surface of each O-Ring.

- Page 102 1. On the Range Cylinder Cover, remove cap screws, cover, and gasket 4. Inspect the Range Piston O-Rings for damage. Remove and replace if damage is present. 2. Remove the 15/16” nut that secures the range yoke. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 103 5. Remove the 2 cap screws that secure the Range Yoke 8. Inspect the O-ring inside the Range Cylinder Housing, Bar to the Range Yoke. remove and replace if damaged. 6. Remove the Range Yoke Bar. 7. Remove the Range cylinder housing 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 104 2. Install the piston O-rings on the piston I.D. and O.D. case. Note: Ensure that the Yoke Bar passes through the eye of the Yoke fork. 3. Install a new gasket on the Range Cylinder Housing Mounting Surface 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 105 70-85 lb-ft (94.91-115.24 N•m). Fork. 9. Install a new gasket on the Cylinder Housing Cover mounting surface. Install the Range cylinder cover 7. Insert the piston, pushing it as far back as far as it will 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 106 MHP/MXP/VHP/VXP Range Cylinder Disassembly and Assembly | Service Procedures TRSM0940 10. Apply Eaton Sealant #71205 or equivalent to the retain- ing cap screws and torque to 20-25 lb-ft (27.12-33.90 N•m) 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 107 During removal if replacing only the O-Rings in the Splitter Cylinder, Auxiliary Section removal is not necessary During installation apply Eaton® Lubricant or equivalent to Shift Cylinder Assembly and insert valve O-Rings so a film covers the entire surface of each O-Ring.

- Page 108 3. Splitter Cylinder 4. O-Ring 12. Capscrew 5. Piston 13. O-Ring 6. O-Ring 14. Hex Flange Head Screw 7. Nut 15. Solenoid Valve 8. O-Ring 9. Gasket 10. Splitter Cylinder Cover 11. Pipe Plug 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 109 1. Ensure transmission is drained of oil. 2. Remove retaining cap screws from the Splitter Cylinder Cover 5. Remove the Splitter Cylinder Housing from the rear of the Auxiliary Case Housing 3. Remove cover and gasket 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 110 2. Install small O-ring in the Cylinder Housing Bore if pre- viously removed. 3. On the Piston O.D., install the Piston O-ring if previ- ously removed. 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 111 Splitter Cylinder Cover 6. Install the O-ring on the ID and OD of the piston. Note: Ensure that the gasket air passage aligns with the housing air passage 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 112 MHP/MXP/VHP/VXP Splitter Cylinder Disassembly and Assembly | Service Procedures TRSM0940 9. Apply Eaton Sealant #71205 or equivalent to the retain- ing cap screws, and install on the cover. Torque to 20-25 lb-ft 2019.07.11 © 2017 Eaton. All rights reserved...

-

Page 113: Disassembly And Assembly

Service Procedures | MHP/MXP/VHP/VXP Splitter Gear Bearing Disassembly and Assembly MHP/MXP/VHP/VXP Splitter Gear Bearing Disassembly and Assembly Special Instructions Special Tools Make sure to use proper drivers for the bearing and sleeve. 3.30” Diameter Bearing Driver Component Identification None 2018.12.12 © 2017 Eaton. All rights reserved... - Page 114 MHP/MXP/VHP/VXP Splitter Gear Bearing Disassembly and Assembly | Service Procedures TRSM0940 Splitter Gear Bearing Disassembly 3. Separate the Bearing Pack Assembly. 1. Remove the internal coiled snap ring. 2. Remove the Tapered Bearing Pack Assembly using bearing driver RR1012TR-4. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 115 Service Procedures | MHP/MXP/VHP/VXP Splitter Gear Bearing Disassembly and Assembly Splitter Gear Bearing Assembly 3. Install Bearing assembly 1. Install the Front Bearing Race 4. Install the Rear Bearing Race. 2. Install the bearing spacer 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 116 MHP/MXP/VHP/VXP Splitter Gear Bearing Disassembly and Assembly | Service Procedures TRSM0940 5. Drive the bearing into place using the bearing driver, RR1012TR-4 6. Install the internal snap ring. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 117 5. Tapered Roller Bearing 15. Spacer 6. Bearing Sleeve 16. Tapered Roller Bearing 7. Snap Ring 17. Output Yoke 8. Spring 18. Hex Flange Screw 9. Synchronizer Assembly 19. Universal Joint Yoke 10. Sliding Clutch 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 118 4. Position the Reduction Gear Rear Washer on the Out- put Shaft with the chamfer side up against the Reduc- 2. With the splined washer facing up, place the washer on tion Gear. the Output Shaft shoulder 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 119 6. Install the Bearing Inner Spacer on the Output Shaft. Set aside once installed. 3. Prepare the Splitter gear for timing. Mark any tooth splitter gear and repeat on the tooth directly opposite of the first marked. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 120 Splitter Gear Bearing Disassembly & Assembly, in this manual. 5. Install the Splitter Gear retainer and 15/16” cap screw. Torque to 190-210 lb-ft (257.61-284.72 N•m). Note: Ensure proper torque is applied to the retainer bolt. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 121: Installation

3” holes to maintain the gearing positions when com- bining with the Auxiliary Mainshaft Assembly. Set the Assembled Auxiliary Mainshaft between the Countershafts with the timing marks on all 3 sets of gearing aligned. Component Identification None 2019.07.11 © 2017 Eaton. All rights reserved... - Page 122 Mark the corresponding tooth with a highly visi- surface. If the countershaft bearings were removed, ble paint pen. Also mark the Splitter Gear mating gears use the proper bearing driver and maul to reinstall the on each countershaft. Countershaft Bearings. 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 123 Reduction Gear match up with the timing surface. Install the Bearing Race in the Bearing Bore. marks on the 2 Auxiliary Countershafts. Also, align the timing marks on the splitter gear to match time. 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 124 10. Position a new gasket on the Rear Bearing Cover, and install the cover. 8. Ensure the rear Auxiliary Mainshaft bearing spacer is installed on the shaft. 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 125 TRSM0940 Service Procedures | MHP/MXP/VHP/VXP Auxiliary Countershaft Installation 11. Apply Eaton Sealant #71205 or equivalent to the retain- 13. Install each Auxiliary Countershaft Retaining Strap with ing cap screws, and install the six (6) cap screws in the 2- 3/8” NC x 1” NC and 1 3/8” NC x 2-1/2” clean cap non-chamfered holes.

- Page 126 4. Install Range Yoke Bar from the rear of the Auxiliary case. Note: Ensure that the Yoke Bar passes through the eye of the Yoke fork. 6. Install the O-ring on the ID and OD of the piston. 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 127 Engage into the Splitter Gear to maintain its position 8. Secure the piston with the retaining nut, torque to 70-85 lb-ft (94.91-115.24 N•m). 2. Install small O-ring in the Cylinder Housing Bore if pre- viously removed 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 128 4. Install new O-rings on the ID and OD of the piston. lb-ft (41-49N•m). Lubricate with silicone. 5. Install new O-ring on the end of the yoke bar inside of the cylinder housing. 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 129 Auxiliary Case. ward as possible. Remove the auxiliary section lifting bracket. 2. Position a new Auxiliary Case Gasket on the mounting surface of the Main Case. 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 130 MHP/MXP/VHP/VXP Auxiliary Countershaft Installation | Service Procedures TRSM0940 Auxiliary Countershaft Shimming and 4. Apply Eaton Sealant #71205 or equivalent to the 19 retaining cap screws. Secure the Auxiliary Section to Installation the main case. Torque to 35-45 lb-ft 1. Remove the Auxiliary Countershaft support straps and install a 0.100”...

- Page 131 4. Install required shim into bearing bore. Install new Auxiliary Countershaft gaskets and install Auxiliary Countershaft Covers. 3. Position new gasket on the Splitter Cylinder Cover mounting surface. 4. Install Splitter Cylinder Cover. Torque cap screws to 30-35 lb-ft. 2019.07.11 © 2017 Eaton. All rights reserved...

- Page 132 TRSM0940 Output Yoke Installation 1. Install the Output Yoke. Ensure yoke is properly seated against Output Shaft. 2. Secure the Output Yoke with the 2 retaining bolts. Torque to 84–92 lb-ft (113–124 N•m). 2019.07.11 © 2017 Eaton. All rights reserved...

-

Page 133: Range Synchronizer Disassembly And Assembly

When compressing the HI range synchronizer springs, cover with a shop rag. This will prevent the springs from leaving the area if compression is not achieved. Component Identification 1. Spring 2. Synchronizer Assembly 3. Sliding Clutch 4. Synchronizer Assembly 2018.12.12 © 2017 Eaton. All rights reserved... - Page 134 2. Grab both sides of the HI Range Synchronizer and pull. 1. Place the low range synchronizer on a bench with the larger ring facing down, (place a shop towel over the assembly to avoid losing any springs). 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 135 Service Procedures | Range Synchronizer Disassembly and Assembly Range Synchronizer Assembly 3. Remove the sliding clutch from the pins of the syn- chronizer ring. 1. Install the Sliding Clutch on the blocker pins with the recessed side up. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 136 LO range synchronizer, seating the springs against the pins. 5. Install the synchronizer assembly on the splines of the auxiliary main shaft with the synchronizer seated against the range reduction gear. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 137: Input Shaft Removal And Installation

Special Tools None • RR1023TR Input Shaft Bearing Puller • RR1019TR Hand Maul • RR1005TR Input Shaft Bearing Driver Component Identification 1. Input Shaft 2. Bearing Cover 3. Input Bearing 4. Input Snap Ring 2018.12.12 © 2017 Eaton. All rights reserved... - Page 138 Note: A pry bar or screwdriver may also be used to Input Shaft. This rubber seal is only used to seal the remove the Input Shaft Bearing. Transmission during shipment. 3. Remove the snap ring from the Input Shaft. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 139 7. Remove the Input Shaft from the Main Drive Gear. 8. Inspect the Input Shaft Bushing, replace if damaged. 4. Install the Input Shaft Bearing onto the Input Shaft. Note: The external snap ring on the Input Shaft Bearing should face out. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 140 Main Case. 6. Install the Input Shaft snap ring. 8. Install the Front Bearing Cover and gasket; torque the six cap screws to 35–45 lb-ft. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 141: Clutch Housing Removal And Installation

Clutch Housing Removal and Installation Special Instructions Special Tools None None Component Identification 1. Main Case 2. Stud 3. Gasket 4. Clutch Housing 5. Cap Screws (x6) 6. Washers (x6) 7. Nuts (x6) 2018.12.12 © 2017 Eaton. All rights reserved... - Page 142 4. Put the 6 nuts and washers on the mounting studs and install the bolts into place. 5. In a cross-pattern sequence, torque the nuts to 30 lb-ft, then rotate clockwise 100°. Torque the bolts to 30 lb-ft, then rotate clockwise 115°. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 143: Shift Bar Housing Removal And Installation

TRSM0940 Service Procedures | Shift Bar Housing Removal and Installation Shift Bar Housing Removal and Installation Special Instructions Special Tools None None Component Identification 1. X-Y Shifter 2. Shift Bar Housing 2018.12.12 © 2017 Eaton. All rights reserved... - Page 144 4. Install the Shift Bar Housing onto the Transmission Main Case. 5. Install the 16 cap screws that fasten the Shift Bar Housing to the Transmission Main Case. Torque cap screws to 35–45 lb-ft. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 145: Shift Bar Housing Disassembly And Assembly

8. Air Valve Shaft 18. Shift Block 9. Reverse / LO Shift Yoke* 19. Shift Rail *Due to design changes please verify the part number on the component to ensure proper part replacement. 2018.12.12 © 2017 Eaton. All rights reserved... -

Page 146: 2017 Eaton. All Rights Reserved

5. Remove Shift Bar retaining cap screws 8. Remove the small interlock pin from the bore as the Neutral notch in the bar clears the rear boss bore. 2018.12.12 © 2017 Eaton. All rights reserved... - Page 147 11. Tilt the Shift Bar Housing on its side to remove the two ing rear, removing the yoke from the bar. 3/4" interlock balls from the housing bore. 10. Remove the actuating plunger from the center boss bore. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 148 Position the shift block on the bar between the used) to avoid damaging the Shift Bar Housing gasket center and rear bosses. surface. 4. Install the actuating plunger in the center boss bore. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 149 9. Install the block and yoke Sock screws, tighten and 12. Position the shift block on the bar between the front lock wire securely. and center bosses, long hub to the housing rear. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 150 14. After all lock screws and safety wire have been installed, flip the Shift Bar Housing over. 15. Install the three tension balls and springs into the bores on the top of the Shift Bar Housing. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 151: Removal

None None Component Identification 1. Upper Idler Lubricant Tube 2. Auxiliary Lubricant Tube 3. Idler Feed Lubricant Tube 4. Halo Lubricant Tube 5. Upper Counter Shaft 6. Main Shaft 7. Lower Counter Shaft 2018.12.12 © 2017 Eaton. All rights reserved... - Page 152 2. Remove the Input Shaft snap ring from the Input Shaft. 5. Remove the six cap screws fastening the bearing retainer ring to the Main Case intermediate wall. 3. Remove Holo Lubrication Tube 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 153 Note: When driving the shaft out of position, the washers that are on either side of the Reverse Idler Gear will drop once the shaft is out. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 154 Counter Shaft. 13. Using the K-Line soft maul with hand guard, strike the case to the left of the front Counter Shaft Bearing to drive it out of the bore. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 155 I.D. of the gear. Note: When removing the snap ring, the tension of the snap ring can cause the ring to spring out. 16. Remove the Keyed Washer from back of the Reverse Gear 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 156 Note: Use caution when lifting the Main Shaft from the Main Case as the Reverse Gear can move freely. If low force gearing is present, the 1st/Rev hub as well as the Reverse gear will move freely. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 157 Counter Shaft Bearing to remove it from the bore. 2. With the upper Counter Shaft still pushed as far toward the case as possible, remove the Input Shaft, Main Drive Gear and spacer as an assembly. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 158 3. Using the K-Line J-hook (RR1004TR), remove the upper and lower Counter Shafts from the Transmission Main Case. 1. Remove the two bolts fastening the Main Feed Tube assembly to the Transmission Case. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 159 3. Straighten the lock on the Suction Strainer. Unseat from the pump, and remove the Suction Strainer from the Main Case. 5. Remove the Oil Pump Cover from the front of the Transmission Main Case. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 160: Oil Pump And Lube Tube Installation

Oil Pump and Lube Tube Installation | Service Procedures TRSM0940 Oil Pump and Lube Tube Installation Special Instructions Special Tools None None Component Identification 1. Suction Strainer 2018.12.12 © 2017 Eaton. All rights reserved... - Page 161 Bar Housing opening while going through the interme- diate wall, then rotated into place to line up with the Oil Pump. 3. Install the Oil Pump into the Transmission Main Case; torque bolts to 8–12 lb-ft. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 162 Transmission Main Case. 1. Using the “O” stamped onto the rear of the Main Case Counter Shafts, mark the corresponding tooth on the Main Drive Gear set (front gear) with highly visible ink or dye. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 163 2. Using a J-hook, install the upper Counter Shaft into the Transmission Main Case. Note: Place the back of the upper Counter Shaft into the rear Counter Shaft Bearing bore and carefully swing the Counter Shaft into place. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 164 Main Drive Gear. Place one corner of he snap ring in 6. Install the Input Shaft Spacer on the Input Shaft. the Main Drive Gear groove. With a small screwdriver, slowly work around the Input Shaft until the snap ring is fully seated. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 165 Counter Shaft and into the intermediate wall of the Transmission Main Case until there is enough room to install the rear Counter Shaft Bearing snap ring. 8. Install the Input Shaft snap ring. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 166 Counter Shaft Bearing onto the Counter Shaft and into the bore of the Transmission Main Case. Note: Using an old race for the front Counter Shaft Bearings helps keep the rollers in place during installation. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 167 16. Install the rear Main Shaft Bearing partially into the case to aid in supporting the Main Shaft assembly. Note: Ensure the Reverse Gear remains tucked against 1st Gear. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 168 RR1012TR-4, drive the rear bearing onto the upper Counter Shaft and into the intermediate wall of the Transmission Main Case until there is enough room to install the rear Counter Shaft Bearing snap ring. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 169 Reverse Idler Shaft by placing the bar on the end of the shaft and striking with the maul. 21. Install the front lower Counter Shaft Bearing retaining washer and bolt and torque to 90–120 lb-ft. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 170 Note: Placing a hand maul in between the 1st and drivers, pry it into place working slowly around the Reverse Gear will assist in keeping the Reverse Gear in Main Shaft unit the snap ring is fully seated. position. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 171 Note: Ensure the Retainer Ring is installed in the mission. proper direction. The inner grove should fit over the bearing. 32. Install both upper and lower Auxiliary Counter Shaft Front Bearing Races into the Transmission Main Case intermediate wall if removed. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 172 35–45 lb-ft. 34. Install the Front Bearing Cover and gasket. Important: Confirm the oil return path from the Front Bearing Cover and the gasket return port are aligned. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 173 Note: Verify the Auxiliary Counter Shafts are still timed to the Auxiliary Reduction Gear before installing. This will allow for easier installation and timing to the Auxil- iary Drive Gear. 2. Install new Gasket on the Main Case. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 174 Transmission Main Case, a timing issue with the Auxiliary Section gearing may be the cause. 5. Install the 19 cap screws that fasten the Auxiliary Sec- tion to the Transmission Main Case. Torque bolts to 35–45 lb-ft. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 175: Low Force Gearing

3. Main Shaft Key 11. 3rd Gear 4. Snap Ring 12. OD Gear 5. Reverse Gear 13. Sliding Clutch 6. Spacer 14. Washer 7. Main Shaft Sleeve 15. Sliding Clutch 8. 1st Gear 16. Sliding Clutch 2018.12.12 © 2017 Eaton. All rights reserved... - Page 176 1. Remove the front (4th and 5th Gear) Sliding Clutch from the Main Shaft 4. Remove Snap Ring that retains the key. 2. From the rear of the Main Shaft, remove the Reverse Gear. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 177 Keep each washer with the corresponding gear Shaft. The stepped washers (left) fit between gears and it was mated against. sliding clutches with the stepped edge facing the slid- ing clutch. The flat no-burn washers fit between gears. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 178 7. Remove the 1st Gear from the Main Shaft. 9. Remove 2nd Gear from the Main Shaft. 10. Remove the 3rd stepped washer from the Main Shaft. 8. Remove the 2nd stepped no-burn washer from the Main Shaft. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 179 11. Remove the 2nd–3rd Gear Sliding Clutch. 13. Remove the 5th flat no-burn washer from the Main Shaft. 12. Remove the 4th no-burn washer and 3rd Gear. 14. Remove 4th Gear (5th for direct drive) from the Main Shaft. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 180 Note: The last or furthest forward no-burn washer is smaller than the rest. This is specific for the front of the Main Shaft as the 4th–5th Gear Sliding Clutch is smaller than the 1st–Reverse and 2nd–3rd Gear Slid- ing Clutches. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 181 3. Main Shaft Key 11. 3rd Gear 4. Snap Ring 12. OD Gear 5. Reverse Gear 13. Sliding Clutch 6. Spacer 14. Washer 7. Main Shaft Sleeve 15. Sliding Clutch 8. 1st Gear 16. Sliding Clutch 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 182 Gearing sliding clutch. Rotate the washer to lock it into place. 1. Place the Main Shaft vertical and hold the noise in a vise or a pilot hole in a piece of wood. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 183 4. Install the Overdrive Gear or Direct Drive Gear (depending on the model of the transmission) and the no-burn washer. Rotate the washer and push the air line through. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 184 10. Install the Main Shaft Key through the slot were the 5/32” air line sits by pushing the air line out with the key until it is seated against the role pin. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 185 TRSM0940 Service Procedures | Main Case Main Shaft Assembly with Low Force Gearing 11. Install the snap ring that retains the main shaft key. 12. Install the sliding clutch hub and sliding clutch. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 186 Flip the Main Shaft up and install the rearward for installation. Direct/Overdrive Sliding Clutch with the wide slot aligned with the keyway. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 187: Gearing Disassembly

11. 1/R Sliding Clutch 4. 5th Gear 12. Reverse Gear 5. 3rd Gear 13. Washer 6. 2/3 Sliding Clutch 14. Spacer 7. 2nd Gear 15. Snap Ring 8. Main Shaft Key 16. Auxiliary Bearing 2018.12.12 © 2017 Eaton. All rights reserved... - Page 188 Main Shaft keyway. Note: When removing no-burn washers or spacers, note their location on the Main Shaft to facilitate reas- sembly. Keep each washer with the corresponding gear it was mated against. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 189 7. Remove the 2nd no-burn washer from the Main Shaft. Main Shaft. 8. Remove 2nd Gear from the Main Shaft. 6. Remove the 1st stepped washer and 1st Gear from the Main Shaft. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 190 9. Remove the 3rd stepped washer from the Main Shaft. 11. Remove the 4th stepped washer and 3rd Gear. 12. Remove the 5th no-burn washer from the Main Shaft. 10. Remove the 2nd–3rd Gear Sliding Clutch. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 191 The stepped washers should have the stepped side contacting the sliding clutches and the flat side contacting the gear. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 192: Main Case Main Shaft Assembly

11. 1/R Sliding Clutch 4. 5th Gear 12. Reverse Gear 5. 3rd Gear 13. Washer 6. 2/3 Sliding Clutch 14. Spacer 7. 2nd Gear 15. Snap Ring 8. Main Shaft Key 16. Auxiliary Bearing 2018.12.12 © 2017 Eaton. All rights reserved... - Page 193 4th/5th sliding clutch. 3. Use a piece of 5/32” air line to push up through the key way groove to lock the stepped and no-burn washers in place as the Main Shaft is built. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 194 7. Install the stepped washer. Rotate the stepped washer stepped washer and push the air line through. and push the air line through. 10. Install the 1st/Reverse Sliding Clutch. Align the wide slot on the sliding clutch with the keyway. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 195 12. Install the key and push the air line down through the Main Shaft until it contacts the roll pin. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 196 Main Case Main Shaft Assembly | Service Procedures TRSM0940 14. Remove the Main Shaft assembly from the holding device. Flip the Main Shaft up and install the Direct/Overdrive Sliding Clutch with the wide slot aligned with the keyway. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 197 Reverse Yoke Ramp. This ramp can be not, remove the switch and recheck it for continuity. seen through the shifter opening. Replace as necessary. Also, check for the presence of the Reverse Pin. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 198 Reverse Pin is longer than the Neutral Pin.) 2. Install the gasket on the switch. 3. Install the Reverse Switch. Torque to 15–20 lb-ft (20– 27 N•m). 4. Connect the OEM wiring connector, making sure the locking tab engages properly. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 199: Electronic Clutch Actuator (Eca) Removal

If vehicle is equipped with an 8-bolt PTO, removal may be Basic hand tools required prior to removing the ECA. Follow PTO manufac- turer’s guidelines for removal. Component Identification 1. ECA 2. ECA Cap Screw 2018.12.12 © 2017 Eaton. All rights reserved... - Page 200 1. Disconnect the negative battery cable. 2. Disconnect the 8-way and 3-way connectors from the ECA. Note: Some models do not use a shield. 4. Remove the 4 cap screws from the ECA mounting flange. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 201 1 turn; then rotate the lower jackscrew 1 turn. with the Cross-Shaft. This allows the Release Yoke to Continue until the ECA is fully displaced from the bore. clear the Release Bearing during installation. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 202 ECA Bracket cap screws. the terminal. Note: Ensure the ECA does not bind on the Cross-Shaft Note: Use only Eaton lubricant part number 5564527 by snugging all cap screws before tightening to the (Nye Lubricants NYOGEL 760G. For MSDS safety or specified torque.

-

Page 203: Low Capacity Inertia Brake (Lcib) Removal

Service Procedures | Low Capacity Inertia Brake (LCIB) Removal and Installation Low Capacity Inertia Brake (LCIB) Removal and Installation Special Instructions Special Tools None Basic hand tools Component Identification 1. Mounting Nuts (x2) 2. Low Capacity Inertia Brake (LCIB) 2018.12.12 © 2017 Eaton. All rights reserved... - Page 204 2. Install the 2 retaining nuts and torque nuts to 140–150 lb-ft (190–203 N•m). Note: The LCIB can only be installed one way. The label is toward the right side of the vehicle and facing the fly- wheel. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 205: Release Yoke And Cross-Shaft(S) Removal

Special Instructions Special Tools None Basic hand tools Component Identification 1. Plug 2. O-ring 3. Upper Cross-shaft 4. Bushing 5. Seal 6. Lock Washer 7. Mounting Screw 8. Release Yoke 9. Lower Cross-shaft 2018.12.12 © 2017 Eaton. All rights reserved... - Page 206 Release Yoke and Cross-Shaft(s). 1. Remove the upper and lower Cross-Shaft mounting cap screws and lock washers from the Release Yoke. 4. Remove the lower Cross-Shaft and Release Yoke. 2. Remove the Cross-Shaft Plug with O-ring. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 207 1. If previously removed, install the 2 upper Cross-Shaft Bushings. Note: Make sure to apply grease to the bushings. 6. If necessary, remove the 2 upper Cross-Shaft Bush- ings. 2. If previously removed, install the upper Cross-Shaft Grease Seal. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 208 1 cap screw and lock washer by hand. 6. If previously removed, install the O-ring onto the Cross-Shaft Plug and then install the Cross-Shaft Plug into the Transmission Housing and torque to 34–48 lb-ft (46–65 N•m). 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 209 Service Procedures | Release Yoke and Cross-Shaft(s) Removal and Installation 7. Tighten the 2 Yoke cap screws to 35–45 lb-ft (47–61 N•m). 8. Grease upper Cross-Shaft assembly, refer to the Clutch Service Manual (CLSM0200) for proper purging proce- dure. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 210 Cobra Lever Removal and Installation | Service Procedures TRSM0940 Cobra Lever Removal and Installation Special Instructions Special Tools None Basic hand tools Component Identification 1. Tower 2. Screw 3. 8-Way Cobra Lever Harness Connector 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 211: Cobra Lever Removal And Installation

Cobra Lever into the tower. 2. Disconnect the 8-way Cobra Lever Harness connector 2. Using a Phillips screwdriver install the 4 screws into and remove the Cobra Lever from the housing. the Cobra Lever Housing. 2018.12.12 © 2017 Eaton. All rights reserved... -

Page 212: Eaton Push Button Shift Control Device (Pbsc

Eaton Push Button Shift Control Device (PBSC) Removal and Installation | Service Procedures TRSM0940 Eaton Push Button Shift Control Device (PBSC) Removal and Installation Special Instructions Special Tools The exact location varies depending on vehicle manufac- Basic hand tools turer. -

Page 213: Removal And Installation

TRSM0940 Service Procedures | Eaton Push Button Shift Control Device (PBSC) Removal and Installation Eaton PBSC Removal Eaton PBSC Installation 1. Using a 1/4” socket, loosen the retaining bolt and dis- 1. Install the Shift Control in the mounting location. Then, connect the 30-way connector from the back of the using a 11/32”... - Page 214 6. 8-way Electronic Clutch Actuator (ECA) Connector 7. Range Solenoid Connector 8. Output Shaft Speed Sensor Connector 9. Engine Speed Sensor Connector 10. Main Shaft Speed Sensor 11. X-Y Shifter Connector 12. Terminating Resistor Connector 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 215: Transmission Harness Removal And Installation

• Main Shaft Speed Sensor will occur. • Gear Select Sensor and Rail Select Sensor • Output Shaft Speed Sensor • Range Valve Solenoids • ECA Speed Sensor • 8-way ECA Connector • X-Y Shifter 2018.12.12 © 2017 Eaton. All rights reserved... -

Page 216: Transmission Electronic Control Unit (Tecu

Transmission Electronic Control Unit (TECU) Removal and Installation Special Instructions Special Tools None Basic hand tools Component Identification 1. Nut 2. Bracket 3. Transmission Electronic Control Unit (TECU) 4. 38-Way Connectors 5. Cap Screw (Located inside 38-way connectors) 2018.12.12 © 2017 Eaton. All rights reserved... - Page 217 • Using a 5/32” hex wrench, unscrew and disconnect the Transmission Harness 38-way Connector and Vehicle Interface 38-way Connector. 5. Remove the Transmission Controller assembly from the locating studs. 3. Using a 7/16” socket, remove the 3 mounting nuts. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 218 (2.82 +/- 0.33 N•m). • Using a 5/32” wrench, reconnect the Vehicle Inter- face 38-way Connector and tighten to 25 +/- 3 lb-in (2.82 +/- 0.33 N•m). • Reconnect the negative battery cable. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 219 2. With ServiceRanger connected perform Clutch ECA Calibration in Service Routines Option. Grade Sensor Calibration 1. Key on, engine off with truck on level ground. 2. With ServiceRanger connected perform Grade Sensor Calibration in Service Routines Option. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 220 X-Y Shifter Removal and Installation | Service Procedures TRSM0940 X-Y Shifter Removal and Installation Special Instructions Special Tools None Basic hand tools Component Identification 1. Cap Screw 2. X-Y Shifter 3. Gasket 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 221: X-Y Shifter Removal And Installation

4. Remove X-Y Shifter and gasket. Warning: Possible Pinch Point - Ensure battery is dis- connected before removing X-Y Shifter. 2. Disconnect the Rail Select and Gear Select Motors from the Transmission ECU (TECU). 2018.12.12 © 2017 Eaton. All rights reserved... - Page 222 1. Ensure Shift Blocks are in the Neutral position, then Housing. move Shift Finger to the center (Neutral) location. Note: Apply Eaton sealant part number 71205 or equiv- Note: If the Shift Finger is not properly aligned, the X-Y alent to the mounting cap screws before installing.

- Page 223 • Turn ignition switch on. Allow the Transmission to 5. Reconnect the Rail Position Sensor and Gear Position power up. Sensor. • Turn ignition switch off. Wait 2 minutes. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 224 The Range Valve may be difficult to remove from the Trans- Basic hand tools mission Housing because of the O-rings. Component Identification 1. Protective Cover (Optional) 2. Cap Screw 3. Valve 4. O-rings 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 225: Range Valve Removal And Installation

When air pressure has been relieved, dis- connect the Transmission Harness from the Range Valve. Note: The harness should be removed from the Range Valve cable tie prior to removing the cap screws. 2018.12.12 © 2017 Eaton. All rights reserved... - Page 226 Range Valve Installation 3. Reconnect the Transmission Harness to the Range Valve and close all air tanks drains. Important: Lubricate O-rings with Eaton Fuller silicone Note: Install the Range Harness back into the cable tie 71214 or equivalent. on the Range Valve.

-

Page 227: Output Shaft Speed Sensor Removal

Speed Sensor location may vary depending on OEM design specifications. The sensor will be located at 10 o’clock on the Output Shaft Housing in heavy-duty models Component Identification 1. Cap Screw 2. 2-Way Directional Output Shaft Speed Sensor 2018.12.12 © 2017 Eaton. All rights reserved... - Page 228 Output Shaft Speed Sensor Removal 3. Remove the speed sensor from the Transmission Rear Bearing Cover. 1. Disconnect the Transmission Harness from the Output Shaft Speed Sensor pigtail connector. 2. Remove the sensor retaining bolt. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 229 3. Apply included material to the Sensor Connector termi- nals. Note: Apply just enough material to cover the end of the terminal. Note: Use only Eaton lubricant 5564527. (Nye Lubri- cants NYOGEL 760G - For MSDS safety or other infor- mation see www.nyelubricants.com) 2018.12.12...

- Page 230 Input Shaft Speed Sensor Removal and Installation | Service Procedures TRSM0940 Input Shaft Speed Sensor Removal and Installation Special Instructions Special Tools None Basic hand tools Component Identification 1. 2-Way Input Shaft Speed Sensor 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 231: Input Shaft Speed Sensor Removal And Installation

3. Remove the Input Shaft Speed Sensor, with O-ring, from the Transmission Shift Bar Housing. 1. Disconnect the Transmission Harness from the Input Shaft Speed Sensor or pigtail connector, if equipped. 2. Using a 3/8” socket, remove the sensor retaining bolt. 2018.12.12 © 2017 Eaton. All rights reserved... - Page 232 Speed Sensor or pigtail connector, if equipped. Important: Clean the mounting surface on the housing and remove any burrs or sharp edges. Important: Lubricate the O-ring with Eaton Fuller silicone 71214 or equivalent. 1. Using a smooth, twisting motion, fully insert the Input Shaft Speed Sensor in the Transmission Shift Bar Housing opening.

- Page 233 Service Procedures | Main Shaft Speed Sensor Removal and Installation Main Shaft Speed Sensor Removal and Installation Special Instructions Special Tools None Basic hand tools Component Identification 1. 2-Way Main Shaft Speed Sensor 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 234: Main Shaft Speed Sensor Removal And Installation

Remove the Main Shaft Speed Sensor, with O-ring, 1. Disconnect the Transmission Harness from the Main from the rear of the Shift Bar Housing. Shaft Speed Sensor pigtail. 2. Using a 3/8” socket, remove the bolt from the retaining clip. 2018.12.12 © 2017 Eaton. All rights reserved... - Page 235 Transmission Harness. Important: Clean the mounting surface on the housing and remove any burrs or sharp edges. Important: Lubricate the O-ring with Eaton Fuller silicone 71214 or equivalent. 1. Use a smooth twisting motion; fully insert the Main Shaft Speed Sensor in the rear Transmission Shift Bar Housing bore 2.

-

Page 236: Electronic Clutch Actuator (Eca) Speed Sensor

Electronic Clutch Actuator (ECA) Speed Sensor Removal and Installation | Service Procedures TRSM0940 Electronic Clutch Actuator (ECA) Speed Sensor Removal and Installation Special Instructions Special Tools None Basic hand tools Component Identification 1. 2-Way Electronic Clutch Actuator (ECA) Speed Sensor 2018.12.12 © 2017 Eaton. All rights reserved... - Page 237 Important: Clean the mounting surface on the housing and tronic Clutch Actuator (ECA) Speed Sensor. remove any burrs or sharp edges. Important: Lubricate the O-ring with Eaton Fuller silicone 71214 or equivalent. 1. Using a smooth twisting motion; fully insert the Elec-...

- Page 238 Electronic Clutch Actuator (ECA) Speed Sensor Removal and Installation | Service Procedures TRSM0940 3. Reconnect the ECA Speed Sensor pigtail to the Trans- mission Harness. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 239 Service Procedures | Rail Position Sensor Removal and Installation Rail Position Sensor Removal and Installation Special Instructions Special Tools None Basic hand tools Component Identification 1. Cap Screw 2. 3-Way Rail Position Sensor 3. Gasket 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 240: Rail Position Sensor Removal And Installation

2. Using a 5/32” hex key wrench, remove the 2 sensor hex key mounting screws. Caution: Carefully allow the sensor to rotate to a relaxed position, or the sensor can snap when the hex key mounting screws are removed. 2018.12.12 © 2017 Eaton. All rights reserved... - Page 241 Note: Install the sensor, so connector opening faces right side of the Transmission. (As viewed from the rear of the transmission) 3. Reconnect the Transmission Harness to the Rail Posi- tion Sensor. 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 242 Gear Position Sensor Removal and Installation | Service Procedures TRSM0940 Gear Position Sensor Removal and Installation Special Instructions Special Tools None Basic hand tools Component Identification 1. Cap Screw 2. 3-Way Gear Position Sensor 3. Gasket 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 243: Gear Position Sensor Removal And Installation

2. Using a 5/32” hex key wrench, remove the two (2) sen- sor hex key mounting screws. Caution: Carefully allow sensor to rotate to a relaxed position, or sensor can snap when the hex key mount- ing screws are removed. 2018.12.12 © 2017 Eaton. All rights reserved... - Page 244 Note: Install sensor so the connector opening faces the front of the Transmission. 3. Reconnect the Transmission Harness to the Gear Posi- tion Sensor. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 245: Appendix

General Tools press, mauls and soft bars are the only tools needed to suc- The following general tools are available from several tool cessfully disassemble and reassemble any Eaton® Fuller® manufacturers such as Snap-On, Mac, OTC and many oth- Transmission. -

Page 246: Tool Specifications

Tool Specifications | Appendix TRSM0940 Special Tools The following special tools are designed for this Eaton® Fuller® Transmission. The address and phone number of the tool supplier are listed after the table. This list is pro- vided as a convenience to our customers. These tools are manufactured by an independent company with no relation- ship to Eaton®... - Page 247 4301157 included in kit K-2394 5/32” Air Line Release Tool Remove 5/32” air lines from push-to-connect fittings 4301158 included in kit K-2394 Air Line Cutting Tool Cut plastic air lines smoothly and squarely 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 248 Tool Specifications | Appendix TRSM0940 Special Tools Manufacturer Below is the address and phone number of the company that makes tools specifically for Eaton® Fuller® Transmis- sions: K-Line Tools 315 Garden Ave. Holland, MI 49424 800-824-5546 www.klineind.com Shop Equipment The following tool will be needed to complete the removal and installation of the Eaton®...

-

Page 249: Oil Leak Inspection Process

Inspect repaired area to ensure oil leak has been eliminated. If the leak(s) still occurs, repeat steps or contact the Roadranger Call Center at 1-800-826-4357. 2018.12.12 © 2017 Eaton. All rights reserved... -

Page 250: Inspection Procedure

When replace- of gear teeth faces presents no threat of transmis- ment is necessary, use only genuine Eaton® Fuller® Trans- sion failure. Often in continued operation of the mission parts to assure continued performance and unit, frosted gears “heal”... - Page 251 Check blocker pins for excessive wear or loose- ness. • Check Synchronizer contact surfaces on the Syn- chronizer cups for wear. Washers • Check surfaces of all washers. Washers scored or reduced in thickness should be replaced. 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 252: Power Flow

5. The rear of the front section Main Shaft is splined into the Auxiliary Drive Gear, and torque is now delivered to the Auxiliary Section. 10th Gear FM, 9th Gear FO & FOM Front Section Torque (1st Gear) 2018.12.12 © 2017 Eaton. All rights reserved... - Page 253 Clutch is rearward and engaged into the Auxiliary Main Shaft Reduction Gear, through the Range Sliding Clutch and then into the Output Shaft (Auxiliary Main Shaft). 1st Gear Low Range (Auxiliary Sliding Clutch Back) 2nd Gear 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 254 Power Flow | Appendix TRSM0940 3rd Gear 6th Gear 4th Gear—FM/Direct Drive Transmission 7th Gear 5th Gear—FO & FOM/Overdrive Transmission 8th Gear 5th Gear—FM/Direct Drive Transmission 4th Gear—FO & FOM/Overdrive Transmission 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 255 TRSM0940 Appendix | Power Flow 9th Gear—FM/Direct Drive Transmission 10th Gear—FO & FOM/Overdrive Transmission 10th Gear—FM/Direct Drive Transmission 9th Gear—FO & FOM/Overdrive Transmission 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 256: Torque Specifications

Description Qty. Size Torque XY Shifter Cap Screws 0.375" 30–40 lb-ft (41–54 N•m) Auxiliary Drive Gear Bearing Retainer Cap Screws 0.375" 35–45 lb-ft (48–61 N•m) 2018.12.12 © 2017 Eaton. All rights reserved... - Page 257 84–120 lb-ft (9.5–13.6 N•m) LCIB Nuts 0.625" 140–150 lb-ft (190–203 N•m) LCIB Studs 0.625" 18 UNC 60 lb-ft (81 N•m) Drive studs until bottomed Release Yoke Pinch Bolts 0.4375" 14 35–45 lb-ft (47–61 N•m) 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 258 See OEM for torque specifica- tion Range/Filter Regulator Plugs 0.125" 27 PTF 84–120 lb-in (9.5–13.6 N•m) 6-Bolt PTO Cover Cap Screws 0.375" 40–45 lb-ft (54–61 N•m) Range Shift Cylinder Cover Cap Screws 0.375" 30–35 lb-ft (41–47 N•m) 2018.12.12 © 2017 Eaton. All rights reserved...

- Page 259 84–92 lb-ft (113–124 N•m) Auxiliary Housing Cap Screws 0.375" 35–45 lb-ft (48–61 N•m) Auxiliary Counter Shaft Rear Bearing Cover Cap 0.375" 30–35 lb-ft (41–47 N•m) Screws Speed Sensor Retaining Bolt 0.25" 8–12 lb-ft (11–16 N•m) 2018.12.12 © 2017 Eaton. All rights reserved...

-

Page 260: Lubrication Specifications

Caution: Do not mix lubricants of different grades. The following conditions, in any combination, can cause Note: For a list of Eaton Approved Synthetic Lubricants, see operating temperatures that exceed 250°F (120°C): TCMT0021 Roadranger Lubricant Products or call 1-800-826-HELP (4357). -

Page 261: Clutch Greasing Guidelines

Apply and bearing wear pad wear. grease until it purges from the rear of the housing. Important: Eaton recommends the use of Roadranger EP2 Grease on the Transmission Input Shaft will extend for release bearing lubrication, or an equivalent Lithium... -

Page 262: Grade Sensor Calibration

Note: Verify vehicle is parked on level ground and the suspension is fully aired (if equipped) and set to proper ride height. 2. Key on with engine off. 3. Select Low mode with the Transmission Driver Interface Device. 2018.12.12 © 2017 Eaton. All rights reserved... - Page 263 Although every attempt has been made to ensure the accuracy of information contained within, Eaton makes no repre- sentation about the completeness, cor- rectness or accuracy and assumes no responsibility for any errors or omis- sions.

Need help?

Do you have a question about the UltraShift PLUS Series and is the answer not in the manual?

Questions and answers