Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Schweitzer Engineering Laboratories SEL-787

- Page 1 SEL-787 Transformer Protection Relay Instruction Manual 20081022 *PM787-01-NB*...

- Page 2 Schweitzer Engineering Laboratories, Inc. reserves all rights and benefits afforded under federal and international copyright and patent laws in its products, including without limitation software, firmware, and documentation. The information in this manual is provided for informational use only and is subject to change without notice. Schweitzer Engineering Laboratories, Inc. has approved only the English language manual.

-

Page 3: Table Of Contents

Front-Panel Settings (SET F Command)....................... 4.96 Report Settings (SET R Command) ......................4.106 DNP Map Settings (SET DNP n Command, n = 1, 2, or 3)..................4.109 Modbus Map Settings (SET M Command)....................4.110 Date Code 20081022 Instruction Manual SEL-787 Relay... - Page 4 SEL Communications Processor ........................C.3 SEL Communications Processor and Relay Architecture ................C.5 Appendix D: DNP3 Communications Overview ................................. D.1 Introduction to DNP3............................D.1 DNP3 in the SEL-787 ............................. D.6 DNP3 Documentation ........................... D.19 SEL-787 Relay Instruction Manual Date Code 20081022...

- Page 5 Appendix I: M Communications IRRORED Overview ................................I.1 Operation ................................I.1 Settings ................................I.5 Appendix J: Relay Word Bits Overview ................................J.1 Definitions ................................J.4 Appendix K: Analog Quantities Glossary Index SEL-787 Relay Command Summary Date Code 20081022 Instruction Manual SEL-787 Relay...

- Page 6 This page intentionally left blank...

- Page 7 List of Tables Instruction Manual Table 1.1 SEL-787 Serial Port Settings....................1.5 Table 2.1 Communication Ports......................2.4 Table 2.2 Communication Card Interfaces and Connectors..............2.5 Table 2.3 Current Card Terminal Allocation..................2.5 Table 2.4 Current/Voltage Card Terminal Allocation ................2.6 Table 2.5...

- Page 8 SET Command Editing Keystrokes..................6.5 Table 6.5 SET Command Format ......................6.5 Table 6.6 Setting Interdependency Error Messages ................6.6 Table 7.1 SEL-787 Communications Port Interfaces ................7.1 Table 7.2 EIA-232/EIA-485 Serial Port Pin Functions .................7.5 Table 7.3 Protocols Supported on the Various Ports ................7.7 Table 7.4 Serial Port Automatic Messages...................7.11...

-

Page 9: Firmware

Table 8.2 Front-Panel Pushbutton Functions ..................8.5 Table 8.3 Possible Warning Conditions (Flashing TRIP LED) ............8.13 Table 8.4 SEL-787 Front-Panel Operator Control Functions .............. 8.15 Table 9.1 Event Types ..........................9.4 Table 9.2 Analog Event Report Columns Definitions................9.7 Table 9.3... -

Page 10: Instruction Manual

DNP3 Access Methods......................D.4 Table D.4 TCP/UDP Selection Guidelines..................... D.6 Table D.5 DNP3 Access Methods......................D.6 Table D.6 SEL-787 Event Buffer Capacity .................... D.9 Table D.7 Port DNP3 Protocol Settings ....................D.10 Table D.8 Serial Port DNP3 Modem Settings ..................D.12 Table D.9 Sample Custom DNP3 AI Map ................... - Page 11 ACSI Models Conformance Statement ................F.26 Table F.29 ACSI Services Conformance Statement................F.28 Table H.1 PMU Settings in the SEL-787 for C37.118 Protocol in Global Settings ......H.4 Table H.2 SEL-787 Serial Port Settings for Synchrophasors ..............H.5 Table H.3 Synchrophasor Order in Data Stream (Voltages and Currents)..........

- Page 12 This page intentionally left blank...

-

Page 13: Overview

With REF (Restricted Earth Fault) Protection ..............2.22 Figure 2.21 SEL-787 Provides Two-Winding Transformer Differential Protection With REF and Voltage-Based Protection ................2.23 Figure 2.22 SEL-787 Provides Autotransformer Differential Protection, including REF Protection ..2.24 Figure 2.23 Example DC Connections ....................... 2.25 Figure 3.1 Serial Port Communication Dialog Box .................. -

Page 14: Settings

Figure 4.56 Settings to Configure Input 1 as a 4–20 mA Transducer Measuring Temperatures Between -50°C and 150°C ....................4.88 Figure 4.57 Analog Output Number Allocation ..................4.89 Figure 4.58 Analog Output Settings ......................4.90 Figure 4.59 DC Mode Processing........................4.90 Figure 4.60 AC Mode Processing........................4.91 SEL-787 Relay Instruction Manual Date Code 20081022... - Page 15 Front-Panel Setting Entry Example................... 6.3 Figure 7.1 EIA-232 DB-9 Connector Pin Numbers..................7.4 Figure 7.2 SEL Cable C234A —SEL-787 to DTE Device ................. 7.5 Figure 7.3 SEL Cable C227A —SEL-787 to DTE Device ................. 7.5 Figure 7.4 SEL Cable C222—SEL-787 to Modem..................7.6 Figure 7.5...

- Page 16 Figure D.8 Sample Custom DNP3 BO Map Settings................D.18 Figure D.9 Binary Output Map Entry in QuickSet Software ........... D.18 ERATOR Figure F.1 SEL-787 Predefined Reports...................... F.6 Figure F.2 SEL-787 Datasets........................F.8 Figure F.3 Goose Quality..........................F.9 SEL-787 Relay Instruction Manual...

-

Page 17: Overview

Phase Reference ........................H.2 Figure H.2 Waveform at Relay Terminals May Have a Phase Shift ............H.3 Figure H.3 Correction of Measured Phase Angle ..................H.3 Figure H.4 Sample MET PM Command Response .................. H.11 Date Code 20081022 Instruction Manual SEL-787 Relay... - Page 18 This page intentionally left blank...

-

Page 19: Overview

Appendix C: SEL Communications Processors. Provides examples of how to use the SEL-787 with the SEL-2032, SEL-2030, and SEL-2020 Communications Processors for total substation automation solutions. Date Code 20081022 Instruction Manual SEL-787 Relay... - Page 20 Briefly describes the serial port commands that are fully described in Section 7: Communications. Conventions Typographic There are three ways to communicate with the SEL-787: Conventions ➤ Using a command line interface on a PC terminal emulation window. ➤ Using the front-panel menus and pushbuttons.

- Page 21 Examples This instruction manual uses several example illustrations and instructions to explain how to effectively operate the SEL-787. These examples are for demonstration purposes only; the firmware identification information or settings values included in these examples may not necessarily match those in the current version of your SEL-787.

- Page 22 Safety and General Information Laser/LED Emitter The SEL-787 is a Class 1 LED Product and complies with IEC 60825-1:1993 + A1:1997 + A2:2001. The following figure shows the compliance label that is located on the left side of the device (when facing the front of the device).

- Page 23 Preface Safety and General Information The following figure shows the LED location specific to the SEL-787 (see Figure 2.9 for the complete rear-panel drawing). Fiber-Optic (LED) Ports LED Location Specific to the SEL-787 LED Safety Warnings and Precautions ➤ Do not look into the end of an optical cable connected to an optical output.

- Page 24 Instructions for Use a mild soap or detergent solution and a damp cloth to carefully clean the SEL-787 chassis when necessary. Avoid using abrasive materials, polishing Cleaning and compounds, and harsh chemical solvents (such as xylene or acetone) on any Decontamination surface of the relay.

- Page 25 Voltage-based and RTD-based protection are available as options. All relay models provide monitoring functions. This manual contains the information needed to install, set, test, operate, and maintain any SEL-787. You need not review the entire manual to perform specific tasks. Features ➤...

-

Page 26: Models, Options, And Accessories

Models, Options, and Accessories Models Complete ordering information is not provided in this instruction manual. See the latest SEL-787 Model Option Table at www.selinc.com, under SEL Literature, Ordering Information (Model Option Tables). Options and accessories are listed below. ➤... - Page 27 ➢ SEL-2600 series RTD Module ➢ A simplex 62.5/125 µm fiber-optic cable with ST connector for connecting the external RTD module to the SEL-787 ➤ SEL-787 Configurable Labels ➤ Rack-Mounting Kits ➢ For one relay ➢ For two relays ➢...

-

Page 28: Applications

SEL-787 effectively. This section presents the fundamental knowledge Logic setting changes, the user may you need to operate the SEL-787, organized by task. These tasks help you have to wait up to two minutes before an additional setting change can become familiar with the relay and include the following: occur. -

Page 29: Table 1.1 Sel-787 Serial Port Settings

Introduction and Specifications Getting Started Establishing The SEL-787 base model has two EIA-232 serial communications ports. The following steps require PC terminal emulation software and an SEL Cable Communication C234A (or equivalent) to connect the SEL-787 to the PC. See... -

Page 30: Figure 1.2 Sta Command Response-No Devicenet Communications Card Or With Eia-232/Eia-485 Communications Card

Introduction and Specifications Getting Started Checking Use the STA serial port command to view the SEL-787 operational status. Analog channel dc offset and monitored component status are listed in the Relay Status status report depicted in Figure 1.2. =>>STA <Enter>... - Page 31 DAT (Date Command) Viewing the Date Type DAT <Enter> at the prompt to view the date stored in the SEL-787. If the date stored in the relay is February 28, 2008, and the DATE_F setting is MDY, the relay will reply:...

- Page 32 Make: 30 A @ 250 Vdc per IEEE C37.90 250 Vdc 10.0 A L/R = 20 ms Continuous Carry: 6 A @ 70°C 4 A @ 85°C Thermal: 50 A for 1 s SEL-787 Relay Instruction Manual Date Code 20081022...

- Page 33 0.050% of ±20 mA (current mode) calibration: 0.25% of ±10 V (voltage mode) 0.9 Nm (8 in-lb) Minimum: Accuracy Variation With ±0.015% per °C of full-scale 1.4 Nm (12 in-lb) Maximum: Temperature: (±20 mA or ±10 V) Date Code 20081022 Instruction Manual SEL-787 Relay...

- Page 34 100 A/m for 1 minute multiples of pickup (within rated range of current) EMC Emissions Conducted Emissions: EN 55011: 1998, Class A Radiated Emissions: EN 55011: 1998, Class A Electromagnetic Compatibility Product Specific: EN 50263: 1999 SEL-787 Relay Instruction Manual Date Code 20081022...

- Page 35 0.0–120.0 seconds, 0.1 second steps Pickup/Dropout Time: <4 cycles Accuracy: ±0. 5% ±0.25 cycle Time Delay: 0.0–240.0 seconds, 0.1 second steps Accuracy: ±0. 5% ±0.25 cycle RTD Protection Setting Range: Off, 1–250°C Accuracy: ±2°C Date Code 20081022 Instruction Manual SEL-787 Relay...

- Page 36 Reactive 3-Phase ±3% of reading for 0.00 < pf < 0.90 Power (kVAR): Apparent 3-Phase ±3% of reading Power (kVA): ±2% of reading for 0.86 ≤ pf ≤ 1 Power Factor: ±2°C RTD Temperatures: SEL-787 Relay Instruction Manual Date Code 20081022...

-

Page 37: Overview

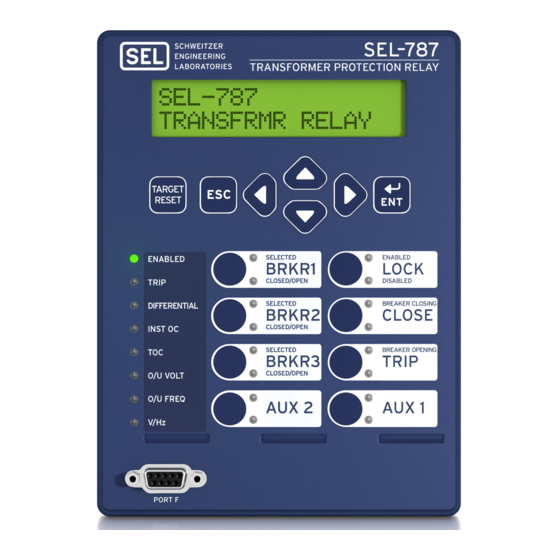

SEL-787. Use these drawings as a starting point for planning your particular relay application. The instructions for using the versatile front-panel custom label option are available on the SEL-787 product page on the SEL website. This allows you to OGIC ® control equations and slide-in configurable front-panel labels use SEL to change the function and identification of target LEDs. -

Page 38: Figure 2.1 Relay Panel-Mount Dimensions

Your SEL-787 offers flexibility in tailoring I/O to your specific application. In total, the SEL-787 has six rear-panel slots, labeled as Slots A, B, C, D, E, and Z. Slots A, B, and Z are base unit slots, each associated with a specific function. -

Page 39: Figure 2.2 Slot Allocations For Different Cards

(The IRIG-B input option is available on terminals B01, B02 for models with Port 3 as an EIA-485 serial port. Models with Port 3 as an EIA-232 serial port can input IRIG-B via the EIA-232 port and an SEL communications processor). Digital or analog. Figure 2.2 Slot Allocations for Different Cards Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 40: Table 2.1 Communication Ports

SEL Fast Message Unsolicited Write ➤ SEL Settings File Transfer ➤ ITS ® SEL M (MBA, MBB, MB8A, MB8B, MBTA, IRRORED MBTB) ➤ Event Messenger ➤ DNP3 Slave Level 2 ➤ C37.118 (Synchrophasor Data) SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 41: Table 2.2 Communication Card Interfaces And Connectors

Phase C Winding 1 current input 07, 08 IAW2 Phase A Winding 2 current input 09, 10 IBW2 Phase B Winding 2 current input 11, 12 ICW2 Phase C Winding 2 current input Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 42: Table 2.4 Current/Voltage Card Terminal Allocation

(wye or delta) PTs and/or neutral ac current input (1 A or 5 A (1 ACI/3 AVI or 1 ACI) nominal). With this card installed, the SEL-787 tracks the frequency (using positive-sequence voltage) and samples at 16 times a cycle—see Processing... -

Page 43: Table 2.7 Rtd (10 Rtd) Card Terminal Allocation

INx02, drives INx02 element 13, 14 INx03, drives INx03 element 15, 16 INx04, drives INx04 element x = 3, 4, or 5 (e.g., OUT401, OUT402, etc., if the card was installed in Slot D). Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 44: Table 2.9 Eight Digital Input (8 Di) Card Terminal Allocation

If you do not see this message and the ENABLED light is turned on, the card was inserted into the wrong slot. Begin again at Step If you do see this message, then proceed to Step Step 7. Press the {ESC} pushbutton. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 45: Figure 2.3 Circuit Board Of Analog I/O Board, Showing Jumper Selection

Position 1 – 2 = I (current) mode Position 2 – 3 = V (voltage) mode Where "JMPX" is the jumper for AI channel "X" Figure 2.3 Circuit Board of Analog I/O Board, Showing Jumper Selection Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 46: Figure 2.4 Jmp1 Through Jmp4 Locations On 4 Ai/4 Ao Board

The current analog output selection is the default setting for JMP1 through JMP4. Figure 2.6 shows JMP1 selected as a voltage analog output. JMP4 Selected as Current Output JMP1 Selected as Voltage Output Figure 2.5 Current Output Jumpers Figure 2.6 Voltage Output Jumpers SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 47: Table 2.10 Jumper Functions And Default Positions

Pins labeled A bypass the password requirement, pins labeled B enable breaker control, and pins labeled C force the relay to the SEL operating system called SEL . In the unlikely event that the SEL-787 suffers an BOOT internal failure, communications with the relay may be compromised. Forcing the relay to SEL provides a means of downloading new firmware. -

Page 48: Figure 2.8 Rear-Panel Connections Of Selected Cards

Main Board With Single Fiber-Optic Ethernet, Fiber- Optic Serial, and EIA-232 Rear Ports Card 10: Main Board With Dual Copper Ethernet, Fiber-Optic Serial, and EIA-232 Rear Ports Figure 2.8 Rear-Panel Connections of Selected Cards SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 49: Figure 2.9 Dual-Fiber, Ethernet, Eia-232 Communication, 3 Di/4 Do/1 Ao, And Current/Voltage (1 Aci/3 Avi) Option

Installation 2.13 Rear-Panel Connections Rear-Panel Connections Rear-Panel and Side- The physical layout of the connectors on the rear-panel and side-panel diagrams of three sample configurations of the SEL-787 are shown in Panel Diagrams Figure 2.9, Figure 2.10, and Figure 2.11. -

Page 50: Figure 2.10 Single Copper Ethernet, 8 Di, Rtd, And 4 Ai/4 Ao Option

Figure 2.10 Single Copper Ethernet, 8 DI, RTD, and 4 AI/4 AO Option PORT 1A PORT 1B PORT 3 PORT 2 (A) Rear-Panel Layout (B) Side-Panel Input and Output Designations Figure 2.11 DeviceNet, Fast Hybrid 4 DI/4 DO, and Current/Voltage Option SEL-787 Relay Instruction Manual Date Code 20081022... - Page 51 Port 3 have an external IRIG-B input at terminals B01 and B02. SEL-787 relays with an EIA-232 serial port option for Port 3 have the IRIG-B available in the EIA-232 port and can be connected to an SEL communications processor.

-

Page 52: Figure 2.12 Control I/O Connections-4 Ai/4 Ao Option In Slot D And Fiber-Optic Port In Slot B

• The fiber-optic serial port is located on the card in Slot B. A Simplex 62.5/125 µm fiber-optic cable is required to connect the SEL-787 with an SEL-2600 series RTD Module. This fiber-optic cable should be 500 meters or shorter. -

Page 53: Figure 2.14 Output Out103 Relay Output Contact Configuration

➤ The relay coil is energized continuously if the SEL-787 is powered and operational. ➤ When the SEL-787 generates a trip signal, the relay coil is de- energized. ➤ The relay coil is also de-energized if the SEL-787 power supply voltage is removed or if the SEL-787 fails (self-test status is FAIL). -

Page 54: Figure 2.16 Single-Phase Voltage Connections

Single Phase-to-Neutral VT Connection SEL-787 Single Phase-to-Phase VT Connection SEL-787 Note: The VT secondary circuit must be grounded in the relay cabinet. Figure 2.16 Single-Phase Voltage Connections SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 55: Figure 2.17 Voltage Connections

Installation 2.19 AC/DC Control Connection Diagrams Direct Connection SEL-787 Wye-Wye VT Connection SEL-787 Open-Delta VT Connection SEL-787 Note: The VT secondary circuit must be grounded in the relay. Figure 2.17 Voltage Connections Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 56: Figure 2.18 Typical Current Connections

Wye-connected PTs are shown in Figure 2.21; see Figure 2.16 Figure 2.17 for other voltage connections. Refer to Figure 2.23 for an example of dc connections for these applications SEL-787 Relay IAW1 52-1 IBW1 ICW1 IAW2 IBW2 52-2 ICW2... -

Page 57: Figure 2.19 Sel-787 Provides Basic Two-Winding Transformer Differential Protection

Note: The CT secondary circuit must be grounded in the relay cabinet. The basic application of the SEL-787 relay is for a two-winding transformer. The SEL-787 base product offering provides six current channels that are used to monitor the two transformer windings. Relay contact inputs can be used to monitor high- and low-side breaker status. -

Page 58: Figure 2.20 Sel-787 Provides Two-Winding Transformer Differential Protection With Ref (Restricted Earth Fault) Protection

(REF) of grounded wye transformer winding. Refer to Figure 2.23, which illustrates tripping control of the two-power circuit breakers. Figure 2.20 SEL-787 Provides Two-Winding Transformer Differential Protection With REF (Restricted Earth Fault) Protection SEL-787 Relay Instruction Manual... -

Page 59: Figure 2.21 Sel-787 Provides Two-Winding Transformer Differential Protection With Ref And Voltage-Based Protection

Note: The CT secondary circuit must be grounded in the relay Installing the optional 1 ACI/3 AVI voltage/current card in Slot E of the SEL-787 provides neutral current and REF protection, as well as three-phase voltage inputs. These voltage inputs provide the relay with 20.0 to 70.0 Hz frequency tracking, over-/undervoltage elements, frequency elements, power elements, and volts-per-hertz protection of the transformer. -

Page 60: Figure 2.22 Sel-787 Provides Autotransformer Differential Protection, Including Ref Protection

This figure shows an autotransformer application with REF protection applied through the optional 1 ACI current input card in Slot E of the relay. In this application, the SEL-787 provides full differential protection, and uses the sum of the high- and low-voltage winding currents to calculate the zero-sequence currents necessary for REF protection. -

Page 61: Figure 2.23 Example Dc Connections

Installation 2.25 AC/DC Control Connection Diagrams Figure 2.23 Example DC Connections Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 62: Upgrade Instructions

2.26 Installation Field Serviceability Field Serviceability The SEL-787 firmware may be upgraded in the field; refer to Appendix B: Firmware Upgrade Instructions for firmware upgrade instructions. You may know when a self-test failure has occurred by configuring an output contact to... -

Page 63: Table 3.1 Sel Software Solutions

Designs user-defined, volts/Hz inverse-time characteristic curve to match any transformer characteristic (refer to Section 4: Protection and Logic Functions). This section describes how to get started with the SEL-787 and QuickSet SEL-5030 software. QuickSet is a ERATOR ERATOR powerful setting, event analysis, and measurement tool that aids in setting, applying, and using the SEL-787. -

Page 64: Figure 3.1 Serial Port Communication Dialog Box

QuickSet. ERATOR Communications QuickSet uses relay communications Port 1 through Port 4, or ERATOR Port F (front panel) to communicate with the SEL-787. Perform the following steps to configure QuickSet to communicate effectively with ERATOR the relay. Step 1. Select Communications from the... -

Page 65: Figure 3.3 Network Communication Parameters Dialog Box

Tools > Terminal or by pressing <Ctrl+T>. Verify proper communications with the relay by opening a terminal window, pressing <Enter> a few times, and verifying that a prompt is received. If a prompt is not received, verify proper setup. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 66: Figure 3.5 Device Response To The Id Command

"DEVID=SEL-787","03D0" "DEVCODE=71","030F" "PARTNO=0787EX1B0X0X7585023X","073D" "CONFIG=11111201","03EB" "iedName =TEMPLATE","0380" "type =SEL-787","028F" "configVersion =ICD-787-R100-V0-Z001001-D20080326","0629" => Figure 3.5 Device Response to the ID Command Locate and record the Z number (Z001001) in the FID string. The first portion of the Z number (Z001…) determines the... - Page 67 Step 3. Type a new database name, click the Open button, and click Yes; the program creates a new empty database. Load devices into the new database as in Copy/Move Settings Between Databases on page 3.5. Date Code 20081022 Instruction Manual SEL-787 Relay...

-

Page 68: Table 3.3 File/Tools Menus

FID string to create a particular version of settings. To get started making SEL-787 settings with the Settings Editor in the Editor Mode, select File > New from the main menu bar, and SEL-787 and 001 from the Settings Editor Selection window as shown in Figure 3.6. -

Page 69: Figure 3.6 Selection Of Drivers

Z number in the FID string (select Tools > Meter & Control > Status). These numbers must match. QuickSet uses this first portion of the Z ERATOR number to determine the correct Settings Editor to display. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 70: Figure 3.8 New Setting Screen

Step 3. To restore the previous value for a setting, right-click the mouse over the setting and select Previous Value. Step 4. To restore the factory default setting value, right-click in the setting dialog box and select Default Value. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 71: Figure 3.9 Expressions Created With Expression Builder

Access the Expression Builder Use the Ellipsis buttons in the Settings dialog boxes of Settings Editor windows to create expressions, as shown in Figure 3.9. Ellipsis Button Created Expression Figure 3.9 Expressions Created With Expression Builder Date Code 20081022 Instruction Manual SEL-787 Relay... - Page 72 Select Tools > Import and Tools > Export on the QuickSet ERATOR menu bar to import or export settings from or to a text file. Use this feature to create a small file that can be more easily stored or sent electronically. SEL-787 Relay Instruction Manual Date Code 20081022...

-

Page 73: Figure 3.10 Composite Screens For Retrieving Events

QuickSet has integrated analysis tools that help you retrieve ERATOR information about relay operations quickly and easily. Use the event information that the SEL-787 stores to evaluate the performance of a system (select Tools > Events > Get Event Files). Figure 3.10 shows composite screens for retrieving events. -

Page 74: Figure 3.11 Saving The Retrieved Event

LED. To change the color of the LED, click in the square and make your selection from the color palette. The front-panel LEDs display the status of the 16 front-panel LEDs. Use the front-panel settings to change the front-panel LED assignment. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 75: Figure 3.12 Device Overview Screen

From here you can clear the Event History, M report, SER, trigger events, and reset metering data. IRRORED You can also reset the targets, synchronize with IRIG, and set the time and date. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 76: Figure 3.13 Control Screen

Meter and Control Figure 3.13 Control Screen To control the Remote bits, click on the appropriate square, then select the operation from the box shown in Figure 3.14. Figure 3.14 Remote Operation Selection SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 77: Table 3.4 Help

Help Description General QuickSet Select Help from the main menu bar ERATOR SEL-787 Settings Select Settings Help from the Help menu bar while the Settings Editor is open. Database Manager Select Help from the bottom of the Database Manager window... - Page 78 This page intentionally left blank...

-

Page 79: Overview

Instruction Manual Overview NOTE: Each SEL-787 is shipped with This section describes the SEL-787 Transformer Protection Relay settings, default factory settings. Calculate the including the protection elements and basic functions, control I/O logic, as settings for your application to ensure well as the settings that control the communications ports and front-panel secure and dependable protection. -

Page 80: Table 4.1 Identifier Settings

Communications), or the Ethernet port (see Section 7: Communications). Application Data It is faster and easier for you to calculate settings for the SEL-787 if you collect the following information before you begin: ➤ Power transformer data: MVA rating, winding configurations and voltages, impedance, etc. -

Page 81: Table 4.2 Configurations And Ratings (Phase Cts, Power Transformer)

The setting units are kilovolts. Table 4.3 shows additional configuration settings for relay models with optional voltage and/or neutral CT inputs. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 82: Table 4.3 Configurations And Ratings (Optional Neutral Ct, Phase Pt)

Voltage Elements. When you use one phase-to-phase voltage, the relay overvoltage and undervoltage elements use the applied phase-to-phase voltage only. When you use one phase- to-neutral voltage, the relay voltage elements use the applied phase-to-neutral voltage only. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 83: Basic Protection

(second and fourth) provide security during energization, while fifth harmonic blocking provides security for overexcitation conditions. Operating Characteristic The SEL-787 has three differential elements (87R-1, 87R-2, and 87R-3). These elements employ Operate (IOP) and Restraint (IRT) quantities that the relay calculates from the winding input currents. -

Page 84: Figure 4.1 Percentage Restraint Differential Characteristic

Winding 1. I1W1C1, I2W1C1, and I3W1C1 are the fundamental frequency A-phase, B-phase, and C-phase compensated currents for Winding 1. Similarly, I1W1C2, I2W1C2, and I3W1C2 are the second-harmonic compensated SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 85: Figure 4.2 Winding 1 Compensated Currents

⏐ΣI1W n C1⏐ IOP1 I1W2C1 ⏐I1W1C1⏐ Σ IRT1 ⏐I1W2C1⏐ I1W1C2 Σ Σ I1F2 ⏐ΣI1W n C2⏐ 100/PCT2 I1H24 I1W2C2 I1H2 I1W1C4 Σ I1F4 ⏐ΣI1W n C4⏐ 100/PCT4 I1W2C4 I1H4 Figure 4.3 Differential Element (87-1) Quantities Date Code 20081022 Instruction Manual SEL-787 Relay... - Page 86 This does not, as yet, produce a trip. The relay still needs the results of the harmonic blocking decision logic, which is described later. SEL-787 Relay Instruction Manual Date Code 20081022...

-

Page 87: Figure 4.4 Differential Element Decision Logic

The blocking prevents improper tripping during transformer inrush or allowable overexcitation conditions. The SEL-787 uses common (cross-phase) blocking by the sum of Date Code 20081022 Instruction Manual... -

Page 88: Table 4.4 Differential Element Settings

TH5D := 1.0 HARMONIC RESTRNT Y, N HRSTR := Y HARMONIC BLOCK Y, N HBLK := N Range shown for I = 5 A; Range for I = 1 A is 0.10–6.20 A. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 89: Figure 4.6 Differential Current Alarm Logic Diagram

TAP • O87P must be greater than or equal to 0.1 • INOM for each tap value. The SEL-787 includes a differential current alarm feature. Set the 87AP level above the highest expected differential current under normal operations (typically lower than O87P setting) and a security delay 87AD. - Page 90 Transformer overexcitation produces odd-order harmonics (primarily fifth harmonic), which can appear as differential current to a transformer differential relay. The SEL-787 measures the amount of fifth- harmonic current flowing in the transformer. You can set the relay to block the percentage restrained differential element if the ratio of fifth-harmonic current to fundamental current (IF5/IF1) is greater than the PCT5 setting.

- Page 91 A phase CT connects to the nonpolarity end of the C phase CT, and so on, in forming the delta. Thus, for WnCTC = 11, the relay uses the following [CTC(m)] matrix: 1 0 –1 • ------ - CTC 11 –1 1 0 0 –1 1 Date Code 20081022 Instruction Manual SEL-787 Relay...

- Page 92 1 –2 –1 –2 1 –1 1 –1 –1 2 CTC 3 ( ) • CTC 4 ( ) • ------ - -- - 0 –1 2 –1 –1 –1 –1 2 –1 SEL-787 Relay Instruction Manual Date Code 20081022...

- Page 93 WnCTC based on system phase rotation. Winding Connection Review Figure 4.7 shows the three basic winding connections, consisting of a wye connection and the two possible delta connections. Date Code 20081022 Instruction Manual SEL-787 Relay...

-

Page 94: Figure 4.7 Winding Connections, Phase Shifts, And Compensation Direction

In the DAC connection the line currents from the A, B, and C line terminals are, respectively, A-C, B-A, and C-B in terms of the winding currents. The phase shift produced by each physical type of delta depends on the system phase rotation. SEL-787 Relay Instruction Manual Date Code 20081022... - Page 95 Two examples illustrate important points about the five steps. For an additional resource, see the “Winding Compensation Settings Worksheet” (SEL_WCTC_R1_0.xls, available on the SEL-787 Product Literature CD). 1. Establish the phase direction for the terminal-A line voltage for each three-phase winding of the transformer.

-

Page 96: Figure 4.8 Example 1 For Wnctc Selection

360 degrees, as the reference. Both windings would then receive adjustments to correlate them with this reference. As Figure 4.8 illustrates, the primary winding direction serves as reference in the example. SEL-787 Relay Instruction Manual Date Code 20081022... - Page 97 SEL-787. The transformer has a 115 kV primary winding that is wye connected, with wye-connected CTs. The 34.5 kV secondary winding is DAB connected, but designated with the A line terminal at the “7 o'clock”...

- Page 98 W1CTC at zero because Winding 1 was the reference winding. However, this setting violates the condition that WnCTC not equal 0. Instead of a zero shift, we must shift Winding 1 360 degrees by setting W1CTC = 12. This solves the zero-sequence SEL-787 Relay Instruction Manual Date Code 20081022...

- Page 99 The current transformer error, e, is equal to ±10 percent. In per unit: e = 0.1 The voltage ratio variation of the power transformer load tap-changer, LTC, is from 90 percent to 110 percent. In per unit: a = 0.1 Date Code 20081022 Instruction Manual SEL-787 Relay...

- Page 100 7 percent. For example, the additional fundamental frequency charging current of a long cable run on the transformer secondary terminals could “dilute” the level of second harmonic seen at the primary to less than 15 percent. SEL-787 Relay Instruction Manual Date Code 20081022...

- Page 101 TH5P • TAPn ≥ 0.05 • I where: n = 1, 2 and I is nominal current of corresponding CT Example of Setting the SEL-787 Relay The example represents a typical transformer application and demonstrates the use of CT compensation settings and tap calculations. Figure 2.19 illustrates the application.

- Page 102 6. Set the differential element characteristic. Select the settings according to our suggestions in the earlier setting descriptions. For this example, we have selected a two slope, variable- percentage differential characteristic for maximum sensitivity SEL-787 Relay Instruction Manual Date Code 20081022...

- Page 103 CT Arrangements Use separate relay restraint circuits for each power source to the relay. In the SEL-787 you may apply two restraint inputs to the relay. You may connect CT secondary windings in parallel only if both circuits meet the following criteria: ➤...

- Page 104 0.1 • I and 1.0 • I A secondary. 4. The SEL-787 calculates settings TAP1 and TAP2 if the ratio /TAP is less than or equal to 7.5. When the relay calculates the tap settings, it reduces CT mismatch to less than 1 percent.

-

Page 105: Figure 4.10 Ref Enable Logic

REF element needs for comparison. The REF implementation in the SEL-787 uses a directional element (REF1F) that compares the direction of a polarizing current, derived from the line-end CTs, with the operating current, obtained from the neutral CT. A zero- sequence current threshold supervises tripping. -

Page 106: Figure 4.11 Ref Directional Element

AND1 gate in Figure 4.11. Assertion of this gate indicates substantial neutral current and no line-end current flow. This logic covers the situation of an internal wye-winding fault with the line-end breaker open. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 107: Table 4.5 Restricted Earth Fault Settings

Determine criterion 1 for load unbalance. The second criterion relates to the relative sensitivity of the winding CTs compared to the neutral CT. See sample calculations REF Current Pickup Level later in this section. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 108: Figure 4.13 Ref Function, Ref1Pol Setting Guide

50REF1P: • MAX INOMn CTRn ≥ • ------------------------------------------------------------- 50REF1P 0.05 • CTRN1 INOMN1 where MAX(INOMn • CTRn) is the greatest primary rating of the CTs being used for the REF function. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 109: Table 4.6 Winding N Maximum Phase Overcurrent Settings (N = 1 Or 2)

50Pn4P := OFF 0.10–19.20 A 50Pn4P := OFF PHASE IOC DELAY 0.00–5.00 sec 50Pn4D := 0.00 PH IOC TRQCTRL 50Pn4TC := 1 OGIC For I = 5 A. For I = 1 A. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 110: Figure 4.14 Instantaneous Overcurrent Element Logic

SEL-787 relay set above eight times the relay current input rating (40 A in a 5 A relay), the overcurrent element also operates on the output of a bipolar peak detector if the current waveform is highly distorted, as is the case with severe CT saturation. -

Page 111: Table 4.7 Winding N Residual Overcurrent Settings (N = 1, 2)

Each element can be torque controlled using appropriate SEL equations OGIC (e.g., when 51P1TC := IN401 the 51P1P element will be operational only if IN401 is asserted). Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 112: Table 4.9 Winding N Maximum Phase Time-Overcurrent (N = 1 Or 2)

MIN RESPONSE TIM 0.00–1.00 sec 51GnMR := 0.00 RES TOC TRQCTRL 51GnTC := 1 OGIC For I = 5 A. For I = 1 A. For 51_C := U_. For 51_C := C_. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 113: Table 4.11 Winding N Negative-Sequence Time-Overcurrent Settings (N = 1, 2)

OGIC For I = 5 A. For I = 1 A. For 51_C := U_. For 51_C := C_. The negative-sequence time-overcurrent element 51QnT responds to the 3I2 current as shown Figure 4.17. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 114: Table 4.12 Neutral Overcurrent Settings

MIN RESPONSE TIM 0.00–1.00 sec 51N1MR := 0.00 NEUT TOC TRQCTRL 51N1TC := 1 OGIC For I = 5 A. For I = 1 A. For 51_C := U_. For 51_C := C_. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 115: Figure 4.18 Neutral Time-Overcurrent Elements 51N1T And 51N2T

= electromechanical induction-disk emulation reset time in seconds (if you select electromechanical reset setting) TD = time-dial setting M = applied multiples of pickup current [for operating time ), M ≤ 1] ), M >1; for reset time (t Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 116: Table 4.14 Equations Associated With U.s. Curves

⎝ ⎠ C4 (Long-Time Inverse) Figure 4.27 ⎝ ⎠ – – ⎛ ⎞ ⎛ ⎞ 0.05 4.85 ---------------------- ---------------- • • ⎝ ⎠ ⎝ ⎠ C5 (Short-Time Inverse) Figure 4.28 0.04 – – SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 117: Figure 4.19 U.s. Moderately Inverse Curve: U1

3.00 30 (25) 2.00 15 (12.5) 1.00 6 (5) 0.50 3 (2.5) .5 .6 .7 .8 .9 1 5 6 7 8 9 Multiples of Pickup Figure 4.19 U.S. Moderately Inverse Curve: U1 Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 118: Figure 4.20 U.s. Inverse Curve: U2

4.00 3.00 30 (25) 2.00 15 (12.5) 1.00 6 (5) 0.50 3 (2.5) .5 .6 .7 .8 .9 1 5 6 7 8 9 Multiples of Pickup Figure 4.20 U.S. Inverse Curve: U2 SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 119: Figure 4.21 U.s. Very Inverse Curve: U3

30 (25) 4.00 3.00 15 (12.5) 2.00 1.00 6 (5) 0.50 3 (2.5) .5 .6 .7 .8 .9 1 5 6 7 8 9 Multiples of Pickup Figure 4.21 U.S. Very Inverse Curve: U3 Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 120: Figure 4.22 U.s. Extremely Inverse Curve: U4

6.00 15 (12.5) 5.00 4.00 3.00 6 (5) 2.00 3 (2.5) 1.00 0.50 .5 .6 .7 .8 .9 1 6 7 8 9 Multiples of Pickup Figure 4.22 U.S. Extremely Inverse Curve: U4 SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 121: Figure 4.23 U.s. Short-Time Inverse Curve: U5

30 (25) 8.00 6.00 5.00 15 (12.5) 4.00 3.00 2.00 6 (5) 1.00 3 (2.5) 0.50 .5 .6 .7 .8 6 7 8 9 Multiples of Pickup Figure 4.23 U.S. Short-Time Inverse Curve: U5 Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 122: Figure 4.24 I.e.c. Class A Curve (Standard Inverse): C1

30 (25) 0.20 15 (12.5) 0.10 0.05 6 (5) 3 (2.5) .5 .6 .7 .8 .9 1 5 6 7 8 9 Multiples of Pickup Figure 4.24 I.E.C. Class A Curve (Standard Inverse): C1 SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 123: Figure 4.25 I.e.c. Class B Curve (Very Inverse): C2

15 (12.5) 0.50 0.40 0.30 6 (5) 0.20 3 (2.5) 0.10 0.05 .5 .6 .7 .8 .9 1 6 7 8 9 Multiples of Pickup Figure 4.25 I.E.C. Class B Curve (Very Inverse): C2 Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 124: Figure 4.26 I.e.c. Class C Curve (Extremely Inverse): C3

0.80 0.70 0.60 3 (2.5) 0.50 0.40 0.30 0.20 0.10 0.05 .5 .6 .7 .8 .9 1 6 7 8 9 Multiples of Pickup Figure 4.26 I.E.C. Class C Curve (Extremely Inverse): C3 SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 125: Figure 4.27 I.e.c. Long-Time Inverse Curve: C4

1500 (1250) 600 (500) 300 (250) 1.00 0.90 0.80 0.70 0.60 150 (125) 0.50 0.40 0.30 60 (50) 0.20 30 (25) 0.10 0.05 Multiples of Pickup Figure 4.27 I.E.C. Long-Time Inverse Curve: C4 Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 126: Figure 4.28 I.e.c. Short-Time Inverse Curve: C5

15 (12.5) 0.70 0.60 0.50 0.40 0.30 6 (5) 0.20 3 (2.5) 0.10 0.05 .5 .6 .7 .8 .9 6 7 8 9 Multiples of Pickup Figure 4.28 I.E.C. Short-Time Inverse Curve: C5 SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 127: Table 4.16 Rtd Settings

RTD-Based Protection RTD-Based Protection RTD Input Function When you connect an SEL-2600 series RTD Module or order the internal RTD card option, the SEL-787 offers several protection and monitoring functions, settings for which are described in Table 4.16. See Figure 2.12 the RTD module fiber-optic cable connections. -

Page 128: Table 4.17 Rtd Resistance Versus Temperature

4.50 Protection and Logic Functions RTD-Based Protection RTD Trip/Warning Levels The SEL-787 provides temperature warnings and trips through use of the RTD temperature measurements and the warning and trip temperature settings in Table 4.16. The relay issues a temperature warning if any of the healthy RTDs indicate a temperature greater than the relay RTD warning temperature setting. -

Page 129: Table 4.18 Undervoltage Settings

OFF, 12.5–300.0 V 59Q2P := OFF NSEQ OV DELAY 0.0–120.0 sec 59Q2D := 5.0 When you connect the SEL-787 voltage inputs to phase-to-phase connected VTs (single-phase or three-phase), as in Figure 2.16 Figure 2.17, the relay provides two levels of phase-to-phase overvoltage and undervoltage elements. -

Page 130: Figure 4.30 Overvoltage Element Logic

Word Bits 59P1D 59P1P 59P1T 59P2D 59P2P 59P2T When DELTA_Y := DELTA |VPP| Relay Word Bits 59P1D 59P1P 59P1T 59P2D 59P2P 59P2T 59P1P, 59P2P, 59Q1P, 59Q2P = Settings Figure 4.30 Overvoltage Element Logic SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 131: Figure 4.31 Overvoltage Element Logic

When this happens, stray flux is induced in nonlaminated components, Elements causing overheating. In the SEL-787 Relay a volts/hertz element detects overexcitation. The SEL-787 provides a sensitive definite time volts/hertz element, plus a tripping element with a composite operating time. The relay calculates the present transformer volts/hertz as a percent of nominal, based on the present and nominal voltages and frequencies. -

Page 132: Figure 4.32 Dual-Level Volts/Hertz Time-Delay Characteristic 24Ccs

Transformer Limit Curve on Generator Voltage Base Generator Manufacturer's Recommended Protection Curve 24D2P2 = 118% 24D2D2 = 1.2 s Relay Characteristic 24IP=108% .001 1000 Time (Minutes) Figure 4.33 Composite Inverse/Definite-Time Overexcitation Characteristic, 24CCS = ID SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 133: Table 4.20 Volts Per Hertz Settings

Figure 4.29. Set 24CCS := OFF if you do not require Level 2 volts/hertz protection. When 24CCS := OFF, the other Level 2 settings are hidden and do not need to be entered. Date Code 20081022 Instruction Manual SEL-787 Relay... - Page 134 0. The elements are allowed to operate when the 24TC control equation equals logical 1, the default setting. You can add OGIC other supervisory conditions if you need these for your application. SEL-787 Relay Instruction Manual Date Code 20081022...

-

Page 135: Figure 4.35 Volts/Hertz Inverse-Time Characteristic, 24Ic

⎜ ⎟ VNOM 10 – ⎜ ⎟ ------------------------------------------------------------------------------- - ⎜ ⎟ 24 IP ⎜ ⎟ ⎜ ------------- - ⎟ ⎝ ⎠ 100% ⎝ ⎠ Figure 4.35 Volts/Hertz Inverse-Time Characteristic, 24IC = 1 Date Code 20081022 Instruction Manual SEL-787 Relay... - Page 136 Power Elements You can enable up to two independent three-phase power elements in the SEL-787 relay. Each enabled element can be set to detect real power or reactive power. When voltage inputs to the relay are from delta connected PTs or when single voltage input is used, the relay cannot account for unbalance in the voltages in calculating the power.

-

Page 137: Table 4.21 Power Element Settings

Where n = 1 or 2 |V AB | 3PWRnT Setting Switch A Switch B PWRnT Position Position +WATTS |V BC | –WATTS +VARS –VARS 20 V Figure 4.37 Three-Phase Power Elements Logic Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 138: Figure 4.38 Power Elements Operation In The Real/Reactive Power Plane

Figure 4.37. If the protection application requires overcurrent protection in addition to the power elements, there may be a race condition, during a fault, between the overcurrent element(s) and the SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 139: Table 4.22 Frequency Settings

Relay Is Tracking Frequency Figure 4.39 Over- and Underfrequency Element Logic Loss-of-Potential The SEL-787 sets Relay Word bit LOP (loss-of-potential) upon detecting a loss of relay ac voltage input such as that caused by blown potential fuses or (LOP) Protection by the operation of molded-case circuit breakers. - Page 140 Include the LOP Relay Word bit in an output contact alarm to notify operation personnel of abnormal voltage input conditions and failures that can be detrimental to the protection system performance if not quickly corrected. SEL-787 Relay Instruction Manual Date Code 20081022...

-

Page 141: Figure 4.40 Loss-Of-Potential (Lop) Logic

INOM is the phase secondary input rating. VNOM and VIWDG are relay settings. Figure 4.40 Loss-of-Potential (LOP) Logic Demand Metering The SEL-787 provides demand and peak demand metering, selectable between thermal and rolling demand types, for the following values: Either Winding 1 or Winding 2 currents: ➤... -

Page 142: Table 4.23 Demand Meter Settings

Demand metering peak recording is momentarily suspended when OGIC control equation setting FAULT is asserted (= logical 1). The differences between thermal and rolling demand metering are explained in the following discussion. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 143: Figure 4.42 Response Of Thermal And Rolling Demand Meters To A Step Input

Step Input (Setting DMTC = 15 minutes) Thermal Demand Meter Response The response of the thermal demand meter in Figure 4.42 (middle) to the step current input (top) is analogous to the series RC circuit in Figure 4.43. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 144: Figure 4.43 Voltage V S Applied To Series Rc Circuit

(1.0 per unit) after a time period equal to setting DMTC = 15 minutes, referenced to when the step current input is first applied. The SEL-787 updates thermal demand values approximately every second. Rolling Demand Meter Response The response of the rolling demand meter in Figure 4.42... - Page 145 5-minute totals: Five-Minute Totals Corresponding Five-Minute Interval 1.0 per unit 0 to 5 minutes 1.0 per unit 5 to 10 minutes 1.0 per unit 10 to 15 minutes 3.0 per unit Date Code 20081022 Instruction Manual SEL-787 Relay...

-

Page 146: Table 4.24 Trip/Close Logic Settings

CL2 := SV03T AND LT02 OR CC2 UNLATCH CLOSE 2 ULCL2 := TRIP2 OR TRIPXFMR The trip logic and close logic for the SEL-787 operate in a similar manner. Each has a control equation setting to set or latch the logic and... -

Page 147: Figure 4.44 Trip Logic

(TDURD) setting. TR Trip Conditions SEL Control Equations OGIC There are three trip logic equations within the SEL-787. They are designed to operate when control equation trip variable setting TRm is asserted OGIC... - Page 148 For example, set 52A1 := IN101 if you connect the 52a contact of breaker 52-1 to input IN101. Figure 4.45 shows a close logic diagram of the breaker 52-1, logic of the breaker 52-2 is similar. SEL-787 Relay Instruction Manual Date Code 20081022...

-

Page 149: Figure 4.45 Close Logic

Figure 4.45 Close Logic CL Close SEL Control Equation OGIC There are two close logic equations within the SEL-787. They are designed to operate when control equation close variable setting CLm is asserted OGIC (m = 1, 2) and to unlatch when... -

Page 150: Table 4.25 Enable Settings

Latch control switches (latch bits are the outputs of these switches) replace traditional latching devices. Traditional latching devices maintain output contact state. The SEL-787 latch control switch also retains state even when power to the device is lost. If the latch control switch is set to a programmable... -

Page 151: Table 4.26 Latch Bits Equation Settings

0. You can use these latch bits in SEL control OGIC equations to create custom logic for your application. The SEL-787 includes 32 latches. Table 4.26 shows the SET and RESET default settings for Latch 1 through Latch 4. The remaining latches are all set to NA. - Page 152 4.27. Math SEL control equation OGIC settings operate on numerical values, using one or more of the Mathematical operators listed in Table 4.27. These numerical values can be mathematical variables or actual real numbers. SEL-787 Relay Instruction Manual Date Code 20081022...

- Page 153 Operator Precedence When you combine several operators and operands within a single expression, the SEL-787 evaluates the operators from left to right, starting with the highest precedence operators and working down to the lowest precedence. This means that if you write an equation with three AND operators, for example SV01 AND SV02 AND SV03, each AND will be evaluated from the left to the right.

- Page 154 IN101 or IN102 asserts. Using these settings, the device triggers a new event report each time IN101 or IN102 asserts anew, if the device is not already recording an event report. You can use the rising-edge operator with SEL-787 Relay Instruction Manual Date Code 20081022...

-

Page 155: Figure 4.49 Result Of Falling-Edge Operator On A Deasserting Input

Thus, what starts out as a mathematical comparison, ends up as a Boolean resultant. For example, if the output of a math variable is not equal to a certain value, an output contact is asserted: OUT102 := MV01 <> 45 Date Code 20081022 Instruction Manual SEL-787 Relay... - Page 156 OUT103 OUT401 OUT401 Figure 4.50 Example Use of SEL Variables/Timers OGIC SV/Timers Settings The SEL-787 includes 32 SEL variables. Table 4.29 shows the pickup, OGIC dropout, and equation settings for SV01 through SV05. The remaining variables are not enabled (see Table 4.25).

-

Page 157: Table 4.30 Counter Input/Output Description

Standard for Programmable controllers—Part 3: Programming languages. Counter 01 Output NOTE: SC01PV For device configurations that include voltage cards, the SEL-787 SC01QU tracks the frequency. When tracking OGIC the frequency, the processing interval SC01R SC01QD varies with the frequency. SC01LD... -

Page 158: Table 4.31 Order Of Precedence Of The Control Inputs

SC01R SC01LD SC01CU SC01CD One Processing Interval Setting = Sample SC01PV = 7 Two Processing Intervals Analog SC01 Relay Word Bits SC01QU SC01QD Figure 4.52 Example of the Effects of the Input Precedence SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 159: Table 4.32 Control Output Equations And Contact Behavior Settings

• • • • • The SEL-787 provides the ability to use SEL control equations to map OGIC protection (trip and warning) and general-purpose control elements to the outputs. In addition, you can enable fail-safe output contact operation for relay contacts on an individual basis. -

Page 160: Table 4.33 General Global Settings

When TRIP output fail-safe is enabled and the TRIP contact is appropriately connected (see Figure 2.15), the breaker is automatically tripped when relay control power fails. Appendix I: M Communications SEL-787 Settings IRRORED IRRORED Sheets for details. Transmit SEL OGIC... -

Page 161: Figure 4.53 Phase Rotation Setting

Demand Metering. Event Messenger The SEL-787 can be configured to automatically send ASCII message on a communications port when trigger condition is satisfied. Use the SET P Points command to set PROTO := EVMSG on the desired port to select the port. This feature is designed to send messages to the SEL-3010 Event Messenger, however, any device capable of receiving ASCII messages can be used. -

Page 162: Table 4.34 Setting Group Selection

Group 1, 2, 3, and 4 are active. With the settings shown above, SS1 is set equal to logical 1, thus setting Group 1 always is active. Synchrophasor The SEL-787 Transformer Protection Relay provides Phasor Measurement Control Unit (PMCU) capabilities when connected to an IRIG-B time source. Measurement... -

Page 163: Figure 4.55 Analog Input Card Adaptive Name

Monitoring for description and Table 5.10 for the settings. Analog Inputs The SEL-787 samples the analog inputs four times per cycle. For analog inputs, set the following parameters for each input: ➤ Analog type ➤ High and low input levels ➤... -

Page 164: Table 4.36 Summary Of Steps

Protection and Logic Functions Global Settings (SET G Command) Signal offset compensation factor calculation procedure: 1. Turn the SEL-787 on and allow it to warm up for a few minutes. 2. Set the analog inputs for each analog channel to the desired range using the AIxxxTYP, AIxxxL, AIxxxH, AIxxxEL, and AIxxxEH settings (for example, ±1 mA). - Page 165 AI301 TYPE (I,V) AI301TYP:= I NOTE: Because the SEL-787 accepts The next three settings define the applicable engineering unit (AI301EU), the current values ranging from –20.48 to lower level in engineering units (AI301EL) and the upper level in engineering 20.48 mA, be sure to enter the units (AI301EH).

-

Page 166: Table 4.37 Analog Input Card In Slot 3

AI301 HI WARN 2 OFF, –99999.000 to +99999.000 AI301HW2 := OFF AI301 HI ALARM OFF, –99999.000 to +99999.000 AI301HAL := OFF Voltage setting range for a voltage transducer, i.e., when AI301TYP := V. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 167: Table 4.38 Output Setting For A Card In Slot 3

Protection and Logic Functions 4.89 Global Settings (SET G Command) Analog Outputs If an SEL-787 configuration includes the four analog inputs and four analog outputs (4 AI/4 AO) card, the analog outputs are allocated to output numbers 1-4. Figure 4.57 shows the x and y variable allocation for the analog output card. -

Page 168: Figure 4.58 Analog Output Settings

=>> Figure 4.58 Analog Output Settings Digital Input To comply with different control voltages, the SEL-787 offers dc debounce as well as ac debounce modes. Therefore, if the control voltage is dc, select the Debounce dc mode of operation, and if the control voltage is ac, select the ac mode of operation. -

Page 169: Table 4.39 Slot C Input Debounce Settings

0. Table 4.39 shows the settings prompt, setting range, and factory default settings for a card in Slot C. See the SEL-787 Settings Sheets for a complete list of input debounce settings. Table 4.39 Slot C Input Debounce Settings... -

Page 170: Table 4.40 Data Reset Setting

DISABLE SETTINGS DSABLSET := 0 OGIC Port Settings (SET P Command) The SEL-787 provides settings that allow you to configure the parameters for the communications ports. See Section 2: Installation for a detailed description of port connections. On the base unit: Port F (front panel) is an EIA-232 port;... -

Page 171: Table 4.43 Ethernet Port Settings

Enable IEC 61850 Protocol (Y, N) E61850 := N Enable IEC 61850 GSE (Y, N) EGSE := N 0–3 EDNP := 0 Enable DNP Sessions Table D.7 for a complete list of the DNP3 session settings. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 172: Table 4.44 Fiber-Optic Serial Port Settings

0–30 min T_OUT := 5 SEND AUTOMESSAGE Y, N AUTO := N HDWR HANDSHAKING Y, N RTSCTS := N FAST OP MESSAGES Y, N FASTOP := N MODBUS SLAVE ID 1–247 SLAVEID := 1 SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 173: Table 4.47 Rear-Panel Devicenet Port Settings

Set FASTOP := N to block binary Fast Operate messages. Refer to Appendix C: SEL Communications Processors for the description of the SEL-787 Fast Operate commands. Set PROTO := DNET to establish communications when the DeviceNet card is used. Table 4.47 shows the additional settings, which can be set only at the rear on the DeviceNet card. -

Page 174: Table 4.48 Display Point And Local Bit Default Settings

LCD display. However, you need to first enable the appropriate number of local bits and display points necessary for your application. When your SEL-787 arrives, four display points are already enabled, but no local bits are enabled. If more display points are necessary for your application, use the EDP setting to enable up to 32 display points. -

Page 175: Table 4.50 Lcd Display Point Settings

A display point is hidden when settings are entered (DPn = XX, where n = 01 through 32 and XX = any valid setting), but nothing shows on the front-panel display. Table 4.51 shows examples of settings that always, never, or conditionally hide a display point. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 176: Table 4.51 Settings That Always, Never, Or Conditionally Hide A Display Point

After connecting a form a (normally open) auxiliary contact from the HV circuit breaker to Input IN101 and a similar contact from the LV circuit breaker to Input IN102 of the SEL-787, we are ready to program the display points, using the following information for the HV breaker (LV breaker similar): ➤... -

Page 177: Figure 4.62 Display Point Settings

LV breaker information on the top line, as shown in Figure 4.66. TRFR 1 HV BRKR:= CLOSED TRFR 1 LV BRKR:= CLOSED Figure 4.65 Front-Panel Display—Both HV and LV Breakers Closed Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 178: Table 4.53 Binary Entry In The Name String Only

Figure 4.68 Front-Panel Display for a Binary Entry in the Name String Only Analog Display Point Entry Composition In general, the legal syntax for analog display points consists of the following two fields or strings: Name, “User Text and Formatting.” SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 179: Table 4.54 Analog Entry In The Name String Only

DP02 := TID, “{16}” ? AI301,TEMPERATURE: <Enter> Table 4.55 Entry in the Name String and the Alias Strings Name Alias Set String Clear String IN101 INPUT IN101 — — AI301 TEMPERATURE — — Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 180: Table 4.56 Example Settings And Displays

First enable enough display points for the analog measurements (e.g. EDP = 5). Figure 4.72 shows the settings to add the three transducer measurements. (Use the > character to move to the next settings category). SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 181: Figure 4.72 Adding Temperature Measurement Display Points

(0–9, A–Z, -, /, ., space) for the remainder: ➤ NLBnn: Name the switch (normally the function that the switch performs, such as SUPERV SW) that will appear on the LCD display. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 182: Figure 4.74 Adding Two Local Bits

SET LB_ LABEL (7 characters; Enter NA to null) SLB02 ? NA <Enter> PULSE LB_ LABEL (7 characters; Enter NA to null) PLB02 ? START <Enter> Save changes (Y,N)? Y <Enter> Settings Saved =>> Figure 4.74 Adding Two Local Bits SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 183: Table 4.57 Target Led Settings

Protection and Logic Functions 4.105 Front-Panel Settings (SET F Command) Target LED Settings The SEL-787 offers the following two types of LEDs. See Figure 8.1 Figure 8.25 for the programmable LED locations: ➤ Six Target LEDs ➤ Eight Pushbutton LEDs... -

Page 184: Table 4.58 Pushbutton Led Settings

Table 4.59 Auto-Removal Settings Settings Prompt Setting Range Factory Default Auto-Removal Enable Y, N ESERDEL := N Number of Counts 2–20 counts SRDLCNT := 5 Removal Time 0.1–90.0 seconds SRDLTIM := 1.0 SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 185: Table 4.60 Ser Trigger Settings

Define the enabled alias settings by entering the Relay Word bit name, a space, the desired alias, a space, the text to display when the condition asserts, a space, and the text to display when the condition deasserts. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 186: Table 4.62 Set R Ser Alias Settings

LDLIST. Setting Name := Setting Prompt Setting Range Factory Default LDP LIST NA, Up to 17 Analog Quantities LDLIST :=NA LDP ACQ RATE 5, 10, 15, 30, 60 min LDAR := 15 SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 187: Table 4.65 Dnp Map Settings

11 characters CO_00 := NA · · · DNP Counter Label Name 11 characters CO_31 := NA Appendix D: DNP3 Communications for complete list of the DNP Map Labels and factory default settings. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 188: Table 4.66 User Map Register Settings

MOD_001 := IAW1_MAG · · · USER REG#125 NA, 1 Modbus Register Label MOD_125 := NA Appendix E: Modbus RTU Communications for a complete list of the Modbus Register Labels and factory default settings. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 189: Overview

Analog Quantities) every 5, 10, 15, 30, or 60 minutes. The data are stored in nonvolatile memory. As many as 4000 time samples are stored. The SEL-787 has a through-fault event monitoring function that gathers current level, duration and date/time for each through fault experienced by the transformer. -

Page 190: Figure 5.1 Complex Power Measurement Conventions

Metering and Monitoring Power Measurement Conventions Power Measurement Conventions The SEL-787 uses the IEEE convention for power measurement. The implications of this convention are depicted in Figure 5.1. Direction of Positive Real and Reactive Power SEL-787 Relay Direction of Positive Real and Reactive Power... -

Page 191: Table 5.1 Measured Fundamental Meter Values

Harmonic metering ➤ Synchrophasor metering Fundamental Table 5.1 details each of the fundamental meter data types in the SEL-787. Section 8: Front-Panel Operations Section 7: Communications describe Metering how to access the various types of meter data using the relay front panel and communications ports. -

Page 192: Table 5.2 Measured Differential Meter Values

153.9 =>> Figure 5.2 METER Command Report With Voltage Option Differential Metering The differential metering function in the SEL-787 reports the fundamental frequency operate and restraint currents for each differential element (87) in multiples of TAP. Table 5.2 shows the value reported. -

Page 193: Table 5.3 Thermal Meter Values

-30 C RTD5 TEST5 75 C RTD6 TEST6 90 C RTD8 TEST8 -10 C RTD10 TEST10 95 C RTD11 TEST11 65 C RTD12 TEST12 open =>> Figure 5.4 METER T Command Report With RTDs Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 194: Table 5.5 Maximum/Minimum Meter Values

Metering and Monitoring Metering Energy Metering The SEL-787 with the voltage option includes energy metering. Use this form of metering to quantify real and reactive energy supplied by the transformer. Refer to Figure 5.1 for the definitions of positive real power, negative real power, positive reactive power, and negative reactive power. -

Page 195: Figure 5.7 Meter M Command Report

Figure 5.8 METER RM Command Response All maximum and minimum metering values are stored to nonvolatile memory four times per day and within one minute of the maximum and minimum metering values being reset. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 196: Table 5.6 Rms Meter Values

Metering and Monitoring Metering Math Variable The SEL-787 includes 32 math variables. When you receive your SEL-787, no math variables are enabled. To use math variables, enable the number of Metering math variables (between 1 and 32) you require, using the EMV setting in the Logic setting category. -

Page 197: Table 5.7 Demand Values

Metering and Monitoring Metering Analog Input The SEL-787 can monitor analog (transducer) quantities that it is measuring if equipped with optional analog inputs. Analog input metering shows Metering transducer values from standard voltage and current transducers. These values can then be used for monitoring automation and control applications. -

Page 198: Table 5.8 Measured Harmonic Meter Values

LAST RESET = 01/23/2008 13:45:37 => Figure 5.13 METER P Command Report Harmonic Metering The harmonic metering function in the SEL-787 reports the current and voltage harmonics through the fifth harmonic and the total harmonic distortion percentage (THD %). Table 5.8 shows the harmonic values reported. -

Page 199: Table 5.9 Synchrophasor Measured Values

Metering and Monitoring 5.11 Load Profiling Synchrophasor The MET PM serial port ASCII command may be used to view the SEL-787 synchrophasor measurements. There are multiple ways to use the MET PM Metering command: ➤ As a test tool, to verify connections, phase rotation, and scaling ➤... -

Page 200: Figure 5.15 Ldp Command Report

Monitor and document this through-fault activity with the through-fault element in the SEL-787. The through-fault element also calculates the cumulative mechanical stress on the transformer windings. Source... -

Page 201: Figure 5.17 Category Iv Transformers Through-Fault Protection Curves

S = Transformer MVA rating (MVA) = Line-to-line voltage (kV) = Transformer impedance (per unit) K = 1250 if (4.5 ≤ I ≤ 0.5 • I MAX_PU > 0.5 • I 2 • (I if I MAX_PU MAX_PU Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 202: Table 5.10 Through-Fault Element Settings

The process to determine the maximum through-fault current for the fault duration starts. ➤ The integration process starts, whereby the element sums the values (Equation 5.3) calculated each processing interval (1/4 of a power system cycle). SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 203: Figure 5.18 Through-Fault Diagram

(FIFO) buffer. The element automatically archives the data when one of the following conditions is true: ➤ The 10-cycle Timer deasserts and the enable signal is already de-asserted. ➤ The 10-cycle Timer is already de-asserted and the enable signal de-asserts. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 204: Figure 5.19 Result Of The Tfe Command

(Duration column) is reported in seconds with processing interval resolution. If the event duration is equal to or greater than 60 seconds, the element appends a “+” to the time value of 60 seconds. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 205: Table 5.11 Through-Faults Events Report Messages

Winding 1 Total Accumulated Percentage of Through Fault Capability: A_Phase = 0.00? 60.20 B_Phase = 0.00? 56.0 C_Phase = 0.00? 52 Are you sure (Y,N)? Y Command Completed =>> Figure 5.20 Preload the Values of the Accumulated Data Date Code 20081022 Instruction Manual SEL-787 Relay... - Page 206 This page intentionally left blank...

-

Page 207: Table 6.1 Methods Of Accessing Settings

Overview IMPORTANT: Upon relay initial The SEL-787 Transformer Protection Relay stores the settings you enter in power up or Port 1 setting changes or nonvolatile memory. Settings are divided into the following eight setting Logic setting changes, the user may... -

Page 208: View/Change Settings With Front Panel

RELAY message appears: Save Changes? NOTE: Each SEL-787 is shipped with default factory settings. Calculate the settings for your application to ensure Select and enter the appropriate command by pushing the {ENT} pushbutton. secure and dependable protection. Select to save the settings changes and to discard the changes. -

Page 209: Figure 6.1 Front-Panel Setting Entry Example

ID Settings Config Settings Diff Element • • Demand Mtr Set Trip/Close Logic Config Menu W1CT 180.00 • • • SINGLEV PTR Setting PHASE PT RATIO PTR=00180.00 Figure 6.1 Front-Panel Setting Entry Example Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 210: Table 6.2 Show Command Options

When you issue the SET command, the relay presents a list of settings one at a time. Enter a new setting or press <Enter> to accept the existing setting. Editing keystrokes are listed in Table 6.4. SEL-787 Relay Instruction Manual Date Code 20081022... -

Page 211: Table 6.4 Set Command Editing Keystrokes

TERSE instructs the relay to skip the settings display after the last setting. Use this parameter to speed up the SET command. If you wish to review the settings before saving, do not use the TERSE option. Date Code 20081022 Instruction Manual SEL-787 Relay... -

Page 212: Table 6.6 Setting Interdependency Error Messages

Group settings, REF element REF Element is only available when setting WnCT := WYE Setting Combination (n = 1 or 2). Invalid n = 1 or 2 Relay forces MVA := OFF prior to this message. SEL-787 Relay Instruction Manual Date Code 20081022... - Page 213 Date _______________ SEL-787 Settings Sheets SET.1 Group Settings (SET Command) of 68 Group______________ SEL-787 Settings Sheets Instruction Manual These settings sheets include the definition and input range for each setting in the relay. You can access the settings from the relay front panel and the serial ports.

- Page 214 SET.2 SEL-787 Settings Sheets Date _______________ of 68 Group Settings (SET Command) Group______________ Differential XFMR DIFF ENABLE (Y, N) (All Differential settings below are hidden if E87 := N) Note: TAP1 and TAP2 are autoset by relay if MVA setting is not OFF.

- Page 215 Date _______________ SEL-787 Settings Sheets SET.3 Group Settings (SET Command) of 68 Group______________ PHASE IOC DELAY (0.00–5.00 sec) 50P13D (Hidden if 50P13P := OFF) PH IOC TRQCTRL (SEL 50P13TC (Hidden if 50P13P := OFF) OGIC PHASE IOC LEVEL (OFF, 0.50–96.00 A [5 A nom.], 50P14P 0.10–19.20 A [1 A nom.])

- Page 216 SET.4 SEL-787 Settings Sheets Date _______________ of 68 Group Settings (SET Command) Group______________ Winding 1 Residual Time Overcurrent All settings below are hidden when W1CT := DELTA. RES TOC LEVEL (OFF, 0.50–16.00 A [5 A nom.], 51G1P 0.10–3.20 A [1 A nom.])

- Page 217 Date _______________ SEL-787 Settings Sheets SET.5 Group Settings (SET Command) of 68 Group______________ PHASE IOC DELAY (0.00–5.00 sec) 50P24D (Hidden if 50P24P := OFF) PH IOC TRQCTRL (SEL 50P24TC (Hidden if 50P24P := OFF) OGIC Winding 2 Residual Overcurrent All settings below are hidden when W2CT := DELTA.

- Page 218 SET.6 SEL-787 Settings Sheets Date _______________ of 68 Group Settings (SET Command) Group______________ RES TOC CURVE (U1, U2, U3, U4, U5, C1, C2, C3, C4, C5) 51G2C (Hidden if 51G2P := OFF) RES TOC TDIAL (0.50–15.00 for U1–U5 OR 0.05–1.00 for 51G2TD C1–C5)

- Page 219 Date _______________ SEL-787 Settings Sheets SET.7 Group Settings (SET Command) of 68 Group______________ EM RESET DELAY (Y, N) 51N1RS (Hidden if 51N1P := OFF) CONST TIME ADDER (0.00–1.00 sec) 51N1CT (Hidden if 51N1P := OFF) MIN RESPONSE TIM (0.00–1.00 sec)

- Page 220 SET.8 SEL-787 Settings Sheets Date _______________ of 68 Group Settings (SET Command) Group______________ RTD5 LOCATION (OFF, AMB, OTH) RTD5LOC := RTD5 IDENTIFIER (10 characters) RTD5NAM := (Hidden if RTD5LOC := OFF or AMB) RTD5 TYPE (PT100, NI100, NI120, CU10) RTD5TY (Hidden if RTD5LOC := OFF) RTD5 TRIP LEVEL (OFF, 1–250 degC)

- Page 221 Date _______________ SEL-787 Settings Sheets SET.9 Group Settings (SET Command) of 68 Group______________ RTD10 LOCATION (OFF, AMB, OTH) RTD10LOC := RTD10 IDENTIFIER (10 characters) RTD10NAM:= (Hidden if RTD10LOC := OFF or AMB) RTD10 TYPE (PT100, NI100, NI120, CU10) RTD10TY := (Hidden if RTD10LOC := OFF) RTD10 TRIP LEVEL (OFF, 1–250 degC)

- Page 222 SET.10 SEL-787 Settings Sheets Date _______________ of 68 Group Settings (SET Command) Group______________ Negative-Sequence Overvoltage (Hidden if voltages not included) NSEQ OV LEVEL (OFF, 12.5–300.0 V) 59Q1P NSEQ OV DELAY (0.0–120.0 sec) 59Q1D (Hidden if 59Q1P := OFF) NSEQ OV LEVEL (OFF, 12.5–300.0 V) 59Q2P NSEQ OV DELAY (0.0–120.0 sec)

- Page 223 Date _______________ SEL-787 Settings Sheets SET.11 Group Settings (SET Command) of 68 Group______________ PWR ELEM DELAY (0.0–240.0 s) PWR2D (Hidden if 3PRW2P := OFF or if EPWR := 3P1) Frequency (Hidden if voltages not included) FREQ1 TRIP LEVEL (OFF, 20.0–70.0 Hz) 81D1TP FREQ1 TRIP DELAY (0.0–240.0 sec)

- Page 224 SET.12 SEL-787 Settings Sheets Date _______________ of 68 Group Settings (SET Command) Group______________ UNLATCH CLOSE 1 EQUATION (SEL ULCL1 OGIC BREAKER 2 STATUS (SEL 52A2 OGIC CLOSE 2 EQUATION (SEL OGIC UNLATCH CLOSE 2 EQUATION (SEL ULCL2 OGIC SEL-787 Relay...

- Page 225 Date _______________ SEL-787 Settings Sheets SET.13 Logic Settings (SET L Command) of 68 Group______________ Logic Settings (SET L Command) Enables OGIC LATCHES (N, 1–32) ELAT OGIC SV/TIMERS (N, 1–32) COUNTERS (N, 1–32) OGIC MATH VARIABLES (N, 1–32) Latch Bits Equations...

- Page 226 SET.14 SEL-787 Settings Sheets Date _______________ of 68 Logic Settings (SET L Command) Group______________ RST15 SET16 RST16 SET17 RST17 SET18 RST18 SET19 RST19 SET20 RST20 SET21 RST21 SET22 RST22 SET23 RST23 SET24 RST24 SET25 RST25 SET26 RST26 SET27 RST27 SET28...

- Page 227 Date _______________ SEL-787 Settings Sheets SET.15 Logic Settings (SET L Command) of 68 Group______________ SV/Timers SV TIMER PICKUP (0.00–3000.00 sec) SV01PU SV TIMER DROPOUT (0.00–3000.00 sec) SV01DO SV INPUT ( SV01 OGIC SV TIMER PICKUP (0.00–3000.00 sec) SV02PU SV TIMER DROPOUT (0.00–3000.00 sec)

- Page 228 SET.16 SEL-787 Settings Sheets Date _______________ of 68 Logic Settings (SET L Command) Group______________ SV TIMER PICKUP (0.00–3000.00 sec) SV13PU SV TIMER DROPOUT (0.00–3000.00 sec) SV13DO SV INPUT ( SV13 OGIC SV TIMER PICKUP (0.00–3000.00 sec) SV14PU SV TIMER DROPOUT (0.00–3000.00 sec)

- Page 229 Date _______________ SEL-787 Settings Sheets SET.17 Logic Settings (SET L Command) of 68 Group______________ SV TIMER DROPOUT (0.00–3000.00 sec) SV25DO SV INPUT ( SV25 OGIC SV TIMER PICKUP (0.00–3000.00 sec) SV26PU SV TIMER DROPOUT (0.00–3000.00 sec) SV26DO SV INPUT (...

- Page 230 SET.18 SEL-787 Settings Sheets Date _______________ of 68 Logic Settings (SET L Command) Group______________ SC CNT UP INPUT (SEL SC03CU OGIC SC CNT DN INPUT (SEL SC03CD OGIC SC PRESET VALUE (1–65000) SC04PV SC RESET INPUT (SEL SC04R OGIC SC LOAD PV INPUT (SEL...

- Page 231 Date _______________ SEL-787 Settings Sheets SET.19 Logic Settings (SET L Command) of 68 Group______________ SC PRESET VALUE (1–65000) SC11PV SC RESET INPUT (SEL SC11R OGIC SC LOAD PV INPUT (SEL SC11LD OGIC SC CNT UP INPUT (SEL SC11CU OGIC SC CNT DN INPUT (SEL...

- Page 232 SET.20 SEL-787 Settings Sheets Date _______________ of 68 Logic Settings (SET L Command) Group______________ SC LOAD PV INPUT (SEL SC18LD OGIC SC CNT UP INPUT (SEL SC18CU OGIC SC CNT DN INPUT (SEL SC18CD OGIC SC PRESET VALUE (1–65000) SC19PV...

- Page 233 Date _______________ SEL-787 Settings Sheets SET.21 Logic Settings (SET L Command) of 68 Group______________ SC CNT DN INPUT (SEL SC25CD OGIC SC PRESET VALUE (1–65000) SC26PV SC RESET INPUT (SEL SC26R OGIC SC LOAD PV INPUT (SEL SC26LD OGIC SC CNT UP INPUT (SEL...

- Page 234 SET.22 SEL-787 Settings Sheets Date _______________ of 68 Logic Settings (SET L Command) Group______________ Math Variables MV01 MV02 MV03 MV04 MV05 MV06 MV07 MV08 MV09 MV10 MV11 MV12 MV13 MV14 MV15 MV16 MV17 MV18 MV19 MV20 MV21 MV22 MV23 MV24...

- Page 235 Date _______________ SEL-787 Settings Sheets SET.23 Logic Settings (SET L Command) of 68 Group______________ Base Output OUT101 FAIL-SAFE (Y, N) OUT101FS := OUT101 OUT102 FAIL-SAFE (Y, N) OUT102FS := OUT102 OUT103 FAIL-SAFE (Y, N) OUT103FS := OUT103 Slot C Output...

- Page 236 SET.24 SEL-787 Settings Sheets Date _______________ of 68 Logic Settings (SET L Command) Group______________ Transmit SEL Equations IRRORED OGIC (Hidden if PROTO is not MBxx on any of the communications ports.) TMB1A TMB2A TMB3A TMB4A TMB5A TMB6A TMB7A TMB8A TMB1B...

- Page 237 Date _______________ SEL-787 Settings Sheets SET.25 Global Settings (SET G Command) of 68 Group______________ Global Settings (SET G Command) General PHASE ROTATION (ABC, ACB) PHROT RATED FREQ. (50, 60 Hz) FNOM DATE FORMAT (MDY, YMD, DMY) DATE_F FAULT CONDITION (SEL...

- Page 238 SET.26 SEL-787 Settings Sheets Date _______________ of 68 Global Settings (SET G Command) Group______________ MESSENGER POINT MP10 AQ (None, 1 analog quantity) MPAQ10 MESSENGER POINT MP10 TEXT (148 characters) MPTX10 MESSENGER POINT MP11 TRIGGER (Off, 1 Relay Word bit) MPTR11...

- Page 239 Date _______________ SEL-787 Settings Sheets SET.27 Global Settings (SET G Command) of 68 Group______________ MESSENGER POINT MP22 TEXT (148 characters) MPTX22 MESSENGER POINT MP23 TRIGGER (Off, 1 Relay Word bit) MPTR23 MESSENGER POINT MP23 AQ (None, 1 analog quantity) MPAQ23...

- Page 240 SET.28 SEL-787 Settings Sheets Date _______________ of 68 Global Settings (SET G Command) Group______________ Phasor Measurement (PMU) EN SYNCHRO PHSOR (Y, N) EPMU (All subsequent PMU settings hidden if EPMU :=N) MESSAGES PER SEC (1, 2, 5, 10) MRATE STATION NAME (16 characters) PMSTN PMU HARDWARE ID (1–65534)

- Page 241 Date _______________ SEL-787 Settings Sheets SET.29 Global Settings (SET G Command) of 68 Group______________ Analog Inputs For the following settings, x is the card position (3, 4, or 5 in Slot C, D, and E, respectively). AIx01 01 TAG NAME (8 characters 0–9, A–Z, _)

- Page 242 SET.30 SEL-787 Settings Sheets Date _______________ of 68 Global Settings (SET G Command) Group______________ 02 HI WARN L2 (OFF, –99999.000 to +99999.000) AIx02HW2 := 02 HI ALARM (OFF, –99999.000 to +99999.000) AIx02HAL := AIx03 03 TAG NAME (8 characters 0–9, A–Z, _)

- Page 243 Date _______________ SEL-787 Settings Sheets SET.31 Global Settings (SET G Command) of 68 Group______________ Analog Outputs For the following settings, x is the card position (3, 4, or 5 in Slot C, D, and E, respectively). AOx01 01 ANALOG QTY (Off, 1 analog quantity)

- Page 244 SET.32 SEL-787 Settings Sheets Date _______________ of 68 Global Settings (SET G Command) Group______________ AOx04 04 ANALOG QTY (Off, 1 analog quantity) AOx04AQ := 04 TYPE (I, V) AOx04TYP := 04 AQTY LOW (–2147483647 to +2147483647) AOx04AQL := 04 AQTY HI (–2147483647 to +2147483647)