Table of Contents

Advertisement

PRODUCT INSTRUCTIONS

Mini Standard V7 3phase Controller

Stock Code

01003

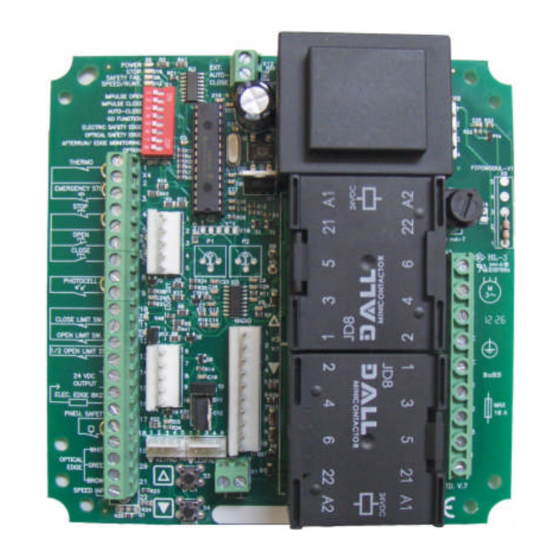

Dalmatic Mini Standard V7 Controller

Controller

Specification

Supply voltage:

Maximum Load

Temperature range

Humidity:

Auxiliary Supply

Safety edge input:

Photo sensor input

Description

The Mini-Std controller has been designed as a controller which provides the

capabilities to operate an industrial door safely under electrical control by means of

a pushbutton station or key switch

Its intended use is to be connected to a suitable motor not exceeding the load for

the controller

The unit incorporates safety features to protect people or property from damage by

automatically reversing a closing door should they be activated

This together with the auto closing function and additional facilities for plug in Loop

Detectors and radio control make this unit very versatile

Connections are provided for Mains supply, Motor power, Travel Limits switches,

Push Buttons, Photocell and Safety Edge and 24VDC Auxiliary power (250mA max)

Description

3ph - 400VAC ± 10% L1,L2,L3,PE ('N' not required)

50/60Hz,

Mains supply protection should be provided by

either 10A/phase MCB Type 'C' or fuse equivalent

Max motor load by 3 x 400VAC: 4 kW

-10...+50°C (operating)

Up to 93% RH non-condensing.

24VDC ± 20% (non-regulated)

Max load: 250mA

(without additional plug-in options)

Pneumatic air switch (N/C Contact)

Electric type - 8k2 termination ± 10%

Optical type (Fraba OSE or Dalmatic TSS/RSS)

Photo-sensor, 24 VDC, Relay O/P N/C

Page 1 of 8

Dallimore Rd, Wythenshawe,

Manchester. M23 9NX

T: +44 (0)161 945 4561

F: +44 (0)161 945 4566

Doc No:

PI-110

Iss:

1

Advertisement

Table of Contents

Summary of Contents for Ellard Mini Standard V7

- Page 1 PRODUCT INSTRUCTIONS Dallimore Rd, Wythenshawe, Manchester. M23 9NX Mini Standard V7 3phase Controller T: +44 (0)161 945 4561 F: +44 (0)161 945 4566 Stock Code Description Doc No: PI-110 01003 Dalmatic Mini Standard V7 Controller Iss: Controller Specification Supply voltage: 3ph - 400VAC ±...

- Page 2 The installation should only be carried out by a trained competent person and in accordance with all local legislation. Please read the instructions in full prior to installation Board Layout Page 2 of 8...

- Page 3 Installation 1) Controller should be mounted in suitable enclosure for the environment and be: a. Vertically mounted and free from vibration b. Not exposed to and is free from all dust and debris c. Fitted with appropriate cable glands to maintain IP rating of enclosure selected d.

- Page 4 Dipswitch Functions Dipswitch Description of function Operation – OPEN direction Dead-man OPEN Impulse OPEN Operation – CLOSE direction Dead-man CLOSE Impulse CLOSE External ‘Auto-Close’ operation (term X12) DISABLED ACTIVE Go function (OPEN-STOP-CLOSE-STOP) DISABLED ACTIVE Electric Safety Edge 8k2 enabled DISABLED ACTIVE Optical Safety Edge enabled DISABLED...

- Page 5 Pneumatic Safety edge (not to used on a new installation) This type of safety edge is not monitored and can become problematic and fail to work should any air-leaks occur, therefore is not compliant for new installations and should be restricted to existing / older installations 1) Ensure the pneumatic safety edge has been fitted correctly and has no air leakage Connect the N/C switch contact to (X4) 17~18...

- Page 6 Service Counter The Mini Std V7 has a settable service interval counter that can be set via the S1 Dipswitches, each dipswitch equates to a set number. S1 Dipswitch D/Sw Count D/Sw Count 1,000 30,000 5,000 40,000 10,000 50,000 20,000 Not used Setting the Service Interval Counter: 1) Note and record all S1 Dipswitch settings...

- Page 7 OF INCORPORATION PRODUCT: 3-phase motor controller MODEL NUMBER: Mini Standard V7 DECLARATION: The product to which this Declaration of Incorporation relates to must only be put into service in a completed machine or system that complies with the requirements of the machinery Directive 2006/42/EC.

- Page 8 Page 8 of 8...

Need help?

Do you have a question about the Mini Standard V7 and is the answer not in the manual?

Questions and answers