Beckhoff EL1918 Operating Instructions Manual

Twinsafe terminal with 8 digital fail-safe inputs

Hide thumbs

Also See for EL1918:

- Operation manual (63 pages) ,

- Operating instructions manual (69 pages)

Summary of Contents for Beckhoff EL1918

- Page 1 Operating Instructions for EL1918 TwinSAFE Terminal with 8 digital fail-safe inputs Version: 1.2.0 Date: 2018-11-05...

-

Page 3: Table Of Contents

2.2.2 Safety concept ......................... 12 2.2.3 The fail-safe principle (Fail Stop) .................. 13 3 Product description.......................... 14 EL1918 – TwinSAFE Terminal with 8 digital fail-safe inputs ............ 14 Intended use ............................ 15 Technical data .......................... 17 Safety parameters ........................... 18 Safe input ............................ 18 Characteristic curve of the inputs .................... 19 Dimensions ............................ 20... - Page 4 Table of contents 4.3.9 Project design limits of EL1918 .................. 40 TwinSAFE reaction times ........................ 40 Diagnosis ............................ 43 4.5.1 Status LEDs........................ 43 4.5.2 Diagnostic LEDs ...................... 43 4.5.3 Flash code display ...................... 44 4.5.4 Diagnosis History...................... 44 4.5.5 Diag History tab ....................... 47 Maintenance ............................ 48...

-

Page 5: Foreword

Product features Only the product features specified in the current user documentation are valid. Further information given on the product pages of the Beckhoff homepage, in emails or in other publications is not authoritative. Disclaimer The documentation has been prepared with care. The products described are subject to cyclical revision. For that reason the documentation is not in every case checked for consistency with performance data, standards or other characteristics. -

Page 6: Safety Instructions

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design. Delivery conditions In addition, the general delivery conditions of the company Beckhoff Automation GmbH & Co. KG apply. Safety instructions 1.2.1... -

Page 7: Description Of Safety Symbols

• Description of Module Fault Link active parameter added. • Version history updated • References added • Description of local logic function added • Foreword updated • Safety instructions adapted to IEC 82079-1. 0.0.2 • Update after review 0.0.1 • First draft EL1918 Version: 1.2.0... -

Page 8: Version History Of The Twinsafe Product

Date Software ver- Hardware Modifications sion version 03.08.2018 First release of the EL1918 References Version Title / description 1.6.0 or newer Operating instructions for EL6910 The document contains a description of the logic functions of the EL6910 and their programming 3.1.0 or newer... -

Page 9: System Description

System description The Beckhoff EtherCAT Terminal system The Beckhoff EtherCAT Terminal system is used for decentralized connection of sensors and actuators to a controller. The components of the Beckhoff EtherCAT Terminal system are mainly used in industrial automation and building management systems. As a minimum, a bus station consists of an EtherCAT Coupler and connected EtherCAT Terminals. -

Page 10: Ethercat Bus Coupler

Fig. 2: Bus Coupler (EtherCAT) Connection technology Bus Coupler Wiring Spring-loaded system Connection cross-section 0.08 mm² ... 2.5 mm², stranded wire, solid wire Fieldbus connection EtherCAT Power contacts 3 spring contacts Current load 10 A Nominal voltage 24 V Version: 1.2.0 EL1918... -

Page 11: Ethercat Terminals

The operating voltage is passed on to following terminals via three power contacts. Terminal strip can be split into galvanically isolated groups by means of potential supply terminals as required. The supply terminals play no part in the control of the terminals, and can be inserted at any locations within the terminal strip. EL1918 Version: 1.2.0... -

Page 12: Twinsafe

2.2.1 The I/O construction kit is extended safely The integrated TwinSAFE safety solution is the logical continuation of the open, PC-based Beckhoff control philosophy. Due to their modularity and versatility, the TwinSAFE components fit seamlessly into the Beckhoff control system. The I/O components are available in the formats Bus Terminal, EtherCAT Terminal, EtherCAT plug-in module and EtherCAT Box. -

Page 13: The Fail-Safe Principle (Fail Stop)

The basic rule for a safety system such as TwinSAFE is that failure of a part, a system component or the overall system must never lead to a dangerous condition. CAUTION Safe state The safe state of the TwinSAFE system is always the switched-off and de-energized state. EL1918 Version: 1.2.0... -

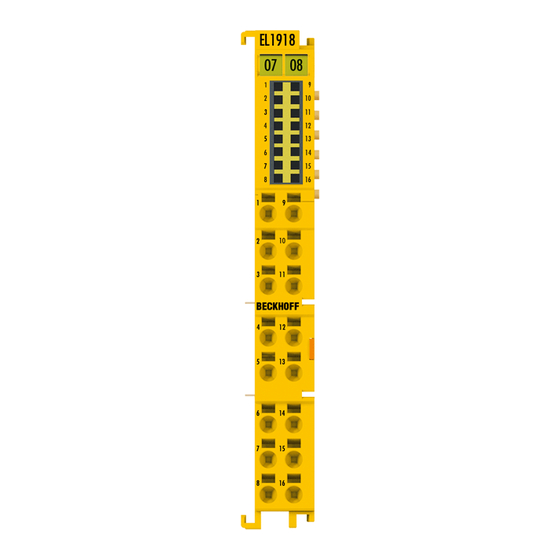

Page 14: Product Description

Product description EL1918 – TwinSAFE Terminal with 8 digital fail-safe inputs The EL1918 is a digital input terminal for sensors with potential-free contacts for 24 V . The TwinSAFE Terminal has 8 fail-safe inputs. With a two-channel connection, the EL1918 meets the requirements of IEC 61508:2010 SIL 3 and EN ISO 13849-1:2015 (Cat 4, PL e). -

Page 15: Intended Use

. Failure to observe this can result in a loss of safety. WARNING Commissioning test Before the EL1918 can be used for the safety-related task, a commissioning test must be carried out by the user so that wiring errors to the sensors can be ruled out. CAUTION Follow the machinery directive! The TwinSAFE components may only be used in machines as defined in the machinery directive. - Page 16 EN 60529, so that the requirement for contamination level 3 according to EN 60664-1 can be reduced to level 2. • The TwinSAFE components must be supplied by a SELV/PELV power supply unit with a maximum volt- age of U <= 36 V Version: 1.2.0 EL1918...

-

Page 17: Technical Data

Output current of the clock outputs typically 3 mA, max. 6.5 mA Input process image 7 bytes Output process image 6 bytes Supply voltage of the EL1918 (PELV) 24 V (–15% / +20%) Signal voltage "0" inputs -3 V ... 5 V (EN 61131-2, type 3) see chapter Characteristic curve of the inputs [} 19] Signal voltage "1"... -

Page 18: Safety Parameters

Element classification Type B 1. Special proof tests are not required during the entire service life of the EL1918 EtherCAT terminal. 2. Classification according to IEC 61508-2:2010 (chapter 7.4.4.1.2 and 7.4.4.1.3) The EL1918 EtherCAT Terminal can be used for safety-related applications within the meaning of IEC 61508:2010 up to SIL3 and EN ISO 13849-1:2015 up to PL e (Cat4). -

Page 19: Characteristic Curve Of The Inputs

Product description Characteristic curve of the inputs The characteristic curve of the inputs is similar to type 3 according to EN 61131-2. Fig. 5: Characteristic curve of the inputs EL1918 Version: 1.2.0... -

Page 20: Dimensions

Product description Dimensions Fig. 6: EL1918 dimensions Width: 12 mm (side-by-side installation) Height: 100 mm Depth: 68 mm Version: 1.2.0 EL1918... -

Page 21: Operation

Please ensure that the digital TwinSAFE components are only transported and stored under the specified environmental conditions (see technical data). 4.2.3 Mechanical installation DANGER Risk of injury! Bring the bus system into a safe, de-energized state before starting installation, disassembly or wiring of the devices! EL1918 Version: 1.2.0... -

Page 22: Fig. 7 Spring Contacts Of Beckhoff I/O Components

• Each bus station must be terminated on the right side with the EL9011 or EL9012 end cap to ensure the protection class and ESD protection. Fig. 7: Spring contacts of Beckhoff I/O components 4.2.3.2 Control cabinet / terminal box The TwinSAFE terminals must be installed in a control cabinet or terminal box with IP54 protection class according to IEC 60529 as a minimum. -

Page 23: Fig. 8 Installation Position And Minimum Distances

The key parameter is always the maximum permitted internally measured temperature of 110°C, above which the TwinSAFE components switch to safe state and report an error. The internal temperature can be read from the TwinSAFE components via CoE. EL1918 Version: 1.2.0... - Page 24 The EL2904 has a rather high waste heat, due to the possibly high output current of the connected actuators. EL1904 Even the EL1904 has a rather high waste heat, although the external load by clock outputs and safe inputs is rather low. Version: 1.2.0 EL1918...

-

Page 25: Fig. 9 Thermally Unfavorable Arrangement Of The Twinsafe Terminals

TwinSAFE terminals by the adjacent power supply units increases the internal terminal temperature, which can lead to the maximum permissible temperature being exceeded. This leads to a diagnosis message "overtemperature”. Fig. 9: Thermally unfavorable arrangement of the TwinSAFE terminals EL1918 Version: 1.2.0... -

Page 26: Fig. 10 Thermally Favorable Arrangement Of The Twinsafe Terminals

The following structure is thermally favorable, since between the coupler / power supply terminal and terminals with rather high waste heat, terminals with low current consumption and thus rather low waste heat are placed. Fig. 10: Thermally favorable arrangement of the TwinSAFE terminals Version: 1.2.0 EL1918... -

Page 27: Fig. 11 Installation On The Mounting Rail

When installing the components, make sure that the locking mechanism doesn't come into conflict with the fixing bolts of the mounting rail. For fastening mounting rails with a height of 7.5 mm under the terminals and couplers, use flat fastening components such as countersunk head screws or blind rivets. EL1918 Version: 1.2.0... -

Page 28: Electrical Installation

(e.g. analog Bus Terminals or digital 4-channel Bus Termi- nals) do not or not fully loop through the power contacts. Potential supply terminals (EL91xx, EL92xx) interrupt the power contacts and thus represent the start of a new supply rail. Version: 1.2.0 EL1918... -

Page 29: Fig. 13 Pe Power Contact

The PE power contact must not be used for other potentials! 4.2.4.2 Overvoltage protection If protection against overvoltage is necessary in your plant, provide a surge filter for the voltage supply to the Bus Terminal blocks and the TwinSAFE terminals. EL1918 Version: 1.2.0... -

Page 30: Fig. 14 Connection Of A Cable To A Terminal Point

The permissible conductor cross-sections can be taken from the following table. Wire cross-section (solid) 0.08 ... 1.5 mm Wire cross-section (stranded wire) 0.25 ... 1.5 mm Wire cross-section (core wire with ferrule) 0.14 ... 0.75 mm Strip length 8 ... 9 mm Version: 1.2.0 EL1918... -

Page 31: Fig. 15 El1918 Connection

Operation 4.2.4.4 Connection of the EL1918 Fig. 15: EL1918 connection Terminal point Input Signal Input 1+ (clock output) Input 1- (safe input) Input 3+ (clock output) Input 3- (safe input) Input 5+ (clock output) Input 5- (safe input) Input 7+ (clock output) -

Page 32: Fig. 16 Cable Routing

The common routing of signals together with other clocked signals in a common cable also reduces the maximum propagation, since crosstalk of the signals can occur over long cable lengths and cause diagnostic messages. Version: 1.2.0 EL1918... -

Page 33: Configuration Of The Terminal In Twincat

See TwinCAT automation software documentation. 4.3.3 Adding an EL1918 An EL1918 is added in exactly the same way as any other Beckhoff EtherCAT Terminal. Open TwinSAFE Terminals item in the list and select the EL1918. Fig. 17: Adding an EL1918 EL1918... -

Page 34: Address Settings On Twinsafe Terminals With 1023 Possible Addresses

TwinSAFE terminal. TwinSAFE addresses between 1 and 1023 are available. DIP switch Address 1023 WARNING TwinSAFE address Each TwinSAFE address may only be used once within a network / a configuration! The address 0 is not a valid TwinSAFE address! Version: 1.2.0 EL1918... -

Page 35: Alias Devices

The alias devices are created in the safety project when the dialog is closed via OK. Alternatively, the user can create the alias devices individually. To this end select Add and New item from the context menu, followed by the required device. EL1918 Version: 1.2.0... -

Page 36: El1918 Parameters In Twincat

Fig. 21: Creating alias devices by the user 4.3.6 EL1918 parameters in TwinCAT After creating the alias device, it can be parameterized according to the user specifications. The FSoE address is set under the Linking tab, and the link to the physical device is created. -

Page 37: Fig. 23 Connection Tab Of The Alias Device

Fig. 23: Connection tab of the alias device The Safety Parameters tab contains the parameters of the EL1918 to be set. The parameters are set separately for each input. Objects 0x8000 and 0x8001 are available for input 1. For all other inputs, the CoE index is increased by 10 hex each, so that objects 0x8070 and 0x8071 are available for input 8. -

Page 38: Process Image Of The El1918

0x0002 / 0.1 ms Input filter for the test pulse signal 4.3.7 Process image of the EL1918 The process image of the EL1918 consists of 7 bytes process data in the input and 6 bytes process data in the output. Fig. 25: Process image of the EL1918 The assignment of the individual signals in the safe data is listed in the following table. -

Page 39: Local Logic Function

Information on creating a safety user program can be found in the documentation for the EL6910 (see References [} 8]). The default project, so that the EL1918 once again behaves as a safe input terminal, can be reactivated by deleting the safety-related user program from the TwinSAFE component. To do this, select the entry Safe Logic, Mapping and Parameter Data in the dialog for deleting the project. -

Page 40: Project Design Limits Of El1918

NOTE Project development TwinCAT 3.1 Build 4022.25 or newer is required to use the internal logic functions. If the EL1918 is used as TwinSAFE slave with the default project, at least an EL6910, EK1960 or newer logic component is required as TwinSAFE master. -

Page 41: Fig. 27 Typical Reaction Time

This results in the following equation for the typical reaction time: with, for example Worst-case reaction time The worst case reaction time is the maximum time required to switch off the actuator in the case of an error. Fig. 28: Worst-case reaction time EL1918 Version: 1.2.0... - Page 42 This error is detected at the output following the expiry of the watchdog time and leads to the switch-off. This results in the following equation for the worst-case reaction: with, for example Version: 1.2.0 EL1918...

-

Page 43: Diagnosis

Diag 3 Global fault or global shutdown No global fault or global (red) on µC1 shutdown on µC1 Diag 4 Global fault or global shutdown No global fault or global (red) on µC2 shutdown on µC2 EL1918 Version: 1.2.0... -

Page 44: Flash Code Display

Both the control entries and the history itself can be found in the CoE object 0x10F3. The entry Newest Message (0x10F3:02) contains the subindex of 0x10F3, which contains the latest diagnostic message, e.g. 0x06 for diagnostic message 1. Version: 1.2.0 EL1918... - Page 45 TwinSAFE device. The age of the diagnostic message can be deduced by calculation with the current timestamp from the CoE object 0x10F8. Bits 5 to 7 reserved Bits 8 to 15 Number of parameters in this diagnostic message EL1918 Version: 1.2.0...

-

Page 46: Fig. 30 Esi/Xml Message Text

The sending of emergency messages to the EtherCAT master is activated by adding the CoE object 0x10F3:05 to the startup list (Transition IP, value 0x0001). If new diagnostic messages arrive, they are entered in object 0x10F3 and additionally sent by emergency to the EtherCAT master. Fig. 31: Startup list Version: 1.2.0 EL1918... -

Page 47: Diag History Tab

Errors within the logic, the function blocks, the connections or the component itself are stored with a corresponding time stamp. Fig. 32: Diag history Use the Advanced… button to open the advanced settings. Here, the user can customize the behavior of the diag history. Fig. 33: Diag history – advanced settings EL1918 Version: 1.2.0... -

Page 48: Maintenance

If the TwinSAFE component was subjected to unacceptable soiling it may no longer be operated! WARNING Have soiled terminals checked! Cleaning of the TwinSAFE component by the user is not permitted! Please send soiled terminals to the manufacturer for inspection and cleaning! Version: 1.2.0 EL1918... -

Page 49: Service Life

• Housing components (polycarbonate, polyamide (PA6.6)) are suitable for plastic recycling. • Metal parts can be sent for metal recycling. • Electronic parts such as disk drives and circuit boards must be disposed of in accordance with national electronics scrap regulations. EL1918 Version: 1.2.0... -

Page 50: Firmware Update Of Twinsafe Products

TwinSAFE component is deleted and replaced by a new version. The latest firmware can be downloaded from the Beckhoff website or requested from Beckhoff Support. The versions are available in an encrypted form and can only be loaded onto the matching TwinSAFE product. -

Page 51: Fig. 35 Firmware Update Of Twinsafe Products - Part 1

Click the button (1) in the TwinCAT system to enter Config mode. Confirm the query with OK (2). After that a further window appears which must be confirmed with Yes (Ja) (3). Deactivate the "Free Run" with No (Nein) (4). The system is now in "Configuration mode". Fig. 35: Firmware update of TwinSAFE products - Part 1 EL1918 Version: 1.2.0... -

Page 52: Fig. 36 Firmware Update Of Twinsafe Products - Part 2

After successful completion you must click OK (12) in the concluding "Function Succeeded" window. You can then switch the system back to Run mode and use the TwinSAFE system. Fig. 37: Firmware update of TwinSAFE products - Part 3 Version: 1.2.0 EL1918... -

Page 53: Appendix

Beckhoff's branch offices and representatives Please contact your Beckhoff branch office or representative for local support and service on Beckhoff products! The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet pages: http://www.beckhoff.com You will also find further documentation for Beckhoff components there. -

Page 54: Certificates

Appendix Certificates Version: 1.2.0 EL1918... - Page 55 Slot and key system and screwless (spring-loaded) connection system........Fig. 2 Bus Coupler (EtherCAT)......................Fig. 3 Overview of EtherCAT Terminals ....................Fig. 4 EL1918 – TwinSAFE Terminal with 8 fail-safe inputs..............Fig. 5 Characteristic curve of the inputs ....................Fig. 6 EL1918 dimensions ........................Fig. 7 Spring contacts of Beckhoff I/O components................

Need help?

Do you have a question about the EL1918 and is the answer not in the manual?

Questions and answers