Table of Contents

Advertisement

Quick Links

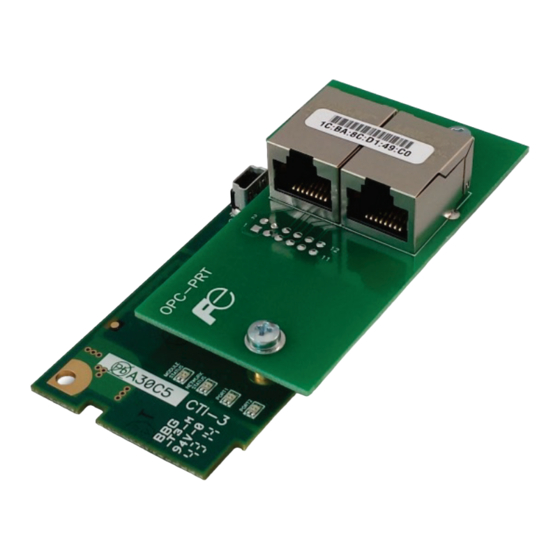

Multiprotocol Ethernet Interface

Thank you for purchasing the OPC-PRT Multiprotocol Ethernet Interface.

•

This product is designed to connect the FRENIC-Ace series of inverters to Ethernet

communication networks. Please read this instruction manual thoroughly in order to become

familiar with the proper interface handling, installation and usage procedures.

Improper handling may inhibit correct operation or cause premature interface failure.

•

Please deliver this instruction manual to the end user of the interface, and retain it in an

•

accessible location.

For inverter usage instructions, please refer to the applicable inverter instruction manual.

•

March 30, 2017

Part #10949

OPC-PRT

Instruction Manual

© 2017 Fuji Electric

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Fuji Electric OPC-PRT

- Page 1 Instruction Manual OPC-PRT Multiprotocol Ethernet Interface Thank you for purchasing the OPC-PRT Multiprotocol Ethernet Interface. • This product is designed to connect the FRENIC-Ace series of inverters to Ethernet communication networks. Please read this instruction manual thoroughly in order to become familiar with the proper interface handling, installation and usage procedures.

- Page 2 Part Number 10949 Printed in U.S.A. ©2017 Fuji Electric. All rights reserved Fuji Electric reserves the right to make changes and improvements to its products without providing notice. Notice to Users PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE-SUPPORT DEVICES OR SYSTEMS.

-

Page 3: Safety Precautions

This instruction manual has been prepared to help you connect your FRENIC-Ace inverter to Industrial Ethernet networks using the OPC-PRT Multiprotocol Ethernet interface card. This instruction manual does not contain inverter usage instructions. Please refer to this instruction manual in conjunction with the applicable inverter instruction manual in order to become familiar with the proper handling, installation and operation of this product. -

Page 4: Installation And Wiring

Installation and Wiring To avoid electrical shock, remove all power from the inverter and wait at least five minutes prior to • starting installation. Additionally, confirm that the DC link bus voltage as measured between the P (+) and N (-) terminals is less than 25 VDC. Installation should be performed only by qualified personnel. - Page 5 Maintenance, inspection, and parts replacement To avoid electrical shock, remove all power from the inverter and wait at least five minutes prior to • starting inspection. Additionally, confirm that the DC link bus voltage as measured between the P (+) and N (-) terminals is less than 25 VDC. Maintenance, inspection, and parts replacement should be performed only by qualified personnel.

-

Page 6: Table Of Contents

− TABLE OF CONTENTS − PRE-OPERATION INSTRUCTIONS ............8 Product Overview ....................8 Features and Specifications ................... 8 Unpacking and Product Confirmation ..............13 1.3.1 Shipment Confirmation ....................13 1.3.2 Component Overview ...................... 14 LED Indicators ....................... 15 1.4.1 Standard LEDs ........................ 15 1.4.1.1 Network Status LED .................... - Page 7 6.2.2 Function Code Group Selection List ................. 37 6.2.3 Function Code List ......................37 6.2.4 Function Code List Filter ....................38 6.2.5 Radix Selection ........................ 38 Dashboard Tab ....................... 39 6.3.1 Information Window ......................39 6.3.2 Virtual Keypad ......................... 40 6.3.3 Gauge Window Navigation....................

- Page 8 9.2.14 ControlLogix Example: Reading and Writing MSG Instructions ........78 Allen Bradley CSP (PCCC) ..................79 9.3.1 Overview ......................... 79 9.3.2 Explicit Messaging Via Read/Write Services ..............79 9.3.3 Inverter Function Code File Number Offset Format ............79 9.3.4 SLC-5/05 Example: Read Function Codes ............... 81 9.3.5 SLC-5/05 Example: Reading and Writing .................

-

Page 9: Pre-Operation Instructions

1 PRE-OPERATION INSTRUCTIONS Product Overview The OPC-PRT Multiprotocol Ethernet interface allows information to be transferred seamlessly between a FRENIC-Ace inverter and several Ethernet-based fieldbus networks with minimal configuration requirements. The interface installs directly onto the inverter, and presents two RJ-45 jacks with an embedded 10BASE-T/100BASE-TX Ethernet switch for connection to the Ethernet network. - Page 10 Table 2: General Hardware Specifications Item Description Power Supply Directly powered by the inverter LED Indicators Module Status, Network Status, 2 x Ethernet Link/Activity USB Port USB 2.0, mini-B 5-pin Table 3: Ethernet Hardware Specifications Item Description Number of Ports 2 (internal switch) Standard IEEE 802.3 10BASE-T/100BASE-TX Ethernet compliant...

- Page 11 Table 5: EtherNet/IP Specifications Item Description Conformance Tested ODVA EtherNet/IP Declaration of Conformity (CT-13) Product Type Code 2 (AC Drive) AC/DC Drive Profile UCMM Class 3 (Explicit) Messaging Class 1 (Implicit I/O) Messaging Class 1 Unicast T→O Class 1 Multicast T→O Number of Connections 16 (Total for both Class 1 and Class 3) Min 1ms...

- Page 12 Table 6: Allen Bradley CSP (PCCC) Specifications Item Description PLC5 Read (DF1 protocol typed read, 0x68) , PLC5 Word Range Read (DF1 protocol word range read, 0x01), Read Services SLC Read (DF1 protocol protected typed logical read with three address fields, 0xA2) PLC5 Write (DF1 protocol typed write, 0x67) , PLC5 Word Range Read (DF1 protocol word range write, 0x00), Write Services...

- Page 13 Table 8: PROFINET Specifications Item Description Conformance Tested PROFINET V2.31 Certificate Protocol Level RT (real-time) RT Conformance Class Class B Netload Class I/O Cycle Time Min 1ms I/O Input Size Max 32 input words, user configurable I/O Output Size Max 32 output words, user configurable Media Redundancy Protocol Client Discovery, set station name, set IP address LLDP...

-

Page 14: Unpacking And Product Confirmation

Check the enclosed items. Confirm that the correct quantity of each item was received, and that no damage occurred during shipment. OPC-PRT interface board with spacer and captive M3 x 12mm screw in lower-right corner (refer to • Figure 1). -

Page 15: Component Overview

Port 2 Link/Activity LED Standoff mounting hole Positioning notch Figure 4: OPC-PRT Component Overview Positioning Notch Aligns with the positioning key on the inverter chassis to ensure that the interface card is installed into the correct communication port (refer to section 2.2). -

Page 16: Led Indicators

LED Indicators 1.4.1 Standard LEDs 1.4.1.1 Network Status LED LED Activity Status Note Device Off The inverter power is off Green Blink / Startup Startup blink sequence Red Blink Green Blink No Connection EtherNet/IP connection is not established Green Off No Connection PROFINET connection is not established Connection... -

Page 17: Installation

• Only one additional option card may be used when the OPC-PRT is installed in the inverter. If two additional option cards are required, please consult with the factory first to confirm compatibility. - Page 18 Interface Card Connector Board Option Case Figure 5: Installation for 15 kW and Smaller Inverters...

- Page 19 Interface Card Connector Board Option Case Figure 6: Installation for 18.5 kW to 22 kW Inverters...

- Page 20 Interface Card Connector Board Option Case Figure 7: Installation for 30 kW and Larger Inverters Engage connector CN1 (on the back of the interface card) into the connector on the connector board. Ensure that the connectors are fully engaged. Ensure that the interface card is fully aligned and seated into the communication port.

- Page 21 will not be pinched and are not located near any power-carrying wiring, such as the inverter’s input power or motor wires. Reinstall all covers removed in step 1. Take a moment to confirm that the Ethernet cables are not being pinched and are not routed near any power-carrying wiring. ...

-

Page 22: Inverter Function Code Settings

3 INVERTER FUNCTION CODE SETTINGS Depending on the desired operation of the overall application, the inverter function codes listed in Table 11 are important for proper operation of the end-to-end communication system. Although there may be many other function codes that will require configuration for your specific application, it is important to understand the manner in which the following function codes will impact successful control of the inverter. -

Page 23: Inverter Reaction To Network Timeout Conditions

Inverter Reaction to Network Timeout Conditions Function codes o27 and o28 specify the inverter’s reaction when a network timeout occurs. Table 13 lists the settings for o27 and o28. Table 13: Inverter Reaction to Network Timeout Conditions (Function Codes o27 and o28) o27 Value o28 Value Inverter reaction when a timeout occurs... -

Page 24: Function Code Numbering And Behavior

4 FUNCTION CODE NUMBERING AND BEHAVIOR Register Numbers All accessible inverter function codes can be referenced by their Modbus register indices, as defined in the RS-485 User’s Manual (24A7-E-0082), section 3 (Table 3.2) and can be conveniently referenced in the configuration studio (section 5.6) and the embedded web server (section 6.2.3). These same register numbers are used when accessing function codes via certain Ethernet protocols. - Page 25 Table 14: Function Code-to-Register Conversion Examples Function Code Group Group Register Example Using Equation 1 Number Code Name F00: (0 x 256) + 0 + 1 = 1 Fundamental F07 (acceleration time 1): (0 x 256) + 7 + 1 = 8 Functions F99: (0 x 256) + 99 + 1 = 100 E00: (1 x 256) + 0 + 1 = 257...

- Page 26 Function Code Group Group Register Example Using Equation 1 Number Code Name Customizable U00: (11 x 256) + 0 + 1 = 2817 Logic Functions U99: (11 x 256) + 99 + 1 = 2916 J00: (13 x 256) + 0 + 1 = 3329 Application J03 (PID proportional gain): (13 x 256) + 3 + 1 = 3332 Functions 1...

-

Page 27: Scanned Function Codes

Function Code Group Group Register Example Using Equation 1 Number Code Name J100: (48 x 256) + 0 + 1 = 12289 PID Control 1 J199: (48 x 256) + 99 + 1 = 12388 Scanned Function Codes The interface card provides network access to the specified list of function codes contained in the param.xml file located in the “WEB”... - Page 28 Table 16: Structure of “Operation status” (Function code M14) Table 17: Structure of “Rotation Speed” (Function code W08)

-

Page 29: Fuji Configuration Studio

5 FUJI CONFIGURATION STUDIO 5.1 Overview The interface card is discovered, configured and updated by the Fuji Configuration Studio PC application (refer to Figure 8). The studio must be installed prior to connecting an interface card to the computer in order to ensure that the appropriate USB drivers are installed. - Page 30 Right-click on it in the Discovered Devices panel and choose Go Online from the context- • sensitive menu. Hit the <ENTER> key on the keyboard when the device is selected in the Discovered Devices • panel. Drag it from the Discovered Devices panel into the Project panel. •...

-

Page 31: General Object Editing Activities

Updating Firmware The studio automatically manages firmware updates when going online with a device and downloading a configuration to a device. Download the latest studio from the product web page to obtain the latest firmware. Do not power off the device or interrupt the connection once the update is in progress as this may corrupt the firmware and/or the configuration. -

Page 32: Ethernet Settings

Right-clicking on it and choosing Copy from the context-sensitive menu. • • Pressing the <CTRL+C> keys on the keyboard. Holding the <CTRL> key and dragging the item to the desired location in the Project panel. • Dragging the item to a new location under a different parent object in the Project panel. •... -

Page 33: Timeout Time

There are two separate elements that comprise the timeout configuration: • The timeout time Timeout Object configuration • 5.4.1.2 Timeout Time The timeout time is the maximum number of milliseconds for a break in network communications before a timeout will be triggered. This timeout setting is configured at the protocol level as part of a driver’s configuration, and used by the protocol drivers themselves to determine abnormal loss-of- communications conditions. -

Page 34: Discovery Over Ethernet

Figure 10: Timeout Object Settings The example is complete. Discovery over Ethernet Depending on the currently-enabled driver, the Configuration Studio will automatically discover the device on the Ethernet network, regardless of whether or not the card’s network settings are compatible with the subnet upon which they reside. -

Page 35: Backup And Restore Parameters

Selecting the device in the Project panel and navigating to Device…Manage Device • Parameters... A parameter is accessible and actively scanned (read from and written to the inverter) only if its corresponding checkbox is enabled. Likewise, a parameter is inaccessible if its checkbox is disabled. Parameters that are accessed more frequently or require a faster update rate should be set to high priority. -

Page 36: Restore Factory Settings

Figure 14: Backup Parameters Figure 15: Restore Parameters Restore Factory Settings The interface card (connected via USB) can be restored to the factory settings. Note that the filesystem will be reformatted, which will destroy all custom modifications and configurations. Please backup the configuration before executing this feature. -

Page 37: Embedded Web Server

6 EMBEDDED WEB SERVER Overview The interface contains an embedded web server (also known as an HTTP server), which allows users to access the inverter’s internal data in a graphical manner with web browsers such as Microsoft Internet Explorer or Mozilla Firefox. In this way, the inverter can be monitored and controlled from across the room or from across the globe. -

Page 38: Function Code Group Selection List

6.2.2 Function Code Group Selection List The Function Code Group Selection List is shown in Figure 18. Individual groups can be selected by clicking on the group name. Multiple groups may also be selected by holding down the CTRL key while clicking on the group names, or a range of groups Figure 18: Function Code Group Selection List... -

Page 39: Function Code List Filter

4.1). The third column contains the function code descriptions, which are used by the filter function. The last column performs two functions: it displays the current value of the function code, and (for writable function codes) also allows changing the function code’s value by clicking on the number in the value column and entering the new value. -

Page 40: Dashboard Tab

Dashboard Tab The Dashboard Tab provides access to a virtual keypad, as well as a variety of gauges, meters and graphs that can be configured to provide an at-a-glance graphical overview of critical application variables in real-time. A total of 10 gauge windows are available (two at a time), and each gauge window can be configured to display any scanned function code’s value via one of six different gauge types. -

Page 41: Virtual Keypad

6.3.2 Virtual Keypad A “virtual keypad” is displayed on the left-hand side of the dashboard tab, and acts as an interface for several useful pieces of control and monitor information. For an overview of the virtual keypad interface, refer to Figure 24. Note that it is recommended to suspend all external protocol-based communications with PLC’s, etc. -

Page 42: Gauge Window Navigation

REV: sets bit #1 (“REV”) and clears bit #0 (“FWD”) in the operation command word (function code • S06). STOP: clears both bit #0 (“FWD”) and bit #1 (“REV”) in the operation command word (function • code S06). RESET: writes a value of “1” to function code S14 (alarm reset command). This will reset a faulted •... - Page 43 Max Value: The gauge’s maximum indicated value. Similar to the Min Value attribute, negative values can be used if desired. Indicated value characteristics can even be inverted by setting the Max Value attribute to a value less than the Min Value attribute. Update Button: Clicking the update button will apply the current configuration attribute settings to the gauge.

- Page 44 Pos/Neg Meter: Refer to Figure 30. Similar to the “meter” gauge, this type of meter also implements a common panel meter-type display format, but in this instance the indicated value can be positive or negative (two’s complement interpretation). In other words, raw function code values of 0...0x7FFF equate to 0...32767 , and values...

-

Page 45: Submitting Changes

At times, it may be convenient to zoom in on a particular gauge or meter in order to more clearly see the indicator, or to fill the computer screen with a particular gauge’s image. This can be easily accomplished with the web browser’s Flash Player plug-in by right- clicking on the gauge and selecting the desired zoom level (refer to Figure 33). -

Page 46: Customizing The Embedded Web Server

Customizing the Embedded Web Server 6.4.1 Customization Overview It is possible for end-users to customize the embedded web server in order to create their own application-specific or corporate “look and feel”. Knowledge of authoring dynamic web content is required. Using windows explorer, it is possible to load customized web server content into the “WEB” folder on the interface card’s file system (refer to section 7.2). -

Page 47: Xtpro Web Browser-Based Implementation

6.4.3 XTPro Web Browser-Based Implementation A representative implementation based upon using a web browser as the client is detailed in Figure 35. In this scenario, the client application is developed by using an active web server authoring tool (such as Adobe Flash®). -

Page 48: Xtpro Hmi-Based Implementation

6.4.4 XTPro HMI-Based Implementation A representative implementation based upon a stand-alone HMI client is detailed in Figure 36. In this scenario, the client application is developed by using tools provided by the HMI manufacturer, and is hosted independently of the actual server device. trogrammer authors HMI (client) content Content is loaded... -

Page 49: File System

7 FILE SYSTEM Overview The interface card’s on-board file system is used by the application firmware. Currently, the application firmware’s main use of the file system is to store XML-encoded configuration files and the embedded web server. The studio must be used to manage the configuration via USB or FTP. Do not manually access the configuration files unless instructed by technical support. -

Page 50: Ftp With Windows Explorer

Figure 39: USB File Access via Windows Explorer FTP with Windows Explorer To use FTP with Microsoft Windows Explorer, first open either “Windows Explorer” or “My Computer”. Please note that the indicated procedure, prompts and capabilities outlined here can vary depending on such factors as the installed operating system, firewalls and service packs. - Page 51 Besides the new “WEB” folder containing the new web server, the update requires a USB or FTP connection as described earlier in this section. To update the web server, complete the following steps: Navigate to the card’s file system (see section 7.2 or 7.3). Backup the “WEB”...

-

Page 52: Firmware

8 FIRMWARE Overview The interface card’s embedded firmware can be updated in the field. Firmware updates may be released for a variety of reasons, such as custom firmware implementations, firmware improvements and added functionality as a result of user requests. Additionally, it may be necessary to load different firmware onto the unit in order to support various protocols. -

Page 53: Protocol-Specific Information

9 PROTOCOL-SPECIFIC INFORMATION This section will discuss topics that are specific to each of the supported protocols. Modbus/TCP 9.1.1 Overview The interface card supports Schneider Electric’s Modbus/TCP protocol, release 1.0. The interface is conformance class 0 and partial class 1 and class 2 compliant, and allows up to 8 simultaneous Modbus/TCP client connections (sockets). -

Page 54: Connection Timeout Options

#3, bit #1. 9.1.4 Connection Timeout Options In the studio’s Project panel, navigate to OPC-PRT…Ethernet…Modbus/TCP Server. The following configuration options will determine the actions to be taken if the connection is abnormally terminated or lost. While this feature provides an additional level of fail-safe functionality for those applications that require it, there are several ramifications that must be understood prior to enabling this capability. -

Page 55: Node Settings

There are no node settings. A node is simply a container for objects. 9.1.6 Holding/Input Register Remap Settings In the studio’s Project panel, add OPC-PRT…Ethernet…Modbus/TCP Server…Node…Holding/Input Register Remap. The holding/input register remap objects are OPTIONAL. By default, all inverter function codes are already mapped as both holding (4X) and input (3X) registers (refer to section 9.1.2). -

Page 56: Ethernet/Ip

1 connections. 9.2.2 Server Settings In the studio, navigate to OPC-PRT…Ethernet…EtherNet/IP Server. Device Name The device name is used for identification of a device on the EtherNet/IP network. This string is accessible as the “product name”... -

Page 57: Connection Timeout Options

9.2.3 Connection Timeout Options In the studio’s Project panel, navigate to OPC-PRT…Ethernet…EtherNet/IP Server. The following configuration options will determine the actions to be taken if the connection is abnormally terminated or lost. While this feature provides an additional level of fail-safe functionality for those applications that require it, there are several ramifications that must be understood prior to enabling this capability. -

Page 58: Generic Class 1 (I/O) Connection Access

Consumed Data Word Offset The consumed data received from the client at this word offset will contain the value to be written to the associated inverter function code. It is recommend to start at word offset 0. Function Code The inverter function code (refer to section 4) associated with the word offset. For the Produced Data Word object, enter a “status”... - Page 59 The AC/DC drive profile implementation provides support for several required CIP objects, which are specified in Table 22. While the various supported attributes of all of these objects are accessible via explicit messaging, the main intent of using the AC/DC drive profile is to interact with the predefined input and output assembly instances via an I/O connection.

-

Page 60: Explicit Messaging Via Get/Set Attribute Single Services

Table 24: Input Instances 70 and 71 Detail Instance Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Running1 Faulted Speed Actual (Low Byte) Speed Actual (High Byte) Ctrl Running2 Running1 From From Ready Warning... -

Page 61: Explicit Messaging Via Data Table Read/Write Services

9.2.8 Explicit Messaging Via Data Table Read/Write Services Data table read (0x4C) and data table write (0x4D) services provide a direct method of accessing the inverter function codes by reference to “tag names”. Tags are read via the EtherNet/IP “data table read” service, and written via the EtherNet/IP “data table write”... - Page 62 Figure 41: Adding a New Module The “New Module” window will open. Refer to Figure 42. Figure 42: Identifying the New Module Assign the Ethernet module a name (we will use “EIP”) and an IP address, deselect “Open Module Properties”, and click OK. Download the configuration.

-

Page 63: Controllogix Example: Eds Add-On Profile (Aop)

9.2.11 ControlLogix Example: EDS Add-On Profile (AOP) This section will demonstrate how to setup and use an EtherNet/IP I/O connection via EDS Add-On Profile. This example only applies to RSLogix5000 V20 (and later) that support EDS Add-On Profile. Otherwise, refer to the I/O examples in section 9.2.12. This section must be completed prior to attempting any of the following AOP example(s). - Page 64 The task summary will list the interface card as the device to register. Click “Next”. “You have successfully completed the EDS Wizard”. Click “Finish”. The interface card is now available as a module. Right click on the 1756-ENBT/A node under the “I/O Configuration” in the controller organizer view and choose “New Module…”...

-

Page 65: Controllogix Example: Eds Add-On Profile (Aop) Generic I/O Messaging

Enter a “Name” which will allow easy identification of the inverter on the network (the tags created in RSLogix 5000 will be derived from this “Name”). Enter the “IP address” of the targeted interface card. Click on the “Connection” tab. Refer to Figure 47. Figure 47: AOP New Module Properties Connection Tab Confirm the setting of the “Requested Packet Interval (RPI)”. -

Page 66: Controllogix Example: Eds Add-On Profile (Aop) Ac/Dc Drive Profile

Configure the Generic I/O connection. Refer to Figure In the “Connection” portion of the dialog box, enter the following information: Name: In this example, select Generic I/O. Size: Because all inverter data is stored as 16-bit function codes, change the data type to “INT array”. - Page 67 change the data type to “INT array”. When done, click “OK”. Switch to online mode and download the project to the PLC. Verify that the newly-added inverter is available and operating correctly by observing any indications shown on the inverter’s icon. When the inverter’s icon is selected, its status and any available error messages will be displayed in the area below the project tree.

-

Page 68: Controllogix Example: I/O Messaging

9.2.12 ControlLogix Example: I/O Messaging This section will demonstrate how to setup and use an EtherNet/IP I/O connection via vendor-specific assembly instances 100 & 150 or 20 & 70 or 20 & 71. EtherNet/IP I/O messaging allows the inverter’s function codes to be directly mapped into tags in the ControlLogix PLC. Once an I/O connection is established, it is automatically synchronized at an interval defined by the Requested Packet Interval (RPI). - Page 69 Input: The Input Assembly is the collection of monitor data that is produced by the interface card and is received as an input to the PLC. Its structure is defined by the Produced Data Configuration as described in section 9.2.4. The Input Assembly Instance must be set to 150 when connecting to the generic I/O assembly instances (or 70/71 when using the ODVA AC/DC drive profile), and the size must be set to the number of 16-bit function codes that we wish to receive from the interface card.

-

Page 70: Controllogix Example: Generic Default I/O Add-On Instruction

By double-clicking “Controller Tags” in the project tree, it is possible to view the newly-added tags. Refer to Figure 56. The Interface_Card:C configuration tag is unused, the Interface_Card:I tag allows viewing of the input data, and the Interface_Card:O tag allows modification of the output data. - Page 71 Figure 57: Generic Default IO Add-On Instruction Double click “Controller Tags” in the controller organizer view and select the “Edit Tags” tab at the bottom. Create the tags in Figure 58. Figure 58: Create Generic Default AOI Tags Double click “MainRoutine” under Tasks …MainTask …MainProgram in the controller organizer view.

-

Page 72: Controllogix Example: Ac/Dc Drive Profile Add-On Instruction

Figure 60: Configure Generic Default AOI The program is now complete. Save, download and run the program. 9.2.12.2 ControlLogix Example: AC/DC Drive Profile Add-On Instruction The AC/DC drive profile add-on instruction is a simple interface to command and monitor the inverter. It is based on the assembly instances 21 &... - Page 73 Figure 63: Create AC/DC Drive Profile AOI Tags Double click “MainRoutine” under Tasks …MainTask …MainProgram in the controller organizer view. Right click on the first ladder logic rung in the MainRoutine window and select “Add Ladder Element...” The “Add Ladder Element” window appears. Select the AC/DC drive profile add-on instruction in the Add-On folder.

- Page 74 Figure 65: Configure AC/DC Drive Profile AOI The program is now complete. Save, download and run the program.

-

Page 75: Controllogix Example: Read A Block Of Function Codes

9.2.13 ControlLogix Example: Read a Block of Function Codes This example program will show how to continuously read a block of function codes from the inverter with a single MSG instruction. Only one read request is outstanding at any given time. Create new Tags. - Page 76 Figure 68: Adding an XIO Element Click OK. Configure the MSG instruction. Edit the “Message Control” field on the MSG instruction to use the previously-created “connection” tag. Refer to Figure 69. Figure 69: MSG Instruction Tag Assignment Click the message configuration button (“…”) in the MSG instruction. The “Message Configuration”...

- Page 77 For the Destination Element, select “data_array[50]”. “Communication” tab settings (refer to Figure 71): Figure 71: Setting the Communication Path Enter the Path to the interface card. A typical path is formatted as “Local_ENB,2,target_IP_address”, where: Local_ENB is the name of the 1756-ENBx module in the local chassis (we •...

- Page 78 Figure 73: Configure XIO Element The program is now complete. Refer to Figure 74. Figure 74: Complete Program Save, download and run the program. To view the values of the function codes being read from the interface card, double-click “Controller Tags” in the controller organizer view. Select the “Monitor Tags”...

-

Page 79: Controllogix Example: Reading And Writing Msg Instructions

9.2.14 ControlLogix Example: Reading and Writing MSG Instructions Often times, applications may need to both read data from and write data to the inverter. To accomplish this task, multiple MSG instructions will need to be implemented in the PLC program. The configuration and execution for implementing multiple MSG instructions is in general identical to that required for implementing just one MSG instruction. -

Page 80: Allen Bradley Csp (Pccc)

Allen Bradley CSP (PCCC) 9.3.1 Overview Ethernet-enabled Allen-Bradley legacy PLCs (such as the PLC5E, SLC-5/05, and MicroLogix series) use a protocol called CSP (Client Server Protocol) to communicate over the Ethernet network. The flavor of CSP used by these PLCs is also known as “PCCC” (Programmable Controller Communication Commands) and “AB Ethernet”. - Page 81 Because both the EtherNet/IP consumed and produced data word configurations are comprised of 32 function code definitions, the targeted “offset/element” must be within the range of 0 to 31 inclusive. Refer to Table 27 for some examples of N50 accesses. Table 27: Examples of EtherNet/IP-Style Bulk Access via File N50 Start Target Max Number of...

-

Page 82: Slc-5/05 Example: Read Function Codes

9.3.4 SLC-5/05 Example: Read Function Codes This example program will show how to continuously read a block of function codes from the inverter with a single MSG instruction. This action is performed via the Typed Read (a.k.a. “PLC5 Read”) message type. Only one read request is outstanding at any given time. Note that the steps for the MicroLogix and PLC5E may vary slightly, but in general are similar. - Page 83 Figure 79: MSG Instruction Selection Select the “XIO” instruction from the “Bit” classification, then click OK. Refer to Figure 80. Figure 80: XIO Instruction Selection Configure the MSG instruction. Set the “Read/Write” field to “Read”, “Target Device” field to “PLC5”, “Local/Remote” field to “Local”, and “Control Block”...

- Page 84 Figure 81: MSG Configuration, "General" Tab In this example, we will be reading a total of 25 function codes beginning at N30:50 (register 2050 / function code M01). To configure this, under “This Controller” set the “Data Table Address” field to N18:1, set the “Size in Elements field” to 25, and set the “Channel” field to 1 (Ethernet).

- Page 85 Figure 83: PLC Program after MSG Instruction Configuration Assign a tag to the XIO element. Double-click on the XIO element located to the left of the MSG block. Type in N20:0/15 (MSG instruction’s enable bit). This configuration causes the MSG instruction to automatically retrigger itself when it completes.

- Page 86 Figure 85: Monitoring the Data Being Read from the Inverter...

-

Page 87: Slc-5/05 Example: Reading And Writing

9.3.5 SLC-5/05 Example: Reading and Writing Often times, applications may need to both read data from and write data to the inverter. To accomplish this task, multiple MSG instructions will need to be implemented in the PLC program. The configuration and execution for implementing multiple MSG instructions is in general identical to that required for implementing just one MSG instruction. -

Page 88: Bacnet/Ip

Firmware Revision: V1.1.31 BACnet Protocol Revision: Product Description: The Fuji Electric FRENIC series is a family of high-performance multifunctional inverters. Other features include ROHS compliance and built-in EMC filter. BACnet Standard Device Profile (Annex L): BACnet Operator Workstation (B-OWS) BACnet Building Controller (B-BC) - Page 89 Device Address Binding: Is static device binding supported? (This is currently for two-way communication with MS/TP slaves and certain other devise.) Networking Options: Router, Clause 6 - List all routing configurations Annex H, BACnet Tunneling Router over IP BACnet/IP Broadcast Management Device (BBMD) Does the BBMD support registrations by Foreign Devices? Character Sets Supported: Indicating support for multiple character sets does not imply that they can all be supported...

- Page 90 Object Types/Property Support Tables: Table 28: BACnet Device Object Types /Properties Supported Object Type Property Device Object Identifier Object Name Object Type System Status Vendor Name Vendor Identifier Model Name Firmware Revision Appl Software Revision Protocol Version Protocol Revision Services Supported Object Types Supported Object List Max APDU Length...

- Page 91 Table 30: BACnet Analog Object Types /Properties Supported Object Type Property Analog Analog Analog Input Output Value Object Identifier Object Name Object Type Present Value Status Flags Event State Out-of-Service Units Priority Array Relinquish Default R – readable using BACnet services W –...

-

Page 92: Default Supported Objects

9.4.2 Default Supported Objects This section will describe the default objects. Since the objects are configurable, the system integrator is responsible for managing, maintaining, and documenting the actual configuration. Always use the studio to confirm the configuration before commissioning the device Table 32: Binary Input Object Instance Summary Active/ Instance ID... -

Page 93: Default Supported Object Details

Table 35: Analog Output Object Instance Summary Instance ID Object Name Description Units FREQ_REF Frequency command ACCEL_TIME Acceleration time Seconds DECEL_TIME Deceleration time Seconds 9.4.3 Default Supported Object Details This section will describe the default objects details. Since the objects are configurable, the system integrator is responsible for managing, maintaining, and documenting the actual configuration. -

Page 94: Server Settings

AO3..Sets the deceleration time in 0.1 second units. Corresponds to function code S09. 9.4.4 Server Settings In the studio’s Project panel, navigate to OPC-PRT…Ethernet…BACnet/IP Server. UDP Port This is the UDP port on which to transmit and receive BACnet/IP packets on the local subnet. The default value is 47808 (0xBAC0). -

Page 95: Analog Output Object Settings

9.4.9 Analog Output Object Settings Object Name The name of the BACnet object. Enter a string of between 1 and 32 characters in length. All object names must be unique within a node. Instance The BACnet object’s instance number. Enter a value between 0…4194302 (0x0…0x3FFFFE). Function Code The inverter function code (refer to section 4) that the BACnet object’s present value will access. -

Page 96: Binary Output Object Settings

Instance The BACnet object’s instance number. Enter a value between 0…4194302 (0x0…0x3FFFFE). Function Code The inverter function code (refer to section 4) that the BACnet object’s present value will access. Data Type Fixed to 16-bit Unsigned. Bitmask Specifies which bit(s) in the 16-bit value designated by the “Function Code” that the binary object will map to. -

Page 97: Binary Value Object Settings

The effect of the “Bitmask” field when reading: When the present value property of a binary object is read by a BACnet client, the bitmask is used to determine the active/inactive state of the object by inspecting the value in the designated function code at the bit location(s) indicated in the bitmask. If all of the bit locations at the designated function code are set, then the object’s state will be returned as “active”. -

Page 98: Multi-State Input Object Settings

Inactive Text Specifies the description of the object’s “inactive” state. Enter a string of up to 32 characters in length. This field is optional and may be left blank. Relinquish Default Defines the default value to be used for an object’s present value property when all entries in the object’s priority array are NULL. -

Page 99: Profinet Io

PROFINET specification. 9.5.3 Connection Timeout Options In the studio’s Project panel, navigate to OPC-PRT…Ethernet…PROFINET IO. The following configuration options will determine the actions to be taken by the card if the PROFINET IO connection is abnormally terminated or lost. - Page 100 The Produced Data Word and Consumed Data Word objects are only applicable when using the I/O module “IN: 32 WORDS, OUT: 32 WORDS”, which is typically the case. The Produced Data Word defines the structure of status data sent from the inverter to the controller. The Consumed Data Word objects will define the structure of the command data sent from the controller (for example, a Siemens PLC) to the inverter.

-

Page 101: Profidrive Profile

9.5.5 PROFIdrive Profile For optimal interoperability, the interface card supports the PROFIdrive profile version 4.1. Use of the PROFIdrive profile is optional and is not recommended unless specifically required in the PROFINET system specification. No explicit configuration of the interface card is necessary in the studio when using the PROFIdrive profile. -

Page 102: Profidrive Reference Speed Setpoint And Actual Speed

Value Significance Description Forward Direction Run in the forward direction 12 - 15 Not used Table 40: ZSW1 Status Word Mapping Value Significance Description Ready To Switch ON Ready to run command ON Not Ready To Switch ON Not ready to run command ON Ready to Operate Ready to run Not Ready To Operate... -

Page 103: Profidrive State Diagram

Running Speed 0x4000 NIST_A = Equation 9 Frequency The “Max Frequency” term which appears in Equation 8 and Equation 9 is obtained from the setting of inverter function code F03 (maximum frequency 1). A normalized value of 0x4000 corresponds to 100% of the maximum frequency. A positive normalized value indicates forward rotation and a negative normalized value indicates reverse rotation. -

Page 104: Profidrive-Specific Parameters

9.5.5.5 PROFIdrive-Specific Parameters The PROFIdrive-specific parameters are shown in Table 41. The parameters are read-only. Table 41: PROFIdrive-Specific Parameters Index Description None NSOLL_A – Speed setpoint A None NIST_A – Speed actual A None STW1 – Control word 1 None ZSW1 –... - Page 105 Figure 90: Successfully Installed GSDML File This will update the Hardware catalog. Locate the device in the Hardware catalog. In the Project tree, double-click on Device & networks. Select the Network view tab and locate the device in the Hardware catalog as shown in Figure 91. Figure 91: Updated Hardware Catalog...

-

Page 106: Add The Device To The Configuration

9.5.7.2 Add the Device to the Configuration Select the device in the Hardware catalog and drag the device into the PROFINET IO system configuration as shown in Figure 92. Figure 92: Add Device to Configuration 9.5.7.3 Select the IO Controller On the device, click “Not assigned”... -

Page 107: Configure The Device Properties

9.5.7.5 Configure the Device Properties Select the device and navigate to the Properties tab. Select the PROFINET interface [X1] node. Assign a unique and compatible IP address for this device as shown in Figure 96. Figure 96: Assign Unique Compatible IP Address Assign a unique PROFINET device name as shown in Figure 97. -

Page 108: Online Device Discovery And Configuration

9.5.7.6 Online Device Discovery and Configuration In the Project tree, expand plc1…Distributed I/O…PROFINET IO-System (100):PN/IE_1. Expand the device and double-click Online & diagnostics. In the next panel, expand Functions and select the Assign IP address node. Click the Accessible devices button. Select the appropriate PG/PC interface and click the Start search button to discover and display the PROFINET devices on the network as shown in Figure 99. -

Page 109: Save The Configuration

Figure 101: Assign Name 9.5.7.7 Save the Configuration The hardware configuration is now complete. Save and perform any necessary compilation of the configuration. Download the application and configuration to the PLC. The PLC application program can then be started. Please consult with the vendor of your PROFINET PLC software for additional programming and configuration details. - Page 110 Figure 102: Add IO-Device Click the Have GSDML… button as shown in Figure 103. Figure 103: Have GSDML Locate and select the GSDML file. Click the Open button to register the GSDML as shown in Figure 104. It is recommended to use the latest GSDML, which is available via the product web page on the internet.

-

Page 111: Add The Device To The Configuration

Figure 105: Updated PROFINET Device Catalog 9.5.8.2 Add the Device to the Configuration Select the device in the PROFINET Device Catalog and click the OK button as shown in Figure 105. The device is added under the Profinet Controller node as shown in Figure 106. Figure 106: Added Device to Configuration 9.5.8.3 Assign IO Module... -

Page 112: Configure The Device Properties

Select a module and drag the module into the available slot. The available slots and modules will vary depending on the specific device. Select a module appropriate for your application. Click the OK button as shown in Figure 108. Figure 108: Add IO Module The module will be reflected in the Navigator panel, under the device as shown in Figure 109. -

Page 113: Save The Configuration

Set the properties to match the configuration on the device. The properties must be appropriate for the application and the PROFINET network. Set the Update Rate (ms). For this example, the Update Rate (ms) is set to “8” ms. Assign a unique Device Name. For this example, the Device Name is set to “interfacecard”. -

Page 114: Troubleshooting

10 TROUBLESHOOTING Although by no means exhaustive, Table 42 provides possible causes behind some of the most common errors experienced when using the interface card. Table 42: Troubleshooting Problem Symptom Solution • Confirm that the interface card connector is properly seated. •... - Page 115 Problem Symptom Solution Confirm that the applicable inverter function codes • Writing to command are set to allow network control (refer to section Unable to control and frequency 3.1). the inverter via function network codes/registers has If using the inverter’s terminal contacts, refer to the •...

- Page 116 47520 Westinghouse Dr. Fremont, CA 94539 Tel: 510.440.1060 Fax: 510.440.1063 http://www.americas.fujielectric.com...

Need help?

Do you have a question about the OPC-PRT and is the answer not in the manual?

Questions and answers