Table of Contents

Advertisement

This manual applies to:

Record serial number of your planter and date purchased:

Monitor Serial Number _______________________________________________

Measured Pulses Per Mile/Km (Radar Distance Sensor) ____________________

Measured Pulses Per Mile/ Km (Magnetic Distance Sensor) _________________

SERIAL NUMBER

The serial number plate is located on the planter frame as shown below. The serial number provides important information

about your planter and is needed to obtain correct replacement parts. Always provide model number and serial number

to your Kinze Dealer when ordering parts or when contacting Kinze Manufacturing, Inc.

Serial number plate

Prior to 2009 production

Kinze

, the Kinze

®

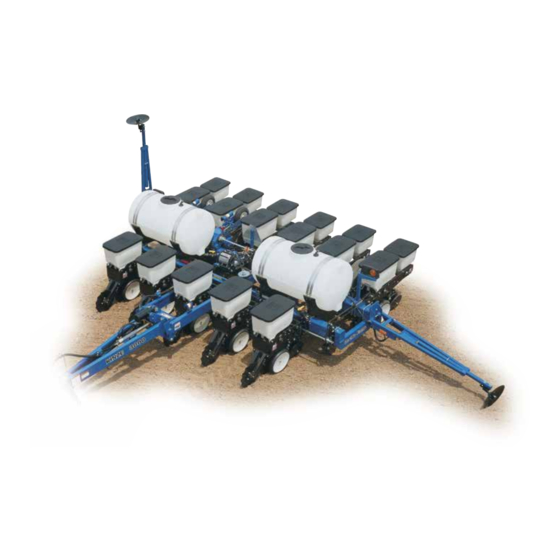

MODEL 3000

RIGID FRAME PLANTER

(Mechanical Seed Metering)

OPERATOR MANUAL

M0188-01

Model: 3000 Rigid Frame Planters

Serial Number: 643579 and later

Model Number __________________________________

Serial Number ___________________________________

Date Purchased __________________________________

2013 production and later

logo, Double Frame

, and Interplant

®

®

Rev. 9/17

3000

Serial number plate

2009 production and later

Serial number plate

are registered trademarks of Kinze Manufacturing, Inc.

®

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Kinze 3000

- Page 1 The serial number plate is located on the planter frame as shown below. The serial number provides important information about your planter and is needed to obtain correct replacement parts. Always provide model number and serial number to your Kinze Dealer when ordering parts or when contacting Kinze Manufacturing, Inc. Serial number plate...

- Page 2 Predelivery/Delivery Checklist M0188-01 Model 3000 Rev. 4/14...

- Page 3 Predelivery/Delivery Checklist M0188-01 Model 3000 TO THE DEALER Predelivery service includes assembly, lubrication, adjustment, and test. This service makes sure planter is delivered to the retail customer/end user ready for field use. PREDELIVERY CHECKLIST Use the following checklist and inspect planter after it is completely assembled. Check off each item found satisfactory or after proper adjustment is made.

- Page 4 Replace if damaged or missing. Check safety/warning lights are working properly. (Signature Of Follow-Up Person/Dealer Name/Date) All registrations must be submitted online at “business.kinze.com” within 5 business days of delivery. Retain a copy of this form for auditing purposes. Tear Along Perforation...

-

Page 5: Table Of Contents

Table of Contents M0188-01 Model 3000 OVERVIEW Seed Hopper ........3-7 Seed Meter Drive Release. - Page 6 Lift Circuit Operation Troubleshooting ....8-2 Model 3000 Operating Tire Pressure....7-12 Piston Pump Troubleshooting .

-

Page 7: To The Owner

M0188-01 Model 3000 Kinze Manufacturing, Inc. would like to thank you for your patronage. We appreciate your confidence in Kinze farm machinery. Your Kinze planter has been carefully designed to provide dependable operation in return for your investment. This manual has been prepared to aid you in planter operation and maintenance. It should be considered a permanent part of the machine and remain with the machine when you sell it. - Page 8 NOTE: Photos in this manual may be of prototype machines. Production machines may vary in appearance. NOTE: Some photos and illustrations in this manual show optional attachments installed. Contact your Kinze Dealer for purchase of optional attachments.

-

Page 9: Warranty

M0188-01 Model 3000 The Kinze Limited Warranty for your new machine is stated on the retail purchaser’s copy of the Warranty And Delivery Receipt form. Additional copies of the Limited Warranty can be obtained through your Kinze Dealer. Warranty, within the warranty period, is provided as part of Kinze’s support program for registered Kinze products which have been operated and maintained as described in this manual. -

Page 10: General Information

M0188-01 GENERAL INFORMATION This manual covers all production years of the Model 3000 planter. Contact your Kinze dealer for additional options which may be available for your specific model year planter. Information in this manual was current at time of printing. However, due to Kinze’s ongoing product improvement, production changes may cause your machine to appear slightly different in detail. -

Page 11: Specifications

* Base machine weights include planter frame including row markers, drive components, tires and wheels, hydraulic cylinders, transport safety chain and Kinze pull row units (closing wheel arms less wheels) with seed hopper and lid and dual quick adjustable down force springs. -

Page 12: General Safety Rules

Use safety chain (not an elastic or nylon/plastic Model 3000 planter consists of 85% recyclable metals, tow strap) to retain connection between towing and 10% recyclable plastic and rubber, and 5% waste. -

Page 13: Safety Instructions, Signs, And Decals

Safety Instructions, Signs, and Decals M0188-01 Model 3000 Following are some common hazard warnings associated with this equipment. Pay close attention to all safety, operating, and maintenance information in this manual and decals applied to your equipment. Contacting or coming close to power... - Page 14 Safety Instructions, Signs, and Decals Model 3000 M0188-01 Safety Signs And Decals All safety/warning lights, reflective WARNING decals, and SMV sign must be in place and visible before transporting machine on public roads or death, serious injury, and damage to property and equipment may result.

-

Page 15: Machine Operation

Machine Operation M0188-01 Model 3000 Following information is general in nature to aid in preparation of tractor and planter for use, and to provide general operating procedures. Operator experience, familiarity with the machine, and the following information should combine for efficient planter operation and good working habits. -

Page 16: Tractor Requirements

Consult your dealer for information on horsepower requirements and tractor compatibility. Requirements vary with planter options, tillage, and terrain. A 12 volt DC electrical system is required for all 3000 series planters. One dual remote hydraulic outlet (SCV) is required for machines equipped with a standard single valve hydraulic system. - Page 17 Machine Operation M0188-01 Model 3000 Pressurized hydraulic fluid can penetrate WARNING body tissue and result in death, serious infection, or other injuries. Fluid injected under skin must be IMMEDIATELY removed by a surgeon familiar with this type of injury. Make sure connections...

-

Page 18: Cylinder Information

Machine Operation Model 3000 M0188-01 CYLINDER INFORMATION Row Marker Cylinder Row Marker Cylinder Lift Assist Cylinder (4 Row 30"/36"/38" (6 Row 36"/38" and (6 Row 30"/36"/38" Slave Lift Cylinder Master Lift Cylinder and 6 Row 30") 8 Row 30") and 8 Row 30") -

Page 19: Hydraulic Hose Information

Machine Operation M0188-01 Model 3000 HYDRAULIC HOSE INFORMATION Part Number A3135 A1076 A1102 A1170 A1138 A1018 Hose Assembly, Hose Assembly, Hose Assembly, Hose Assembly, Hose Assembly, Hose Assembly, Description ⅜" x 100" ⅜" x 30" ¼" x 95" ¼" x 90"... - Page 20 Machine Operation Model 3000 M0188-01 Hydraulic Hose Information (Continued) Part Number A1086 A3119 A3175 A1019 A1079 A1090 Hose Assembly, Hose Assembly, Hose Assembly, Hose Assembly, Hose Assembly, Hose Assembly, Description ⅜" x 28" ⅜" x 36" ⅜" x 38" ⅜" x 44"...

-

Page 21: Hydraulic Lift Operation

Machine Operation M0188-01 Model 3000 HYDRAULIC LIFT OPERATION Uncontrolled movement of equipment WARNING can cause loss of control and could result in death, serious injury, or damage to property and equipment. Install all safety pins before transporting equipment. Master cylinder... -

Page 22: Safety Lockups

Machine Operation Model 3000 M0188-01 SAFETY LOCKUPS Safety lockups are provided for each cylinder (including optional Interplant self-leveling hitch) and must be in place when working on a raised planter, transporting, or during storage. Safety lockup in storage location Safety lockup installed Place a safety lockup on each cylinder rod and secure in place with pin. -

Page 23: Transporting Planter

Machine Operation M0188-01 Model 3000 TRANSPORTING PLANTER Contacting or coming close to power DANGER lines or other high energy sources will cause death or serious injury. Keep away from power lines or high energy sources at all times. All safety/warning lights, reflective... -

Page 24: Seed Rate Transmission Adjustment

Machine Operation Model 3000 M0188-01 SEED RATE TRANSMISSION ADJUSTMENT Seed rate transmissions allow simple, rapid changes of sprockets to obtain Drive sprocket desired planting population. By removing lynch pins on hexagon shafts, sprockets can be interchanged with those from the sprocket storage rod bolted to the transmission. -

Page 25: Shear Protection

Machine Operation M0188-01 Model 3000 SHEAR PROTECTION Shear pins protect the planter driveline and row unit components from damage. 1. Determine where binding has occurred before replacing a pin. Turn shaft by hand (with the aid of a wrench) and check for misalignment and seized parts. -

Page 26: Wrap Spring Wrench

Machine Operation Model 3000 M0188-01 WRAP SPRING WRENCH Chain idlers use wrap spring wrenches to release and adjust transmission chain tension. Rotate wrap spring wrench knurled collar while rotating chain idler away from chain to release chain tension. Release chain tension Rotate chain idler into chain while rotating handle to tension idler spring. -

Page 27: Hydraulic Row Marker Operation

Model 3000 planters are equipped with a single or optional dual valve hydraulic system to control row markers. A single valve system lifts a row marker when the planter is raised. Row markers lower on alternate sides each time planter is lowered. -

Page 28: Row Marker Speed Adjustment

Machine Operation Model 3000 M0188-01 An optional dual valve hydraulic system allows planter to be raised and lowered without operating row markers. Row markers are controlled on alternating sides through a tractor SCV. The sequencing valve directs flow to marker on opposite side each time a row marker is raised. -

Page 29: Row Marker Adjustments

7. Do a field test to ensure markers are properly adjusted. NOTE: A notched marker blade is available from Kinze through Concave side faces towards planter. your Kinze Dealer for use in more severe no till conditions. Row marker disc blade angle adjustment 2-15 Rev. 9/17... -

Page 30: Ridge Planting

Machine Operation Model 3000 M0188-01 RIDGE PLANTING Planter toolbar height can be raised 3" (8 cm) for ridge planting. 1. Relocate 20" transport axles to lower rear holes in ground drive wheel arm. New axle location. Transport axle Move contact drive wheel arm here. -

Page 31: Field Test

Machine Operation M0188-01 Model 3000 FIELD TEST Perform a field test with any change of field and/or planting conditions, seed size or planter adjustment to ensure proper seed placement and operation of row units. See “Rate Charts”, “Checking Seed Population” and “Checking Granular Chemical Application Rate”. -

Page 32: Determining Pounds Per Acre (Brush-Type Meter)

Machine Operation Model 3000 M0188-01 3. Measure 1∕1000 of an acre (hectare). See chart for correct distance for row width being planted. For example, if planting 30" (76 cm) rows 1∕1000 of an acre (hectare) would be 17' 5" (13.12 m). -

Page 33: Water Tank

Machine Operation M0188-01 Model 3000 WATER TANK The water tank is to only be filled with clean water or preferably potable water (water meeting local standards for drinking). The tank holds 4 gallons (15 L) of water. Be sure to check for regulations pertaining to this use. - Page 34 This page left blank intentionally.

-

Page 35: Row Unit Operation

Row Unit Operation M0188-01 Model 3000 PLANTING DEPTH Planting depth adjustment handle Planting depth is maintained by adjustable row unit gauge wheels. Depth adjustment range is approximately ½" to 3½" (1.27 to 8.89 cm). 1. Raise planter to remove weight from wheels. -

Page 36: Closing Wheel Shield (Rubber Or Cast Iron "V" Closing Wheels)

Row Unit Operation Model 3000 M0188-01 CLOSING WHEEL SHIELD (RUBBER OR CAST IRON “V” CLOSING WHEELS) Optional closing wheel shield is installed on underside of closing wheel arm to help prevent root balls and stalks from clogging closing wheels. Closing wheel shield... -

Page 37: Covering Discs/Single Press Wheel Adjustment

Row Unit Operation M0188-01 Model 3000 COVERING DISCS/SINGLE PRESS WHEEL ADJUSTMENT Adjusting bolt ½" Locking nut Press wheel down force adjustment Check operation of covering discs/single press wheels after adjusting planting depth. Initial press wheel down force spring setting is 2½" (6 cm) between mounting arm tab and locking nut. -

Page 38: Brush-Type Seed Meter

Row Unit Operation Model 3000 M0188-01 BRUSH-TYPE SEED METER Upper Disc Color-Code Brush Seed Size Crop (Disc Part No.) Retainer Cells Range *Lubricant Graphite Soybean Black GD11122 2200 to 4000 seeds/lb. (GA5794) Talc (4,840 to 8,800 seeds/kg) Specialty Soybean Dark Blue... -

Page 39: Finger Pickup Seed Meter

Row Unit Operation M0188-01 Model 3000 Turn seed disc counterclockwise when installing on meter hub while tightening two wing nuts that retain disc. Seed disc should have slight resistance when rotated counterclockwise after wing nuts are tight. Brush-type seed meter attaches to seed hopper same as finger pickup seed meter. -

Page 40: Additives

Row Unit Operation Model 3000 M0188-01 ADDITIVES Lubricant Application Rate Graphite Mix one tablespoon of powdered graphite with seed each time hoppers are filled. Regular graphite use prolongs life of Conventional Hoppers 1 Tbs. (15 mL)/Hopper Fill the seed meter components, improves seed spacing, and may Talc reduce buildup of seed treatments. -

Page 41: Seed Hopper

Row Unit Operation M0188-01 Model 3000 SEED HOPPER Seed hopper has a capacity of 1.9 bushels. Use clean seed and make certain there are no foreign objects inside when filling seed hopper. Replace hopper lids after hoppers are filled to prevent accumulation of dust or dirt in seed meter which can cause premature wear. -

Page 42: Row Unit Chain Routing

Row Unit Operation Model 3000 M0188-01 ROW UNIT CHAIN ROUTING Row unit drive chains must be properly tensioned and aligned for proper operation and to minimize wear. Inspect and replace weak, worn or broken springs, idlers, and idler bushings. Pull row unit meter drive... -

Page 43: Quick Adjustable Down Force Springs Option

Row Unit Operation M0188-01 Model 3000 QUICK ADJUSTABLE DOWN FORCE SPRINGS OPTION Quick adjustable down force springs increase penetration in hard soil and keep row unit from bouncing in rough field conditions. Two springs per row, one on each side parallel arms, are used unless equipped with row unit mounted no till coulters. -

Page 44: Frame Mounted Coulter (Pull Row Only)

Row Unit Operation Model 3000 M0188-01 FRAME MOUNTED COULTER (PULL ROW ONLY) Frame mounted coulters with 1" bubbled, 1" fluted (8 flutes) or ¾" fluted (13 flutes) blades are used on pull row units only. Spring anchor bar Springs provide down pressure on coulter for maximum penetration while exerting less shock load on row unit. -

Page 45: Row Unit Mounted Disc Furrower (Pull Row Only)

Row Unit Operation M0188-01 Model 3000 ROW UNIT MOUNTED DISC FURROWER (PULL ROW ONLY) Disc furrowers are used to clear crop residue, dirt clods, and dry soil from in front of row units for a clean and smooth seed bed. The disc furrower may be equipped with 12" solid blades or 12" notched blades. Notched blades are for heavier residue conditions and cut crop residue and move it aside to prevent plugging or pushing. -

Page 46: Row Unit Mounted Residue Wheel

Row Unit Operation Model 3000 M0188-01 ROW UNIT MOUNTED RESIDUE WHEEL Row unit mounted residue wheel are used on pull and push row units. Style A Style B Two adjustable springs on each residue wheel parallel links provide down force adjustment. Position 1 provides minimum down pressure and position 3 maximum down pressure. - Page 47 Row Unit Operation M0188-01 Model 3000 SPIKED CLOSING WHEEL Spiked closing wheels crumble the sidewall, allowing roots to pentrate soil. They can be used on pull row units and push row units. Align spiked closing wheels straight across from each other, in most rearward holes on closing wheel arm.

-

Page 48: Row Unit Mounted No Till Coulter

Row Unit Operation Model 3000 M0188-01 ROW UNIT MOUNTED NO TILL COULTER Blade adjustment holes. Style A (Two sleeves for installing coulter Style B (One sleeve for installing coulter mounted residue wheels) mounted residue wheels) Row unit mounted no till coulters with 1" bubbled, 1" fluted (8 flutes) or ¾" fluted (13 flutes) blades may be used on pull row units and push row units (¾"... -

Page 49: Granular Chemical Hopper And Drive

Row Unit Operation M0188-01 Model 3000 GRANULAR CHEMICAL HOPPER AND DRIVE Agricultural chemicals can cause death WARNING or serious injury to persons, animals, and plants or seriously damage soil, equipment, or property. Read and follow all chemical and equipment manufacturers labels and instructions. -

Page 50: Granular Chemical Banding Options

Row Unit Operation Model 3000 M0188-01 GRANULAR CHEMICAL BANDING OPTIONS Granular chemical banding options allow 4½" slope-compensating banding, straight drop in-furrow placement or 14" rear banding. NOTE: Granular chemical rear bander is not compatible with covering discs/single press wheel option. -

Page 51: Interplant Push Row Unit Lockups

Row Unit Operation M0188-01 Model 3000 INTERPLANT PUSH ROW UNIT LOCKUPS Push row unit lockups are designed to allow the push row units to be locked in the raised position. Improper lifting of row units can cause CAUTION serious injury. An empty row unit requires minimum 84 lb (38.1 kg) lift. - Page 52 Row Unit Operation Model 3000 M0188-01 To lock in raised position: 3. Using the lift lever, raise the push row unit to allow the spring loaded lockups to snap out of locked 1. Set row unit down pressure springs to minimum position.

-

Page 53: Interplant Push Row Unit Clutch Sprocket

Row Unit Operation M0188-01 Model 3000 INTERPLANT PUSH ROW UNIT CLUTCH SPROCKET Push row unit clutch sprocket disengages interplant drive from push row unit drill shaft when only pull row units are used. DISENGAGE Rotate knurled collar ¼ turn. Rock drill shaft slightly using a ⅞"... - Page 54 This page left blank intentionally.

-

Page 55: Fertilizer

Fertilizer M0188-01 Model 3000 DOUBLE DISC FERTILIZER OPENER Pin storage position Pin lockup position Maintain 1∕32" - 1∕16" (.8 - 1.58 mm) gap at closest point. Double disc fertilizer opener Position double disc fertilizer openers to place fertilizer no closer than 2" (5 cm) to either side of row. Fertilizer depth is approximately 4"... -

Page 56: Notched Single Disc Openers (Style A & B)

Fertilizer Model 3000 M0188-01 NOTCHED SINGLE DISC OPENERS (STYLE A & B) Middle screw sets blade Opener mount angle. Tighten first! Disc blade ½" hex head cap screws Jam nuts 5∕16" hex head cap screws R.H. Opener Shown ⅜" lock nuts... - Page 57 Fertilizer M0188-01 Model 3000 1. Adjust knife to disc blade contact. Loosen or tighten ⅜" lock nuts to adjust knife’s entire leading edge against disc blade. Turn blade and check for slight resistance without freewheeling. Readjust knife to blade’s tight spot as needed.

-

Page 58: Residue Wheel Attachment For Notched Single Disc Fertilizer Opener

Fertilizer Model 3000 M0188-01 RESIDUE WHEEL ATTACHMENT FOR NOTCHED SINGLE DISC FERTILIZER OPENER Notched single disc opener residue wheel attachment Residue wheel attachment for notched single disc fertilizer opener is used where row unit mounted residue wheel attachments cannot be installed. Residue wheel is attached to notched single disc fertilizer opener with ⅝" x 7½" and ½"... -

Page 59: Hd Single Disc Fertilizer Opener

Fertilizer M0188-01 Model 3000 HD SINGLE DISC FERTILIZER OPENER Spring preset nut Inside blade depth Spring adjustment nut. Preset Outside blade depth adjustment nut. Block R.H. configuration shown (Overhead view) HD single disc opener Recommended placement of fertilizer with HD single disc fertilizer opener is 3½" - 4" (8.8 - 10.1 cm) from row. - Page 60 Fertilizer Model 3000 M0188-01 Adjust liquid drop tube/scraper so there is slight contact between blade and scraper lower leading edge, and ¼" (6.35 mm) clearance between liquid drop tube trailing edge and blade. Blade should turn with minimum amount of drag.

-

Page 61: Dry Fertilizer Attachment

Fertilizer M0188-01 Model 3000 DRY FERTILIZER ATTACHMENT Agricultural chemicals can cause death WARNING or serious injury to persons, animals, and plants or seriously damage soil, equipment, or property. Read and follow all chemical and equipment manufacturers labels and instructions. Dry fertilizer option installed... -

Page 62: Granular Chemical Application Field Check

Fertilizer Model 3000 M0188-01 GRANULAR CHEMICAL APPLICATION FIELD CHECK Temperature, humidity, speed, ground conditions, flowability of different material, or meter obstructions can affect granular chemical rate of delivery. Agricultural chemicals can cause death WARNING or serious injury to persons, animals, and plants or seriously damage soil, equipment, or property. - Page 63 Fertilizer M0188-01 Model 3000 CLEANING Disconnect drive shaft and hoses Rotate lid to back and rotate hopper forward Dry fertilizer hoppers tip forward for dumping and ease of cleaning. Disconnect drive shaft from transmission and/or adjacent hopper. LOOSEN HOSE CLAMPS AND REMOVE HOSES FROM EACH HOPPER. Remove rear ½" x 1¼"...

-

Page 64: Liquid Fertilizer Attachment

Fertilizer Model 3000 M0188-01 LIQUID FERTILIZER ATTACHMENT Agricultural chemicals can cause death WARNING or serious injury to persons, animals, and plants or seriously damage soil, equipment, or property. Read and follow all chemical and equipment manufacturers labels and instructions. Overfilling tank can cause siphoning,... - Page 65 Fertilizer M0188-01 Model 3000 Placing fertilizer too close to seeds NOTICE or in excessive amounts can cause germination or seedling damage. Check with your fertilizer dealer or manufacturer for correct amount and placement. OPTIONAL SQUEEZE PUMP Squeeze pump rate of liquid fertilizer application is determined by combination of sprockets on squeeze pump drive and driven shafts.

- Page 66 Fertilizer Model 3000 M0188-01 Avoid excessive pressure using quick fill NOTICE attachment or rubber plugs installed in manifold may be forced out. If either end pump hoses run off back plate, loosen hose clamps on intake manifold and rotate hose as follows: 1.

-

Page 67: Rate Charts

Rate Charts M0188-01 Model 3000 GENERAL PLANTING RATE INFORMATION These planting rate charts apply to Kinze Model 3000 Rigid Frame Planters. Sprocket combinations in these charts are NOTICE for average conditions. Changes in sprocket combinations may be required for desired planting population. - Page 68 Rate Charts Model 3000 M0188-01 PLANTING RATES FOR FINGER PICKUP SEED METERS (STANDARD DRIVE) APPROXIMATE SEEDS/ACRE FOR VARIOUS ROW WIDTHS Transmission Sprockets Recomm. Speed Average Seed 30" Rows 36" Rows 38" Rows Drive Driven Range (MPH) Spacing In Inches 16,186...

- Page 69 Rate Charts M0188-01 Model 3000 PLANTING RATES FOR BRUSH-TYPE SEED METERS (STANDARD DRIVE) APPROXIMATE SEEDS/ACRE FOR VARIOUS ROW WIDTHS Transmission 60 Cell Average 48 Cell Average Speed Sprockets Soybean Or High-Rate Milo/ Seed Specialty Soybean Or High- Seed Range Grain Sorghum...

- Page 70 Rate Charts Model 3000 M0188-01 PLANTING RATES FOR BRUSH-TYPE SEED METER (STANDARD DRIVE) APPROXIMATE SEEDS/ACRE FOR 15"/18"/19" ROW WIDTHS Transmission 60 Cell Average 48 Cell Average Speed Sprockets Soybean Or High-Rate Milo/ Seed Specialty Soybean Or High- Seed Range Grain Sorghum...

- Page 71 Rate Charts M0188-01 Model 3000 PLANTING RATES FOR BRUSH-TYPE SEED METERS (STANDARD DRIVE) APPROXIMATE SEEDS/ACRE FOR VARIOUS ROW WIDTHS Transmission 36 Cell Average 30 Cell Average Speed Sprockets Seed Seed Range Acid-Delinted Large Cotton Milo / Grain Sorghum or Spacing...

- Page 72 Rate Charts Model 3000 M0188-01 PLANTING RATES FOR BRUSH-TYPE SEED METERS (STANDARD DRIVE) APPROXIMATE HILLS/ACRE FOR VARIOUS ROW WIDTHS Due to variations in cotton seed size, meters equipped with 12 cell acid-delinted hill-drop cotton discs plant from 3 to 6 seeds per cell.

- Page 73 Rate Charts M0188-01 Model 3000 DRY INSECTICIDE APPLICATION RATES APPROXIMATE POUNDS/ACRE AT 5 MPH FOR VARIOUS ROW WIDTHS Meter Setting 30" Rows 36" Rows 38" Rows CLAY GRANULES 10.7 11.4 13.1 10.9 10.3 14.2 11.8 11.2 15.5 12.9 12.3 16.4 13.7...

- Page 74 Rate Charts Model 3000 M0188-01 DRY HERBICIDE APPLICATION RATES APPROXIMATE POUNDS/ACRE AT 5 MPH FOR VARIOUS ROW WIDTHS CLAY GRANULES Meter Setting 30" Rows 36" Rows 38" Rows 10.7 11.6 12.6 10.5 10.0 13.6 11.3 10.7 14.6 12.1 11.5 15.7 13.1...

- Page 75 Rate Charts M0188-01 Model 3000 DRY FERTILIZER APPLICATION RATES APPROXIMATE RATE IN POUNDS PER ACRE Drive Driven Low Rate Position High Rate Position Sprocket Sprocket 30" Rows 36" Rows 38" Rows 30" Rows 36" Rows 38" Rows High rate setting Low rate setting NOTE: Uneven delivery may result from attempting to use lower rates than indicated by chart.

- Page 76 Rate Charts Model 3000 M0188-01 LIQUID FERTILIZER SQUEEZE PUMP APPLICATION RATES GALLONS PER ACRE Drive Driven 30" Rows 36" Rows 38" Rows Drive Driven 30" Rows 36" Rows 32" Rows 21.2 17.7 16.7 22.5 18.8 17.8 26.9 22.4 21.2 11.8 30.3...

- Page 77 Rate Charts M0188-01 Model 3000 LIQUID FERTILIZER PISTON PUMP APPLICATION RATES GALLONS PER ACRE Applies to Model LM-2455-R And NGP-6055 Pump With 18 Tooth Sprocket Pump Setting 4 Row 30" 16.5 24.8 32.6 41.3 49.5 57.8 66.0 74.3 83.5 4 Row 36"...

- Page 78 This page left blank intentionally.

-

Page 79: Kpm I Electronic Seed Monitor

Applicable) remaining active rows from that section. NOTE: All 3000 Series primary harnesses STEP 1 Press SELECT key once to show one are hard-wired into the safety/warning light section. The flashing icon shows the harness or control console harness included as section not selected. - Page 80 KPM I Monitor Operation Model 3000 M0188-01 WARNINGS AND ALARMS EXAMPLE: System is setup to display rear/front sections. Press SELECT key. FRONT icon flashes 1. System Alarms - A system alarm is activated and REAR section displays on the bar graph. After when the monitor detects a faulty sensor or one 1 minute FRONT icon stops flashing.

- Page 81 KPM I Monitor Operation M0188-01 Model 3000 NOTE: This warning will not trigger unless a 7. Seed Counting Sensor Too Dirty Warning - minimum time of continuous planting has passed. After seed counting sensors end their internal self-calibration, the monitor may detect one or NOTE: If all rows show a seed rate of zero, the more sensors are either too dirty or blocked.

- Page 82 KPM I Monitor Operation Model 3000 M0188-01 FIELD OPERATION PROGRAMMING/CONNECTING SEED TUBES (MTR28e/MTR28c/MTR28d/MTR28b) STEP 1 All seed tubes w/sensors must disconnected from the harness and monitor Press ON/OFF key to turn monitor on must be off. and off. STEP 2 Press ON key. The monitor automatically Information regarding each section is enters the setup procedure.

- Page 83 KPM I Monitor Operation M0188-01 Model 3000 STEP 4 Press and hold the OK key to confirm STEP 5 Plug each seed tube w/sensor into the selection and continue holding until row harness in a predetermined order. Row numbers display. During confirmation, the 1 first, row 2 second and so on up to 18 display alternates between “NEW”...

- Page 84 KPM I Monitor Operation Model 3000 M0188-01 STEP 7 If this condition is satisfied, press and hold STEP 8 Follow STEPS 5 through 7 to install the the OK key to save the setup for the current second section. If no seed tubes are section.

-

Page 85: Kpm Ii Stack-Mode Electronic Seed Monitor

KPM II Monitor Operation M0188-01 Model 3000 KPM II STACK-MODE ELECTRONIC The software design of the KPM II Stack-Mode console allows use of an add-on SMM console for SEED MONITOR simultaneous viewing of seed flow bar graphs for (MTR41e) standard and/or Interplant System rows (up to 36 ®... - Page 86 KPM II Monitor Operation Model 3000 M0188-01 MONITOR KEY FUNCTIONS SEED POPULATION/SEED SPACING • Immediately displays average seed Push keys allow the user to select or change the POPULATION and the average seed SPACING of operating mode, the active displays or the current all active rows.

- Page 87 KPM II Monitor Operation M0188-01 Model 3000 STEP 1 Press SELECT key once to show one UPPER LCD FUNCTIONS section. The flashing icon shows the section that is not selected. The selected section (MTR29h) icon is continuously displayed on the LCD.

- Page 88 KPM II Monitor Operation Model 3000 M0188-01 ROW SPACING LOWER LCD FUNCTIONS Press the arrow keys to ROW SPACING to display the current spacing between rows in inches or (MTR29g) centimeters. The ROW SPACING icons turn on, displaying a 3 digit, one decimal place format. In the...

- Page 89 KPM II Monitor Operation M0188-01 Model 3000 SEED POPULATION/SEED SPACING FIELD AREA/TOTAL AREA Each AREA FIELD/TOTAL key press alternates Each SEED POP/SPACING key press alternates between field area and total area. between seed population and seed spacing. Field area displays total number of acres or hectares Seed population displays the average number of using a 6 digit, one decimal place format.

-

Page 90: Programming - Changing Audible Alarm Volume

KPM II Monitor Operation Model 3000 M0188-01 PROGRAMMING - CHANGING AUDIBLE STEP 4 To exit without saving, press and release ALARM VOLUME the OK key. The monitor restores the lower LCD to show the item setting and the arrow STEP 1 To enter programming mode, press and icon flashes, allowing the user to select hold the SETUP key. -

Page 91: Programming - Row Spacing

KPM II Monitor Operation M0188-01 Model 3000 PROGRAMMING - UNITS (METRIC OR ENGLISH) PROGRAMMING - ROW SPACING STEP 1 Press and hold SETUP key to enter STEP 1 Application mode (rear/front, left/right programming mode. The monitor emits or four sections) must be active before several short beeps, followed by a long entering programming mode. - Page 92 KPM II Monitor Operation Model 3000 M0188-01 NOTE: The monitor limits entry of row spacing from 10.0 inches (25.4 cm) to 99.9 inches (253.7 cm). If the monitor is configured to a rear/front configuration, the limits change to a minimum of 5.0 inches (12.7 cm) and a maximum of 49.9...

- Page 93 KPM II Monitor Operation M0188-01 Model 3000 • In field conditions, measure 330 feet ( PROGRAMMING - SPEED mile) or 100 meters, depending on the unit of measurement selected. STEP 1 Press and hold SETUP key to enter programming mode. Monitor emits several •...

- Page 94 KPM II Monitor Operation Model 3000 M0188-01 NOTE: If a discrepancy occurs and digits must be changed, follow STEPS 1 and 2 to enter the programming mode and proceed as follows: •Press the OK key and the flashing arrow becomes solid. The least significant digit of the displayed value will be blinking.

- Page 95 KPM II Monitor Operation M0188-01 Model 3000 AREA COUNTER/SPEEDOMETER MODE The four possible data communication bus errors are: If the monitor is installed with only a radar distance sensor (no seed tubes attached), the monitor becomes LCD Display Error Condition a speedometer.

-

Page 96: Replacing A Faulty Sensor

KPM II Monitor Operation Model 3000 M0188-01 4. Section Not Selected Warning - If the monitor REPLACING A FAULTY SENSOR was programmed for two sections and only one is currently selected for display (by pressing the NOTE: Stack-Mode Seed Sensors are identified by SELECT key), the icon of the disabled section a blue 3-pin connector. - Page 97 KPM II Monitor Operation M0188-01 Model 3000 Lower LCD shows speed (MPH or KM/H) at power FIELD OPERATION Press ON/OFF key to turn monitor on. (MTR29g/MTR29b/MTR29a/MTR29c/MTR29f/MTR29c/MTR29f) Information regarding each section is displayed alternately every 5 seconds. (MTR28e) REAR/FRONT CONFIGURATION (Without SMM Console Installed) •...

- Page 98 KPM II Monitor Operation Model 3000 M0188-01 CLEARING FIELD AREA (MTR29n/MTR28b) To reset the counter, press the UP or DOWN arrow keys to move the arrow in the lower display to FIELD AREA. Press UP and DOWN arrow keys at the same time and hold them down for a short period of time to clear data.

- Page 99 KPM II Monitor Operation M0188-01 Model 3000 STEP 3 The monitor automatically defaults to rear/ PROGRAMMING/CONNECTING SMM CONSOLE, front. Press SELECT key once for left/right SHAFT ROTATION SENSORS, SEED TUBES AND/ and twice for four sections (front right/front OR RADAR/MAGNETIC DISTANCE SENSORS left/rear right/rear left).

- Page 100 NOTE: SMM console may not be applicable to all models. SEED AREA SPEED SELECT SCAN POP. FIELD CLEAR SETUP NOTE: Model 3000 planters select the rear ENTER configuration only. EXIT NOTE: SMM console may not be applicable to all models. 6-22 Rev. 6/11...

- Page 101 KPM II Monitor Operation M0188-01 Model 3000 NOTE: Illustrated using rear/front configuration. STEP 5 (If Applicable) Connect SMM console into The KPM II Stack-Mode console shows LEFT in junction Y-harness which was installed the left/right configuration, REAR in the rear/front...

- Page 102 KPM II Monitor Operation Model 3000 M0188-01 NOTE: Illustrated using rear/front configuration. STEP 6 If the monitor system includes shaft rotation The KPM II Stack-Mode console shows LEFT in sensors, these should be installed at this the left/right configuration, REAR in the rear/front time.

- Page 103 KPM II Monitor Operation M0188-01 Model 3000 STEP 6 (Continued) STEP 7 Determine which row you want as number one and plug seed tube w/sensor into 12060211 harness. ® Continue plugging in sensors along with shaft rotation sensors if so equipped. Row 1 first, row 2 second and so on up to 18 rows.

- Page 104 KPM II Monitor Operation Model 3000 M0188-01 STEP 7 (Continued) NOTE: Illustrated using rear/front configuration. The KPM II Stack-Mode console shows LEFT in the left/right configuration, REAR in the rear/front configuration and REAR LEFT/FRONT LEFT in the four sections configuration.

- Page 105 KPM II Monitor Operation M0188-01 Model 3000 NOTE: Illustrated using rear/front configuration. STEP 8 When all seed tubes for the current section The KPM II Stack-Mode console shows LEFT in (rear/front, left/right or four section) are the left/right configuration, REAR in the rear/front...

- Page 106 KPM II Monitor Operation Model 3000 M0188-01 STEP 8 (Continued) 12060211 ® • KPM II ® SETUP FRONT REAR SCAN SEED POPULATION SPACING UNITS SEED SPACING SPEED FIELD REAR AREA VOLUME SETUP TOTAL AREA AREA SEED POP. FIELD SELECT SPEED...

- Page 107 KPM II Monitor Operation M0188-01 Model 3000 NOTE: Illustrated using rear/front configuration. STEP 9 Follow STEPS 6, 7 and 8 to install the The KPM II Stack-Mode console shows LEFT in second, third and fourth sections (If the left/right configuration, REAR in the rear/front Applicable).

- Page 108 KPM II Monitor Operation Model 3000 M0188-01 STEP 9 (Continued) 12060214 12060213 ® ® • • KPM II KPM II ® ® Row Installed Rows Installed FLASHING FLASHING 13 14 15 16 17 18) (1213 14 15 16 17 18)

- Page 109 KPM II Monitor Operation M0188-01 Model 3000 STEP 9 (Continued) STEP 10 With the lower display showing “GNDSPD”, connect the distance sensor. The monitor 12060215 will display “PICKUP” if a magnetic distance sensor is connected or “RADAR” ® if a radar distance sensor is installed. Only one distance sensor can be connected at a time.

- Page 110 KPM II Monitor Operation Model 3000 M0188-01 NOTE: Illustrated using rear/front configuration. NOTE: To reprogram the system to monitor more The KPM II Stack-Mode console shows LEFT in or less rows (up to the maximum of 18 per section, the left/right configuration, REAR in the rear/front...

-

Page 111: Row-By-Row Alarm Level Setting

KPM II Monitor Operation M0188-01 Model 3000 NOTE: Illustrated using rear/front configuration. ROW-BY-ROW ALARM LEVEL SETTING The KPM II Stack-Mode console shows LEFT in (Requires Version V2.05 Or Higher Software - the left/right configuration, REAR in the rear/front KPM II Stack-Mode Monitors Only) configuration and FRONT LEFT/REAR LEFT in the four sections configuration. - Page 112 KPM II Monitor Operation Model 3000 M0188-01 STEP 3 Press the OK key. Row number starts flashing. STEP 4 Arrow UP or DOWN to desired row. STEP 5 Press SELECT key. “AVG” starts flashing. STEP 6 Arrow UP or DOWN to choose one of the following options.

-

Page 113: Kpm Iii Electronic Seed Monitor Ver. 3.01

KPM III Monitor Operation M0188-01 Model 3000 KPM III ELECTRONIC SEED MONITOR VER. 3.01 INTRODUCTION KINZE The KPM III electronic seed monitor system consists of: • A tractor mounted KPM III console powered by tractor 12 VDC battery receives and displays information from planter mounted sensors. - Page 114 KPM III Monitor Operation Model 3000 M0188-01 ROTARY ENCODER KNOB MONITOR KEY FUNCTIONS • Turn knob clockwise to increase or counterclockwise to decrease value of Push keys select or change operating mode, active displays, item. or the current configuration. Depending on operating mode •...

- Page 115 STEP 5 Use arrow keys or turn knob to adjust backlighting. Status Kinze Planter Monitor III The effect of the adjustment will be visible on display. Status Plant Lifetime Area: 0.00 RowPop 1.

- Page 116 NOTE: Press F2 key next to Plant any time Plant option is one digit select one digit at a time. When desired available to return to Planter Configuration screen. quantity is displayed above number pad, press Enter key to return to “Kinze Planter Configuration” screen. Status Setup Mode...

- Page 117 KPM III Monitor Operation M0188-01 Model 3000 STEP 8 If applicable, turn knob or use arrow keys to advance GENERAL SETTINGS to “Vacuum”. Press knob or Enter key and a drop (PROGRAMMING INTERPLANT CONDITION, ROW SPACING down menu will appear. Select correct number of...

- Page 118 KPM III Monitor Operation Model 3000 M0188-01 SEED METER SETTINGS STEP 3 Turn knob or use arrow keys to highlight “Crop Type”. Press knob or Enter key to display crop drop down STEP 1 Scroll to ‘‘2. Seed Meter Settings” by turning rotary menu.

- Page 119 KPM III Monitor Operation M0188-01 Model 3000 STEP 9 (If Applicable) Turn knob or use arrow keys to STEP 1 Select ‘‘3. Row Unit Alarm Levels’’ by turning knob or highlight “Interplant”. Press knob or Enter key to using arrow keys. Press knob or Enter key to display display Interplant drop down menu.

- Page 120 KPM III Monitor Operation Model 3000 M0188-01 STEP 3 Use the knob or arrow keys to highlight the “File DATA LOGGING MODE Name” box. Press the knob or Enter key and a drop down list of the files will be displayed. Select “Add STEP 1 Scroll to ‘‘4.

- Page 121 “Front Rows” line. When correct number is displayed on “Front Rows” line, press Enter key to return to “Kinze Planter Configuration” screen. NOTE: To prevent configuration from being changed select Cancel, then press knob, Enter key or ESC key.

- Page 122 KPM III Monitor Operation Model 3000 M0188-01 Kinze Planter Configuration Status Setup Mode Sensors Installed Planter Type Front Rows Speed Coil Pick-Up Plant Configuration: Front / Rear Rear Rows Vacuum 1. General Settings 2. Seed Meter Settings Logdata Shafts 3. Row Unit Alarm Levels 4.

- Page 123 KPM III Monitor Operation M0188-01 Model 3000 STEP 2 To confirm note below turn knob or use arrow keys REPROGRAMMING SPEED SENSOR to highlight “OK” button, then press knob or Enter key to confirm. If single Interplant row is not to be This setting must be specified when monitor is first configured.

- Page 124 KPM III Monitor Operation Model 3000 M0188-01 STEP 6 Plug in Magnetic Distance Sensor (MDS) and press STEP 2 Press F6 key next to Done. Display will return to F1 key next to Install. Press knob or Enter key to Setup Mode screen.

- Page 125 KPM III Monitor Operation M0188-01 Model 3000 Connect shaft rotation sensors or speed sensors PROGRAMMING/CONNECTING SEED TUBES, SHAFT the same way seed sensors were connected, ROTATION SENSORS, AND/OR RADAR/MAGNETIC making sure to work from left to right across planter. DISTANCE SENSORS...

- Page 126 KPM III Monitor Operation Model 3000 M0188-01 • In field conditions, measure 330 feet or 100 meters, SPEED SENSOR CALIBRATION/PROGRAMMING depending on the unit of measurement selected. Place a marker at the start point and end point. STEP 1 Turn knob or use arrow keys to highlight ‘’10. Calibrate Speed Sensor”...

- Page 127 KPM III Monitor Operation M0188-01 Model 3000 When correct distance pulse count is known, calibration is not Monitor will display current pulses per mile/kilometer using a 6 needed and the following steps may be used. digit, no decimal place format labeled “Distance Pulse Count”.

- Page 128 ‘‘2. Acre Count Mode’’. Press knob or Enter key. STEP 7 Turn knob or use arrow keys to highlight “OK” button. Press knob or Enter key to save changes. Status Kinze Planter Monitor III NOTE: Implement width entered in acre count mode has no Plant Lifetime Area: 0.00 effect on planting mode settings.

- Page 129 Select ‘‘5. Test Mode’’ by turning rotary encoder F2 key next to “Plant”. knob or using arrow keys. Press knob or Enter key to display highlighted item. STEP 2 Press F6 key until “Kinze Planter Monitor III” screen appears. Status Kinze Planter Monitor III STEP 3 Turn rotary encoder knob or use arrow keys to highlight ‘‘3.

- Page 130 KPM III Monitor Operation Model 3000 M0188-01 STEP 5 TEST MODE screen displays test run data (seed • Press F3 key next to Scan. Monitor scans through each row in count) for each row. ascending order displaying average seed population for each row.

- Page 131 KPM III Monitor Operation M0188-01 Model 3000 ROW SPACING ACCURACY • Press F2 key next to Spacing to display seed spacing keys. “Average Spacing” will appear in bottom L.H. corner of display. NOTE: Soybeans will not show Skips/Multiples. • Press F3 key next to Accuracy to display drop down menu. Select RowPop either “Skips/Multiples”...

- Page 132 KPM III Monitor Operation Model 3000 M0188-01 SPEED/SHAFT ROTATION RowPop Spacing Accuracy 9 10 11 12 Area Other 9 10 11 12 8.03 Average Spacing RowPop Spacing Spacing Choose Item to Display Shaft RPM Ground Speed Area Battery Vacuum Seed Delivery Shaft RPM...

- Page 133 KPM III Monitor Operation M0188-01 Model 3000 Row can be removed by pressing F2 key next to WARNINGS AND ALARMS Remove. A box appears asking for confirmation to remove row. “OK” box is highlighted in box. STEP 1 Seed Rate Alarm - A seed rate alarm is activated whenever row average seed population drops below threshold set for that row.

- Page 134 KPM III Monitor Operation Model 3000 M0188-01 STEP 3 Counting Sensors Not Communicatining With NOTE: If a sensor has been ignored, sensor configuration screen displays as shown below. Monitor - If monitor detects a communication error between sensor and monitor, monitor beeps twice.

- Page 135 KPM III Monitor Operation M0188-01 Model 3000 STEP 6 Add Interplant Row Error – Planter monitor FIELD OPERATION configuration must contain an odd number of front rows before single Interplant row unit can be added. Press ON/OFF key to turn monitor ON.

- Page 136 KPM III Monitor Operation Model 3000 M0188-01 Enable Area Counter AREA MANAGEMENT • Highlight desired ‘‘Area Counter’’ by turning rotary encoder knob There are 42 area counters: Total Area, Field Area and Area or using arrow keys. Counters 1 through 40. Total Area is always active but may be cleared.

- Page 137 KPM III Monitor Operation M0188-01 Model 3000 NOTE: If “Total area” is highlighted and F3 key next to Clear AREA COUNTERS is pressed the following request for confirmation displays. STEP 1 On Planter Configuration screen press F4 key next Status...

- Page 138 KPM III Monitor Operation Model 3000 M0188-01 CLEARING FIELD AREA STEP 4 Turn knob or use arrow keys to highlight faulty sensor and press F2 key next to Remove. STEP 1 Display Plant screen to reset counter. Install Setup Mode...

-

Page 139: Lubrication And Maintenance

Model 3000 LUBRICATION Following pages show locations of all lubrication points. Proper lubrication of moving parts helps ensure efficient operation of your Kinze planter and prolongs the life of friction producing parts. Uncontrolled machine can crush or WARNING cause loss of control resulting in death, serious injury, or damage to property and equipment. -

Page 140: Drive Chains

Lubrication and Maintenance Model 3000 M0188-01 DRIVE CHAINS Lubricate all transmission and drive chains daily with a high quality chain lubricant. Extreme operating conditions such as dirt, temperature, or speed may require more frequent lubrication. If a chain becomes stiff, it should be removed, soaked, and washed in solvent to loosen and remove dirt from joints. - Page 141 Lubrication and Maintenance M0188-01 Model 3000 DRIVE CHAINS (CONTINUED) Liquid Fertilizer Drive Chain Contact Wheel Drive Chains (Squeeze Pump Shown) Seed Rate Transmission Assembly and Reverser Interplant Drive Chain (Double Frame) Plate Chains Dry Fertilizer Drive Chain Interplant Drive Chain (Single Frame)

-

Page 142: Bushings

Lubrication and Maintenance Model 3000 M0188-01 BUSHINGS Lubricate bushings at frequency indicated. Check each bolt for proper torque. If bolt is loose, removed it and inspect bushing for cracks and wear. Replace bushing if necessary. Use only hardened flat washers. Replace damaged flat washers with proper part. Torque hardware to 130 ft-lb (176.2 N-m). -

Page 143: Interplant Push Row Unit Lockups

Lubrication and Maintenance M0188-01 Model 3000 INTERPLANT PUSH ROW UNIT LOCKUPS 2 Per Row LIQUID FERTILIZER PISTON PUMP Plug CRANKCASE OIL LEVEL Check crankcase oil daily and maintain at plug level. Fill as Plug needed with EP 90 weight gear oil. Total oil capacity is approximately ¾... -

Page 144: Grease Fittings

NOTE: Numbers on illustration below correspond to photos on following pages showing lubrication frequencies. Model 3000 6 Row 30" (70 cm) Planter Shown 2. Low Profile Row Marker Assembly - 2 Per 1. Conventional Row Marker Assembly - 4 Per... - Page 145 Lubrication and Maintenance M0188-01 Model 3000 Row Unit 3. Seed Rate Transmission Assembly - 1 (Idler) Gauge Wheel Arms - 1 Per Arm (Seals installed with lip facing out to allow grease to purge dirt from seal. Pump grease into arm until fresh grease appears between washers and arm.)

- Page 146 Lubrication and Maintenance Model 3000 M0188-01 Fertilizer Openers Notched Single Disc Fertilizer Opener - 1 HD Single Disc Fertilizer Opener - 2 (Located On Wheel Arm And Opener Mount) Residue Wheel Attachment For Use With Notched Single Disc Fertilizer Opener - 1...

- Page 147 Lubrication and Maintenance M0188-01 Model 3000 Dry Fertilizer Attachment Squeeze Pump/Piston Pump Drive Chain Idler - 1 Per Idler (Squeeze Pump Shown) Dry Fertilizer Hopper - 2 Per Hopper Dry Fertilizer Transmission - 1 Per Transmission Liquid Fertilizer Piston Pump - 2 (Fill on outboard stuffing box until lubricant seeps out of drain hole in bottom.)

-

Page 148: Mounting Bolts And Hardware

All hardware used on the Kinze planter is Grade 5 (high strength) unless otherwise noted. Grade 5 cap screws are marked with three radial lines on the head. Hardware must be replaced with equal size, strength, and thread type. - Page 149 Lubrication and Maintenance M0188-01 Model 3000 TORQUE VALUES CHART - PLATED HARDWARE Grade 2 (No marks) Grade 5 (3 marks) Grade 8 (6 marks) Diameter Coarse Fine Coarse Fine Coarse Fine 50 in-lb 56 in-lb 76 in-lb 87 in-lb 9 ft-lb (12 N-m) 10 ft-lb (14 N-m) ¼"...

-

Page 150: Tire Pressure

Do not weld or heat wheel assembly. Heating increases tire pressure. Contact drive MODEL 3000 OPERATING TIRE PRESSURE Transport/ground drive - 7.50" x 20" ..Inflate to 40 psi (275.7 kPa) Contact drive - 4.10" x 6" ....Inflate to 50 psi (344.7 kPa) -

Page 151: Chain Tension Adjustment

Lubrication and Maintenance M0188-01 Model 3000 CHAIN TENSION ADJUSTMENT Drive chains equipped with a spring loaded idler are self-adjusting. The only adjustment is to shorten chain if wear stretches chain and reduces spring tension. Check idler pivot periodically to ensure they rotate freely. -

Page 152: Finger Pickup Seed Meter Inspection/Adjustment

Lubrication and Maintenance Model 3000 M0188-01 FINGER PICKUP SEED METER Brush INSPECTION/ADJUSTMENT Notch in bearing housing Remove meter from seed hopper by removing two thumbscrews which secure mechanism to hopper. Remove baffle from meter assembly by removing three cap screws. -

Page 153: Finger Pickup Seed Meter Cleaning

Lubrication and Maintenance M0188-01 Model 3000 Remove four cap screws around edge of housing cover and nut from belt idler mounting bolt. Rotation Belt housing cover Cap screw Idler Indentations mounting bolt Worn Carrier Plate If belt is replaced, make sure paddles are correctly oriented as shown. -

Page 154: Brush-Type Seed Meter Maintenance

Lubrication and Maintenance Model 3000 M0188-01 BRUSH-TYPE SEED METER MAINTENANCE Meter housing Stainless Steel Wear Band Upper brush Seed disc Upper brush Lower brush retainer Use clean, high quality seed. Damaged or cracked Seed, hulls, or foreign materials can become lodged in upper brush and greatly reduce meter accuracy. - Page 155 Lubrication and Maintenance M0188-01 Model 3000 Seed Disc Wear Seed loading slots Seed pocket Agitation groove area (Shaded area)- where most wear occurs Most seed disc wear is found in the agitation groove area (area between seed loading slots). Wear affects planting accuracy at high RPM.

- Page 156 Lubrication and Maintenance Model 3000 M0188-01 Stainless Steel Wear Band Stainless steel wear band Area where most wear Occurs on wear band If wear band wears through or if meter is NOTICE used without wear band in place, meter housing may be damaged.

-

Page 157: Drag Closing Attachment

Lubrication and Maintenance M0188-01 Model 3000 DRAG CLOSING ATTACHMENT Inspect each drag closing attachment and replace any worn or broken parts before storing planter. Check for loose hardware and tighten as needed. Drag Closing Attachment GAUGE WHEEL ADJUSTMENT Machine bushings... -

Page 158: Gauge Wheel Arm Bushing And/Or Seal Replacement

Bushings/Seals Gauge Wheel Pivot Spindle NOTE: Gauge Wheel Arm Bushing and Seal Driver Kit (G1K296) is available through your Kinze 1. Remove gauge wheel and arm assemblies from Dealer. shank assembly. 2. Remove ½" x ¾" cap screw that locks pivot 1. -

Page 159: 15" Seed Opener Disc Blade/Bearing Assembly

Lubrication and Maintenance M0188-01 Model 3000 15" SEED OPENER DISC BLADE/ BEARING ASSEMBLY Approximately 1" ± ½" (3 ± .5 cm) of blade-to-blade contact should be maintained to properly open and form seed trench. As blade diameter decreases due to wear, it is necessary to relocate machine bushings from inside to outside to maintain 1"... -

Page 160: Seed Tube Guard/Inner Scraper

Lubrication and Maintenance Model 3000 M0188-01 REPLACE BEARING ONLY 1. Remove gauge wheel, scraper, bearing cap, cap screw, washer and disc blade/bearing assembly. 2. Remove ¼" rivets from bearing housing to expose bearing. 3. After installing new bearing, install three evenly spaced ¼" cap screws into three of six holes in bearing housing to hold bearing and bearing housing in place. -

Page 161: Frame Mounted Coulter

Lubrication and Maintenance M0188-01 Model 3000 FRAME MOUNTED COULTER NOTE: Torque ⅝" spindle hardware to 120 ft. lbs. (162.7 N-m) See “Frame Mounted Coulter” in Row Unit Operation section of this manual for depth and spring adjustment. Replace 16" diameter coulter blade (1" fluted, 1" bubbled or ¾"... -

Page 162: Row Unit Mounted Disc Furrower

Lubrication and Maintenance Model 3000 M0188-01 ROW UNIT MOUNTED DISC FURROWER Lubricate bushings in support arm mounting bracket at frequency indicated in Lubrication of this section. Check each bolt for proper torque. If bolt is loose, it should be removed and bushing inspected for cracks and wear. -

Page 163: Row Unit Mounted Bed Leveler

Lubrication and Maintenance M0188-01 Model 3000 ROW UNIT MOUNTED BED LEVELER Lubricate bushings in mounting bracket and links at frequency indicated in Lubrication of this section. Check each bolt for proper torque. If bolt is loose, it should be removed and bushing inspected for cracks and wear. Replace bushing if necessary. -

Page 164: Row Unit Mounted No Till Coulter

Lubrication and Maintenance Model 3000 M0188-01 ROW UNIT MOUNTED NO TILL COULTER STYLE A STYLE B (Two sleeves for coulter mounted residue wheels) (One sleeve for coulter mounted residue wheels) Check nuts and hardware periodically for proper torque. NOTE: Torque ⅝" spindle hardware to 120 ft-lb (162 N-m). -

Page 165: Granular Chemical Attachment

Lubrication and Maintenance M0188-01 Model 3000 SPIKED CLOSING WHEEL Inner parts of spiked closing wheel will begin to wear at approximately 70% of life. Flip/reverse wheel to utilize remaining life of wheel. Row Unit Spiked Closing Wheel GRANULAR CHEMICAL ATTACHMENT Before storing planter, disengage granular chemical drive by rotating throwout knob ¼... -

Page 166: Row Marker Sequencing/Flow Control Valve Inspection

Lubrication and Maintenance Model 3000 M0188-01 ROW MARKER SEQUENCING/FLOW CONTROL VALVE INSPECTION Pressurized hydraulic fluid can penetrate WARNING body tissue and result in death, serious infection, or other injuries. Fluid injected under skin must be IMMEDIATELY removed by a surgeon familiar with this type of injury. -

Page 167: Row Marker Bearing Lubrication Or Replacement

Lubrication and Maintenance M0188-01 Model 3000 ROW MARKER BEARING LUBRICATION OR REPLACEMENT Grease seal Outer cup Bearing Flat washer Spindle Slotted hex nut Dust cap Inner cup Marker blade Hub shield Bearing Cotter pin Retainer 1. Remove retainer and marker blade. -

Page 168: Wheel Bearing Repack Or Replacement

Lubrication and Maintenance Model 3000 M0188-01 WHEEL BEARING REPACK OR REPLACEMENT Jam nuts Bearing cup Inner bearing Outer bearing Spindle Bearing cup Raise tire clear of ground and remove wheel. Remove double jam nuts and slide hub from spindle. Remove bearings and cups and discard if bearings are being replaced. Clean hub and dry. Remove bearings only and not cups if repacking. -

Page 169: Piston Pump Storage

Lubrication and Maintenance M0188-01 Model 3000 Liquid fertilizer piston pump PISTON PUMP STORAGE Entrance of air into pump will cause NOTICE rapid and severe corrosion. KEEP AIR OUT OF PUMP! NOTE: SUSPENSION FERTILIZER must be flushed from pump for ANY storage period. -

Page 170: Electrical Wiring Diagram For Light Package

MONITOR +12V Black MONITOR GROUND Green MONITOR DATA 3-Pin Connector 3-Pin Connector Light package supplied on Model 3000 planter meets ASABE Standards. For correct wiring harness to be wired into lights on your tractor, check with tractor manufacturer. 7-32 Rev. 6/11... -

Page 171: Hydraulic Hose Life

Lubrication and Maintenance M0188-01 Model 3000 HYDRAULIC HOSE LIFE Pressurized hydraulic fluid can penetrate WARNING body tissue and result in death, serious infection, or other injuries. Fluid injected under skin must be IMMEDIATELY removed by a surgeon familiar with this type of injury. -

Page 172: Hydraulic System Schematic

Lubrication and Maintenance Model 3000 M0188-01 HYDRAULIC SYSTEM SCHEMATIC Slave Cylinder Master Cylinder Sequence Valve L.H. Marker Cylinder R.H. Marker Cylinder Red - Pressure Blue - Return Green - Master to Slave Pressure 4 Row - Planter Raising Assist Cylinder... -

Page 173: Hydraulic System Schematic (With Interplant Self-Leveling Hitch)

Lubrication and Maintenance M0188-01 Model 3000 HYDRAULIC SYSTEM SCHEMATIC (WITH INTERPLANT SELF-LEVELING HITCH) Slave Cylinder Master Cylinder L.H. Marker Cylinder R.H. Marker Cylinder Sequence Valve Red - Pressure Blue - Return Green - Master to Slave Pressure Interplant ® Lift Cylinder... - Page 174 This page left blank intentionally.

-

Page 175: Closing Wheel Troubleshooting

Troubleshooting M0188-01 Model 3000 CLOSING WHEEL TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Closing wheel(s) leave severe Too much closing wheel down Adjust closing wheel pressure. imprint in soil. pressure. Closing wheel(s) not firming soil Insufficient closing wheel Adjust closing wheel pressure. -

Page 176: Lift Circuit Operation Troubleshooting

Replace rephasing valve and adjust as stated above or replace piston. Install seal kit. Consult your Kinze Dealer for leak testing and rephasing valve adjustment if necessary. Slave cylinder leaking. Raise and lower planter. Check piston rephasing As planter lowers, side with valve for contamination. -

Page 177: Piston Pump Troubleshooting

Troubleshooting M0188-01 Model 3000 PISTON PUMP TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Pump hard or impossible to prime. Valves fouled or in wrong place. Inspect and clean valves. Air leak in suction line. Repair leak. Pump set too low. Adjust pump setting. -

Page 178: Row Marker Operation Troubleshooting

Troubleshooting Model 3000 M0188-01 ROW MARKER OPERATION TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Same marker always operating. Inadequate oil flow to sequencing TEST: Raise planter and install valve. Most commonly associated transport lockups. Attempt to raise Rod ends and lower planter. All hydraulic with single valve system (lift and oil will be directed to markers. -

Page 179: Seed Meter (Brush-Type) Troubleshooting

Troubleshooting M0188-01 Model 3000 SEED METER (BRUSH-TYPE) TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Low count. Meter RPM too high. Reduce planting speed. Seed sensor not picking up all Clean seed tube. seeds dropped. Switch meter to different row. If problem stays with same row, replace sensor. -

Page 180: Seed Meter (Finger Pickup) Troubleshooting

Troubleshooting Model 3000 M0188-01 SEED METER (FINGER PICKUP) TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION One row not planting seed. Drive release not engaged. Engage drive release mechanism. Foreign material in hopper. Clean hopper and finger carrier mechanism. Seed hopper empty. Fill seed hopper.

Need help?

Do you have a question about the 3000 and is the answer not in the manual?

Questions and answers

When adjusting discs to 2 inches or less there is about 1/4 inches gap by seed tub protecter

To adjust Kinze 3000 discs to achieve a 2-inch or less setting without a gap by the seed tube protector:

1. Check the disc blades for wear. A new disc measures 15 inches, while a worn-out disc is around 14.2 inches.

2. Lift the gauge wheel and inspect if the seed tube guard is visible. If the seed tube guard is clearly seen, the blades are near the wear limit.

3. Use a 5/8-inch wrench to check the seed tube guard clearance. If the wrench slides over it, the blades are worn out.

4. If needed, replace the disc blades to maintain proper contact and avoid gaps by the seed tube protector.

5. Ensure the discs are adjusted so that they maintain slight contact without excessive resistance.

This will ensure proper seed placement and avoid gaps in the seed trench.

This answer is automatically generated