Table of Contents

Advertisement

Quick Links

UniCel

EC

REP

Beckman Coulter Ireland, Inc.

Mervue Business Park,

Mervue Galway,

Ireland 353 91 774068

BECKMAN COULTER, INC. • 4300 N. Harbor Blvd., Fullerton, CA 92835 U.S.A.

®

DxC Synchron

Clinical Systems

Instructions For Use

For In Vitro Diagnostic Use Only

This manual is intended for

UniCel

UniCel

© Copyright 2005 Beckman Coulter, Inc.

®

DxC 600

®

DxC 800

A13914-AB

October 2005

®

®

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Beckman Coulter UniCel DxC Synchron 800

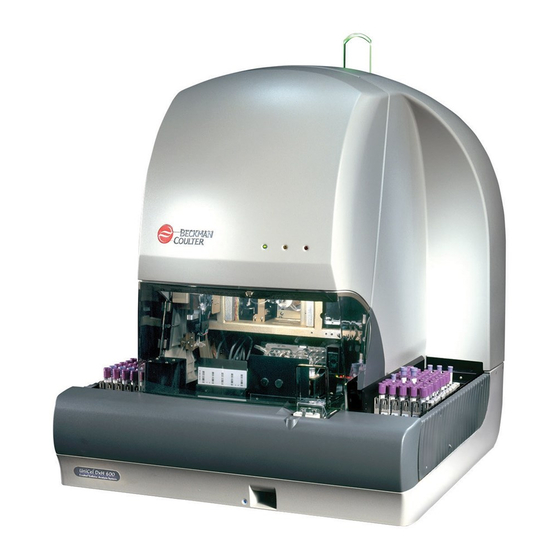

- Page 1 This manual is intended for ® UniCel DxC 600 ® UniCel DxC 800 Beckman Coulter Ireland, Inc. Mervue Business Park, Mervue Galway, Ireland 353 91 774068 © Copyright 2005 Beckman Coulter, Inc. BECKMAN COULTER, INC. • 4300 N. Harbor Blvd., Fullerton, CA 92835 U.S.A.

-

Page 3: Table Of Contents

Table of Contents CHAPTER 1 General Information..................1-1 General Information..................1-1 Manual Conventions ..................1-2 How to Use this Manual ................1-3 Summary of Hazards ..................1-4 Summary of Precautions ................1-7 Symbols and Labels ..................1-12 CHAPTER 2 System Description ................... 2-1 System Description .................. - Page 4 Sample Comments Setup ................4-25 Special Calculations Definition ..............4-26 Timed Urine and Creatinine Clearance Results........... 4-29 Setup Summary.................... 4-30 Units/Precision Setup................... 4-31 User Defined Chemistries Setup..............4-32 Bar Code Setup .................... 4-33 Maximum Sample Program Age ..............4-34 Reserved Racks/Obstruct Detect ..............4-35 Disable Service Monitor ................

- Page 5 Printing QC Ranges ..................6-14 QC File List ....................6-15 QC Summary ....................6-16 QC Chart (Levey-Jennings) ................. 6-17 QC Log ......................6-19 Archive QC ....................6-22 Restore and Review Archived Data............. 6-24 CHAPTER 7 Sample Programming ..................7-1 Overview......................7-1 Prior to Programming ..................

- Page 6 Three-Month Maintenance ................ 10-44 Four-Month Maintenance ................10-50 Six-Month Maintenance ................10-55 As-Needed/As-Required Maintenance ............10-68 CTS Wick Replacement Procedure ............10-121 CHAPTER 11 System Status and Commands ................ 11-1 Overview...................... 11-1 System Status ....................11-2 Status Summary ................... 11-2 Status-Cycle Count ..................

- Page 7 Result Errors and Codes ................13-18 Error Code – Definitions................13-21 Common Error Messages and Corrective Actions ........13-29 GLOSSARY INDEX UniCel DxC Systems Instructions For Use A13914 Table of Contents October 2005 Page 5 of 6...

- Page 8 Table of Contents UniCel DxC Systems Instructions For Use A13914 Page 6 of 6 October 2005...

-

Page 9: Chapter 1 General Information

General Information Intended Use CHAPTER 1 General Information General Information Intended Use ® ® The UniCel DxC Synchron Clinical Systems are fully automated, computer- controlled clinical chemistry analyzers designed for the in vitro determination of a variety of general chemistries, therapeutic drugs, and other chemistries. Analysis can be performed on serum, plasma, urine, or cerebrospinal fluid (CSF) and whole blood (sample type is chemistry dependent). -

Page 10: Manual Conventions

Manual Conventions Manual Conventions Manual Conventions Manual Conventions This Manual uses the following printed and visual cues to guide the user in responding to printed directions. Table 1.1 Conventions Used in this Manual Convention Description Icon buttons and Icon buttons and dialog box buttons are written in bold. Dialog box buttons Example: Select the Samples icon. -

Page 11: How To Use This Manual

How to Use this Manual Manual Format How to Use this Manual Manual Format Information in this manual is presented in modular units. Each unit of information is described by a brief title in the left margin. Many units consist of a table which presents a procedure, process, or description. Procedure Tables Procedure tables are the most common type of table in this manual. -

Page 12: Summary Of Hazards

Summary of Hazards Introduction Summary of Hazards Introduction This section summarizes the hazards associated with the DxC System. Individual hazards associated with a specific procedure in this manual are included in Warning or Caution boxes within the procedures for that task. Please read this section and the following Summary of Precautions before operating the system. - Page 13 10% bleach solution, or use your laboratory decontamination solution. Then follow your laboratory procedure for disposal of hazardous materials. If the UniCel DxC system needs to be decontaminated, call your Beckman Coulter Service Representative for assistance.

- Page 14 If the equipment is used in a manner not specified by Beckman Coulter, Inc., the protection provided by the equipment may be impaired.

-

Page 15: Summary Of Precautions

Beckman Coulter Microtube™ Precautions • Beckman Coulter Microtubes™ are designed for use on specific Synchron systems. Using the appropriate Microtube is essential for proper system operation. • The sample height in the Microtube is critical for correct sample aspiration on all Synchron systems. - Page 16 Summary of Precautions Biohazard Precautions • The use of non-Beckman Coulter, third party Microtubes, which have not been designed and tested on Synchron Systems may result in system damage and/or short sampling. Biohazard Precautions All biohazard precautions should be observed when doing maintenance, service, or troubleshooting on the system.

- Page 17 Summary of Precautions CTS Tracking Loss Precautions CTS Tracking Loss Precautions For systems with 1-Blade Thick CTS, if there is an unusual loss of network communication, then a message tells you that if you move a tube to a different instrument, remove its cap.

- Page 18 DI water. When running in the CTS mode, if tubes off-loaded from the UniCel DxC Systems have water or droplets of water on the caps, disable the CTS and call Beckman Coulter Technical Support. Note: Oil on a cap is normal.

- Page 19 System Configuration Change Precautions Changes to the System Configuration Data should only be done at the request or at the direction of Beckman Coulter, Inc. Entry of incorrect information will lead to system errors. System Restore Precautions...

-

Page 20: Symbols And Labels

Symbols and Labels Introduction Symbols and Labels Introduction The following is a list of symbols and labels used on the DxC Systems. You will find them affixed to the appropriate components of the system, as described briefly below. Instrument Power Switch, ON This symbol located on the main power switch indicates that the analyzer power is ON when this portion of the switch is in the down position. - Page 21 Symbols and Labels CPU Power OFF Switch CPU Power OFF Switch This symbol is located on the face of the Computer (CPU) unit and indicates the OFF state when pressed. Primary Electrical Ground This symbol is used to indicate an electrical ground. Keyboard Connection This symbol is found above the connection between the computer and the keyboard.

- Page 22 Symbols and Labels Mouse Port Connection Mouse Port Connection This symbol is found next to the connection between the computer and the mouse port. High Voltage Electric Shock Risk This symbol indicates high voltage is present and /or there is a risk of electric shock when working in this area.

- Page 23 Symbols and Labels Laser Bar Code Caution Laser Bar Code Caution A label reading, "CAUTION. LASER LIGHT ACCESSIBLE. WHEN COVER IS OPEN OR REMOVED, DO NOT STARE INTO BEAM." is placed on the cover of any laser-based code reader. Do not stare into laser light beam when cover is open or removed.

- Page 24 Symbols and Labels ISE Cover Caution ISE Cover Caution A label reading, "THE ISE COVER SHOULD REMAIN IN PLACE DURING SYSTEM OPERATION." is placed on top of the ISE module frame under the ISE cover to indicate that the ISE cover should remain in place during system operation. THE ISE COVER SHOULD REMAIN IN PLACE DURING SYSTEM OPERATION.

- Page 25 21 CFR CHAPTER I, SUBCHAPTER J MANUFACTURED DECEMBER 2004 LABEL P/N 448229 AB BECKMAN COULTER, INC MADE IN U.S.A. MARCA REG A011540L.EPS Ethernet/Serial Port Label This label is found on the right side of the system and identifies connections for the Ethernet and serial ports.

- Page 26 It is very important that customers understand and follow all laws regarding the proper decontamination and safe disposal of electrical equipment. For Beckman Coulter products bearing this label please contact your dealer or local Beckman Coulter office for details on the take back program that will facilitate the proper collection, treatment, recovery, recycling and safe disposal of device.

-

Page 27: Chapter 2 System Description

System Description Introduction CHAPTER 2 System Description System Description Introduction The following chapter briefly describes the system components, operational theories, principles of measurement, programming structure, and operator controls. Detailed information is located in the UniCel DxC Synchron Clinical Systems Reference Manual. -

Page 28: Operational Conditions

Operational Conditions Shipping Damage Each DxC System is carefully examined and checked by Beckman Coulter, Inc. before it is shipped. When you receive your new DxC System, visually inspect the shipping container for damage. If there is damage, notify the Beckman Coulter Service Representative before he or she arrives at your facility to install your system. - Page 29 Operational Conditions Power Requirements Power Requirements Table 2.3 Power Requirements Item Requirement Operating range 180–264 V AC, RMS 220 V AC nominal, approximately 15 A at low line, exclusive of power on surge Frequency 47–63 Hz (50/60 Hz nominal) BTU generated DxC 600: 7,200 BTU/hour at nominal (estimated) DxC 800: 7,500 BTU/hour at nominal (estimated) DxC PC: 979 BTU/hour...

- Page 30 Operational Conditions Water Requirements Water Requirements Table 2.5 Water Requirements Item Specification Flow Rate 0.6 L/min peak flow rate 16 L/hr, minimum continuous flow rate Temperature +15°C to +25°C Water quality NCCLS Type II deionized water, except for total bacteria count < 10 cfu/mL Water pressure Deionized water entering the system must be 30–90 psig.

-

Page 31: System Components

System Components DxC Systems System Components DxC Systems A UniCel DxC System can be divided into the following components: • Sample Handling Components • Modular Chemistry System • Cartridge Chemistry Reagent Handling System • Hydropneumatic System • Operation and Control Components A Closed Tube Sampling System has optional components listed below: •... - Page 32 System Components DxC Systems A015901P.EPS Figure 2.2 UniCel DxC 800 Analyzer System Description UniCel DxC Systems Instructions For Use A13914 Page 2-6 October 2005...

-

Page 33: Sample Handling System

Sample Handling System Introduction Sample Handling System Introduction The Sample Handling system is composed of the following components: • Sample racks • Autoloader/Offload track • Priority load position • Shuttle • Bar code reader • Cap piercer assembly (optional) • Sample Carousel •... - Page 34 16 × 100 mm tubes 16 × 92 mm tubes 16.5 × 100 mm tubes Beckman Coulter 0.5 mL Cup Insert (P/N 476399) (2 of 2) Rack ID Labels Sheets of bar-coded rack ID labels are supplied with the system. They can be applied...

- Page 35 Sample Handling System Autoloader/Offload Track Autoloader/Offload Track When viewed from the front of the system, the autoloader is on the left and holds up to 25 sample racks in preparation for presentation to the DxC 800 system. The DxC 600 system has room to load a maximum of 14 racks.

- Page 36 Sample Handling System Priority Load Button Priority Load Button Typically, rack placement and removal is under microprocessor control. The operator may choose to use the reserved positions by pressing the PRIORITY LOAD button and placing the priority rack in the space provided by the system. (Refer to Figure 2.4.) The rack will load into one of the reserved positions on the Sample Carousel.

- Page 37 Sample Handling System 1-Blade Thick CTS (Closed Tube Sampling) Cap Piercer Assembly (optional) 1-Blade Thick CTS (Closed Tube Sampling) Cap Piercer Assembly (optional) CAUTION This Cap Piercer contains a razor sharp blade assembly. CAUTION Do NOT use this Cap Piercer assembly with foil-capped tubes. This would give level sense errors.

- Page 38 Sample Handling System Sample Carousel Sample Carousel The ten-rack position Sample Carousel is a motor-driven turntable. (Refer to Figure 2.5.) Under normal operation, eight of the Sample Carousel positions are available for routine processing and two positions are reserved for priority racks. A015903P.EPS 1.

-

Page 39: Modular Chemistry (Mc) System

Modular Chemistry (MC) System Introduction Modular Chemistry (MC) System Introduction The Modular Chemistry system consists of the following major assemblies: • Reagent storage area • Ratio pump • Sample probe • Electrolyte injection cup (EIC) • Flow cell assembly • Chemistry reaction modules A detailed description of each component is presented in the following paragraphs. - Page 40 Modular Chemistry (MC) System Reagent Bar Code Reader (Modular) Reagent Bar Code Reader (Modular) Behind the left side door of the system there is a hand-held bar code reader. (Refer to Figure 2.6.) When this reader is held up to the label of one of the modular reagents and the trigger is pressed, the identity of the reagent, the lot number and reagent volume are automatically entered into the reagent load screen.

- Page 41 Modular Chemistry (MC) System Electrolyte Injection Cup (EIC) Electrolyte Injection Cup (EIC) The EIC mixes the sample and buffer prior to delivery of the sample (now diluted) to the flow cell. 1. Waste outlet 4. Reference inlet 2. Flow Cell outlet 5.

- Page 42 Modular Chemistry (MC) System Flow Cell Assembly Flow Cell Assembly The flow cell assembly houses the seven electrodes that perform the analysis of sodium, potassium, chloride, carbon dioxide, and calcium. (Refer to Figure 2.9.) 1. Inlet port 6. Exit port for waste (large tube) 2.

- Page 43 Modular Chemistry (MC) System Chemistry Reaction Modules (Basic Components) Chemistry Reaction Modules (Basic Components) Each of the six Chemistry Reaction Modules have similarities in their design. These common elements are described below. (Refer to Figure 2.10.) Unique design elements of the modules are described under the specific module headings later in this section.

-

Page 44: Cartridge Chemistry (Cc) Reagent Handling System

Cartridge Chemistry (CC) Reagent Handling System Introduction Cartridge Chemistry (CC) Reagent Handling System Introduction The Cartridge Chemistry Reagent Handling system is composed of the following components: • Reagent cartridges • Reagent carousel • Reagent probe assembly • Reagent mixer assembly •... - Page 45 Cartridge Chemistry (CC) Reagent Handling System Reagent Carousel Reagent Carousel The Reagent Carousel Compartment provides an on-instrument storage area for the individual reagent cartridges. A total of 59 reagent cartridges can be stored in the carousel at one time. (Refer to Figure 2.12.) The storage compartment is refrigerated and fan-cooled to maintain a temperature of...

- Page 46 Cartridge Chemistry (CC) Reagent Handling System Reagent Mixer Assembly A015908P.EPS 1. Reagent Mixer 2. CC Reagent Probe A 3. CC Reagent Probe B 4. Collar Wash Figure 2.13 CC Reagent Probe Area Reagent Mixer Assembly This assembly consists of a mechanical structure that supports a single, moveable crane.

-

Page 47: Cuvette Reaction System

Cuvette Reaction System Introduction Cuvette Reaction System Introduction The Cuvette Reaction system consists of the following components: • Reaction carousel assembly • Photometer assembly • LPIA (Large Particle Immuno Assay) or NIPIA (Near-Infrared Particle Immuno Assay) module (optional) • Cuvette wash station The Cuvette Reaction system involves the process of obtaining absorbance readings from each cuvette during the analysis cycle. - Page 48 Cuvette Reaction System Photometer Assembly A015909P.EPS 1. LPIA module 2. Reaction carousel 3. Photometer Figure 2.14 Reaction Carousel Area (Typical – Cover Removed) Photometer Assembly Attached to the reaction carousel support frame is the Photometer assembly. This consists of a xenon pulse lamp, a discrete 10-position silicon-diode detector array, a monochromator housing unit, and associated electronic circuitry.

- Page 49 Cuvette Reaction System Cuvette Wash Station Cuvette Wash Station The Cuvette Wash Station, (refer to Figure 2.15), consists of four coaxial probes, an elevator assembly, and the associated tubing. A motor controls the vertical motion required by the elevator to raise and lower the probes during the wash stage.

-

Page 50: Hydropneumatic System

Hydropneumatic System Introduction Hydropneumatic System Introduction The main components of the Hydropneumatic System are mounted on a slide-out drawer that allows for easier operator access. (Refer to Figure 2.16 Figure 2.17.) When fully extended, the drawer locks open. To close, lift up on the metal tabs, located on each side of the bottom runner of the hydropneumatic unit, and push the drawer inward. - Page 51 Hydropneumatic System Function A015911P.EPS 1. Waste exit 5. Vacuum accumulator 2. Waste B exit 6. Waste B canister 3. DI water inlet On/Off 7. Waste canister 4. DI water reservoir Figure 2.17 DxC 800 Hydropneumatics (left side) UniCel DxC Systems Instructions For Use A13914 System Description October 2005 Page 2-25...

-

Page 52: Operation And Control Components

Operation and Control Components Operator Controls Operation and Control Components Operator Controls The operator interfaces with various control devices such as the keyboard, monitor and push-button controls during a routine run. Basic operating functions are controlled and reviewed from the monitor. Calibration functions are also controlled from the monitor. Information is selected and entered into the system through touch screen monitors, from a mouse, and/or at a keyboard. -

Page 53: Main Operator Screen And Program Structure

Main Operator Screen and Program Structure Main Operator Screen Main Operator Screen and Program Structure Main Operator Screen DxC System operating and programming functions are initiated from the main operator screen at the DxC analyzer (refer to Figure 2.18). In addition, the screen provides status information to help determine the present state of the system. - Page 54 Main Operator Screen and Program Structure Printing Data From a Screen To load an alternate language, select the desired language from the Choose a Language dropdown list and select the <Install Manual> button. You can then view the IFU Manual in the selected language as described in the preceding paragraph. To view the License Agreement, simply select the <License>...

- Page 55 Main Operator Screen and Program Structure Function Selection Icons and Program Structure Table 2.10 Main Operator Screen Status Functions , continued Status Indicator Status Description System Status This indicator appears just below the Function Selection Icons on the left side of the Operator screens (refer to item 3 on Figure 2.18).

- Page 56 Main Operator Screen and Program Structure Function Selection Icons and Program Structure Main F1 Results F2 Unload F8 Log F9 Pre Run System Replicates F10 Post Run F1 Sample Sample Replicate Serum Index F2 Edit F2 Demog Off-line Dilution Factor Samples F3 Urine Manual ORDAC...

- Page 57 Main Operator Screen and Program Structure Function Selection Icons and Program Structure Rgts/Cal F1 Load F1 Clear F2 Params F10 Done F3 No Load Load calibrator diskette F4 Cal Calibrator acceptance limits F5 List Modify set points F6 Options Slope/Offset adjustment Within lot calibration Enzyme Validator Calibration override...

- Page 58 Main Operator Screen and Program Structure Function Selection Icons and Program Structure F1 Chems Setup 1. Auto Serum Index/ORDAC F1 Restore F2 UDR F10 Done F3 Define 2. Chem Config/Sample Type F4 Clear F1 Date F5 Insert F2 Time F6 Delete 3.

- Page 59 Main Operator Screen and Program Structure Function Selection Icons and Program Structure Setup, 12. Special Calculations F1 View continued F2 Define F3 Delete F10 Done 13. Setup Summary F10 Done 14. Units/Precision F1 Restore F10 Done 15. User-Defined Chemistries F1 Define F1 Restore F2 Delete F9 Cancel...

- Page 60 Main Operator Screen and Program Structure Function Selection Icons and Program Structure All CC Subsystems Utils 1. Prime F1 Prime All Hydropneumatic Subsystems All MC Subsystems Prime DxC Prime CTA Prime CTA Auto-Gloss CTS Auto-Gloss CTS Blade Wash Reagent Delivery Subsystem Sample Delivery Subsystem F2 CC Cuvette Wash...

- Page 61 Main Operator Screen and Program Structure Function Selection Icons and Program Structure Utils, 3. Event Log Display continued Copy Time Clear Print Done 1. Chemistry Errors 2. Motion Errors 3. Status Monitor Errors 4. Other Instrument Errors 5. Instrument Events 6.

- Page 62 Main Operator Screen and Program Structure Function Selection Icons and Program Structure Performance Verification Tests Utils, 6. PVT Sub-Functional Area continued Test Selection - Based on Functional Area Selected F10 Exit 7. Modem System Parameters 8. Backup/Restore Alignment Data Files Backup Restore Cancel...

-

Page 63: Theory Of Operation

Theory of Operation Introduction Theory of Operation Introduction The UniCel DxC Synchron Clinical Systems are microprocessor-controlled, random access clinical analyzers capable of processing a wide variety of operator-selected chemistries in a single run. Cartridge Chemistries (CC) The optical system of the DxC enables rate, endpoint, and nonlinear analyses to be performed simultaneously. -

Page 64: Cartridge Chemistry: Calibration Theory

Cartridge Chemistry: Calibration Theory Introduction Cartridge Chemistry: Calibration Theory Introduction Calibration determines the relationship between measured reaction responses and known concentrations. Calibration factors are derived from this relationship. These factors are used to convert the measured reaction responses to final concentration results. - Page 65 Cartridge Chemistry: Calibration Theory Endpoint and First-Order Calibration Formulas Endpoint and First-Order Calibration Formulas The calibration factor is determined by using one of the following equation sets where reaction and blank are used from the usable replicates. Table 2.12 Calculation of Calibration Factors for Endpoint and Rate Chemistries Type Formula...

- Page 66 Cartridge Chemistry: Calibration Theory Endpoint and First-Order Calibration Formulas Table 2.12 Calculation of Calibration Factors for Endpoint and Rate Chemistries , continued Type Formula Blanked FOR HIGH CALIBRATOR LEVEL: Endpoint (Reaction ABS - Blank ABS) = Delta ABS rep1 Chemistries (Reaction ABS - Blank ABS) = Delta ABS rep2 (Delta ABS...

- Page 67 Cartridge Chemistry: Calibration Theory Endpoint and First-Order Calibration Formulas Table 2.12 Calculation of Calibration Factors for Endpoint and Rate Chemistries , continued Type Formula Blanked FOR HIGH CALIBRATOR LEVEL: Endpoint Chemistries Blank Volume Blank Correction Factor = (with Volume Total Reaction Volume Correction) Volume of Reagent(s) (and Sample) at Blank Read Volume of Total Reagent and Sample at Reaction Read...

- Page 68 Cartridge Chemistry: Calibration Theory Endpoint and First-Order Calibration Formulas Table 2.12 Calculation of Calibration Factors for Endpoint and Rate Chemistries , continued Type Formula Nonblanked FOR HIGH CALIBRATOR LEVEL: Rate Reaction Rate = Rate rep1 Chemistries Reaction Rate = Rate rep2 (Rate + Rate...

- Page 69 Cartridge Chemistry: Calibration Theory Endpoint and First-Order Calibration Formulas Table 2.12 Calculation of Calibration Factors for Endpoint and Rate Chemistries , continued Type Formula Blanked Rate FOR HIGH CALIBRATOR LEVEL: Chemistries (Reaction Rate - Blank Rate) = Delta Rate rep1 (Reaction Rate - Blank Rate) = Delta Rate rep2 (Delta Rate...

- Page 70 Cartridge Chemistry: Calibration Theory Endpoint and First-Order Calibration Formulas Table 2.12 Calculation of Calibration Factors for Endpoint and Rate Chemistries , continued Type Formula Blanked Rate FOR HIGH CALIBRATOR LEVEL: Chemistries (with Volume Blank Volume Blank Correction Factor = Correction) Total Reaction Volume Volume of Reagent(s) (and Sample) at Blank Read Volume of Total Reagent and Sample at Reaction Read...

- Page 71 Cartridge Chemistry: Calibration Theory Non-Linear Chemistries Non-Linear Chemistries Non-linear chemistries include drugs and specific protein assays. Unlike the first-order rate and endpoint chemistries, which exhibit a linear response to increasing concentration, the calibration curves for non-linear chemistries exhibit logarithmic (S-shaped) or other nonlinear relationships. For this reason, curve fitting interpolation techniques are employed to construct the calibration curve.

- Page 72 Cartridge Chemistry: Calibration Theory Non-Linear Calibration Formulas Table 2.13 Math Models for Non-Linear Chemistries Type Formula Model #1 Math Model #1 is the four-parameter log-logit function most commonly used with reagents that use antibodies. R = R –a–b∗1n(conc) 1 + e E014420L.EPS Sample values are determined using the calculated curve parameters and the math model.

- Page 73 Cartridge Chemistry: Calibration Theory Drugs of Abuse Testing (DAT) Chemistries Table 2.13 Math Models for Non-Linear Chemistries , continued Type Formula Model #9 Math Model #9 is an extension to model #1, the four-parameter log- logit function. R = R 1 + c ∗...

- Page 74 Cartridge Chemistry: Calibration Theory Enzyme Verification Enzyme Verification Enzyme verification is a means of adjusting enzyme chemistry reporting units to IFCC methods. This feature is available for ALP, ALT-, AST-, CHE, CK-, GGT and LD. Verification also allows results to be adjusted for country specific correlation needs. Verification is similar to calibration except that normalization factors are applied to the sample result in the form of a slope and offset adjustment, whereas calibration factors would be applied to the reaction response.

-

Page 75: Modular Chemistry: Calibration Theory

Modular Chemistry: Calibration Theory Calibration Theory Modular Chemistry: Calibration Theory Calibration Theory Modular chemistries are calibrated using two to three levels of calibrator (chemistry dependent). Four replicates per level are assayed. Data from two middle replicates of each level is used to set the system response. The highest and lowest replicates are discarded. -

Page 76: Cartridge Chemistry: Principles Of Measurement

Cartridge Chemistry: Principles of Measurement Spectrophotometric Methods Cartridge Chemistry: Principles of Measurement Spectrophotometric Methods Spectrophotometric methods rely on the principle that a sample, such as a patient sample, a control, or a calibrator, when mixed with one or more appropriate chemical reagents, produces a substance that has the ability to absorb light at specific wavelengths. -

Page 77: Chapter 3 Preparing Samples For Analysis

Routine Operation Overview Daily Procedure CHAPTER 3 Preparing Samples for Analysis Routine Operation Overview Daily Procedure The following table shows an example of daily work flow using the DxC Synchron Clinical Chemistry System. NOTICE This procedure assumes that the initial system setup has been completed. Step Action If necessary, start the system. -

Page 78: Sample Programming And Processing

Sample Programming and Processing Introduction Sample Programming and Processing Introduction Sample programming provides the ability to identify samples, select tests to run, describe samples, and designate how to run samples. Samples are programmed through a host computer or Laboratory Information System (LIS or at the analyzer). The minimum information required to save a sample program includes: •... - Page 79 16 × 100 16 × 100 mm tubes 16.5 × 92 mm tubes Beckman Coulter 0.5 mL Cup Insert (P/N 476399) NOTICE Adapters are provided to adapt various sized sample tubes (secondary tubes) to the short racks. These adaptors must only be used in racks designated as reserved.

- Page 80 • Remove the cap. • Determine sufficient volume. • Check for fibrin or other materials resulting from storage. Beckman Coulter • Pipette the sample into a Synchron Microtube™. Synchron • Verify there are no bubbles at the bottom of the tube.

- Page 81 DI water. When running in the CTS mode, if tubes off-loaded from the UniCel DxC Systems have water or droplets of water on the caps, disable the CTS and call Beckman Coulter Technical Support. Note: Oil on a cap is normal.

- Page 82 Sample Programming and Processing Reserved Racks The 16 × 100 tubes must be run in a non-reserved 16 × 100 mm rack. NOTICE If a sample ID is manually cleared, the CTS tracking information is cleared on that instrument only. If a sample ID is reused and the tube requires piercing, the sample ID must be cleared on the instrument that is loaded first.

- Page 83 Sample Programming and Processing Reserved Racks for HbA1c, or IBCT Reserved Racks for HbA1c, or IBCT There are two separate fields for specific tests. One for HbA1c and one for IBCT. If a rack number is entered into one of these fields, any samples run in that rack will only function for that specific test.

-

Page 84: How To Use Reserved Racks

Recommended Use of Reserved Racks Green Racks Series 350–400 to run: • nesting cups • capillary collection containers • Beckman Coulter Microtubes™ Gray Racks Series 601 to run: • "Barcoded" Calibrators and Controls Purple Racks • Series 401–420 to run HbA1c •... - Page 85 How to Use Reserved Racks Recommended Use of Reserved Racks Assigning or Reassigning Reserved Racks Step Action Select the Setup icon from the menu bar. Select the <Page Down> button on the right side of the screen. Select <17> Reserved Racks/Obstruction Detection. Type 17 in the Option Number field and press [Enter].

- Page 86 How to Use Reserved Racks Bar Code Labeling Bar Code Labeling The use of bar code labels is a highly accurate and efficient method for identifying and processing laboratory samples. However, the system must be able to identify and read every bar code label to process each sample correctly.

- Page 87 How to Use Reserved Racks Processing Bar Coded Samples Processing Bar Coded Samples Generally, previous sample programming will not need to be cleared before placing a bar coded sample on the instrument. If the lab reuses Sample IDs, previous programming must be cleared. Step Action Load tubes in a rack with the bar code labels visible through the slot on the...

- Page 88 How to Use Reserved Racks Processing Unreadable Bar Coded Samples Processing Unreadable Bar Coded Samples If a sample bar code is unreadable and the LIS needs to be queried, use manual assignment. A manual assignment is rack and position and a Sample ID with no other information.

- Page 89 How to Use Reserved Racks Processing Samples Manually Step Action , continued Identify samples using the table below: If… Then… Sample has a readable bar • Type in the sample ID. code, • If previous programming appears, it may be necessary to clear it. •...

- Page 90 How to Use Reserved Racks Adding Tests or Rerunning a Sample Adding Tests or Rerunning a Sample Step Action Select the Samples icon from the menu bar. Select Rerun [F6]. Type the sample ID, rack, or rack and position for rerun. One or more samples can be programmed to rerun.

- Page 91 How to Use Reserved Racks Range of Sample IDs When to Clear Samples Samples should be cleared as follows: If... Then... Sample programming has been completed. Clear sample programming. A sample ID has to be reused. Clear that sample ID first. A sample rack can not be programmed due to Clear that programming.

- Page 92 How to Use Reserved Racks Procedure for Clearing Samples Procedure for Clearing Samples Step Action Select the Samples icon from the menu bar. Select Clear [F7]. Sample may be cleared by Sample ID(s), Rack/Position, or by Date/Time created. Type in the specific criteria for deletion. NOTICE Clearing Rack/Position does not clear programming for sample(s) programmed in those positions with associated Sample IDs.

-

Page 93: Chapter 4 System Setup Options

Overview Introduction CHAPTER 4 System Setup Options Overview Introduction This chapter summarizes the 29 System Setup options depicted on the Setup screens shown in Figure 4.1 Figure 4.2 below: E015930S.EPS Figure 4.1 Setup Screen (scrolled to the top) E015931S.EPS Figure 4.2 Setup Screen (scrolled to the bottom) UniCel DxC Systems Instructions For Use A13914 System Setup Options... - Page 94 Overview Introduction For detailed step-by-step instructions on using the System Setup option, refer to the UniCel DxC Synchron Clinical Systems Reference Manual. System Setup Options UniCel DxC Systems Instructions For Use A13914 Page 4-2 October 2005...

-

Page 95: Password Setup

Password Setup Introduction Password Setup Introduction The Password Setup option allows the operator to: • Assign up to 100 user names and their passwords • Assign Administrator or Operator level privileges to each user name • Define/edit or delete user name/password setup •... - Page 96 Password Setup Defining/Editing Password Setup Step Action , continued The Password Setup dialog box shows Page 1 (of 10) of the users with password security. If necessary, select <Page Down> on the right side of the screen to show the user desired. Select New [F1] to enter the password setup for a new user.

-

Page 97: Auto Serum Index/Ordac

NOTICE The analytical ranges for each analyte are system limits found in the respective CISs. These are the ranges that Beckman Coulter has verified can be achieved by the system. There is no flagging associated with values exceeding these limits. - Page 98 Auto Serum Index/ORDAC Auto Serum Index Auto Serum Index The Auto Serum Index function, when enabled, automatically analyzes every sample for the detection of hemolysis, icerus and lipemia and numeric values (index) for the relative concentrations (range) are included in the report. The values are printed below the Special Calculations area of a patient report.

-

Page 99: Configuring The Chemistry Menu

Configuring a Beckman Coulter Chemistry The chemistry menu, available in sample programming, quality control, panel definition and other screens, is defined by the user. To define Beckman Coulter chemistries, select <2> Chemistry Configuration/Sample Type from the Setup screen. Place the cursor in an open field in the Configuration Chemistry screen and press Chems [F1]. - Page 100 The Delete Chemistry function requires that you first clear the calibration, sample programming and control (QC) information from the instrument before deleting the chemistry from the system. Where it is used, Beckman Coulter recommends that you remove chemistries from the system following the sequence and procedures below to...

- Page 101 Configuring the Chemistry Menu Deleting a Chemistry Step Action , continued Remove the reagent cartridge.To remove the reagent cartridge DIG: • Select the position for the chemistry to be removed. • Select Load [F1]. • If prompted by the instrument to remove the reagent cartridge, open the reagent carousel door to remove the cartridge.

- Page 102 Configuring the Chemistry Menu Deleting a Chemistry 3. Remove the chemistry from the Quality Control (QC) program. A. If a control is defined solely for that chemistry and is no longer needed, the entire control definition should be deleted. Step Action Select the QC icon from the menu bar.

- Page 103 Configuring the Chemistry Menu Beckman Coulter Defined Chemistries with Units and Precision 4. Deleting a chemistry from the system (Example: DIG) Step Action Select the Setup icon from the menu bar. Select <2> Chemistry Configuration/Sample Type. Type 2 in the Option Number field and press [Enter].

- Page 104 Configuring the Chemistry Menu Beckman Coulter Defined Chemistries with Units and Precision Table 4.1 UniCel DxC 600/800 Beckman Coulter Defined Chemistries with Acronyms Units and Precision , continued Beckman Coulter Defined Chemistry Acronym Units Precision Benzodiazepine BNZG mA/min X.XX Calcium...

- Page 105 Configuring the Chemistry Menu Beckman Coulter Defined Chemistries with Units and Precision Table 4.1 UniCel DxC 600/800 Beckman Coulter Defined Chemistries with Acronyms Units and Precision , continued Beckman Coulter Defined Chemistry Acronym Units Precision Hemoglobin A1c HbA1c2 X.XX Immunoglobulin A...

- Page 106 Configuring the Chemistry Menu Beckman Coulter Defined Chemistries with Units and Precision Table 4.1 UniCel DxC 600/800 Beckman Coulter Defined Chemistries with Acronyms Units and Precision , continued Beckman Coulter Defined Chemistry Acronym Units Precision Tobramycin µg/dL Total Bilirubin TBIL...

-

Page 107: Setting The Default Sample Type

Setting the Default Sample Type Introduction Setting the Default Sample Type Introduction Default Sample Type allows for definition of the default sample type for all programmed samples. The sample type may be changed for individual samples while in the sample programming function. Setup To set the default sample type, select <2>... -

Page 108: Date/Time Setup

Date/Time Setup Introduction Date/Time Setup Introduction The Date/Time option allows the user to set the date and time, choose the date/time formats that appear on all screens and reports, and restore date and time defaults. The first time the instrument is powered up, the user must set the date and time. Once set, changes to accommodate situations such as converting to daylight-savings time are performed through this option. -

Page 109: Demographics Setup

Demographics Setup Introduction Demographics Setup Introduction The Demographics Setup option provides the ability to select the demographics fields that appear in the demographics display/printout of the Program Samples function. Setup From the Setup screen, select <4> Demographics Setup to enable, disable and restore defaults to demographic fields. -

Page 110: Patient Results - Immediate Reporting Setup

Patient Results – Immediate Reporting Setup Introduction Patient Results – Immediate Reporting Setup Introduction Immediate Reporting Setup provides the option to print and/or send-to-host results as they are completed on the system. When the STAT reporting option is selected, any MC chemistry programmed as a STAT will immediately print and/or be sent to the host as soon as it is completed. -

Page 111: Panels

Panels Introduction Panels Introduction The Panels option allows grouping of analyses commonly programmed and run together. Defining, Editing and Deleting Panels The operator may define a maximum of 50 panels, and must assign a unique name to each. From the Setup screen, select <6> Panels to show the Panel Summary screen, then select [F1] to define, edit or [F2] to delete panels. -

Page 112: Replicates

Replicates Introduction Replicates Introduction The Replicates option allows the operator to set up the number of replicates per sample, which is applied to all sample programs. The replicates per sample may also be edited by accessing a specific sample program. A maximum of 20 replicates may be assayed from a sample. -

Page 113: Report Setup

Report Setup Introduction Report Setup Introduction This feature allows the operator to select the following options: • Enable or disable printing of Patient and Control Reports • Define a Report Header to print at the top of each report • Select from a variety of Patient Report formats •... -

Page 114: Reportable Ranges Setup

• Instrument Printable Range • Reportable Range Analytical Range The Analytical Range is an internal system limit verified by Beckman Coulter. A result exceeding the Analytical Range is flagged OIR HI or OIR LO (Out of Instrument Range). Refer to the Synchron Clinical Systems Chemistry Information Manual for Analytical Ranges by analyte. - Page 115 Reportable Ranges Setup Suppress Results Option The default for a Reportable Range is the Printable Range. The default for Suppress Results is OFF (box is not checked). The system must be in Standby or Stopped to edit these ranges. From the Setup screen, select <9> Reportable Ranges to define, edit, or suppress a reportable result.

-

Page 116: Reference/Critical Ranges Setup

Reference/Critical Ranges Setup Reference Range and Critical Ranges Reference/Critical Ranges Setup Reference Range and Critical Ranges Reference and Critical Range Setup options allow the operator to define the normal and critical ranges for each analyte by age group, gender and sample type. Up to 32 age ranges may be defined. -

Page 117: Sample Comments Setup

Sample Comments Setup Introduction Sample Comments Setup Introduction The Sample Comments option allows the operator to define a maximum of 20 comments for use in the Sample Programming screen. Setup From the Setup screen, select <11> Sample Comments to define, edit or delete sample comments. -

Page 118: Special Calculations Definition

The system must be in Standby or Stopped to define, edit or delete operator-defined Special Calculations or to enable/disable them. The default for any Special Calculation is disabled. Beckman Coulter Predefined Special Calculations Defaults Table 4.2 Beckman Coulter Predefined Special Calculations Defaults... - Page 119 Special Calculations Definition Beckman Coulter Predefined Special Calculation Formulas Table 4.2 Beckman Coulter Predefined Special Calculations Defaults , continued Calculation Unit Precision Sample Type Crea Clearance (1) mL/min T Urine Crea Clearance (2) mL/sec T Urine ApoA/ApoB Ratio None Serum...

- Page 120 Special Calculations Definition Beckman Coulter Predefined Special Calculation Formulas Table 4.4 UniCel DxC 800 Predefined Special Calculation Formulas Calculation Formula Osmality (1) (1.86 × NA) + (GLUCm/18) + (BUNm/2.8) + 9 Osmality (2) (1.86 × NA) + (GLUCm/18) + (UREAm) + 9...

-

Page 121: Timed Urine And Creatinine Clearance Results

Timed Urine and Creatinine Clearance Results Introduction Timed Urine and Creatinine Clearance Results Introduction When Timed Urine is designated as the sample type for a Sample ID, the Results report will reflect: • the concentration of the sample aliquot placed on the instrument. •... -

Page 122: Setup Summary

Setup Summary Introduction Setup Summary Introduction The Setup summary provides a condensed reference to: • the software version number. • the chemistry database version. The Setup Summary may be viewed at any time. Setup From the Setup screen, select <13> Setup Summary, to review the Setup Summary. System Setup Options UniCel DxC Systems Instructions For Use A13914 Page 4-30... -

Page 123: Units/Precision Setup

Units/Precision Setup Introduction Units/Precision Setup Introduction The Units/Precision option allows the operator to select the units and number of decimal places for each viewed and printed result. When the units are altered, all features affected by the change, such as reference ranges and calibration values, will automatically convert to match the new units. -

Page 124: User Defined Chemistries Setup

User Defined Chemistries Setup Introduction User Defined Chemistries Setup Introduction With User Defined Chemistries, a maximum of 100 chemistries may be defined on the UniCel DxC. Setup From the Setup screen, select <15> User-Defined Chemistries. For detailed information about User Defined chemistries, refer to CHAPTER 9, User Defined Reagents in this manual. -

Page 125: Bar Code Setup

Bar Code Setup Introduction Bar Code Setup Introduction The Bar Code Setup option allows the operator to: • Enable/disable sample bar code mode of operation • Enable/disable sample bar code types • Configure sample bar code parameters • Restore defaults The four sample bar code types that may be used on the DxC are: •... -

Page 126: Maximum Sample Program Age

Maximum Sample Program Age Introduction Maximum Sample Program Age Introduction This feature refers to the age of the sample program. The operator may define the time limit allowed before the same sample ID can be reloaded on the system. The operator is notified of the time conflict by a pop-up window when the time limit has been exceeded. -

Page 127: Reserved Racks/Obstruct Detect

Reserved Racks/Obstruct Detect Introduction Reserved Racks/Obstruct Detect Introduction The Reserved Rack/Obstruction Detection option allows the operator to: • Enable/disable the CTS (Cap Piercer) option. • Enable/disable obstruction detection • Assign reserved rack numbers for small sample volume containers • Reserve a rack number or numbers for the analysis of HbA1c or IBCT samples. •... -

Page 128: Disable Service Monitor

Disable Service Monitor Introduction Disable Service Monitor Introduction The Disable Service Monitor option permits the service monitor to be disabled. When the Metering Counter is activated, the Service Monitor must be disabled. Refer to the Synchron Clinical Systems Metered-Use Manual for information regarding the metering option. -

Page 129: Host Communications

Host Communications Introduction Host Communications Introduction Table 4.5 following lists the Host communications parameters, the options of each, and the default values. Table 4.5 Host Communications Parameter Table Parameter Options Default Device ID 0–99 Flow Control Software (XON/XOFF) Software (XON/XOFF) Hardware (RTS/CTS) No Flow Data Transmission Mode Transmission OFF,... -

Page 130: Language/Keyboard Setup

Language/Keyboard Setup Introduction Language/Keyboard Setup Introduction The Language/Keyboard Setup option allows the operator to select from the following languages and keyboards for instrument operation: • English • French • German • Italian • Spanish • Japanese Setup From the Setup screen, scroll down and select <21> Language/Keyboard to select and activate the desired language or keyboard. -

Page 131: Printer Setup

Printer Setup Introduction Printer Setup Introduction The Printer Setup option allows selection of paper size. Setup From the Setup screen, scroll down and select <22> Printer Setup to choose one of three paper sizes. The system must be in Standby to make modifications. The default paper size is U. -

Page 132: Service Setup

After exiting from Service Setup the screen returns to normal. Enabling Service Setup This feature is password protected and can only be accessed by Beckman Coulter personnel. Disabling Service Setup The Service Monitor mode can be disabled at any time. Refer to... -

Page 133: System Configuration

Beckman Coulter. The instrument serial number is also shown in this area. View/Edit System Configuration This feature is password protected and can only be accessed by Beckman Coulter personnel. CAUTION Changes to the information in this area should only be done at the request or at the direction of Beckman Coulter, Inc. -

Page 134: Version Upgrade

Version Upgrade Introduction Version Upgrade Introduction The Version Upgrade option allows the operator to load a new version of operating software onto the system. Setup From the Setup screen, scroll down and select <25> Version Upgrade to load an upgrade to operating software. The system must be in Standby or Stopped state to load new software. -

Page 135: Status Alarm/Annunciator

Status Alarm/Annunciator Introduction Status Alarm/Annunciator Introduction The Status Alarm/Annunciator option allows the operator to: • Select from 5 different audible alarm patterns • Test the audible alarm • Disable the audible alarm Setup From the Setup screen, scroll down and select <26> Status Alarm/Annunciator to select an alarm pattern, test or disable the alarm. -

Page 136: Chemistry Update

Chemistry Update Introduction Chemistry Update Introduction The Chemistry Update option allows the operator to load a new version of chemistry database software that: • Updates chemistries on the existing menu • Adds new chemistries Setup From the Setup screen, scroll down and select <27> Chem Update to load a new version of chemistry database software. -

Page 137: Auto Generation Of Control

Auto Generation of Control Introduction Auto Generation of Control Introduction When this feature is enabled, if a sample is loaded with a defined control ID, the instrument will automatically run any chemistry that is on-board and runnable for that control. When Auto Generation of Control is enabled, the automatic Multiple Cartridge option is available. - Page 138 Auto Generation of Control Setup System Setup Options UniCel DxC Systems Instructions For Use A13914 Page 4-46 October 2005...

-

Page 139: Chapter 5 Reagent Load/Calibration

Reagent Load Introduction CHAPTER 5 Reagent Load/Calibration Reagent Load Introduction This chapter describes how to load reagents onto the DxC 800 and DxC 600 systems and calibrate chemistries using the Reagent Load/Calibration Screen. The DxC system loads and removes both cartridge (CC) and modular (MC) chemistries bulk reagents. Reagent information encoded on the container label can be read by the bar code reader or entered manually from the keyboard. - Page 140 Reagent Load Rgts/Cal Screen Overview Rgts/Cal Screen Overview If the Rgts/Cal icon is red or yellow, select it and look for chemistries that are highlighted red or yellow. (Refer to Figure 5.1.) Red highlighted chemistries will not run. Yellow highlighted chemistries will run, but check the reagent volume before starting.

- Page 141 Reagent Load Sorting Reagent Status Table 5.1 Reagent Status Messages , continued Message Explanation Level Sense Error Level sense check failed to properly detect reagent in one or more compartments. Reagent status is not applicable for a chemistry (e.g., an electrolyte chemistry).

- Page 142 Reagent Load Load/Unload Reagent A015919P.EPS 1. Reagent Name 2. Serial Number 3. Lot Number 4. Expiration Date Figure 5.2 MC Reagent Information Reagent information is encoded on the label and read by the bar code reader when the reagent is loaded or unloaded from the system. This information makes each container unique and allows the DxC to maintain an accurate inventory of MC reagents.

- Page 143 Reagent Load Load/Unload Reagent A015920P.EPS 1. BUNm/UREAm 6. CREm 2. PHOSm 7. Electrolyte Buffer 3. GLUCm 8. Electrolyte Reference 4. TPm 9. CO Acid 5. ALBm Figure 5.3 DxC 800 Leftmost Compartment A015921P.EPS 1. GLUCm 2. CO Acid 3. Electrolyte Buffer 4.

- Page 144 Reagent Load Load/Unload Reagent A015922P.EPS 1. Wash Concentrate II 2. No Foam solution 3. CTS Auto-Gloss Figure 5.5 DxC 600/800 Center Compartment Modular chemistry reagent bottles are selected from the Rgts/Cal screen and replaced as necessary according to volume. Reagent volume levels are automatically tracked by the system after the initial volume is set.

- Page 145 Reagent Load Load/Unload Reagent Step Action , continued Remove the reagent from the system. It is not necessary to scan the bar code of the reagent bottle when removing it. Note: The No Foam container (located in Figure 5.5, item 2) is refilled by pouring a fresh bottle of No Foam solution into the empty container on the instrument.

- Page 146 Reagent Load Load/Unload Reagent Step Action , continued Use the hand-held bar code reader to scan the reagent bar code of each new bottle. The system will "beep" to indicate a successful bar code read. Check the monitor to verify that the reagent data is shown. Once scanned, the reagent screen is updated with current reagent information.

- Page 147 Reagent Load Load/Unload Reagent A016485P.EPS 1. Reagent Name 2. Lot Number 3. Expiration Date 4. Serial Number Figure 5.7 CC Reagent Information Load/Unload Cartridge Chemistries (CC) Step Action Select the Rgts/Cal icon from the menu bar. Select all positions to be loaded or unloaded. Selected positions will be highlighted.

- Page 148 Reagent Load Load/Unload Reagent Step Action , continued To unload reagent: When the screen prompts you to remove the cartridge (1), open the reagent carousel door. The cartridge to unload will be positioned on either the upper or lower reagent carousel. A blinking bar code reader indicates which carousel position to unload from the upper and lower deck.

- Page 149 Reagent Load Reagent Parameters Reagent Parameters Calibration parameters specific for a particular reagent lot are included with certain multipoint, non-linear reagent cartridges. These parameters are referred to as Reagent Lot Specific Parameters. The Reagent Lot Specific Parameters, contained in four bar codes, are included on a card in the Reagent Kit.

- Page 150 Reagent Load Reagent Parameters Step Action , continued To manually load reagent parameters: • Type in the parameter information, from the parameter card, on each line of the Load Reagent Parameters dialog box. Note: Readable parameters coincide with each bar code on the card. •...

-

Page 151: System Calibration

System Calibration Introduction System Calibration System Calibration Introduction System calibration is used to standardize the analysis of samples to existing conditions. Refer to the Synchron Clinical Systems Chemistry Information Manual for detailed information regarding such conditions. In general, system calibration is required when: •... -

Page 152: Loading A Calibrator Diskette

Loading a Calibrator Diskette Loading a Calibrator Diskette Serum based calibrators require a calibrator diskette to be loaded on the system. The calibrator diskette is loaded only one time per lot number. • To check what lot number is currently loaded on the system, select the Rgts/Cal icon, then select Options [F6]. -

Page 153: Calibrator Assignment

Calibrator Assignment Calibrator Assignment To calibrate a reagent, first assign the rack/position or calibrator ID. The assignments can be reused or new assignments can be programmed with each new calibration. Note: A reserved rack must be used when placing a calibrator cup in a tube. Step Action Select the Rgts/Cal icon from the menu bar. -

Page 154: Calibration Status

Calibration Status Introduction Calibration Status Introduction Calibration status, as well as reagent status, is accessed from the Rgts/Cal Screen. Calibration status is shown to determine which chemistries require calibration. Calibration Status The following messages are used to indicate calibration status. Table 5.2 Calibration Status Messages Message... -

Page 155: Reagent And Calibration Status Warnings

Reagent and Calibration Status Warnings Introduction Reagent and Calibration Status Warnings Introduction When a reagent or chemistry calibration needs attention, a yellow or red warning highlight appears in the applicable place on the Reagent Status/Calibration Status screen. The highlight color depends on the reagent or calibration status. Conditions that Cause a Calibration Status Warning The table below lists the Calibration Status conditions and their related highlights. -

Page 156: Requesting A Calibration

Requesting a Calibration Calibrating DxC Chemistries With Bar Code Labels Requesting a Calibration Calibrating DxC Chemistries With Bar Code Labels From the Rgts/Cal screen, check the Calibration Time Left column shown in days:hours:minutes and the Cal Status column to see which chemistries require calibration. - Page 157 Requesting a Calibration Calibrating DxC Chemistries Using Assigned Calibrator Racks Calibrating DxC Chemistries Using Assigned Calibrator Racks From the Rgts/Cal screen, check the Calibration Time Left column shown in days:hours:minutes and the Cal Status column to see which chemistries require calibration.

-

Page 158: Calibration Failure Messages

Calibration Failure Messages Introduction Calibration Failure Messages Introduction If there is a failure during calibration, for modular chemistry (MC) or cartridge chemistry (CC), there is a pop-up message which shows: • The chemistry that failed and • The associated error code(s). After a failure message, the operator can: •... -

Page 159: Within-Lot Calibration

Within-Lot Calibration Introduction Within-Lot Calibration Introduction The Within-Lot Calibration option provides multiple reagent load of cartridges of the same lot number without having to calibrate each cartridge. The calibration factor established from a fresh cartridge (less than 8 hours on board the instrument) will be stored and applied to subsequently loaded cartridges of the same lot. - Page 160 Within-Lot Calibration Within-Lot Calibration Status Screen E015926S.EPS Figure 5.10 Within-Lot Calibration Dialog Box Note: If the within-lot calibration mode is disabled, any existing cartridges that are using the within-lot calibration factor will retain that factor until the cartridge is depleted or until another calibration is requested. When a chemistry is deselected, the following message appears: "If chemistries are deselected, a new calibration factor will need to be generated for all subsequent reagent packs loaded.

- Page 161 Within-Lot Calibration Within-Lot Designations E015927S.EPS Figure 5.11 Within-Lot Calibration Status Screen Within-Lot Designations The designations wf, w, and ws follow the reagent lot numbers of those chemistries selected for within-lot calibration. These designations are defined below. Table 5.4 Definitions of Within-Lot Designations Designation Description Reagent has been enabled for within-lot calibration and the...

- Page 162 Within-Lot Calibration Within-Lot Calibration Limitations Table 5.4 Definitions of Within-Lot Designations , continued Designation Description Reagent has been enabled for within-lot calibration but is a stand- alone (the calibration factor currently used applies only to this cartridge). A reagent receives this designation if: •...

-

Page 163: Enzyme Validator

Enzyme Validator Introduction Enzyme Validator Introduction The Enzyme Validator option provides the ability to obtain IFCC/DGKCh (refer to "Additional Information" below) equivalent answers for selective enzymes, or to obtain IFCC/DGKCh equivalent answers for the non-IFCC/non-DGKCh formulation enzymes. • The Synchron Enzyme Validator set is a human serum, albumin-based value assigned material and is used like a calibrator. -

Page 164: Calibration Override

Calibration Override Introduction Calibration Override Introduction The Calibration Override option allows the system to override a failed calibration and obtain results based on the failed calibration factors. Calibration Override is available only when an attempt to calibrate the chemistries has been previously made and failed, the status Cal Failed is shown. -

Page 165: Chemistry Bypass

Chemistry Bypass Introduction Chemistry Bypass Introduction In the event of a calibration failure for a chemistry which has been previously sample programmed, Chemistry Bypass permits the continuation of analysis of all other programmed tests without having to deprogram a failed chemistry. The chemistry can be bypassed while the system status is Standby, Disabled or Running. -

Page 166: Extending Calibration Time

Extending Calibration Time Introduction Extending Calibration Time Introduction The Extending Calibration Time option allows the extension of a calibration that has exceeded the recommended calibration time. The system shows a warning message approximately fifteen minutes prior to the calibration timeout. At this point, the operator can choose to recalibrate the chemistry in question or extend the calibration time. -

Page 167: Calibration Acceptance Limits

Calibration Acceptance Limits Introduction Calibration Acceptance Limits Introduction Calibration absorbance or ADC values are compared to preprogrammed back-to-back, span, and range limits to determine acceptable performance. If calibration errors in accuracy, precision, sensitivity, or linearity are detected by the system computer, error flags are generated. -

Page 168: Calibrator Set Point Modifications

Calibrator Set Point Modifications Introduction Calibrator Set Point Modifications Introduction The Calibrator Set Point Modifications option allows editing of the programmed calibrator set points. This option can be used to alter any chemistry provided it: • has calibration data. • uses three or less calibrator levels. •... - Page 169 Calibrator Set Point Modifications Modifying Calibrator Set Points Step Action , continued Move the cursor to the set point to be modified and type in the desired value. If a previously modified set point is to be returned to the original default value for that calibrator or chemistry, select desired chemistry, move cursor to the applicable set point and select <Restore Defaults>.

-

Page 170: Slope Offset Adjustment

Slope Offset Adjustment Introduction Slope Offset Adjustment Introduction The Slope Offset Adjustment option allows adjustment of the slope (m) or the y-intercept offset (b) of the regression equation used for results calculations. Modifications are made on a per chemistry basis. The default value for the slope is equal to "1"... - Page 171 Slope Offset Adjustment Slope Offset Recommendations Step Action Select the Rgts/Cal icon from the menu bar. Select Cal Options [F6]. Select Slope/Offset adjustment using the pull-down menu. Move cursor to the slope and/or offset to be modified. Use <Page Up> or <Page Down> from the screen or the keyboard counterparts to locate the Chem.

-

Page 172: Reprint Calibration Reports

Reprint Calibration Reports Introduction Reprint Calibration Reports Introduction The five most recent calibration reports for a given calibrator (chem position) may be printed for an historical perspective. Reprinting Calibration Reports The following steps explain how to reprint the current or previous calibration report. Step Action Select the Rgts/Cal icon from the menu bar. -

Page 173: Chapter 6 Quality Control

Quality Control Introduction CHAPTER 6 Quality Control Quality Control Introduction This task is performed when your laboratory protocol indicates that control material should be analyzed. A daily analysis of at least two levels of control materials is highly recommended. In addition, these controls should be run with each new calibration, with each new lot of reagents, and after specific maintenance or troubleshooting activities. - Page 174 Quality Control Accuracy and Precision Flags Accuracy and Precision Flags The DxC utilizes the following Westgard rules for evaluation of QC data. • 1-2S: Result Between ± 2SD and ± 3SD From the Assigned Mean If the result is between ± 2 and ± 3 standard deviations from the assigned mean, the result: - is flagged as >...

- Page 175 Quality Control Additional QC Precision Rules Additional QC Precision Rules Some additional Westgard QC rules are helpful when determining whether the system is in control. These are not flagged by the DxC QC package but can help in determining system performance. (Refer to Figure 6.1.) •...

-

Page 176: Defining A Control

Defining a Control Introduction Defining a Control Introduction The operator may define up to 100 controls. The minimum input required to save a control definition is control name, lot number, QC file number, sample type, and one chemistry selection per control. The maximum number of configurable chemistries is 175 per control. - Page 177 Defining a Control Defining a Control Defining a Control Follow the steps below to define or edit a control. NOTICE When defining a control, it is important to select the Sample Type (Step 7) before selecting the chemistries (Step 8). Failure to follow the procedure as described may result in the wrong units being assigned to a chemistry.

- Page 178 Defining a Control Defining a Control Step Action , continued Select Chems [F1]. A list of configured chemistries will appear. Add or remove chemistries by selecting and adding to the list, or by selecting and removing from the list. Use the scroll bar to access all chemistries. Select <OK>...

- Page 179 Defining a Control Deleting Controls from Definition Screen Step Action , continued Select Done [F10] to leave the definition screen and to save the control. Minimum requirements to save a control definition are control name, lot number and QC file name. If the control definition is not complete, a warning message will appear specifying which information is missing.

-

Page 180: Control Id Assignments

Control ID Assignments Introduction to Assigning QC Bar Codes Control ID Assignments Introduction to Assigning QC Bar Codes A maximum of eight bar codes (control IDs) per control may be defined. Even if a predefined control ID exists, before running the test, first use the sample programming screen to program the tests for the bar-coded controls. -

Page 181: Running Control Samples

Running Control Samples Introduction Running Control Samples Introduction Once the control has been defined, the control sample is run on the instrument with or without bar code labels. Then following procedures describe how to run a control sample for each condition Running Control Samples With Bar Code Labels and Auto Generation of Control Enabled Step Action... - Page 182 Running Control Samples Manually Running Control Samples Manually Running Control Samples Step Action Select the Samples icon from the menu bar. Clear the QC sample ID to be used. • Select Clear [F1]. • Type the QC sample ID into the Sample ID(s) field. •...

-

Page 183: Editing A Control Definition

Editing a Control Definition Introduction Editing a Control Definition Introduction The assigned mean, SD, constituent code, and bar code IDs of a previously defined control may be edited. The QC File Number associated with any defined control may not be edited. Editing Precautions •... -

Page 184: Reviewing A Control Definition

Reviewing a Control Definition Introduction Reviewing a Control Definition Introduction A control definition can be reviewed from either current QC data or archived QC data. Archived QC data may not be modified, only printed. Current QC data may be reviewed, deleted, or printed. Reviewing a QC Follow the steps below to review a control previously defined. -

Page 185: Deleting A Control

Deleting a Control Introduction Deleting a Control Introduction Previously defined controls may be deleted and removed from the system. Clearing QC ranges and applicable data can be done for Current QC data only. Controls may also be deleted through define, edit, and review QC functions. Deleting a Control Follow the steps below to delete a previously defined control. -

Page 186: Printing Qc Ranges

Printing QC Ranges Introduction Printing QC Ranges Introduction The entire database of controls may be printed. Printing QC Ranges Follow the steps below to print QC ranges. Step Action Select the QC icon from the menu bar. Select the control to be printed or type the item number. From the QC screen, select Print [F10]. -

Page 187: Qc File List

QC File List Introduction QC File List Introduction QC File List allows the operator to view and/or print a list of QC files by control name, chemistry name or QC file number. The QC File List is accessible from either Current QC data or Archived QC data. -

Page 188: Qc Summary

QC Summary Introduction QC Summary Introduction • The QC Summary report contains the mean, SD, CV and number of results (N) for any control run within a specified date interval. The printed report contains the cumulative mean, SD, CV and (N)umber of accumulated results. •... -

Page 189: Qc Chart (Levey-Jennings)

QC Chart (Levey-Jennings) Introduction QC Chart (Levey-Jennings) Introduction QC Chart shows the results of a control for a specified period (default is current date) in a graphic form, showing the position of data points relative to the assigned mean and standard deviation. The results are listed by date and time, most recent results first. - Page 190 QC Chart (Levey-Jennings) Accessing QC Charts Step Action , continued The chemistries defined for the selected control are listed. All chemistries appear to be selected. For convenience, there are two ways to select the chemistries to chart: • To chart most of the chemistries shown, select all chemistries which should NOT be charted.

-

Page 191: Qc Log

QC Log Introduction QC Log Introduction QC Log shows results with information about the relationship of those results to the assigned mean, SD and previous results for a specified data interval. Also shown are data point deletions. The QC Log may be viewed and/or printed from either the hard disk or the floppy disk. - Page 192 QC Log Delete a Data Point Step Action , continued Use the scroll bar to access additional data. Data are shown as follows: • Data points > 2 SD appear in yellow. • Data Points > 3 SD appear in red. •...

- Page 193 QC Log Adding a QC Action Log Comment Adding a QC Action Log Comment An action log comment may be added from the QC log screen. Step Action Select a data point by selecting the check box next to the data point. Select Action [F4].

-

Page 194: Archive Qc

Archive QC Introduction Archive QC Introduction The Archive QC function archives control definition (control name, lot number, sample type, QC File number, QC Log selected chemistries, assigned mean and SD, constituent code, and cumulative mean, SD and N) and results to a floppy disk. Archiving is available from the hard disk only. - Page 195 Archive QC How to Archive QC Step Action , continued Select <OK> or <Cancel>. Note: If the operator answers <OK> to the delete QC data prompt, a warning appears. Press [Enter] to initiate deletion. Select a date interval for QC data deletion by typing a Start date and an End date in the date range fields.

-

Page 196: Restore And Review Archived Data

Restore and Review Archived Data Introduction Restore and Review Archived Data Introduction Archived data can be reviewed from a floppy disk. Review options available from the floppy include review of demographics and cumulative statistics for a control file, viewing and printing of QC File List, QC Log, QC Summary and Control Ranges. No modifications to the archived control files are allowed. - Page 197 Restore and Review Archived Data Reviewing Archived Data Step Action , continued Select any of the following options: • Review [F1] to review archived control definition. • QC File List [F4] to view and Print archived QC File lists. • Log [F5] to view the Log for the archived data. •...

- Page 198 Restore and Review Archived Data Reviewing Archived Data Quality Control UniCel DxC Systems Instructions For Use A13914 Page 6-26 October 2005...

-

Page 199: Chapter 7 Sample Programming

Overview Introduction CHAPTER 7 Sample Programming Overview Introduction Sample programming provides the ability to identify samples, select tests to run, describe samples, and designate how to run samples. The minimum information required to save a sample program includes: • a Sample ID or •... -

Page 200: Prior To Programming

Prior to Programming Prior to Programming Prior to Programming Prior to Programming Prior to programming, it is necessary to verify rack status and sample carousel status. These options will determine which racks are available for programming, for rack assignment, and for determining the instrument status. Rack Status Patient samples, controls, or calibrators may be assigned to racks which are then loaded onto the system for sample processing. - Page 201 Prior to Programming Verifying Sample Carousel Status: Main Operator Screen Table 7.1 Sample Status Designations Sample Status Meaning In Progress Sample has been identified and is currently being sampled for programmed tests. Incomplete Sample has completed all tests possible and has some tests which are still pending.

-

Page 202: Identifying Samples

Identifying Samples Introduction Identifying Samples Introduction Samples may be identified by a Sample ID or by a rack/cup position or both. Rack and Position Mode and Bar Code Mode setup options affect where the cursor starts within sample programming and which fields are required to save sample programs. - Page 203 Identifying Samples Limitations Limitations The instrument stores up to 10,000 unique Sample IDs. When this limit is exceeded, the system overwrites the oldest sample program. Duplicate Sample IDs are not allowed. If Sample IDs are reused by the laboratory, set the Maximum Sample Program Age feature to help alert you to conflicts.

- Page 204 Identifying Samples Manually Assigning Rack and Position Manually Assigning Rack and Position It is only necessary to manually assign a rack and position if: • the system is set up in bar code mode and a sample will not be bar coded, •...

-

Page 205: Selecting Tests

Selecting Tests Introduction Selecting Tests Introduction Tests can be manually selected at the instrument using several methods: • by programming panels. • by typing the chemistry configuration number(s) in the chemistry entry box. • by selecting the chemistry button(s). Chemistry Identifiers Color is used to indicate chemistry information. -

Page 206: Programming Functions

Programming Functions Introduction Programming Functions Introduction Entering a dilution factor and programming a Manual Overrange Detection and Correction (ORDAC) feature are discussed below. Entering a Dilution Factor A dilution factor may be entered to be applied to the results of a specified sample. The dilution factor represents an off-line dilution prepared by the operator. -

Page 207: Batch Programming

Batch Programming Introduction Batch Programming Introduction Batch Programming provides programming of multiple samples with the same chemistries, sample type, dilution factor, and status. Any Panel, Comment, Demographics, Dilution Factor, Sample Type, or Chemistry programmed will apply to all sample positions designated within the batch. This information may be edited at any time on an individual position basis once the batch programming is completed. - Page 208 Batch Programming Batch Programming Step Action , continued A batch may be programmed with Sample IDs only, rack/cup designations only or both, as follows: Identification Procedure Rack/cup with Sample IDs Type rack numbers and number of samples desired in the batch. Select <OK>...

-

Page 209: Chapter 8 Results Recall

Overview Introduction CHAPTER 8 Results Recall Overview Introduction Results Recall allows patient and control results to be recalled, reviewed, updated, and printed. Results can be recalled, viewed, and printed by: • individual Sample ID or a list of Sample IDs •... -

Page 210: Recalling Results By Sample Id

Recalling Results by Sample ID Introduction Recalling Results by Sample ID Introduction Results can be recalled by an individual Sample ID and/or by a range of Sample IDs. Recalling by Sample ID Individual Sample IDs and/or a range of Sample IDs can be entered. Data and results may be reviewed and/or sent to the host. -

Page 211: Recalling Results By Rack And Position

Recalling Results by Rack and Position Introduction Recalling Results by Rack and Position Introduction Results can be recalled by rack and position. Recalling by Rack and Position Follow the steps below to enter rack(s) and position(s) for recall. Step Action Select the Results icon from the menu bar. - Page 212 Recalling Results by Rack and Position Recalling by Rack and Position Step Action , continued Select a function button from the bottom of the screen to select a desired output option. • Results [F1] - to view results on the screen. •...

-

Page 213: Recalling Results By Patient Id

Recalling Results by Patient ID Introduction Recalling Results by Patient ID Introduction Results can be recalled by Patient ID. Recalling by Patient ID Follow the steps below to recall a result by Patient ID. Step Action Select the Results icon from the menu bar. From the Recall Results By screen, type the Patient ID (a maximum of 15 alphanumeric characters) in the Patient ID field. -

Page 214: Recalling Results By Run Date/Time

Recalling Results by Run Date/Time Introduction Recalling Results by Run Date/Time Introduction Results can be recalled by Run Date and/or Time. Recalling by Run Date/Time Follow the steps below to recall results by Run Date and/or Time. Step Action Select the Results icon from the menu bar. From the Recall Results By screen, type the desired date and time ranges in the From fields and To fields. -

Page 215: Displaying Recalled Results

Displaying Recalled Results Introduction Displaying Recalled Results Introduction All recalled results may be viewed on the screen. Displaying Results Follow the steps below to view results on the screen. Step Action From the Recall Results By screen, select the results to be viewed, as previously described in this chapter. -

Page 216: Critical Result Rerun Editing

Critical Result Rerun Editing Introduction Critical Result Rerun Editing Introduction When a sample is rerun, the two results are shown in the Recall Results screen. The first result is always listed at the top and the rerun result is listed under the first result. The operator can delete one of the results and keep the other result. - Page 217 Critical Result Rerun Editing Deleting a Critical Rerun Result Step Action , continued Select Prev [F8] to view a previously shown sample. Select Next [F9] to view other samples if more than one sample result was recalled. Select Done [F10] when completed. (2 of 2) UniCel DxC Systems Instructions For Use A13914 Results Recall...

-

Page 218: Printing Recalled Results