Medivators ADVANTAGE PLUS User Manual

Endoscope cleaning and disinfection system

Hide thumbs

Also See for ADVANTAGE PLUS:

- Site requirements (20 pages) ,

- Maintenance instructions manual (12 pages)

Summary of Contents for Medivators ADVANTAGE PLUS

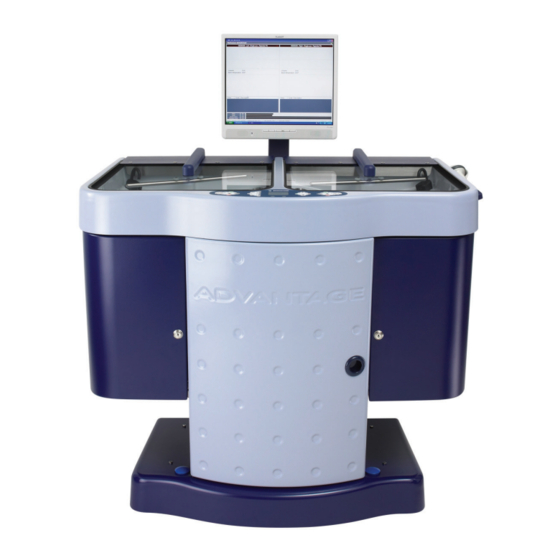

- Page 1 User Manual Endoscope Cleaning and Disinfection System (With optional cleaning cycle that eliminates manual cleaning)

- Page 2 All rights reserved. This publication is protected by copyright. Copying, disclosure to others, or the use of this publication is prohibited without the express written consent of Medivators Inc. Medivators reserves the right to make changes in the specifications shown herein without notice or obligation. Contact your Medivators representative or Medivators customer service for more information.

-

Page 3: Table Of Contents

TABLE OF CONTENTS CHAPTER 1 Using this manual ........................5 Safety ............................6 Operator Safety ........................7 Installation and Maintenance ....................9 Guidelines for Reliable Disinfection ..................10 Professional Guidelines ......................12 Reprocessor Specifications ....................13 Dimensions and Clearances ....................14 Installation Specifications .....................15 Storage ..........................16 Transport ..........................16 Symbols and Icons ........................17 Warning Summary ........................18 CHAPTER 2... - Page 4 Reprocessing Cycle Errors ....................119 Control Errors (SCU) ......................126 Warning Errors ........................130 CHAPTER 6 MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor Software ...138 ® ® Management Program ......................140 Endoscope Registration ......................145 User (operator) Registration ....................150 Physician/Assistant Registration ..................153 Reports ..........................155 Events ..........................159 Systems ..........................161...

-

Page 5: Chapter 1 Using This Manual

See Service Manual for servicing instructions. Contact your service representative for additional service information. Medivators ADVANTAGE PLUS Features The MEDIVATORS ADVANTAGE PLUS System was designed for ease of use and maintenance in the disinfection of endoscopes. Features include: •... -

Page 6: Safety

The ADVANTAGE PLUS system is indicated to provide high level disinfection of heat sensitive semi-critical endoscopes and related accessories. Manual cleaning of endoscopes is not required prior to placement in the ADVANTAGE PLUS system. The endoscopes must be pre-cleaned immediately after use. -

Page 7: Operator Safety

Regulatory Compliance The MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor complies with EN ® ® 60601-1-2 Electromagnetic Compatibility (EMC) Standards. The reprocessor is ETL and cETL certified and listed for safety per IEC Standard IEC 61010-1, UL Standard UL 61010-1 and Canadian Standard CAN/CSA-C22.2 No. 61010-1 for laboratory equipment. - Page 8 • For peracetic acid (PAA) disinfectant handling guidelines, refer to the American National Standard recommended practice titled, Chemical Sterilants and High Level Disinfectants: A Guide to Selection and Use (AAMI TIR7:1999) and/or Safe Handling and Biological Decontamination of Reusable Medical Devices in Health Care Facilities and in Nonclinical Settings (AAMI/ANSI ST35:2003). The documents are available from the Association for the Advancement of Medical Instrumentation.

-

Page 9: Installation And Maintenance

Prior to undertaking any service or maintenance operations or when resetting the GFI, ensure that the MEDIVATORS ADVANTAGE PLUS System is disconnected from the main power supply. If service or maintenance operations are to be conducted on the water system, ensure that the MEDIVATORS ADVANTAGE PLUS System is isolated from the main water supply. -

Page 10: Guidelines For Reliable Disinfection

Potable water is the minimum standard, Medivators recommends the use of a high quality water pre filtration system that filters incoming water to a minimum of 0.1 micron. A typical water pre-filtration system, such as the one offered by Medivators, filters incoming water through a 1 micron, 0.4 micron, and 0.1 micron series of filters. - Page 11 Endoscope Cleaning and Testing The MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor may be used with all ® ® makes and sizes of flexible, immersible endoscopes that can be internally and externally disinfected. Proper endoscope disinfection is required because endoscopes have multiple internal valves and channels that have the potential to harbor microorganisms that could cross-contaminate patients.

-

Page 12: Professional Guidelines

Professional Guidelines The following organizations have published recommended guidelines for cleaning and disinfecting endoscopes. Society of Gastroenterology Assoc. for Professionals in Infection Nurses and Associates, Inc. Control and Epidemiology, Inc. 401 North Michigan Ave. 1275 K Street NW, Suite 1000 Chicago, IL 60611-4267 Washington, DC 20005-4006 Tel: 800-245-7462... -

Page 13: Reprocessor Specifications

Reprocessor Specifications General Specifications The basic reprocessor specifications required for installation and operation of the MEDIVATORS ® ADVANTAGE PLUS Automated Endoscope Reprocessor are summarized in Table 1 . ® Table 1 Reprocessor Specifications Equipment Type Laboratory Equipment Electrical rating 100-240 VAC, 50/60 Hz... -

Page 14: Dimensions And Clearances

Dimensions and Clearances Figure 1 Front Dimensions Figure 2 Side Dimensions & Clearance... -

Page 15: Installation Specifications

If the ADVANTAGE PLUS model purchased did not include the air compressor, the system may utilize house compressed air (dry, oil free) which must meet these required air pressure specifications : 58 to 125 PSI with a minimum flow volume of 1.5 CFM, maximum particle size is 5 microns, maximum dew point... -

Page 16: Storage

For all other moves, place the MEDIVATORS ADVANTAGE PLUS System on a pallet with a kraft liner. Before moving MEDIVATORS ADVANTAGE PLUS System, ensure the electrical cord, drain line and water supply are either disconnected or are appropriate lengths to accommodate the relocation of the machine. -

Page 17: Symbols And Icons

Symbols and Icons Symbol Symbol Meaning Symbol Symbol Meaning LIO software shortcut Cancel Management software Next shortcut Server software shortcut Release All Expert Operation Start Cancel Stop Menu Active report, filter applied. Open/Close Edit OK/Enter Expand Scroll Down Export data Scroll Up Filter data Start... -

Page 18: Warning Summary

Warning Summary WARNING Portable and mobile communication devices can affect electrically-operated medical equipment WARNING Connecting a chemical container with the incorrect fluid may cause the endoscope to be improperly disinfected. Do not use the endoscope on a patient if this occurs. WARNING Wear personal protective equipment (PPE) (clothing, mask, gloves &... - Page 19 WARNING Use only fluids approved by Medivators Inc. Check the expiration date of the disinfectant in the reprocessor each day. Never use disinfectant beyond the manufacturer’s expiration date, even if the MRC level is acceptable. Never use disinfectant that tests below the acceptable MRC level, even if it has not yet reached the expiration date.

- Page 20 NOTE...

-

Page 21: Chapter 2

CHAPTER 2 OPERATOR CONTROLS This chapter describes the MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor ® ® operator controls, and how to set up and program the reprocessor. -

Page 22: Chapter 2 Main Components

2. PC Monitor: Displays messages, menu selections, and the operational status. 3. Basin Lid: Cover for the left or right basin of the MEDIVATORS ADVANTAGE PLUS System. Open the lid to add or remove endoscopes. 4. Control Panel: Used to select settings, operate the reprocessor, and view system messages, errors and warnings. - Page 23 AER Back View ® ® 1. PC: Runs the programs on the MEDIVATORS ADVANTAGE PLUS System that disinfect the reprocessor and endoscopes. 2. PC Monitor: Displays messages, menu selections, and the operation status. 3. Base Shroud: Covers and protects the bottom of the MEDIVATORS ADVANTAGE PLUS System.

- Page 24 Interior Components Figure 3 MEDIVATORS ADVANTAGE PLUS System Top View ® ® 1. Basin Lid: Cover for the left or right basin of the MEDIVATORS ADVANTAGE PLUS Automated ® ® Endoscope Reprocessor. Open the cover to load or remove endoscopes.

- Page 25 5. Alcohol Reservoir: Holds alcohol that may be used in the alcohol/air purge process. 6. Leak Test (Low) Pressure Gauge: Measures air pressure in the endoscope sheath and MDS system. Must be set to 0.25 bar (3.75 psi). Only to be adjusted by trained MEDIVATORS technicians. 7. Sample Ports: Dispenses RAPICIDE PA High Level Disinfectant for MRC testing at the end of ®...

- Page 26 PC Monitor and Connections Figure 5 PC Monitor and Connections 1. On/Off Switch : Turns the computer on or off. 2. USB Ports : Connector between the PC and external peripherals, (i.e. mouse and keyboard) 3. Power Connection : Bottom of monitor in back (not shown) 4.

- Page 27 Control Panel The control panel allows the operator to select settings, operate the reprocessor, and view system messages, errors and warnings, and cycle information. It consists of five main groups: 1. Left and right basin control buttons 2. Function buttons 3.

- Page 28 Basin Control Buttons Each module is controlled by its own keypad grouping. The group shown in Figure 7 is for the right module. Figure 7 Basin Control Buttons • Press the Open/Close button to open or close the lid on the basin. Note that during disinfection, the lids will not open.

- Page 29 Touchpad and Mouse Buttons Figure 8 Touchpad and Buttons The touchpad works as a mouse to enter information. Moving your finger on the pad causes the cursor to move on the monitor. Tapping the touchpad or pressing the left button has the same result as clicking the left button on a mouse.

- Page 30 Function Buttons Figure 9 Function Buttons Table 1 Function Buttons Function Press Button Result (No. of times) I/O Inputs / Outputs, left basin I/O Inputs / Outputs, right basin I/O Inputs / Outputs, both basins Re-opens program window — — Opens system parameters.

- Page 31 Help (?) — — Selection Buttons • Pressing the OK button is the same as clicking on the button in the software. • The Cancel button corresponds to the button in the software. • Pressing the Scroll Up button allows you to scroll up through a list on the monitor. •...

- Page 32 Note: Before a new type of endoscope is reprocessed or if you have any questions about a connection block, contact your field service representative. Accessories Endoscope accessories, buttons and valves may be disinfected in MEDIVATORS ADVANTAGE PLUS system. Use the provided mesh bag. Data Entry...

-

Page 33: Software System

1. LIO (Logic Input/Output) is the main software program that operators use to perform and run an endoscope cycle. This part of the software controls the MEDIVATORS ADVANTAGE PLUS System and is what runs and displays on the PC monitor. This program is used most often by daily operators of the reprocessor. - Page 34 1. Verify the PC is on, Windows is running. 2. Find the MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor folder on the ® ® Windows desktop and double click on it. It is titled “ADV”. Figure 13 MEDIVATORS ADVANTAGE PLUS System Folder on the Desktop...

- Page 35 3. Double click on the LIO icon to start the MEDIVATORS ADVANTAGE PLUS Automated ® ® Endoscope Reprocessor operational program. 4. Double click the Print Server icon to start the cycle log print service.

- Page 36 Figure 14 LIO in the MEDIVATORS ADVANTAGE PLUS System Window User Screen The monitor displays all necessary information for operating and maintaining the MEDIVATORS ® ADVANTAGE PLUS Automated Endoscope Reprocessor. Use the buttons on the control panel, to access ®...

- Page 37 Figure 15 Typical Program Screen Menu Bar Each program has a separate release version shown in the upper left corner of the screen. If a system error occurs, a red message bar appears here until the error is resolved. The Expert Operation icon appears in the upper right of the menu bar. Double clicking the icon will display a login dialog box.

- Page 38 Module and Program Status The status of each module is indicated in the main section of the screen. Program operations for the left module are on the left side of the screen; operations for the right module are on the right side of the screen. Running program operations for each module are indicated in the section.

- Page 39 Login Name and Password Many processes on the MEDIVATORS ADVANTAGE PLUS System require you to supply a login name and password. This confirms that you have the proper authorization to run each program. Data gathered from each process, including the operator’s name, is stored in the database and printed on reports.

- Page 40 Figure 17 Login Name Selection To enter your password, click on the appropriate numeric buttons in the window. If you enter an incorrect password, click the CLR button and enter the password again. Press the OK button to continue. Figure 18 Password Entry...

-

Page 41: Printing

1. Check for the printer icon in the system tray. The Print Server utility supports the printing of the Cycle Logs on the certificate printer. Figure 19 System Tray 2. If the icon is not present, display the Windows desktop by minimizing all open programs. 3. Open the MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor folder by ®... - Page 42 Figure 20 Desktop Detail 4. Double-click on the PrintService icon. Figure 21 MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor Folder ® ® 5. The PrintService icon should now appear in the System Tray. Set the Default Printer 1. Click on Start > Settings > Printers.

-

Page 43: Backup

This configuration provides a backup of the entire computer system. The MEDIVATORS ADVANTAGE PLUS endoscope reprocessor uses MICROSOFT SQL Server 2008 Express to generate the database files. The databases should be backed up on a regular basis. Although the mirrored hard drives do provide protection against a single hard drive failure, regular backups of the database to a remote location (CD, memory stick or remote server) will protect against database corruption or complete system failure. -

Page 44: Fluid System

Fluid System Fluid Reservoir Status The system monitors the use of disinfectant, alcohol, and detergent. The percentage of fluid remaining appears in the footer of all screens. Figure 24 Reservoir Levels WARNING Refilling the container with the incorrect fluid may cause the endoscope to be improperly disinfected. - Page 45 The detergent and alcohol reservoirs serve both the left and right modules. Each reservoir is threaded into a captive header and is removed by unscrewing the body. The alcohol must be 70% isopropyl. The detergent must be INTERCEPT Detergent manufactured by Medivators Inc. ® Figure 25 Alcohol and Detergent Reservoirs NOTE: Upon refilling of the detergent or alcohol reservoirs, the Replace Fluids Utility must be run.

- Page 46 Figure 26 Parts A and B Part A uses a blue cap, and is positioned to the left as you look into the front of the MEDIVATORS ADVANTAGE PLUS System. Part B uses a white cap, and is positioned to the right as you look into the front of the MEDIVATORS ADVANTAGE PLUS System.

- Page 47 4. Install a Disinfection Block on each basin connection manifold. Figure 27 Disinfection Block 5. Press the Menu button for the left module on the control panel. The left side of the MEDIVATORS ® ADVANTAGE PLUS System controls this utility.

- Page 48 Figure 28 Program Selection 8. Select Water Line Disinfect from the Select Program screen and click the OK button. Figure 29 Water Line Disinfect 9. When the Program Set Selection screen opens, choose the self-disinfection cycle and then click on the OK button: Disinfect...

- Page 49 Figure 30 Program Set Selection 10. Select either Normal Start or Delayed Start and click on the OK button. Figure 31 Normal Start...

- Page 50 Figure 32 Delayed Start 11. If a delayed start is selected, a screen opens called Select the Time. It lists start times in 15 minute increments for the next 7 days. Note that the dates are listed in MM/DD/YYYY, where M = month, D = day, and Y = year.

- Page 51 Figure 34 Summary/Information Screen 13. Press the Start button to initiate the water line disinfection. Disinfectant is flushed through the water line and water filled. The disinfectant remains in the water filter and water lines while the system is disinfected. The water lines and filter are flushed, the basin is rinsed and the utility terminates.

- Page 52 NOTES...

-

Page 53: Chapter 3

CHAPTER 3 OPERATION This chapter explains how to prepare and disinfect an endoscope in the MEDIVATORS ADVANTAGE ® PLUS Automated Endoscope Reprocessor. ®... -

Page 54: Chapter 3 System Startup

Figure 1 Air Pressure Controls Proper operation of the MEDIVATORS ADVANTAGE PLUS System reprocessor requires that the air pressure be set and maintained at the values shown in the table below. - Page 55 25.5 – 30 psi (1.7 – 2.0 bar) If the pressure control readings do not fall within the acceptable ranges, contact technical service. Do not attempt to adjust the settings yourself as damage may occur to the MEDIVATORS ADVANTAGE ®...

- Page 56 Figure 3 Drain Filters Fluids WARNING: Refilling a reservoir with the incorrect fluid may cause the endoscope to be improperly disinfected. Do not use the endoscope on a patient if this occurs. Always wear appropriate personal protective equipment (PPE) when handling endoscopes or disinfectant solutions.

- Page 57 Figure 4 Program Selection Screen 4. When the Select Fluid Type screen opens, select Alcohol and click the OK button. Figure 5 Select Fluid Type Screen 5. Enter the code found on the manufacturer’s container and press OK button. Endoscope repr...

- Page 58 Figure 6 Container Code 6. Remove, refill and replace the reservoir. Loading Detergent (Optional) Detergent is an optional feature and may not be configured in the system. Note: The MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor cleaning phase ® ® requires the use of INTERCEPT detergent.

- Page 59 Remove, refill and replace the detergent reservoir. 1. Press the Menu button on the control panel. Log in to the system. 2. When the Program Selection screen opens, select Replace Fluids and click the OK button. Figure 7 Program Selection Screen 3.

- Page 60 Figure 9 Container Code 5. Remove, refill and replace the reservoir.

- Page 61 Loading Disinfectant WARNING Use only RAPICIDE PA High Level Disinfectant. ® Check the expiration date of the disinfectant on the machine each day. Never use disinfectant beyond the manufacturer’s expiration date, even if the MRC level is acceptable. Never use disinfectant that tests below the acceptable MRC level, even if it has not yet reached the expiration date.

-

Page 62: Prepare The Endoscope

Prepare the Endoscope Caution: When using the cleaning cycle, endoscopes must be precleaned according to SGNA and facility guidelines. Manual cleaning of the endoscopes is not required. It is recommended that reprocessing using the cleaning cycle be performed within one hour after the procedure. If the cleaning cycle is not chosen, endoscopes must be manually cleaned before placing in the Reprocessor for disinfection. - Page 63 Figure 12 Set the Insertion Tube in Basin 5. Fit the light guide tube in a counterclockwise circle in the basin. 6. Select the proper connection block and channel separator from the endoscope hookup guide. Figure 13 Fit the Light Guide Tube in Basin Install the Channel Separator Note: Reference the endoscope hookup application guide for the correct channel separator.

- Page 64 Figure 14 Fitting the Separator Install the Connector Block 1. Hold the connector block with the handle positioned to the right in Figure 15. Figure 15 Fitting the Connector Block 2. Place the block lightly over the manifold as shown in Figure 16 making sure that none of the hoses run or are pinched under the block.

- Page 65 Figure 16 Press Block Over the Manifold 3. Lock the connector block in place by moving the handle to the left as shown in Figure 17. Figure 17 Close the Handle WARNING Inspect the seating of the connector block to the manifold. Failure to achieve a proper connection could result in an endoscope that is not disinfected and therefore should not be used on a patient.

- Page 66 Connection of the Endoscope Channels 1. Connect the endoscope channels. The names of the connections of the different channels may be found in the endoscope user manual. See Figure 18 for details on how to hookup the endoscope to the connectors.

- Page 67 WARNING Verify the connection tubing does not interfere with the spray head and confirm that the spray function is working during the cycle. Failure to do this could result in an endoscope that is not disinfected and therefore should not be used on a patient. Figure 19 Sprayer Must Turn Freely...

-

Page 68: Disinfection Process Summary

Disinfection Process Summary The complete reprocessing cycle in the MEDIVATORS ADVANTAGE PLUS Automated Endoscope ® ® Reprocessor is comprised of a number of specific steps designed to ensure proper endoscope disinfection. These steps include: startup, washing, disinfectant, rinse, alcohol, and air phases. All steps must be properly followed and should not be modified beyond manufacturer recommendations. -

Page 69: Run The Disinfection Program

Run the Disinfection Program Normal Start Data entry must be carried out carefully. Each selection or input must be checked and confirmed by the operator. Entering erroneous information may lead to machine faults or inadequate disinfection of an endoscope channel. 1. - Page 70 6. From the Endoscope Selection window, choose the instrument code or endoscope that you wish to disinfect by using the scroll buttons or, bar code reader. Click the OK button. Note: The endoscope code or ID is required for the disinfection program to run. If pre-programmed endoscope codes have been entered by your system administrator, the specific disinfection program for that endoscope is selected automatically.

- Page 71 10. When the Physician Assistant Selection window opens, select the desired name by scrolling with the Scroll Down button, or use the bar code reader. Then click the OK button. Note: The patient code, physician code, and assistant code on your MEDIVATORS ADVANTAGE PLUS ® ®...

- Page 72 Figure 24 Process Window Delayed Start When selecting an delayed start, the endoscope is placed in the basin but the disinfection cycle will not begin until a pre-determined time. This is an administrative function and is available only during the time period as set up and allowed by the system administrator.

- Page 73 3. When the Select the Time window opens, scroll down to select the desired start time and date. Click the OK button. Figure 26 Select the Time 4. The Delay Start program window opens. Verify that the data on the screen is correct, and then click the Start button.

-

Page 74: Cycle Interruptions

Chapter 5: Troubleshooting. 6. The reprocessing cycles is initiated at the selected start time. Cycle Interruptions Introduction At startup and during the disinfection program cycle, the MEDIVATORS ADVANTAGE PLUS ® ®... - Page 75 Program Errors Restarting a Program In a certain instances, a program may be restarted after an error is displayed to restart the program if the following conditions are true: To restart the program: 1. Press the Start button. 2. If the program restarts and progresses without any further errors, the disinfection cycle is valid. 3.

- Page 76 Status: Shutdown The endoscope cannot be removed from the machine. Continue the disinfection program. After the current program is completed, run the disinfection program again. Except for the operator login name, all entered data are automatically copied from the previous run if these steps are followed: 1.

-

Page 77: Taking A Sample Of Disinfectant - Check Mrc

Taking a Sample of Disinfectant – Check MRC At the end of a cycle, the system will prompt to collect disinfectant. 1. Open the center door to access the sample port. 2. Wearing protective gloves, take a sample of the disinfectant from the sample port by pressing a sample cup up against the metal prong. - Page 78 2. If the test strip indicates a fail again, open a new bottle of test strips and test the concentration again with a new test strip. 3. If it continues to fail, contact Medivators Technical Support or your Medivators Distributor.

-

Page 79: Complete The Disinfection Process

Complete the Disinfection Process When the disinfection process is complete, the process LED indicator light blinks green, the message “Completed” displays on the LCD screen, and the alarm sounds. Table 2 Post-Disinfection Program Status Status Description ACTIVE The program is progressing correctly. CORRECT The endoscope was disinfected without any faults or program interruptions. - Page 80 Table 3 Post-Disinfection Instrument Status Status Description DISINFECTED The endoscope was run through a complete disinfection program. NOT APPLICABLE The program is not an endoscope disinfection program. Warning: The endoscope can be used only if the connectors are correctly connected after the program.

-

Page 81: Reports

4. Disconnect the channel adapters 5. Remove the channel separator(s). 6. Take the connector block out of the basin and hang up the block to dry. 7. Take the endoscope out of the basin. 8. If appropriate, fit the valves. 9. - Page 82 All completed cycle logs may be viewed and reprinted at any time from the Management program. 1. Display the Windows desktop by minimizing all running programs. 2. Double click on the MEDIVATORS ADVANTAGE PLUS System ADV icon to open the folder. Figure 29 MEDIVATORS ADVANTAGE PLUS System Desktop Folder...

- Page 83 Figure 30 Management Icon 4. Log in to the Management system. 5. On the Management screen sidebar, click on the General tab. Figure 31 Management Screen 6. On the sidebar, click on the Cycles icon. 7. On the blank Cycle Reports screen, set the From Date and To Date parameters, and then click on the Generate icon in the toolbar.

- Page 84 Figure 32 Cycle Log Screen Figure 33 Cycle Reports Screen 9. The Cycle Details screen appears. Click on the plus sign to the left of each line to expand the report. Click on the printer icon to print a copy of the report.

-

Page 85: Shutdown

Figure 34 Cycle Details Screen Shutdown Use the following process to shutdown the reprocessor at the end of the day. 1. Clean the system by wiping down all surfaces with a non-scouring cleansing agent. Use a lime dissolving, non-scouring agent for the rinse basin and inside the lids. Use soap and water to clean the rubber gaskets. -

Page 86: Procedure Summary

PLUS System when it is not is use. Prolonged Downtime • If the MEDIVATORS ADVANTAGE PLUS System will be unused for more than seven days, it should be powered off. • The tubing, blocks, and filters in the machine contain a lot of water where bacterial growth may occur. -

Page 87: Chapter 4

CHAPTER 4 MAINTENANCE This chapter contains basic service procedures required for maintaining the MEDIVATORS ADVANTAGE ® PLUS Automated Endoscope Reprocessor. Strict adherence to these requirements guarantees optimum ® continuous quality in endoscope reprocessing. Failure to perform required maintenance may result in... -

Page 88: Chapter 4 Daily Maintenance

Verify a sufficient flow of water into the basin or replace the system filters. • Check that all O-rings on the connection columns are present and undamaged. • Replace the screens in the rinse basin if they are soiled. At the end of each day, clean the MEDIVATORS ADVANTAGE PLUS system: ® ®... -

Page 89: Monthly Maintenance

Basin Drain Screen Using a screen hook, remove and clean the screen. Check for wear and replace as needed. Air Filter Replacement The MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor has four (4) air filters. ® ® Each filter should be replaced every 6 months. - Page 90 Figure 1 Filter Location 1. Remove one filter at a time. Move the filter away from the machine to allow access to the fittings. Figure 2 Quick Connect Fitting...

- Page 91 4. Press on Quick Connect fittings to release the filter. Figure 3. Pressing Quick Connect button. 5. Remove and discard the filter assembly. 6. Replace the filter by attaching the Quick Connect fittings. Ensure that the color coded fittings match. 7.

-

Page 92: Water Filter Replacement

The water filtration system removes particulates and biological contaminants as small as 0.1 micron from the supply water. During the water line disinfection procedure, the entire water filtration system and the incoming water line for the MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor ®... - Page 93 Water filters should be replaced at a minimum every three months for the 1.0 micron and 0.4 micron filters and every six months for the 0.1 micron filter. If the water pressure drops below 40 PSI or the difference between the gauges is greater than 5 PSI the corresponding filter needs to be replaced. The following conditions must be met before changing a filter: •...

- Page 94 Figure 6 Filter Cartridges in place 1. Relieve the pressure in the filtration system by opening the bleeder valve on the filter system (rotate down). 2. Check the inlet pressure gauge to ensure that the pressure is at zero. 3. Place an empty container under the 1 micron filter housing and disconnect the Quick Connect fitting at the bottom of the housing.

- Page 95 Figure 8 Remove Housing and Filter 5. Place a new filter in the housing, ensuring that the O-ring is in place. Figure 9 Check O-Ring 6. Thread the housing onto the header and tighten by hand only. 7. Repeat the procedure to replace the 0.4 micron and 0.1 micron filter.

- Page 96 Figure 10 Open Bleed Valve 8. To remove the 0.1 micron filter rotate the used filter cartridge counterclockwise, pull downward, and discard. 9. To install a new 0.1 micron filter insert a new filter cartridge into the housing header and rotate clockwise until the tabs lock into place figure 11.

- Page 97 12. Run the Water Sample Utility • Push Menu button • Log in • Select: Program • Select: Utility Program • Choose: Take Water Sample 13. Place a container under the bleed valve outlet tube and slowly open the bleed valve (13 fig. 4). Let the water run until it is a steady stream.

- Page 98 NOTE...

-

Page 99: Chapter 5

CHAPTER 5 TROUBLESHOOTING This chapter lists error messages you may encounter while using the MEDIVATORS ADVANTAGE ® PLUS Automated Endoscope Reprocessor. If the suggested action does not solve a problem or if the ® error recurs, contact your Technical Service representative. -

Page 100: Chapter 5 Introduction

• System Errors: A communication problem identified by the prefix C with errors ranging from C-001 through C-099. This is an error caused by the Windows based PC or MEDIVATORS ADVANTAGE PLUS system. • Bar Code Errors: A bar code problem identified by the prefix M with errors ranging from M-910 through M-940. - Page 101 Onscreen Program Progress The disinfection program consists of phases and steps. For each disinfection cycle, the phase names, status, and run codes appear on the monitor. Information for the left module appears on the left side of the screen; information for the right module is on the right side. Figure 1 Disinfection Program in Process...

- Page 102 Program Information This field displays operator and endoscope information as well as the normal progress of the disinfection program. The expected end time, on the left, of each window is fixed. Time remaining on the right, is measured from the start of the cycle. This counter normally decreases as a cycle progresses, but may increase or become fixed if an error occurs.

- Page 103 2. MEDIVATORS ADVANTAGE PLUS System PC to an external server (optional) The two left-most fields on the bar indicate if the MEDIVATORS ADVANTAGE PLUS System is connected to the database. The next field to the right indicates if the PC is correctly connected to the MEDIVATORS ADVANTAGE PLUS SCU.

-

Page 104: Error Overview

Error Overview Screen reports and errors are summarized by category and number in the following tables. More specific information including potential causes, and actions for each error are included following that. For complex problems, it is advisable to notify the maintenance department and/or your supervisor. System Errors Code Description... - Page 105 Endoscope Errors Code Description S-102 Start not allowed: vent hookup block S-103 Endoscope leak or connected incorrectly S-104 Minor endoscope leak, cycle continuing safely S-105 Leak test vented but pressure remains high S-106 The block is not pressurized or is not connected S-112 Start not allowed: vent hookup block S-113...

-

Page 106: No Incoming Water Flow

S-155 No pressure: water channel S-156 Water channel disconnected S-157 Water channel disconnected S-162 Start not allowed: vent hookup block S-163 No flow: extra channel S-164 Blocked extra channel S-165 No pressure: extra channel S-166 Extra channel disconnected S-167 Extra channel disconnected S-172 Start not allowed: Vent hookup block S-173... -

Page 107: Water Inlet Flow Too High

S-282 Water inlet flow too high S-283 Water inlet flow too low S-285 No water supply S-286 Volume measurement V1 > V2 S-287 Volume measurement V1 < V2 S-288 Unrequested inlet water detected S-289 External water supply valve failed S-292 Basin temperature sensor defective S-293 Basin temperature too high... - Page 108 Control Errors (SCU) Code Description S-300 SCU message: F.../S…/T… S-301 SCU in “OK” state S-302 SCU : wrong configuration S-304 SCU no connection S-310 Spray arm speed below minimum S-311 Spray arm speed above maximum S-350 Manual control active S-360 Stopped by the operator Warnings Errors Code...

-

Page 109: System Errors

W-821 Disinfectant in supply lines, (Lid locked) System Errors Asi error: %d: %s C-001 Cause: There is a temporary interruption in the connection between the SCU and the MEDIVATORS ® ADVANTAGE PLUS Automated Endoscope Reprocessor machine. ® Action: Check the message at the lower left of the screen. If it says “SCU connected” then the connection has been restored. - Page 110 The clock has been synchronized with the server computer (%s) C-019 Cause: If the MEDIVATORS ADVANTAGE PLUS System clock and the server clock have a time difference of more than 30 seconds, the check will be synchronized. Action: No action is required.

- Page 111 There is a cable fault. • A cable is loose. • There is a program error. • The MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor control ® ® unit is defective. • There is a blown or defective fuse. Action: Contact the maintenance department and the system manager.

- Page 112 If an SCU error occurs, then it is not possible to carry out a correct disinfection cycle. If the error is repaired, then this C-032 message appears and the recovery program is automatically selected. The endoscope is rinsed with water so that it can be safely removed from the MEDIVATORS ADVANTAGE ®...

-

Page 113: Barcode Errors

Internal LIO failure : %s C-099 Cause: A wrong selection was executed when setting the machine system parameters. Action: Report the error to the MEDIVATORS ADVANTAGE PLUS system manager to correct the settings. Then restart the program. Bar Code Errors Unknown barcode... -

Page 114: Endoscope Errors

Cause: The read tag is entered incorrectly or is not reported in the management database. Action: Report the situation to the MEDIVATORS ADVANTAGE PLUS System manager along with a request to add the correct tag code to the endoscope list. - Page 115 If there is a leak, report it to the maintenance department. If the endoscope is not leaking, see other causes of the error below. Cause: Very tiny leak in the leak test system of the MEDIVATORS ADVANTAGE PLUS Automated ®...

- Page 116 Block not pressurized or not connected S-106 Cause: The endoscope is not properly connected. Action: Stop the machine and check if the leak test connections and the terminal block are properly placed. Connect the leak test and block again. Start the program. Cause: Machine fault.

- Page 117 S-113, S-123, S-133, No flow: channel S-143, S-153, S-163, S-173 This report occurs for the following channels: • • Suction • Elevator • Biopsy • • Extra • Water Action: First try the process step again by pressing the Start button.

- Page 118 A hose is detached. Action: Verify all hoses are still connected to the endoscope then start the program again. Cause: Incorrect parameter set. Action: When in doubt or if the wrong parameter is set, report the problem to the MEDIVATORS...

-

Page 119: Reprocessing Cycle Errors

ADVANTAGE PLUS System manager. S-116, S-126, S-136, Channel disconnected S-146, S-156, S-166, S-176 This control checks interconnected endoscope channels and the message is given per channel, i.e.: • • Suction • Elevator • Biopsy • • Extra • Water Cause: There is a connector loose from the endoscope. - Page 120 down for technical service. Wrong connection block S-203 The machine disinfection automatically started and checked whether the hot water block is fitted. Cause: No connection block is present: Action: Place the machine disinfection connection block and then press the Start button.

- Page 121 Action: Report the fault to Maintenance. Alcohol sensor defective S-241 Cause: The alcohol sensor is out of alignment or faulty. Action: Report the fault to the maintenance department Start not allowed: Check alcohol pressure sensor S-242 Cause: The alcohol sensor is out of alignment or faulty. Action: Report the fault to the maintenance department.

- Page 122 Action: Report the fault to instrument service for repairs. Basin suddenly empty S-273 Cause: The drain valve leaks due to contamination. The rinse basin empties during rinsing. Action: Check if there is still any liquid in the basin. If the basin is empty, press the Stop button and report the fault to the maintenance department.

- Page 123 No incoming water flow S-281 Cause: There is water in the rinse basin but the volume is not measured. Action: Press the Stop button. Consult the maintenance department. Water inlet flow too high S-282 Press the Start button to attempt to run the process step again. If the message recurs, press the Stop button.

-

Page 124: Cause: Action

External water supply valve failed S-289 Cause: The water supply valve on the filter unit is leaking, so machine disinfection can not be performed. Action: Report the error to the maintenance department. Basin temperature sensor defective S-292 This error occurs independently of the software and is an extreme situation. Pressing the Stop button has no effect. - Page 125 Air cylinder not discharged (cylinder pressurized) S-832 Cause: The cylinder is used to check connectivity from the endoscope to the MEDIVATORS ADVANTAGE PLUS system. The cylinder can not be vented after the check is performed. Action: Report the error to maintenance.

-

Page 126: Control Errors (Scu)

Control Errors (SCU) S-300 The report codes are as follows: • F = error number • S = step number where the error occurred in the program After an error S-300, the phase is stopped and the program automatically goes to the post-rinse phase (a safe run down process). - Page 127 Error Number Description Additional Details F041 Air channel To control flow, the relevant channel sensor must read high or low for a minimal period of time. A “high” error occurs if a pump F042 Biopsy channel or valve is broken, or if the sensor is defective or blinks. A “low” F043 Jet channel error may be caused by a partially-blocked channel or terminal...

- Page 128 Error Number Description Additional Details F053 Dosing reservoir A not Part A dosing reservoir not emptied at end of delivery empty F054 Dosing reservoir B not Part B dosing reservoir not emptied at end of delivery empty F055 Dosing reservoir A not full Part A dosing reservoir is not full at start of delivery F056 Dosing reservoir B not full...

- Page 129 SCU in “OK” state S-301 SCU : Wrong configuration S-302 The PC communicates with the SCU operation interface in the MEDIVATORS ADVANTAGE PLUS ® ® Automated Endoscope Reprocessor. This interface transmits a signal every 20 msec to check the status of the signal in and out of the PC.

-

Page 130: Warning Errors

Stopped by operator S-360 Cause: During an active program, the Stop button was pressed. Action: The message is automatically stored in the run report. Warning Errors SCU: No connection W-701 Cause: A communication error occurred between the PC and the electronics drive controller. 1. - Page 131 SCU: Incorrect status W-704 Cause: The safety control program rejected the run and the LED is red. Action: Open the cover so the message disappears and the red LED goes out. This takes 4 seconds. The control program is now on stand-by. SCU: in “OK”...

- Page 132 Lid will not close W-713 Action: Press the Start button to close the cover or close the cover carefully by hand and test to see if it moves. Cause: The cover is blocked. Action: See if the blockage can be seen and attempt to remove it if possible. If no blockage can be seen, report the problem to the maintenance department.

- Page 133 Sensor S17 Minimum level high W-744 Cause: There is water in the rinse basin or a sensor defect. Action: Close the cover to allow the basin to run empty. Report the warning to the maintenance department. Sensor S24 : Alcohol high W-749 Cause: A sensor is out of alignment or the alcohol dosage system is clogged.

- Page 134 W-764, W-765, W-766, W-767, Sensor high W-768, W-769, W-770 This message appears when the machine is in stand-by and one of the channel sensors is high. This report occurs for the following channels: • • Suction • Biopsy • • Extra •...

- Page 135 Open lid to complete cycle W-810 Cause: The program is finished. This report indicates how the program needs to be shut down. Action: Press the Open/Close button and follow the instructions on the screen. After selecting the correct operator ID, the cover opens automatically and the program shuts down. Disinfectant in the basin (lid locked) W-820 Cause:...

- Page 136 NOTE...

- Page 137 CHAPTER 6 SYSTEM ADMINISTRATION This chapter is meant for Administrative Use Only. It shows the System Administrator how to setup and manage all process-specific data, along with the daily operations of the MEDIVATORS ADVANTAGE ® PLUS Automated Endoscope Reprocessor machines, server and programs. The System Administrator ®...

-

Page 138: Medivators Advantage Plus

This program runs on every computer with the MEDIVATORS ADVANTAGE PLUS machine connected. 2. Management is the MEDIVATORS ADVANTAGE PLUS System database for user and cycle run information. The system administrator has access to input data, process reports, and manage multiple MEDIVATORS ADVANTAGE PLUS machines. - Page 139 1. Launch the Server Program if it is not already running. 2. Launch the Management program by going to Start > All Programs > MDS > Management, or by double clicking on the Management shortcut in the MEDIVATORS ADVANTAGE PLUS system folder on the computer desktop.

-

Page 140: Management Program

Management Program Structure The Management program is subdivided into general and configuration applications. These are available as links on the management screen. Figure 3 Management Screen... - Page 141 Setup The Management software is delivered with many base settings already established. However, before the MEDIVATORS ADVANTAGE PLUS System can be released for use, the hospital administrator or service technician must enter customer-specific data for the following: • Instruments (if different from those already in the base settings) •...

-

Page 142: Data Management

Note: File the forms in a safe location so that you maintain a record of the passwords that you assign. There is no other method available to retrieve passwords. The following sections provide detailed instructions to assist you in entering data specific for your facility. Navigation The name of a button usually appears if you mouse over it. - Page 143 2. Copy the file(s) to the desired location via Windows Explorer. Importing Data Only MEDIVATORS ADVANTAGE PLUS System-specific files such as program parameter sets, endoscope codes, and user information can be imported. Two file formats are available: • XLS = Microsoft Excel files •...

- Page 144 Figure 4 Import Data Wizard Exporting Data Data can be exported only if the Export Data button is present in the button bar. 1. Click the Export Data button so the Export Dialog screen appears. 2. Using the menu, select the formats appropriate for the application (program) to which the file will be transferred.

-

Page 145: Endoscope Registration

The barcode label for the operator can be placed on the operator’s ID badge or on the barcode scanner shelf mounted on the right side of the MEDIVATORS ADVANTAGE PLUS system. The supplied set is numbered 100 to 199 and includes 2 barcode labels per number. Duplicate barcode labels can be ordered with part number 67199-157. - Page 146 The MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor has different programs ® ® for different types of endoscopes. The objective is to monitor only those channels that are connected, preventing the generation of incorrect failure messages. Each endoscope requires a specific connector block and a specific parameter set.

- Page 147 Figure 6 Endoscope Fields Adding Endoscope Types Before entering data for specific endoscopes, the endoscope types must be entered: 1. Click on the Edit icon to enable editing. 2. Click on the New button at the top of the Endoscopes Type window at the lower left of the screen.

- Page 148 Reference the Hookup Application Guide for the applicable hookup part number and parameter set. Additional parameter sets may be required upon acquiring new or additional endoscopes. To add a new parameter copy the parameter set to the program Files/MDS/Import folder. Open the Management program using the shortcut in the MEDIVATORS ADVANTAGE PLUS Automated ®...

- Page 149 Endoscope Replacement If an endoscope is replaced by a new one, data traceability may be lost. There are two solutions: 1. Consecutively number the endoscope codes. Although the old endoscope is no longer used, the code and data remain stored in the system. 2.

-

Page 150: User (Operator) Registration

User (Operator) Registration Users/Operators Users are the people who have access to the system data and operate the MEDIVATORS ADVANTAGE ® PLUS Automated Endoscope Reprocessor machine. For security and data protection, operator access is ® limited to specific programs and functions. - Page 151 Entering Data Figure 7 Users Screen Adding a New User To add a new user, follow these steps: 1. Click on the Edit icon to enable editing. 2. Click on the Add button to add an empty record at the top of the list. 3.

- Page 152 Changing User Data To modify user data, follow these steps: 1. Click on the Edit icon to enable editing. 2. Select the field to be changed and enter the new information. 3. Click on another line to save the data. 4.

-

Page 153: Physician/Assistant Registration

Bar Code • Type (Physician or Assistant) Note: If an MEDIVATORS ADVANTAGE PLUS System operator assists in a patient examination, then the operator’s name must be registered as an operator and as an assistant. Figure 8 Physician and Assistant Window... - Page 154 Adding Physician Information Doctor and Assistant information is entered by doing the following: 1. Click on the Physician/Assistants icon on the left side of the screen. 2. Click on the Edit icon at the top of the window if editing is turned off. 3.

-

Page 155: Reports

Reports Introduction By clicking on the Runs icon on the left side of the Management General window, program data can be called up. The information is based on the cycles run and data entered. If the database is large, searching specific items may be time consuming. Non-applicable criteria can be excluded. - Page 156 Selecting Report Criteria Time Period Selection 1. Narrow down your search criteria by gathering data from a specific time period. 2. With buttons “from date” and “to date” select the dates for your report. 3. Click on the arrow key to the right of each date window. 4.

- Page 157 7. A selection can be made from: • Assistants • Patients • Endoscope code • Physicians • Operators • Run status • Parameters • Systems • Left or right side of the MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor. ® ®...

- Page 158 Run Report By pressing the Run Report button, the report overview is set up and the report is shown on the screen. 1. Click on the upper blue bar to sort the list in the appropriate column. Click again to reverse the selection.

-

Page 159: Events

Events The Events overview is accessed from the icon on the left side of the Management General screen. 1. The selected time period is set from the buttons “from date” and “to date.” 2. Pressing the Selection button retrieves the overview. 3. - Page 160 Figure 14 Programs Screen The program window shows a list of program folders. The folders are labeled with the following codes: Instrument disinfection programs Recovery program after an interrupted disinfection Water line disinfect parameter sets...

-

Page 161: Systems

To select a specific program, follow these steps: 1. Click the plus sign in front of a folder to view the programs inside. 2. Select the program you want by clicking on the name. 3. Click on the Open File button. 4. - Page 162 MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor machines are selected by ® ® their serial number. This can be found on the name plate inside the front door. To select a machine and its parameters, follow these steps: 1. Select the machine by clicking on the serial number in the System Overview window.

-

Page 163: Lio Expert Operations

ADVANTAGE PLUS System LIO Window ® ® Expert Operation is a special application of the LIO program. It is used to carry out operations that fall outside the normal use of the MEDIVATORS ADVANTAGE PLUS System. ® ® Expert Operation is launched by double clicking on the icon in the upper right of the window. A login... - Page 164 System Figure 17 Unit Left Expert Operation • Selecting either the Unit Left or Unit Right icons allows that half of the system to be monitored and manually operated: • If a sensor sends a signal to an input, the indicator turns green. •...

- Page 165 WARNING The Reset button must be pressed before another program can be started. Figure 18 ASC Window Clicking the ASC icon opens the status overview for the SCU master and safety controller. In the overview, master states are marked gray, green, or red. A state that is gray is inactive, a green state is running OK, and deviations are red.

- Page 166 You can see input and output status onscreen by clicking the In/Outputs icon. The data comes from the IFM-ASi controller in the MEDIVATORS ADVANTAGE PLUS Automated Endoscope Reprocessor ® ® The controller communicates between the MEDIVATORS ADVANTAGE PLUS system and the PC.

-

Page 167: Networking

MEDIVATORS ADVANTAGE PLUS System units on a local area network. One PC, either part of an MEDIVATORS ADVANTAGE PLUS System unit or a separate stand-alone PC, may be used as the Server. The other MEDIVATORS ADVANTAGE PLUS System units are considered Clients of the Server. - Page 168 ® Automated Endoscope Reprocessor as clients connected to a single server PC. It is assumed the PCs are running Windows XP and the MEDIVATORS ADVANTAGE PLUS System PC software has not been installed on any of the machines. Server (Database PC) 1.

- Page 169 18. Install the LIO and Print Service applications from the MDS PC software setup file. Enter the name of the Server PC (MDS-Server) when asked for the “Server name or server ip-address”. 19. Go to the MEDIVATORS ADVANTAGE PLUS System folder in Program Files, click on your right mouse button and select “Sharing and Security…”.

- Page 170 19. Open “My Network Places” from your desktop and click on “Entire Network --> Microsoft Windows Network”. 20. You should see a MEDIVATORS ADVANTAGE PLUS System folder with two PC’s inside (the shared MDS-server and MDS-4010 folder). Server (Database PC) 21.

-

Page 171: Registration Forms

APPENDIX A REGISTRATION FORMS Sample registration forms are provided for system administration functions. - Page 172 NOTES...

- Page 173 MEDIVATORS ADVANTAGE PLUS System ® ® Instrument Registration Form Endoscope code Instrument type Brand Bar code Type code Serial number Internal ID Tag code Date Endoscope code Instrument type Brand Bar code Type code Serial number Internal ID Tag code...

- Page 174 NOTES...

- Page 175 MEDIVATORS ADVANTAGE PLUS System ® ® Operator Registration Form Name Login Name Group Bar code Tag code Staff code Password Date Name Login Name Group Bar code Tag code Staff code Password Date Name Login Name Group Bar code Tag code...

- Page 176 NOTES...

- Page 177 MEDIVATORS ADVANTAGE PLUS System ® ® Physician Registration Form Name Staff code Bar code Specialist or Assistant Date Name Staff code Bar code Specialist or Assistant Date Name Staff code Bar code Specialist or Assistant Date Name Staff code Bar code...

- Page 178 NOTES...

- Page 179 APPENDIX B REPLACEMENT PART NUMBERS...

- Page 180 REPLACEMENT PART NUMBERS Description Order # Accessory Bags CB12-0002 Active Vapor Management Filter MF01-0068 Air Filter (Pkg. 8) MF01-0028 Air Compressor Filter Kit 3-9-452 Basin Drain Filter (Pkg. 12) MF01-0059 Basin Drain Filter Hook (ea.) 5-6-170 Barcode Tags (100-199) 67199-157 Barcode Tags (200-299) 67199-158 Barcode Tags (300-399)

- Page 181 APPENDIX C WARRANTY...

- Page 182 NEW PRODUCT WARRANTY Limited Warranty Subject to the terms below, Medivators Inc. (the “Company”) warrants that its products (the “Products”) will conform to the Company’s written specifications (where applicable) and will be free from defects in material and workmanship under normal use and service for the following periods (the “Warranty Period”): Endoscope reprocessors and associated equipment, and Irrigation Pumps: fifteen (15) months from date of shipment from the Company or one (1) year from the date of installation, whichever occurs first.

- Page 183 CUSTOMER’S REQUIREMENTS. THE COMPANY’S RESPONSIBILITY FOR DEFECTS IN A PRODUCT IS LIMITED SOLELY TO REPAIR, REPLACEMENT OR REFUND OF THE PURCHASE PRICE AS SET FORTH IN THIS WARRANTY STATEMENT. TO THE EXTENT PERMITTED BY LAW, THE COMPANY SHALL NOT, UNDER ANY CIRCUMSTANCES, BE LIABLE TO CUSTOMER FOR CONSEQUENTIAL, INCIDENTAL, INDIRECT, PUNITIVE OR SPECIAL DAMAGES OR LOSSES, INCLUDING WITHOUT LIMITATION, DAMAGES ARISING OUT OF OR IN CONNECTION WITH ANY MALFUNCTIONS, DELAYS, LOSS OF PROFIT, INTERRUPTION OF SERVICE, OR LOSS OF BUSINESS...

- Page 184 Manufactured in the USA by: Medivators BV Cantel Medical Asia/Paci c Pte. Ltd. Cantel Medical Devices (China) Co. Ltd. Medivators Inc. Unit 804-805, Innov Tower Block A, 14605 28th Avenue North Sourethweg 11 1A International Business Park Hongmei Road, Xuhui 200233 Shanghai...

Need help?

Do you have a question about the ADVANTAGE PLUS and is the answer not in the manual?

Questions and answers

How do you reprint the last disinfection cycle?

To reprint the last disinfection cycle log on the MEDIVATORS® ADVANTAGE PLUS® system, follow these steps:

1. Double-click the printer icon in the system tray to redisplay the current cycle log.

2. If needed, access all completed cycle logs through the Management program:

- Minimize all running programs to display the Windows desktop.

- Double-click the MEDIVATORS ADVANTAGE PLUS System ADV icon to open the folder.

- Double-click the Management icon.

- Log in to the Management system.

- Click on the "General" tab in the Management screen sidebar.

- Click on the "Cycles" icon.

This allows viewing and reprinting of previous cycle logs as required.

This answer is automatically generated