Miller LMSW-52 Owner's Manual

Portable resistance spotwelders

Hide thumbs

Also See for LMSW-52:

- Owner's manual (32 pages) ,

- Technical manual (32 pages) ,

- Owner's manual (28 pages)

Summary of Contents for Miller LMSW-52

- Page 1 OM-716 199 981D 2006−04 Processes Resistance Spot Welding Description MSW-41, MSW-41T, LMSW-52, And LMSW-52T Portable Resistance Spotwelders Visit our website at www.MillerWelds.com...

- Page 2 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING ........1-1. - Page 4 Notes...

-

Page 5: Section 1 − Safety Precautions - Read Before Using

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING spotom _7/05 Y Warning: Protect yourself and others from injury — read and follow these precautions. 1-1. Symbol Usage Means Warning! Watch Out! There are possible hazards with this procedure! The possible hazards are shown in the adjoining symbols. -

Page 6: Additional Symbols For Installation, Operation, And Maintenance

D Reduce duty cycle before starting to weld again. D Read Owner’s Manual before using or servic- ing unit. D Use only genuine Miller/Hobart replacement parts. 1-4. California Proposition 65 Warnings Y Welding or cutting equipment produces fumes or gases which... -

Page 7: Principal Safety Standards

1-5. Principal Safety Standards Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1, Code for Safety in Welding and Cutting, CSA Standard W117.2, from from Global Engineering Documents (phone: 1-877-413-5184, website: Canadian Standards Association, Standards Sales, 178 Rexdale www.global.ihs.com). Boulevard, Rexdale, Ontario, Canada... -

Page 8: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION spot_fre7/05 Y Avertissement : se protéger et protéger les autres contre le risque de blessure — lire et respecter ces consignes. 2-1. Signification des symboles Signifie Mise en garde ! Soyez vigilant ! Cette procédure présente des risques de danger ! Ceux-ci sont identifiés par des symboles adjacents aux directives. -

Page 9: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

LIRE LES INSTRUCTIONS. respecter le cycle opératoire nominal. D Réduire le facteur de marche avant de poursui- D Lire le manuel d’utilisation avant d’utiliser ou vre le soudage. d’intervenir sur l’appareil. D Utiliser uniquement des pièces de rechange Miller/Hobart. OM-716 Page 5... -

Page 10: Principales Normes De Sécurité

2-4. Proposition californienne 65 Avertissements Y Les équipements de soudage et de coupage produisent des Pour les moteurs à essence : fumées et des gaz qui contiennent des produits chimiques dont Y Les gaz d’échappement des moteurs contiennent des l’État de Californie reconnaît qu’ils provoquent des malforma- produits chimiques dont l’État de Californie reconnaît qu’ils tions congénitales et, dans certains cas, des cancers. -

Page 11: Section 3 − Introduction

(406 mm) (19.1 kg) (20.4 kg) *Based on 10 second time period; means unit can weld for 5 seconds out of each 10 second time period. Model MSW-41, 41T LMSW-52, 52T 6 in 12 in 18 in 6 in 12 in... - Page 12 B. Dressing The Tips New Tip Used Tip Requiring Dressing Dressing Method − Keep top diameter same as a new tip. d = <1/8 in (3.2 mm) diameter for 1.5 kVA models; 5/32 in (4 mm) for 2.5 kVA models Tools Needed: OM-716 Page 8...

-

Page 13: Installing Or Cleaning Tongs

4-2. Installing Or Cleaning Tongs Y Turn off and unplug welder. Y OSHA and/or local codes may require addi- Be sure tong ends are clean tional guarding to suit the application. corroded before installing. Clean tongs with fine steel wool. Bottom Tong: Bottom Tong Hole In Spatter Guard... -

Page 14: Adjusting Tong And Hand Lever Pressure

4-3. Adjusting Tong And Hand Lever Pressure Tools Needed: 9/16, 11/16 in Ref. ST-800 156 Y Turn off and unplug welder. splash out around the nugget area. To decrease tong pressure, loosen the rear If tong pressure is too weak, parts are nut and turn the front nut up to the pivot cast- Y Excessive tong pressure can dam- loose when the tongs close, severe arc-... -

Page 15: Installing Handle

4-4. Installing Handle MSW 41 And 41T Models MSW 52, And 52T Models Tools Needed: Ref. ST-802 056-A 7/16, 3/8 in Y Turn off and unplug welder. Install handle onto the spot welder as shown above. For 52, and 52T Models, install han- Wodden Handle dle onto either side as desired for either right- Handle Bolt... -

Page 16: Mounting Control Box

4-5. Mounting Control Box Push-in slots are provided on rear of box for wall mounting if desired. The slots will fit over 1/4 inch hex- head screws. To mount box, pro- ceed as follows: Control Box Push-In Slots (Not Shown) Use slots as template and install screws at desired locations leaving 1/8 inch stickout. -

Page 17: Connecting Input Power (Non-T Models)

4-7. Connecting Input Power (Non-T Models) Y Input power supply wiring and receptacle must meet National Electrical Code and all other code requirements. Operate spot welder from a sepa- rately fused or circuit breaker pro- tected circuit, and use correct size input conductors. -

Page 18: Section 5 − Operation

SECTION 5 − OPERATION 5-1. Controls (T Models) Spot Weld Timer And Pilot Light Weld time adjusts from 0 to 5 seconds. The pilot light turns on when the weld cycle begins and off when the cycle ends. Hand Lever Use lever to open and close tongs. -

Page 19: Section 6 − Maintenance And Troubleshooting

SECTION 6 − MAINTENANCE AND TROUBLESHOOTING 6-1. Routine Maintenance Y Disconnect power before maintaining. Every Use 3 Months 6 Months Blow Off Vacuum Replace Inspect Unit Unreadable Tips Labels During Heavy Service, Clean Monthly 6-2. Overload Protection For 220 Volts Model Y Turn Off unit and disconnect input power. - Page 20 Trouble Remedy Clean ends of tongs and tong holders (see Section 4-2). Check power switch (T models only) and/or start switch. Replace if necessary. Longer than normal weld time required. Dress or replace tips (see Section 4-1). Clean workpieces. Adjust tong pressure (see Section 4-3). Clean ends of tongs and tong holders (see Section 4-2).

-

Page 21: Section 7 − Electrical Diagrams

SECTION 7 − ELECTRICAL DIAGRAMS SA-162 466-B Figure 7-1. Circuit Diagram For 110 Volts T-Models SA-072 065-B Figure 7-2. Circuit Diagram For 220 Volts T-Model OM-716 Page 17... - Page 22 SA-162 467-B Figure 7-3. Circuit Diagram For 110 And 220 Volts Non-T Models OM-716 Page 18...

- Page 23 Notes OM-716 Page 19...

-

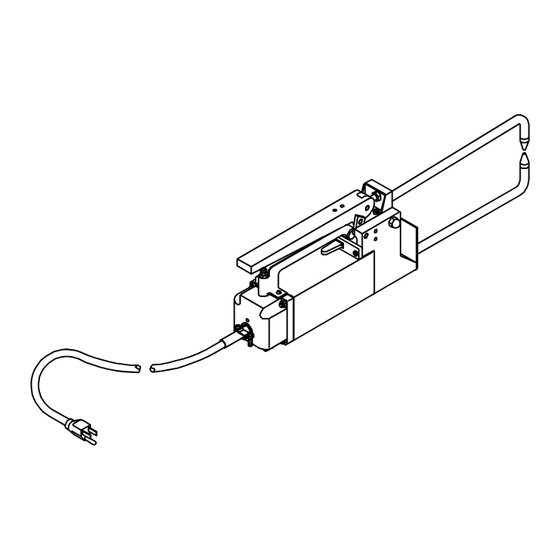

Page 24: Section 8 − Parts List

SECTION 8 − PARTS LIST Hardware is common and not available unless listed. ST-145 048-D Figure 8-1. Main Assembly Quantity Model Item Dia. Part Mkgs. Description 41,41T 52,52T Figure 8-1. Main Assembly ....019 643 HANDLE, carrying . - Page 25 Quantity Model Item Dia. Part Mkgs. Description 41,41T 52,52T Figure 8-1. Main Assembly (continued) ....010 714 PIN, spring CS .312 x 1.750 ......

- Page 26 Replace Coils At Factory Or Factory Authorized Service Station. Quantity Model Item Part Description 41,41T 52,52T Figure 8-2. Transformer, Power Main (Fig 8-1- Item 38) 095 345 095 354 ..026 601 INSULATION .

- Page 27 Quantity Model Item Dia. Part Mkgs. Description 115V 230V Figure 8-3. Timer, Spot (230V Illustrated) 041 081 041 082 ......NAMEPLATE, (order by model and style numbers) .

- Page 28 Figure 8-4. Spot Welder Tips 6” (152 mm) 040 197 3-1/2” (89 mm) Standard Flat 12” (305 mm) 040 198 18” (457 mm) 040 199 STANDARD 040 211 040 212 6” (152 mm) 040 200 3-1/2” (89 mm) Offset 12” (305 mm) 040 201 18”...

- Page 29 Notes...

- Page 30 Notes...

- Page 31 Effective January 1, 2006 (Equipment with a serial number preface of “LG” or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other Warranty Questions? guarantees or warranties expressed or implied. LIMITED WARRANTY − Subject to the terms and conditions...

- Page 32 Contact the Delivering Carrier to: File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. © PRINTED IN USA 2006 Miller Electric Mfg. Co. 2006−01...

Need help?

Do you have a question about the LMSW-52 and is the answer not in the manual?

Questions and answers