Table of Contents

Troubleshooting

Summary of Contents for Miller Electric BLUE STAR 6000 TM-499C

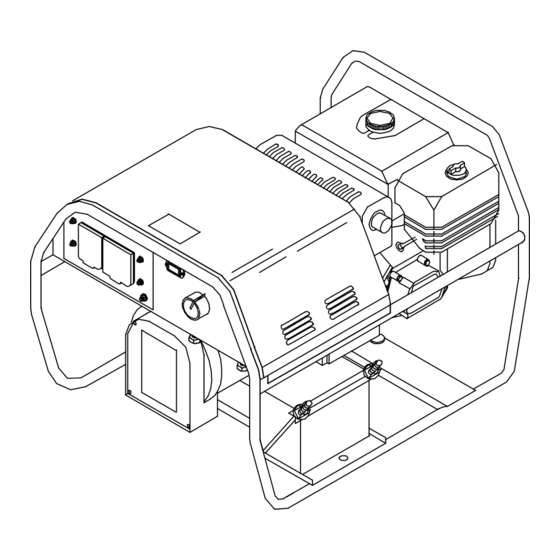

- Page 1 TM-499C August 2004 Eff. w/Serial Number LA124002 (Kohler) Eff. w/Serial Number LB086216 (Honda) Processes Stick (SMAW) Welding Description Engine Driven Welding Generator Blue Star 6000 Visit our website at www.MillerWelds.com...

-

Page 2: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS FOR SERVICING 1-1. Symbol Usage ..............1-2. - Page 3 TABLE OF CONTENTS SECTION 11 − DISASSEMBLY AND REASSEMBLY 11-1. Disassembly Of Unit ..............11-2.

-

Page 5: Section 1 − Safety Precautions For Servicing

SECTION 1 − SAFETY PRECAUTIONS FOR SERVICING 1-1. Symbol Usage Means Warning! Watch Out! There are possible hazards with this procedure! The possible hazards are shown in the adjoining symbols. Y Marks a special safety message. Means “Note”; not safety related. 1-2. -

Page 6: California Proposition 65 Warnings

STEAM AND HOT COOLANT can burn. D If possible, check coolant level when engine is cold to avoid scalding. D Always check coolant level at overflow tank, if present on unit, instead of radiator. D If the engine is warm, checking is needed, and there is no overflow tank, follow the next two statements. -

Page 7: Section 2 − Definitions

SECTION 2 − DEFINITIONS 2-1. Symbol Definitions Engine Choke Engine Oil Positive Hours Circuit Breaker SECTION 3 − SPECIFICATIONS NOTE This unit uses either a Kohler or a Honda engine. Differences between models are noted throughout this manual. 3-1. Weld, Power, And Engine Specifications Rated Welding Weld Output... -

Page 8: Dimensions, Weights, And Operating Angles

3-2. Dimensions, Weights, And Operating Angles Dimensions Height 20-3/4 in (527 mm) Width 22-3/4 in (577 mm) Depth 31-1/4 in (793 mm) 31-1/4 in (793 mm) 10-1/2 in (268 mm) 13-45/64 in (348 mm) 22-3/4 in (577 mm) 1-3/4 in (44 mm) 19-1/2 in (495 mm) 13/32 in (10 mm) Dia. -

Page 9: Fuel Consumption (Honda-Powered Units)

3-4. Fuel Consumption (Honda-Powered Units) 3-5. Duty Cycle 100% Duty Cycle at 100 Amperes CC/DC Continuous Welding 802 122 Duty cycle is the percentage of 10 minutes that unit can weld at rated load without overheating. Y Exceeding duty cycle can damage unit void... -

Page 10: Generator Power Curves

3-6. Generator Power Curves A. 60 Hz Model B. 50 Hz Model TM-499 Page 6 LOAD AMPS LOAD AMPS The generator power curves show the ac power available in amperes at the receptacles. 198 570... -

Page 11: Volt-Ampere Curves

3-7. Volt-Ampere Curves A. 60 Hz Model B. 50 Hz Model LOAD AMPS LOAD AMPS The volt-ampere curve shows the minimum and maximum voltage and amperage output capabilities of the welding generator. Curves of all other settings fall between the curves shown. -

Page 12: Section 4 − Installation

SECTION 4 − INSTALLATION 4-1. Installing Welding Generator Movement Location 4-2. Grounding Generator To Truck Or Trailer Frame Electrically bond generator frame to vehicle frame by metal-to-metal con- tact. TM-499 Page 8 Airflow Clearance 18 in (460 mm) 18 in (460 mm) 18 in (460 mm) -

Page 13: Grounding Generator When Supplying Building Systems

4-3. Grounding Generator When Supplying Building Systems Use ground device as stated in electrical codes. 4-4. Engine Prestart Checks (Kohler-Powered Units) 1/2 in (13 mm) Closed Closed Open GND/PE Full Gasoline Full Equipment Grounding Terminal Grounding Cable Use #10 AWG or larger insulated copper wire. -

Page 14: Engine Prestart Checks (Honda-Powered Units)

4-5. Engine Prestart Checks (Honda-Powered Units) Open 4-6. Connecting The Battery (Electric-Start Models Only) Tools Needed: 3/8, 1/2 in TM-499 Page 10 1/2 in (13 mm) Full Gasoline Full Y Connect negative (−) cable last. Check all fluids daily. Engine must be cold and on a level surface. -

Page 15: Connecting To Weld Output Terminals

4-7. Connecting To Weld Output Terminals Tools Needed: 3/4 in 4-8. Selecting Weld Cable Sizes* Weld Output Terminals Y Stop engine before Welding connecting to weld out- Amperes put terminals. Y Do not use worn, dam- aged, undersized, or poorly spliced cables. This chart is a general guideline and may not suit all applications. -

Page 16: Section 5 − Operating The Welding Generator

SECTION 5 − OPERATING THE WELDING GENERATOR 5-1. Controls (Kohler-Powered Units) 50 Hz 60 Hz Weld and generator power output stops if generator overheats or engine speed is too low. Engine Switch Use switch to open ignition circuit, and to stop engine. -

Page 17: Controls (Honda-Powered Units) (See Section 5-3)

5-2. Controls (Honda-Powered Units) (See Section 5-3) Recoil-Start Electric-Start 60 Hz 50 Hz 802 094-A / 802 095 / 495 187 TM-499 Page 13... -

Page 18: Description Of Controls (Honda-Powered Units) (See Section 5-2)

5-3. Description Of Controls (Honda-Powered Units) (See Section 5-2) Weld and generator power output stops if generator overheats or engine speed is too low. Engine Switch On models with recoil-start, use switch to open ignition circuit, and to stop engine. On models with electric-start, use switch to open ignition circuit, and to start and stop en- gine. -

Page 19: Section 6 − Operating Auxiliary Equipment

SECTION 6 − OPERATING AUXILIARY EQUIPMENT NOTE The welding generator provides power while welding and with the Current control in any position. However, under these conditions equipment connected to the welding generator may be subject to larger than normal voltage fluctuations. It is recommended that only lamps be powered under these conditions. -

Page 20: Optional Generator Power Panels

6-2. Optional Generator Power Panels Generator Power Panel 495 315 Generator Power Panel 495 278 (Canada−CSA) Generator Power Panel 495 289 (Australia) Y If unit does not have GFCI recep- tacles, use GFCI-protected exten- sion cord. Y Power may still be present at a re- ceptacle when a circuit breaker trips. -

Page 21: Generator Power Panel Ratings

6-3. Generator Power Panel Ratings NOTE Unless otherwise stated, the rating of duplex outlets is the combined load of all receptacles. Total power from generator NOT to exceed 5500 Watts (60 Hz) or 5000 Watts (50 Hz) Panel Panel Protected Receptacle 495 218 495 315... -

Page 22: Wiring Instructions For Optional 120/240 Volt Twistlock Plug (Nema L14-30P)

6-4. Wiring Instructions For Optional 120/240 Volt Twistlock Plug (NEMA L14-30P) Tools Needed: 120 V SECTION 7 − MAINTENANCE NOTE Follow the storage procedure in the engine owner’s manual if the unit will not be used for an extended period. 7-1. -

Page 23: Routine Maintenance

7-2. Routine Maintenance Check fluid levels. See Section 4-4 or 4-5 Service air cleaner element. See engine manual. Change oil. See engine manual and maintenance label. Clean Fuel sediment cup. Clean fuel tank and strainer. Repair or replace cracked cables. Recycle engine fluids. -

Page 24: Overload Protection (Honda-Powered Units)

7-3. Overload Protection (Honda-Powered Units) 7-4. Adjusting Engine Speed (Kohler-Powered Units) Top View TM-499 Page 20 Ignition Circuit Breaker (Electric-Start Models Only) The circuit breaker protects the en- gine battery charging circuit. A short circuit or a battery connected in reverse polarity will trip the circuit breaker. -

Page 25: Adjusting Engine Speed (Honda-Powered Units)

7-5. Adjusting Engine Speed (Honda-Powered Units) Tools Needed: 1/4, 3/8 in 1400 150 rpm 3720 50 rpm (60 Hz) 3250 50 rpm (50 Hz) After tuning engine, check engine speeds. See table for proper no load speeds. If necessary, adjust speeds as follows: Start engine and run until warm. -

Page 26: Section 8 − Theory Of Operation

SECTION 8 − THEORY OF OPERATION Engine Supplies force to turn revolving fields. Revolving Field (Rotor) Turns at 3700 rpm maximum (60 Hz) for weld and power. The speed and excitation current of the field coils determine voltages in stator windings. - Page 27 Main Rectifier Voltage Feedback Signal Voltage Feedback Signal Current Feedback Signal Positive (+) Weld Output Terminal Changes ac weld current to dc. 10 Suppressor VR1/R2 Protects SR2 from overload. 11 Stabilizer L1 Smooths weld output current. 12 Shunt Provides weld current feedback to control board PC1.

-

Page 28: Section 9 − Explanation Of Electrical Parts

SECTION 9 − EXPLANATION OF ELECTRICAL PARTS 9-1. Safety Precautions − Read Before Using This Guide Y WARNING: ELECTRIC SHOCK can kill. D Disconnect input power or stop engine before servicing. D Do not touch live electrical parts. D Do not operate machines with covers removed. D Have only qualified persons install, use, or service equipment. - Page 29 PART NAME CLAMP A spring-loaded connection device. A good example would be the “work clamp” used to connect the weld cable from a power source to the workpiece that will be welded. CONTACTOR A heavy duty relay. Usually used to make and break the welding arc or primary power.

- Page 30 PART NAME IGBT A device that is used as an “electronic switch”. When a signal is applied to the gate (G), current is allowed to flow from the emitter (E) to the collector (C). This device is typically used in “Inverter” designed welding machines to control the welding output.

- Page 31 PART NAME MOTOR A device that converts electrical energy into mechanical energy. Typically used to feed wire in a MIG welding system, or pump coolant in a recirculating liquid-cooling system. OPERATIONAL Usually referred to as an “Op-Amp”, this IC AMPLIFIER chip is very versatile and widely used on PC boards.

- Page 32 PART NAME A Silicon Controlled Rectifier (SCR) is an electrical device with three connections, anode, cathode, and gate. It will allow current to flow in only one direction and will only do so after receiving a signal on the gate lead. SCR’s are used to change AC to DC and to control the output to a load such as a welding arc.

- Page 33 PART NAME PRESSURE A change in the pressure of a gas or liquid SWITCH will actuate this switch. TEMPERATURE Typically used to protect engines, this switch SWITCH is actuated by heat. WATER FLOW A switch that is actuated by the flow of a SWITCH liquid.

- Page 34 PART NAME TRANSFORMER A device that changes AC voltage from one magnitude to another. Typically used to reduce high primary voltages to lower welding voltages. TRIAC An electronic AC switch. It is turned on by a gate signal similar to an SCR. TWISTED WIRE Wires are twisted to prevent “electrical noise”...

-

Page 35: Section 10 − Troubleshooting

SECTION 10 − TROUBLESHOOTING 10-1. Troubleshooting Tables Welding Trouble No weld output. Check weld connections. Disconnect equipment from receptacles when starting unit. Check resistance and connections of resistor R3; R3 is 20 ohms 5%. Replace R3 if necessary. Check engine speed, and adjust if necessary (see Section 7-4 or 7-5). Output stops if engine speed is too low. - Page 36 Trouble High weld output. Check Current Control R1 setting. Check engine speed, and adjust if necessary (see Section 7-4 or 7-5). Check resistance and connections of suppressor VR1/R2. R2 is 1000 ohms 5%. Replace VR1/R2 if necessary. Check slip rings, and install new brushes if necessary (see Section 10-7). Check control board PC1 and connections, and replace if necessary (see Section 10-5).

- Page 37 Trouble Disconnect leads 3 and 4 from brushes, and check continuity across slip rings. Replace rotor if necessary. Disconnect stator exciter leads (black) from integrated rectifier SR1, and check continuity between exciter leads. Replace stator if necessary. High power output at ac receptacles. Check engine speed, and adjust if necessary (see Section 7-4 or 7-5).

- Page 38 Trouble Engine stopped during normal Check fuel level (see Section 4-4 or 4-5). operation. Open fuel valve (see Section 4-4 or 4-5). Close fuel valve before moving unit or carburetor may flood and make starting difficult. Check oil level (see Section 4-4 or 4-5). Engine stops if oil level is too low. Check low oil level shutdown switch, and replace if necessary.

- Page 39 Notes Work like a Pro! Pros weld and cut safely. Read the safety rules at the beginning of this manual. TM-499 Page 35...

-

Page 40: Troubleshooting Circuit Diagram For Welding Generator (Use With Section 10-3)

10-2. Troubleshooting Circuit Diagram For Welding Generator (Use With Section 10-3) TM-499 Page 36 V3, R5 See Section 10-4 for waveforms A,B,C,D V6, A, B C, D See Section 8 for PC2 information See also Section 10-5 for PC1 data... - Page 41 197 857-E TM-499 Page 37...

-

Page 42: Test Points And Values (Use With Section 10-2)

10-3. Test Points And Values (Use With Section 10-2) Voltage Readings Tolerance − 10% unless specified Condition − 70 F (21 C); cold machine (no warm-up); no load Weld/power rpm unless specified Reference − single arrow: reference to circuit common (lead 11); double arrow: reference to points indicated Wiring Diagram −... -

Page 43: Waveforms For Section

10-4. Waveforms For Section 10-2 Waveforms shown are for 60 Hertz models; waveforms for 50 Hertz models are similar. 5 ms 50 V A. DC/CC Open-Circuit Voltage, No Load, 60 Hz 5 ms 20 V B. 25 Volts DC, 185 Amperes (Resistive Load), 60 Hz Test Equipment Needed: TM-499 Page 39... -

Page 44: Control Board Pc1 Testing Information

10-5. Control Board PC1 Testing Information Test Equipment Needed: TM-499 Page 40 Be sure plugs are secure before testing. See Section 10-6 for specific values during testing. Receptacle RC5 Receptacle RC4 LED1 LED1 lights when board energized. 802 524 / 198 221-A... -

Page 45: Control Board Pc1 Test Point Values

10-6. Control Board PC1 Test Point Values Receptacle 18 volts ac input with respect to pin 2 18 volts ac input with respect to pin 1 +50 volts dc output with respect to pin 4 −50 volts dc output with respect to pin 3 +200 volts dc input with respect to pin 6 Circuit common Circuit common (shield) for shunt input... -

Page 46: Replacing Brushes And Cleaning Slip Rings

10-7. Replacing Brushes And Cleaning Slip Rings Tools Needed: TM-499 Page 42 1/4 in (6 mm) Or Less − Replace 7/16 in − 1/2 in (11 − 12 mm) New Y Stop engine. Generator End Panel Brush Assembly Brush Holder Brushes Remove end panel. -

Page 47: Checking Unit Output After Servicing

10-8. Checking Unit Output After Servicing Pre-Operational Checks Wipe engine surfaces clean. Check labels; replace labels that are unreadable or damaged. Check fuel and oil (see Section 4-4 or 4-5). Check and correct any fluid leaks. Clean weld output and battery terminals. Tighten connections. Clean outside of entire unit. -

Page 48: Section 11 − Disassembly And Reassembly

SECTION 11 − DISASSEMBLY AND REASSEMBLY 11-1. Disassembly Of Unit TM-499 Page 44 Use Section 10-2 to determine if trouble is in stator, rotor, engine or combination of these components. Remove cover. Mark and discon- nect stator leads. Disassemble in sequence shown. Y Use hoist and lifting strap to carefully remove engine/ generator assembly. -

Page 49: Removing Rotor And Reassembling Generator

11-2. Removing Rotor And Reassembling Generator Removing Rotor Cut screwdriver slot in end of rod. Reassembling Generator 1 in 7-1/2 in (25.4 mm) (191 mm) 5/16 in 24 threads (8 mm) per inch Tools Needed: Y Do not damage rotor or sta- tor windings during this pro- cedure. -

Page 50: Section 12 − Electrical Diagrams

SECTION 12 − ELECTRICAL DIAGRAMS The circuits in this manual can be used for troubleshooting, but there might be minor circuit differences from your machine. Use circuit inside machine case or contact distributor for more information. The following is a list of all diagrams for models covered by this manual. Model Serial Or Style Number Welding Generator... - Page 51 197 857-E Figure 12-2. Circuit Diagram For Welding Generator Eff. w/ Serial No. LA124002 And Following (Kohler) Or LA347885 And Following (Honda) (1 Of 2) TM-499 Page 47...

- Page 52 197 857-E Figure 12-3. Circuit Diagram For Welding Generator Eff. w/ Serial No. LA124002 And Following (Kohler) Or LA347885 And Following (Honda) (2 Of 2) TM-499 Page 48...

- Page 53 197 858-C Figure 12-4. Wiring Diagram For Welding Generator Eff. w/ Serial No. LA124002 And Following (Kohler) Or LA347885 And Following (Honda) TM-499 Page 49...

- Page 54 Apply small amount of conductive electric com- pound (Part No. 603 978) to terminals where factory-applied compound had been present. 201 026-A Figure 12-5. Wiring Diagram For Generator Power Panels Eff. w/ Serial No. LA124002 And Following (Kohler) Or LA347885 And Following (Honda) (1 Of 2) TM-499 Page 50...

- Page 55 Apply small amount of conductive electric com- pound (Part No. 603 978) to terminals where factory-applied compound had been present. 201 026-A Figure 12-6. Wiring Diagram For Generator Power Panels Eff. w/ Serial No. LA124002 And Following (Kohler) Or LA347885 And Following (Honda) (2 Of 2) TM-499 Page 51...

- Page 56 SC-198 222 Figure 12-7. Circuit Diagram For Control Board PC1 Eff. w/ Serial No. LA124002 And Following (Kohler) Or LA033425 And Following (Honda) TM-499 Page 52...

- Page 57 TM-499C August 2004 Processes Stick (SMAW) Welding Description Engine Driven Welding Generator Eff w/LA124002 Thru LB111747 (Kohler Only) For OM-499 (197 850) Revisions * Thru B...

-

Page 58: Section 13 − Parts List For La124002 Thru Lb111747 (Kohler Only)

SECTION 13 − PARTS LIST FOR LA124002 THRU LB111747 TM-499 Page 54 (KOHLER ONLY) Figure 13-1. Main Assembly Hardware is common and not available unless listed. 802 509... - Page 59 Item Dia. Part Mkgs....+495 247 ....495 096 .

- Page 60 Hardware is common and not available unless listed. Generator Power Panel 196 914 (CSA) Generator Power Panel 495 253 (South Africa) Item Dia. Part Mkgs. Figure 13-2. Generator Power Panels (Figure 13-1, Item 39) Generator Power Panel 196 914 (CSA) .

- Page 61 TM-499C August 2004 Processes Stick (SMAW) Welding Description Engine Driven Welding Generator Eff w/LB111748 Thru LC061260 (Kohler) Eff w/LB086216 Thru LC061260 (Honda) For OM-499 (197 850) Revision C...

-

Page 62: Section 14 − Parts List For Lb111748 Thru Lc061260 (Kohler) And Lb086216 Thru Lc061260 (Honda)

SECTION 14 − PARTS LIST FOR LB111748 THRU LC061260 (KOHLER) AND LB086216 THRU LC061260 (HONDA) Hardware is common and not available unless listed. 802 509-A Figure 14-1. Main Assembly TM-499 Page 58... - Page 63 Eff w/LB111748 Thru LC061260 (Kohler) / LB086216 Thru LC061260 (Honda) Item Dia. Part Mkgs....+495 247 ....495 096 .

- Page 64 Eff w/LB111748 Thru LC061260 (Kohler) / LB086216 Thru LC061260 (Honda) Item Dia. Part Mkgs....172 661 ....495 193 .

- Page 65 Eff w/LB111748 Thru LC061260 (Kohler) / LB086216 Thru LC061260 (Honda) Generator Power Panel 196 914 (CSA) Generator Power Panel 495 253 (South Africa) Generator Power Panel 495 219 (USA) Generator Power Panel 495 288 (S. America) Generator Power Panel 495 298 (USA) Hardware is common and not available unless listed.

- Page 66 Eff w/LB111748 Thru LC061260 (Kohler) / LB086216 Thru LC061260 (Honda) Item Dia. Part Mkgs. Figure 14-2. Generator Power Panels (Figure 14-1, Item 39) Generator Power Panel 196 914 (CSA) . . . CB1, CB2 . . . 495 182 ..

- Page 67 TM-499C August 2004 Processes Stick (SMAW) Welding Description Engine Driven Welding Generator Eff w/LC061261 Thru LC552236 (Kohler & Honda) For OM-499 (197 850) Revisions D Thru F...

-

Page 68: Section 15 − Parts List For Lc061261 Thru Lc552236 (Kohler & Honda)

SECTION 15 − PARTS LIST FOR LC061261 THRU LC552236 (KOHLER & HONDA) Hardware is common and not available unless listed. 802 509-A Figure 15-1. Main Assembly TM-499 Page 64... - Page 69 Eff w/LC061261 Thru LC552236 (Kohler & Honda) Item Dia. Part Mkgs....+495 247 ....495 096 .

- Page 70 Eff w/LC061261 Thru LC552236 (Kohler & Honda) Item Dia. Part Mkgs....495 236 ....172 661 .

- Page 71 Eff w/LC061261 Thru LC552236 (Kohler & Honda) Generator Power Panel 495 218 (USA) Generator Power Panel 495 253 (South Africa) Generator Power Panel 495 219 (USA) Generator Power Panel 495 288 (S. America) Generator Power Panel 495 298 (USA) Figure 15-2. Generator Power Panels Hardware is common and not available unless listed.

- Page 72 Eff w/LC061261 Thru LC552236 (Kohler & Honda) Item Dia. Part Mkgs. Figure 15-2. Generator Power Panels (Figure 15-1, Item 39) Generator Power Panel 495 218 (USA) ....495 220 .

- Page 73 TM-499C August 2004 Processes Stick (SMAW) Welding Description Engine Driven Welding Generator Eff w/LC552237 And Following (Kohler & Honda) For OM-499 (197 850) Revisions G And H...

-

Page 74: Section 16 − Parts List For Lc552237 And Following

SECTION 16 − PARTS LIST FOR LC552237 AND FOLLOWING Hardware is common and not available unless listed. 802 509-A Figure 16-1. Main Assembly TM-499 Page 70... - Page 75 Item Dia. Part Mkgs....+495 247 ....495 096 .

- Page 76 Item Dia. Part Mkgs....176 365 ....Figure 16-2 ..

- Page 77 Generator Power Panel 495 218 (USA) Generator Power Panel 495 253 (South Africa) Generator Power Panel 495 219 (USA) Generator Power Panel 495 288 (S. America) Generator Power Panel 495 298 (USA) Hardware is common and not available unless listed. Generator Power Panel 495 315 (USA) Generator Power Panel 495 289 (Australia) Generator Power Panel 495 290 (Europe)

- Page 78 Item Dia. Part Mkgs. Figure 16-2. Generator Power Panels (Figure 16-1, Item 39) Generator Power Panel 495 218 (USA) ....495 220 ..

- Page 79 Notes...

- Page 80 1635 West Spencer Street Appleton, WI 54914 USA International Headquarters−USA USA Phone: 920-735-4505 Auto-Attended USA & Canada FAX: 920-735-4134 International FAX: 920-735-4125 European Headquarters − United Kingdom Phone: 44 (0) 1204-593493 FAX: 44 (0) 1204-598066 PRINTED IN USA 2004 Miller Electric Mfg. Co.

Need help?

Do you have a question about the BLUE STAR 6000 TM-499C and is the answer not in the manual?

Questions and answers