Table of Contents

Advertisement

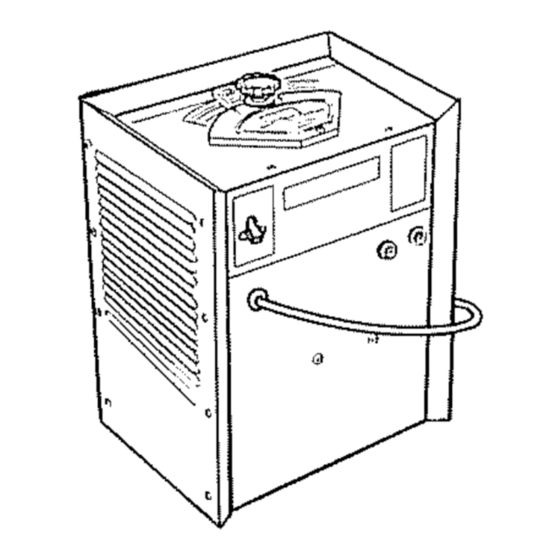

MODEL N_ °

113.201372 _

Serial

Number

Model and serial

number may be found

at the rear

of the cabinet.

You should record both

model and serial number

in a safe place for

future use,

CAUTION:

Read

SAFETY

UNSTRUCTIONS

carefully

230

AMP

DUAL

RANGE

ARC

WELDER

® assembly

e operating

® repair parts

Sold by SEARS,

ROEBUCK

AND

CO., Chicago,

IL 60684

U.S.A.

Part No. 61337

Printed in U S A

Advertisement

Table of Contents

Summary of Contents for Craftsman 113.201372

- Page 1 MODEL N_ ° 113.201372 _ Serial Number Model and serial number may be found at the rear of the cabinet. You should record both model and serial number in a safe place for future use, DUAL RANGE CAUTION: WELDER Read ®...

- Page 2 SAFETY gNSTRUCTIONS TO OPERATOR For your own protection, read and observe all instructions hydrocarbon vapors coming from degreasing, included in this manual as well as the following specific cleaning, or spraying operations The heat of the rays safety precautions: react with solvent vapors...

- Page 3 SECURE _ll!! FULL ONE YEAR WARRANTY ON CRAFTSMAN ELECTRIC WELDER If this Craftsman Electric Welder fails to perform properly, due to a defect in material or workmanship, within one year from the date of purchase, Sears will repair it free of charge,...

- Page 4 UNPACKING CHECKUNG CONTENTS SET-UP INSTRUCTIONS received by the purchaser Remove all items from This Craftsman welder is shipped complete in one carton carton and identify item as shown in the exploded view illustration These "Loose Parts" should be accounted for...

- Page 5 _i_i ii _' 6 Slide the handle back into place on electrode holder and position it until the hole in handle is directly over the head handle locking screw Tighten screw clockwise just enough to secure the Inandle on electrode holder ATTACHING THE WORK CLAMP SCREW...

- Page 6 OPERATnNG CONTROLS _TAL TABLE AT THE SAME TIM REGARDING POTENTIAL SHOCK CABINET The name "dual range" arc welder is derived from the fact CONNECT ONLY A GROUNDING POWER SOURCE that your new arc welder is equipped with two separate CONFORMING TO THE NATIONAL ELECTRICAL...

- Page 7 OPERATING RNSTRUCTIONS We feel that welding with your new Craftsman dual range arc welder is as simple as A B C A Determine what diameter electrode should be used by gauging the piece to be welded on the material thickness...

- Page 8 TROUBLE SHOOTING WARNING: Removal of the welder cabinet top for any reason must be done by a qualified service technician. TROUBLE SHOOTING CHART TROUBLE PROBABLE CAUSE SUGGESTED REMEDY 1. Use 50 ampere fuses of the delayed 1. Improperly fused or Fan and welder do not action type such as "'Fusetron"...

- Page 9 A COMPREHENSIVE GUIDE FOR YOUR NEW CRAFTSMAN ARC WELDER WHAT iT W_LL DO CONTAINS: INFORMATION ABOUT o VARIOUS TYPES OF RODS o USEFUL ACCESSORIES TIPS ON CUTTING, WELDING AND BRAZING ,,,J Form No SP574-4...

- Page 10 IJELD gT Y©U SELF TABLE CONTENTS Page Your WelderandWhat It Will Oo ..... How the CraftsmanContactRodSimplifiesWelding 1-3 What Happens WhenYou Weld? ....ReadBeforaWelding ....... LearnBy Doing ......PositionWelding ......1-11 Cast-IronWelding ......1-14 HardSurfacing WornCutting Edges ..1-15 TheTwin CarbonArc Torch ....

- Page 11 WELDER and what it will do = °. Your CRAFTSMAN Arc Welderis a sturdilyconstructed end thoroughlytestedmachineengineered to give many years of efficient trouble-free service. It is listed by Underwriters' Laboratories, incorporated,which meansthat it passes all requirements of safety,fire hazardand temperaturerise...

- Page 12 READ 5EFORE WELDI NG When operating a welder, certain precautions must be taken to prevent minor injuries to yourself others, Although injuries may not be serious or per- manent, knowing how to use the protective equip- ment to safeguard against them is the first step in learning to weld_...

- Page 13 LEARN BY DOBNG OFWELG OIRECTiON Experience has proven that short periods of practice at first attempting to weld. insert a small, mild-steel welding regular intervals are the best way to teach yourself how electrode in the electrode holder and connect the welding to weld.

- Page 14 Figure 5 Figure Figure 3 Figure 4 To widen the head, work the Fill the crater, when starting To lay a weld bead only two Watch the weld puddle to movements are used, dowfi- a new rod, by striking the red from side to side slight keep the slag from flowing ward and in the direction the...

- Page 15 CURRENTTOO LOW TRAVELTOO FAST Arc is difficult to maintain. Small bead undercut in Vurylittle peflctrationHigh some places. Rough top bead, and little penetration CURRENTTOO HIGH ARC TOO LONG Wide thin bead, undercut, Surface of weld rough Crater pointed and long, Rod melts off in globules Rod hurns off very fast, Arc makes hissing sound.

- Page 16 FLAT WELDING SLIGHT / / St;EEl" GAP / , METAL k___J\ BACK-UP STKIP Figure TACK Figure • WELOS REINFORCEMEHT Figure 5 Flat welding includes all types of joints in which the weld is horizontal, and the electrode is fed down as in the practice Figure 6 welds of previous pages The five types of joints in figure 1 can be welded in the flat position...

- Page 17 Run the first pass on beveled plates with a 5/32-1rich rod and use as high a current as you can handle to obtain a small bead on the underslde_ If this is not done, insufficient UNDERCUT GASPOCKET penetration will result, as shown in figure 11.

- Page 18 SIZE UNBERCUT f _P _,,-CENTER _OF SEAM Figure 8 Figure 9 Figure Figure INTEBMII_ENT WELOS !EXCESS STAGGERED Figure INTER- MITTENT WELOS Figure 16 Figure 17 LAPWELDS WELDON BOTH SIDES LAPWELDS AT ENDOF JOINT Figure Figure will come with experience. If the arc is advanced too fast, should be nearly flat with a slight radius at the sides or or held too close to the vertical plate, undercutting...

- Page 19 _¸ _ POSMTION WELDING weld, run a few practice beads to get the feel of the arc_ Tack-weld a piece of scrap iron to an old practice plate so it is positioned vertlcal]y (fig 3). Use l/B-inch rods for the first welds and a current of about 75 to 115 amperes BUTT WELD Experiment with various amperage...

- Page 20 VERTICAL*UP 90° WELOIHG Figure Figure 4", Figure Use 1/8 and 5/32-1nch rods for all vertical-up welds and weave (fig 9). This will produce a "shelf" upon which additional metal is deposited _ntermlttenfly as the welding start by running practice beads from bottom to top of a progresses.

- Page 21 UHRERCUT F igure Figure DEPOSITMETAL OH GOWHSTROKE OVER-LAPPED I]ACI(-U p STRIP Figure Figure HORIZONTAL WELDING Horlzontal welding refers to one type of butt weld between one side_ if the seam has numerous gaps, use a back-up two plates in a vertlcal plane. For practice, set up a plate strip, albwlng a slight gap between edges of 1/8-inch...

- Page 22 METAL BENDS WHEN COOLED DISTORTION TRENOS Figure WHEN COOLING Egff W[LO [RtH Y_LO Figure Figure 20 Figure Figure surrounding metal is free to move (not clamped or tacked) To simulate actua! conditions tack-weld a piece with an it cannot resist these forces and bends (flg_ 22) irregular edge to another piece leaving numerous gaps...

- Page 23 of the fractured surface to line up the two pieces Tack-weld brush each bead before depositing the next Then continue or clamp parts in position If the crack has not separated to fill the groove with short weld beads as before, working the casting, a vee-groove can be chipped out with a dla- rapidly when depositing and peening the bead Allow plenty mond-polnt...

- Page 24 To prepare the torch for use, connect its two cables to the TRUMB KHOB ground electrode cables of the welding machine. Grounding of the work is not necessary as the operation the arc flame is entirely independenL With the thumb knob CARBORELECTRODES on the handle in the "off"...

- Page 25 bent and edges fused together by melting down the excess metal to form a bead (fig 6) No filler rods are required Figure The carbon-arc torch is ideally suited for brazing soldering small tubing+ Cast and malleable iron can be brazed with excellent results A bronze filler red and common brazing flux are used Rust, paint or grease must be cleaned from the area...

- Page 26 BOLT AND RIVET CUTTING MOVE ROD UPANO--_. Removing rusty bolts or rivets is an easy job with an electric DOWN VERTICALLY _:..., _ _'_ arc welder The arc is struck on the head or nut of the bolt and worked around in a slight circular movement until the head is completely melted off (fig.

- Page 27 The Craftsman, High-Frequency Attachment may be used vapor or liquid cleaners, Files, chisels and stainless wire with any Craftsman welder or other single-phase, trans- brushes may be used Grinding is not recommended, Liquid...

- Page 28 (3) ADD (2) MOVE THE PUDDLE TILLER METAL TORCH DIRECTION _,/,//////////,',/,/,,'/,,////,,/ _/27_ (1) DEV_.LOP OF WELD"._ _///I/I///f////////////J WORE PIECE (5) MOVETORCH ADDITION OF TO LEADING EDGE_ FILLER METAL (VERT CAL -_s°'_ (4) REMOVE R OD OT POD L POSITIO_ _////////////_;///////////_/_ Figure electrodes are alloyed with small percentages...

- Page 29 WELDgNG $PEC FmCATmONS E-6Gll MILD STEEL AC-DC GENERAL APPLICATIONS: Farm Equipment o Sheet Metal o Car and Truck • Body and Fender = Pipe o Tanks o Maintenance o Jigs and Fixtures o Cabinets o General Repairs oStructuralSteel SIZES AND HEATS (AMPS) 1/8"...

- Page 30 E-6013 MBLD STEEL AC-DC multi-purpose all position GENERAL APPLICATIONS: Farm Equipment o Car and Truck o Sheet Metal o Pipe o Tanks e Boilers = Structural Steel o Maintenance Repairs o General Repair Work SIZES AND HEATS (AMPS) 3/32" 118" 5/32"...

- Page 31 WELDWNG SPECIJFICATiONS HARD SURFACING AC-DC medium chrome-carbon electrode GENERAL APPLICATIONS: Tractor Grousers and Rollers o Scraper Blades o Agri- cultural Implements Plow Shares o Hitches • Power Shovel o Dipper Teeth and Drive Sprockets = Coal Cutters e Conveyor Rolls • Mining Buckets •...

- Page 32 Starts on contact with smooth surge-free arc, also restrikes instantly. This Craftsman electrode has powdered iron in the coating which makes welding easier and faster_ The slag is easy to remove in most cases self-peeling as the...

- Page 33 Jm=LDBNG SPECNF CAT ONS MACHINABLE CAST AC-DC machineable welds on all cast irons GENERAL APPLICATIONS: Cylinder Blocks o Crankcases o Valve Seats e Defective Castings o Gears o Sprockets e Casting Repairs in General o Garages o Farms o Shops SIZES HEATS (AMPS)

- Page 34 REPAIR PARTS PARTS LIST FOR CRAFTSMAN 230 AMP WELDER MODEL 113o201372 43 27 45 45 41 27 = Transformer not replaceable°...

- Page 35 PARTS LIST FOR CRAFTSMAN 230 AMP WELDER MODEL 113.201372 Always Order by Part Number - not by Key Number Part I(ey J Part No., Description Description No.. 28 130284 61331 Plate, Selector +Holder, Electrode 61276 51439 +Clamp, Work Spacer 61277...

- Page 36 ISears I 230 AMP DUAL RANGE ARC WELDER SERVICE Now that you have purchased your 230 amp arc welder, should a need ever' exist for' repair parts or service, simply contact Sears Service Center and most Sears, Roebuck and Co. stores. Be sure to provide all pertinent facts when you call or visit MODEL NO.