Advertisement

L_

MODEL NO.

113.23801

LATHE ONLY

MODEL NO.

113.238160

AND

113.238180

LATHE WITH MOTOR

Serial

Number

Model and serial

number may be found

under belt guard.

You should record both

model and serial number

in a safe place for

future use.

CAUTION:

Read

GENERAL and

ADDITIONAL

SAFETY

INSTRUCTIONS

carefully

CRRFTSMRH®

12-/NCH

WOOD-TURNING

LA THE

®assembly

= operating

, repair

parts

Sold

by

SEARS,

ROEBUCK

AND

CO.,

Chica_o,

IL.

60684

U,S,,_._

I

Advertisement

Table of Contents

Summary of Contents for Craftsman 113.238180

- Page 1 MODEL NO. 113.23801 LATHE ONLY MODEL NO. 113.238160 113.238180 LATHE WITH MOTOR Serial CRRFTSMRH® Number Model and serial number may be found under belt guard. 12-/NCH You should record both model and serial number WOOD-TURNING LA THE in a safe place for future use.

-

Page 2: General Safety Instructions

FULL ONE YEAR WARRANTY ON CRAFTSMAN WOOD LATHE " _ :_|f within one year from the date of purchase, this Craftsman Wood Lathe fails due to a defect in material workmanship, Seers will repair it, free of charge. WARRANTY SERVICE... -

Page 3: Safety Instructions

addifiona safety instructions [or wood turning lathes Safety is a combination of operator common sense and Never operate Lathe with protective cover alertness at all times when the Lathe is being used. the unused shaft end of the motor removed. WARNING: FOR YOUR OWN SAFETY,... - Page 4 additional safety instructions for wood turning mathes WARNING': DO :NOT: ALLOW FAMILIARITY WARNING: FOUR STEP LATHE (GAINED FROM FREQUENT USE OF YOUR MOTOR PULLEYS FURNISHED MACHINE) BECOME COMMONPLACE, SIGNED TO RUN THE LATHE AT THE COR- ALWAYS REMEMBER THAT CARELESS RECT SPEEDS WHEN...

-

Page 5: Motor Specifications

motor specifications electrican requirements This power too! is equipped with a 3-conductor cord This Lathe is designed to use a 1725 RPM motor only. Do grounding type plug which has a grounding prong, approved not use any motor that runs faster than 1725... - Page 6 Screw Pan Hd. Ty. A No. 8 x 1/2 ..Wrench, Hex 3/16 ....6" Tool Rest ....Screw. Type 23 Pan 10-32 x 3/8 ..Book{el, How To Operate Nut, Hex 3/4-16 ....Your Craftsman Lathe ..... Spur, Center ....k___.

- Page 7 Position the motor over the mounting holes. NOTE" When using a Craftsman double shaft motor, make sure the 5/8" dia. shaft is to the left when facing the front FOOl the Lathe•...

- Page 8 Re_n_e the: headstock pu_l!ey using the 5/32" set- - = scre_Wrench_ 1-i. Find four pan head thread cutting screws 3/8" long four Iockwashers from among loose parts, : Attach the belt guard with these screws and Iockwash- ere, The arrows in this illustration show the location the screws.

- Page 9 17.Place a straightedge such asapiece o _wood, m etal o r framing square a cross t hepulleys t o see if [heya_e in linewitheach other, t f they are, t ighte_ d_e othe_ * .wo motormounting b olts.If theyarenot in line,toosen thetwomotor bolts andmove themotor s ideways...

-

Page 10: On/Off Switch

2..F_n_ t wo points anda spurand cupcenter a mong t he loose parts. T o insert p ointintocenters, place center between, jaws of a vise. DO not tighten vice. Insert point into center wltfr a hammer nail gently around the base of the point until secure. - Page 11 2. To turn Lathe ON .., _NSERT finger under switch lever and pull END of switch out. 3. To turn Lathe OFF PUSH lever in. Never leave the Lathe unattended until it has come to a complete stop and you have removed the switch key.

-

Page 12: Check Motor Rotation

4. To lock switch in OFF position HOLD switch with one hand, REMOVE key with other hand. WARNING: YOUR OWN SAFETY, WAYS LOCK SWITCH "OFF". WHEN HOLD LATHE IS NOT IN USE ,. , REMOVE KEY AND KEEP IT IN A SAFE PLACE . ..ALSO,.. THE EVENT OF A POWER FAILURE (ALL... -

Page 13: Getting To Know

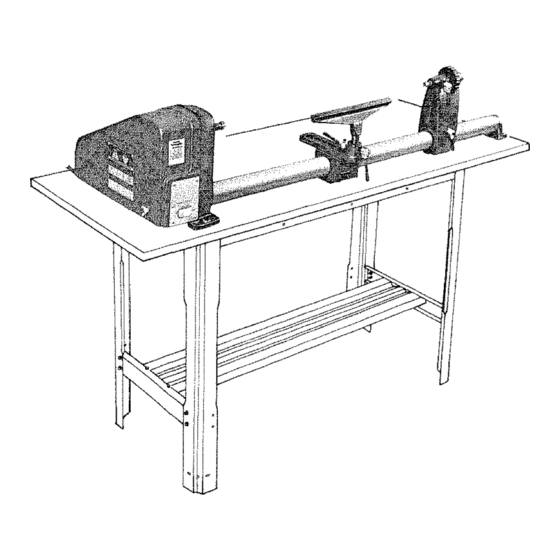

getting to know your wood lathe HANDWHEEL SPUR TAILSTOCK CENTER CUP CENTER SPINDLE LOCK TAILSTOCK 1NDEX HOLE BELT GUARD TOOL REST TOOL REST "_ BASE TOOL BASE 11TAILSTOOK FOOT TAILSTOCK LOCK SPEED TOOL/REST LOCK SWITCH ON-OFF HEADSTOCK BELTGUARD LOC K 4. - Page 14 geffing fo know your wood 10. SPUR:CENTER AND CUP CENTER.. •. are used spindle turning and should always be in alignment. ALIGNING CENTERS If the centers are not in line as shown, make the follow- ing adjustments. I. Make sure the tailstock ram are locked when...

- Page 15 i ¸ 12, SPEED CHART ..Indicates generalrecommended speeds for various sizes of workpieces. basic lathe operations CHANGING SPEEDS The belt is shown positioned on the second steps from ROTATE MOTOR the outside end of the pulleys. This causes the lathe to COUNTERCLOCKWISE PULLEY run 2250...

-

Page 16: Spindle Turning

asnc lathe operatRons "b ¸ , SPINDLE TURNING. If you have never done any amount of wooc turning, we suggest that you practice using the various wood turning tools. Start with a smatl spindle turning; Be sure to study the "'Handbook" which you received with... - Page 17 I/8" Adjust the tool rest approximately 1/8" away from the corners of the wood and 1/8'" above the center line. Note angted position tool rest base. Lock the tool rest base and the tool rest, TOOL REST WOOD Look at the speed chart. Notice that a 2"...

- Page 18 INDEXING spindle pulley contains 36 equalty spaced holes, The index pin engages with these holes to keep the spindle from turning white a mark on the workpiece, example: To locate the position of six spokes in a wheel: 1, Pull the index pin outward and turn it so that the small cross pin slips into the slot, This wilt allow...

-

Page 19: Maintenance

maintenance WARNING: FOR YOUR OWN SAFETY, TURN to keep the surfaces clean and allow the tool rest and taif- SWITCH "OFF" REMOVE PLUG FROM stock to more more freely. POWER SOURCE OUTLET BEFORE MAINTAIN- ING OR LUBRICATING YOUR LATHE. If the power cord is worn or cut, or damaged... - Page 20 :trouble shooting TROUBLE SHOOTING CHART im,,,,,,,,,,, ....... u,,,,,,,,,,,,,,,,,,, PROBABLE CAUSE ......R EM"EDY TROUBLE Motor wilt not run. 1, Defective On-Off switch. 1. Replace defective parts before using Lathe Defective sw:itch cord. again. Defective sw_tch box receptacle. 2, Motor protector open, Consult...

- Page 21 recommended accessories RECOMMENDED ACCESSOR! ES ITEM CAT. NO. Work Bench ..... 9-10266, 9-10278, 9-10271 Motor Pulley (Four Step) I/2"' Bore ..9-27921 Moto_ Pulley (Four Step) 5/8" Bore ..9-27922 Drill Chuck 1/2" Capacity with No. 1 M,T. Shank ....9-22342 Work Arbor...

- Page 22 repair parts...

- Page 23 £ ¢,4 w,,- %..- ,:.o £ • uo %,.- _00oooooo_o ¢oo P... r.. o i'-,., m. ¢0 %..,.r. < Z:53 >_0 .£ < <...

- Page 24 ?2-iNCH owners manual WOOD°TURNING LATHE SERVICE that have purc'nased your 12" Wood-Turning Lathe should a need ever exist repair parts service, simply contact Sears Service Center most Sears, Roebuck and Co. stores. Be sure to provide all pertinent facts when you MODEL NO.