Advertisement

Quick Links

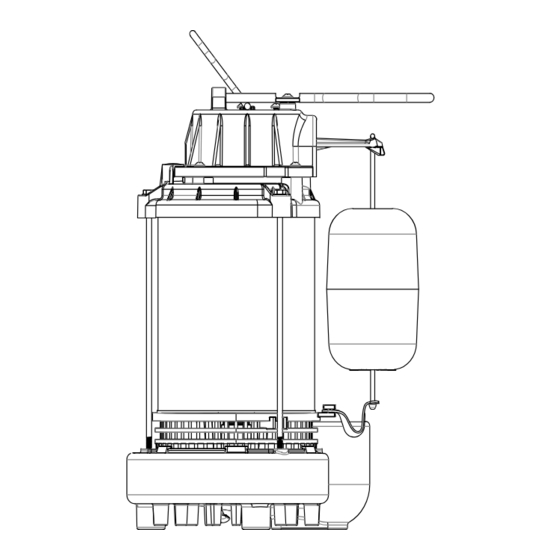

Operating Instructions and Parts Manual

SPECIFICATIONS

POWER SUPPLY REQUIREMENTS

MOTOR

HORSEPOWER

CIRCUIT REQUIREMENTS

DIMENSIONS

ON LEVEL (FACTORY SET)

OFF LEVEL (FACTORY SET)

CONSTRUCTION

MOTOR HOUSING

Stainless Steel

MOTOR SHAFT

Carbon Steel

IMPELLER

Dual Glass Reinforced Thermoplastic

VOLUTE

Cast Iron

PUMP DISCHARGE

1-1/2 in. NPT

PERFORMANCE (Gal/hr)

Discharge Head (Lift Distance)

Model

HP

0 ft

5 ft

1000RSDS

1

6360

5700

500RSDS

1/2

4980

4140

330RSDS

1/3

4440

3780

© 2023, RIDGID TOOL COMPANY

120 V, 60 Hz

Single Phase, Dielectric Oil Filled

1 HP ...............( 1000RSDS )

1/2 HP ............ (500RSDS)

1/3 HP ............ (330RSDS)

15 A (minimum)

12 in. high x 7-1/2in. base (ALL MODELS)

Approximately 9 in. (ALL MODELS)

Approximately 4 in. (ALL MODELS)

10 ft

15 ft

20 ft

4980

4140

3240

3240

2100

720

2940

1920

660

Intended for Indoor Use Only

Dual Suction Sump Pumps

Please read and save these instructions. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property

damage! Retain instructions for future reference.

www.homedepot.com

Dual Suction Series

600004W-005 D 11/23

Advertisement

Summary of Contents for RIDGID Dual Suction Series

- Page 1 0 ft 5 ft 10 ft 15 ft 20 ft 1000RSDS 6360 5700 4980 4140 3240 500RSDS 4980 4140 3240 2100 330RSDS 4440 3780 2940 1920 Intended for Indoor Use Only www.homedepot.com 600004W-005 D 11/23 © 2023, RIDGID TOOL COMPANY...

-

Page 2: Safety Signal Words

INSTALLATION MANUAL DUAL SUCTION SUMP PUMP UNPACKING DESCRIPTION Inspect this unit before it is used. Occasionally, products are damaged during shipment. If the pump or components are damaged, return Sump Pumps are automatic pumps used to remove ground the unit to the place of purchase for replacement, or call Customer water from sump pits. - Page 3 INSTALLATION MANUAL ALWAYS DISCONNECT THE PUMP from power supply before installing, servicing or making any adjustments. TOUJOURS METTRE LA POMPE HORS TENSION avant de procéder à DO NOT USE AN EXTENSION CORD OR SURGE PROTECTOR. Extension l’installation, à l’entretien ou à des réglages. cords and/or surge protectors could present a safety hazard if not DO NOT WALK on the floor when water is present until all power is sized properly, become damaged or the connection falls into the...

- Page 4 INSTALLATION MANUAL IT IS REQUIRED TO USE RIGID PIPING AND FITTINGS to secure the pump in the basin and reduce pump movement. Pump movement can prevent the switch from operating correctly. Do not use flexible hosing. IL EST NÉCESSAIRE D’UTILISER DES TUYAUX ET DES RACCORDS RIGIDES pour fixer la pompe dans le système et réduire les mouvements de la pompe.

- Page 5 INSTALLATION MANUAL TYPICAL SUMP INSTALLATION Vertical Float Submersible Sump Pump 1. This installation must be in accordance with the National Electric Code and all applicable local codes and ordinances. 2. Clean the basin of all debris. 3. Set the pump on a solid, level surface. Do not place pump directly on clay, earth, gravel, or sand.

-

Page 6: Troubleshooting Warnings

INSTALLATION MANUAL TROUBLESHOOTING WARNINGS 1. Submersible pump models have permanently lubricated bearings and require no additional lubrication. 2. Submersible pumps contain dielectric oil for cooling. ALWAYS DISCONNECT THE PUMP FROM POWER SUPPLY before Dielectric oil can be harmful to the environment. Follow state installing, servicing or making any adjustments. -

Page 7: Routine Maintenance

INSTALLATION MANUAL TROUBLESHOOTING (CONTINUED) Symptoms Possible Cause(s) Suggested Remedies Pump trips GFCI 1. Bad GFCI 1. Contact and electrician to replace GFCI 2. Bad pump 2. Replace pump Pump will not 1. Switch 1. Replace pump shut off 2. Switch obstructions 2. -

Page 8: Repair Kits

WARRANTY & SERVICE PARTS SHEET - REPLACEMENT PARTS REPAIR KITS ALL MODELS REF. NO. DESCRIPTION PART NUMBER FLOAT KIT 60038-WYN1... - Page 9 LIMITED WARRANTY For five years for 1000RSDS, 500RSDS, and 330RSDS models from the date of purchase, from an authorized dealer, RIDGID Pumps will repair or replace, at its option for the original purchaser, any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by RIDGID Pumps to be defective in materials or workmanship.