Makita BO3710, BO3711 - Finishing Sander Manual

- Instruction manual (45 pages) ,

- Technical information (7 pages) ,

- Instruction manual (37 pages)

Advertisement

SPECIFICATIONS

| Model | BO3710 | BO3711 |

| Pad size | 93 mm x 185 mm | |

| Abrasive paper size | 93 mm x 228 mm | |

| Orbits per minute (min -1 ) | 11,000 | 4,000 - 11,000 |

| Overall length | 253 mm | |

| Net weight | 1.6 kg | |

| Safety class |  /II /II | |

- Due to our continuing program of research and development, the specifications herein are subject to change without notice.

- Specifications may differ from country to country.

- Weight according to EPTA-Procedure 01/2014

Intended use

The tool is intended for the sanding of large surface of wood, plastic and metal materials as well as painted surfaces.

Power supply

The tool should be connected only to a power supply of the same voltage as indicated on the nameplate, and can only be operated on single-phase AC supply. They are double-insulated in accordance with European Standard and can, therefore, also be used from sockets without earth wire.

Noise

The typical A-weighted noise level determined according to EN62841:

Sound pressure level (L pA ): 72 dB (A)

Uncertainty (K): 3 dB (A)

The noise level under working may exceed 80 dB (A).

Wear ear protection

Vibration

The vibration total value (tri-axial vector sum) determined according to EN62841:

Work mode: sanding metal plate

Vibration emission (a): 3.5 m/s 2 h

Uncertainty (K): 1.5 m/s 2

NOTE: The declared vibration emission value has been measured in accordance with the standard test method and may be used for comparing one tool with another.

NOTE: The declared vibration emission value may also be used in a preliminary assessment of exposure.

The vibration emission during actual use of the power tool can differ from the declared emission value depending on the ways in which the tool is used.

Be sure to identify safety measures to protect the operator that are based on an estimation of exposure in the actual conditions of use (taking account of all parts of the operating cycle such as the times when the tool is switched off and when it is running idle in addition to the trigger time).

FUNCTIONAL DESCRIPTION

Always be sure that the tool is switched off and unplugged before adjusting or checking function on the tool.

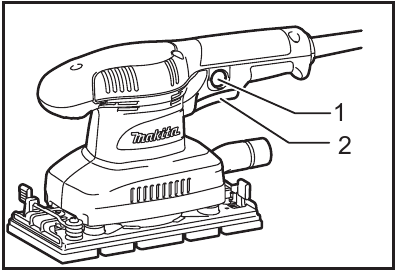

Switch action

- Lock button

- Switch trigger

Before plugging in the tool, always check to see that the switch trigger actuates properly and returns to the "OFF" position when released.

To start the tool, simply pull the switch trigger. Release the switch trigger to stop.

For continuous operation, pull the switch trigger and then push in the lock button.

To stop the tool from the locked position, pull the switch trigger fully, then release it.

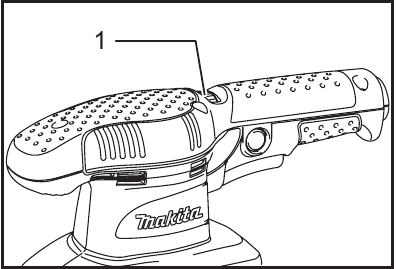

Speed adjusting dial

For BO3711 only

- Speed adjusting dial

- If the tool is operated continuously at low speeds, the motor will get overloaded and heated up.

- The speed adjusting dial can be turned only as far as 5 and back to 1. Do not force it past 5 or 1, or the speed adjusting function may no longer work.

The tool speed can be infinitely adjusted between 4,000 and 11,000 orbits per minute by turning the speed adjusting dial, which is marked 1 to 5. Higher speed is obtained when the dial is turned in the direction of number 5, lower speed is obtained when it is turned in the direction of number 1. Adjust the desired tool speed for the kind of work.

ASSEMBLY

Always be sure that the tool is switched off and unplugged before carrying out any work on the tool.

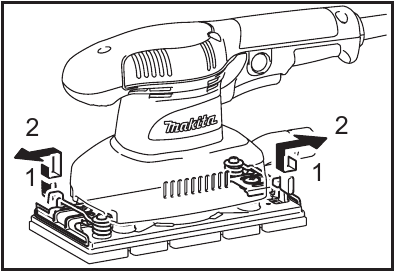

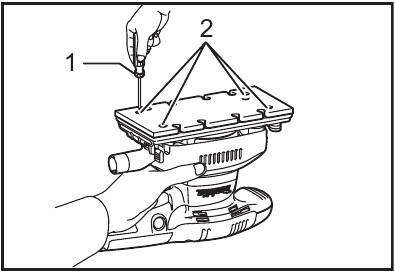

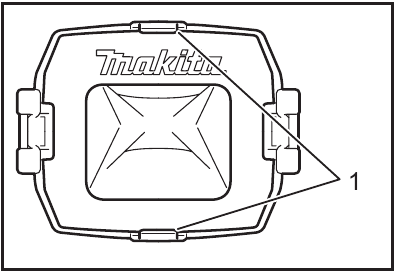

Installing or removing abrasive paper

For conventional type of abrasive paper with pre-punched holes (standard equipment):

Press down the clamp lever (1 in the figure) and with the clamp lever pressed down slide it toward the tool (2 in the figure) and the clamper will be released.

Insert the paper end between a clamper and the pad aligning the holes in the paper with those in pad. Then return the clamp lever to the original position to secure it. Release the other clamp lever by repeating the same procedure. While pulling abrasive paper to maintain the proper tension, insert and secure the other end of abrasive paper between another clamper and the pad and return the clamp lever to the original position.

To remove the paper, release the clamper as stated above.

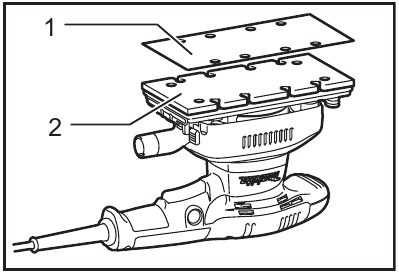

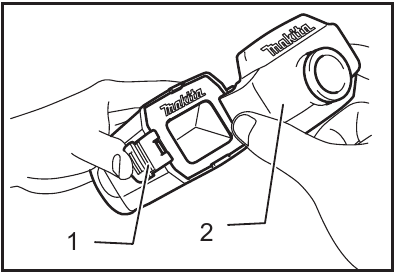

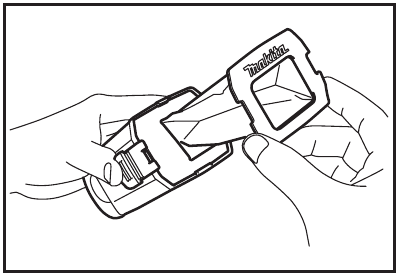

For conventional type of abrasive paper without pre-punched holes (available on the market):

- Punch plate

- Abrasive paper without prepunched holes

Press down the clamp lever 1 and with the clamp lever pressed down slide it toward the tool 2 and the clamper will be released.

Insert the paper end between a clamper and the pad aligning the paper edges even and parallel with the sides of the base. Then return the clamp lever to the original position to secure it.

Release the other clamp lever by repeating the same procedure. While pulling abrasive paper to maintain the proper tension, insert and secure the other end of abrasive paper between another clamper and the pad and return the paper clamp lever to the original position.

Place the punch plate (optional accessory) over the paper so that the guide of the punch plate is flush with the sides of the base. Then press the punch plate to make holes in the paper.

To remove the paper, release the clamper as stated above.

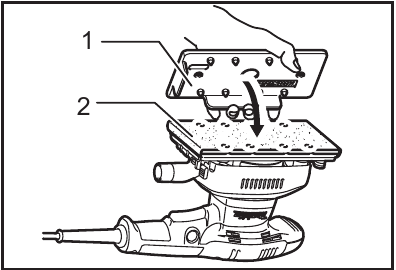

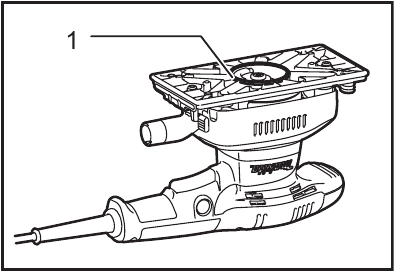

For hook-and-loop type of abrasive paper with pre-punched holes (optional accessory):

Always use hook-and-loop type of abrasive papers. Never use pressure-sensitive abrasive paper.

- Screwdriver

- Screw

Remove the pad for the conventional type of abrasive paper from the tool with a screwdriver. Install the pad for the hook-and-loop type of abrasive paper (optional accessory) on the tool. Tighten the screws firmly to secure the pad.

- Abrasive paper

- Pad

Remove all dirt or foreign matter from the pad. Attach the paper to the pad, aligning the holes in the paper with those in the pad.

- O-ring

When removing the pad, O ring may come out of the tool. When this occurs, return the O ring to the original position and then install the pad.

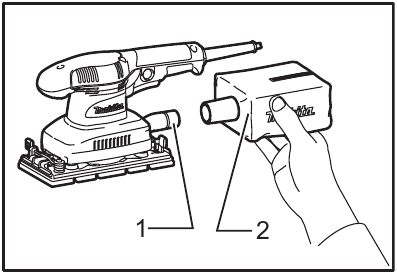

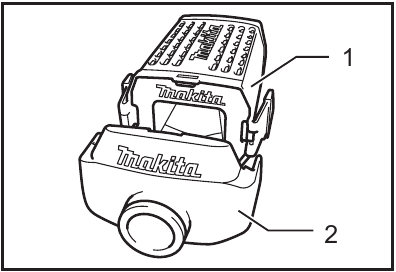

Dust bag

Optional accessory

- Dust spout

- Dust bag

Attach the dust bag onto the dust spout. The dust spout is tapered. When attaching the dust bag, push it onto the dust spout firmly as far as it will go to prevent it from coming off during operation.

For the best results, empty the dust bag when it becomes approximately half full, tapping it lightly to remove as much dust as possible.

Installing filter

Optional accessory

- Holding tab

Make sure that the logo on the cardboard lip and the logo on the dust box are on the same side, then install the filter by fitting the cardboard lip in the groove of each holding tab.

- Dust box

- Dust nozzle

Make sure that the logo on the cardboard lip and the logo on the dust nozzle are on the same side, then install the dust nozzle on the dust box. Removing dust box and filter.

- Latch

- Dust nozzle

Remove the dust nozzle by pushing the two latches.

Remove the filter first by pinching the logo side of its cardboard lip, then by pulling the cardboard lip downwards to move it out of the holding tab of the dust box.

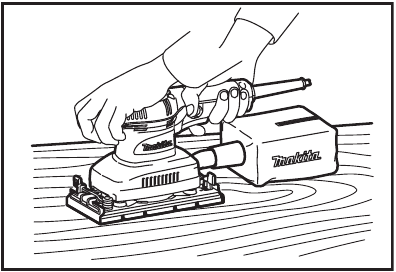

OPERATION

- Never run the tool without the abrasive paper. You may seriously damage the pad.

- Never force the tool. Excessive pressure may decrease the sanding efficiency, damage the abrasive paper or shorten tool life.

Hold the tool firmly. Turn the tool on and wait until it attains full speed. Then gently place the tool on the workpiece surface. Keep the pad flush with the workpiece and apply slight pressure on the tool.

MAINTENANCE

Always be sure that the tool is switched off and unplugged before attempting to perform inspection or maintenance.

NOTICE:

- Never use gasoline, benzine, thinner, alcohol or the like. Discoloration, deformation or cracks may result.

To maintain product SAFETY and RELIABILITY, repairs, carbon brush inspection and replacement, any other maintenance or adjustment should be performed by Makita Authorized Service Centers, always using Makita replacement parts.

OPTIONAL ACCESSORIES

- These accessories or attachments are recommended for use with your Makita tool specified in this manual. The use of any other accessories or attachments might present a risk of injury to persons. Only use accessory or attachment for its stated purpose.

If you need any assistance for more details regarding these accessories, ask your local Makita Service Center.

- Abrasive paper (with pre-punched holes)

- Hook-and-loop type of abrasive paper

- Punch plate

- Backing pad (For use with hook-and-loop type of abrasive paper)

- Backing pad (For use with conventional type of abrasive paper)

- Dust bag

- Dust box

- Filter

- Hose

NOTE:

- Some items in the list may be included in the tool package as standard accessories. They may differ from country to country.

DEVICE SAFETY WARNINGS

- Always use safety glasses or goggles. Ordinary eye or sun glasses are NOT safety glasses.

- Hold the tool firmly.

- Do not leave the tool running. Operate the tool only when hand-held.

- This tool has not been waterproofed, so do not use water on the workpiece surface.

- Ventilate your work area adequately when you perform sanding operations.

- Some material contains chemicals which may be toxic. Take caution to prevent dust inhalation and skin contact. Follow material supplier safety data.

- Use of this tool to sand some products, paints and wood could expose user to dust containing hazardous substances. Use appropriate respiratory protection.

- Be sure that there are no cracks or breakage on the pad before use. Cracks or breakage may cause a personal injury.

SAVE THESE INSTRUCTIONS.

DO NOT let comfort or familiarity with product (gained from repeated use) replace strict adherence to safety rules for the subject product. MISUSE or failure to follow the safety rules stated in this instruction manual may cause serious personal injury.

Documents / ResourcesDownload manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Thank you! Your question has been received!

Need Assistance?

Do you have a question about the BO3710 that isn't answered in the manual? Leave your question here.