Summary of Contents for GE CRxVision

- Page 1 Measurement & Control Technologies Computed Radiography Vision CRxVision Operating Manual V1.2 LL ID 42124462...

- Page 2 Table of Contents CRxVision Operating Manual V1.2...

-

Page 3: Table Of Contents

Preventive Maintenance ....................22 Quality Control ......................22 Environmental Protection ....................23 Safety Directions ......................24 General safety instructions..........................25 Getting started with the CRxVision ...............26 Starting the Digitizer Remote Display ................27 Starting Rhythm RT ......................27 Starting the CRxVision ....................28 Scanning an Image .......................29 Stopping the CRxVision ....................31 Before Switching Off............................31... - Page 4 Operating the CRxVision ................32 Scanning multiple Image Plates..................33 Re-erasing an Image Plate ...................34 Cleaning the Optics Unit ....................35 Troubleshooting ......................38 Digitizer Remote Display ..........................38 Connection Problems ..........................38 Removing a jammed image plate ........................39 Technical Specifications ................42 CRxVision ........................42 Image Plates .........................45...

-

Page 5: Revision History

1 Revision History CRxVision Operating Manual V1.2... - Page 6 Version Date Changes 2013-10-18 Initial version 2013-10-30 Changes after certification 2013-11-07 Adaptations due to new screw type for user accessible parts CRxVision Operating Manual V1.2...

-

Page 7: Introduction To This Manual

2 Introduction to this Manual CRxVision Operating Manual V1.2... -

Page 8: Scope

Scope This manual contains information for safe and effective operation of the CRxVision digitizer system. It describes the basic operation with Rhythm RT. For more details on Rhythm RT or Rhythm RT Lite consult the online manual of the respective application. -

Page 9: Disclaimer

Disclaimer GE Measurement & Control Technologies assumes no liability for use of this document if any unauthorized changes have been made to the content or format. Every care has been taken to ensure the accuracy of the information in this document. -

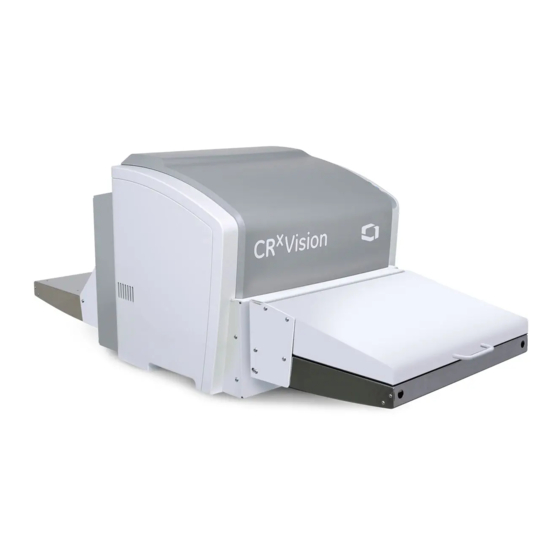

Page 10: Introduction To Crxvision

Intended Use CRxVision: The CRxVision will be used in an industrial environment by qualified staff to scan X-ray or Gamma-ray exposed image plates for non destructive testing applications. It results in a digital image which is sent to the dedicated workstation. -

Page 11: Configuration

IPS for CRxVision IPS2 for CRxVision IPC2 for CRxVision Workstation for image processing and identification. The data transmission is performed via network. Two configurations are possible: Via local network Via point-to-point network connection CRxVision Operating Manual V1.2... -

Page 12: Image Plate Details

* The bottom side looks gray, as the ferromagnetic layer is gray, and the protective coating is transparent. NOTE: The top layer (blue or white) is facing towards the radiation source and needs to be on top when inserting the image plate in the CRxVision for scanning. -

Page 13: Connections

The CRxVision interfaces with the user via: The Power Button The Erase Button The Status Indicator The Digitizer Remote Display for CRxVision status and error messages The Rhythm RT or Rhythm RT Lite graphical user interface CRxVision Operating Manual V1.2... -

Page 14: The Erase Button

After pressing the erase button, the status indicator is continuously lighting up in blue and the CRxVision starts erasing the next inserted image plate. If no image plate has been inserted after 60 seconds, the system automatically returns to standby mode. -

Page 15: Compatibility

Compatibility The CRxVision must only be used in combination with other equipment or components if these are expressly recognized by GE as compatible. Changes or additions to the equipment must only be carried out by persons authorized to do so by GE. Such changes must comply with best engineering practices and all applicable laws and regulations. -

Page 16: Environmental Compliance

Operation Continuous operation Connectivity The CRxVision is connected to the workstation via network connection and uses the DICOM protocol to communicate with the workstation. Training The user must have received adequate training on the safe and effective use of the product before attempting to work with it. -

Page 17: Installation

CRxVision and that it is easily accessible. Caution: If the CRxVision is installed inside of an X-ray room it must be protected from stray radiation by proper shielding. - Page 18 The CRxVision is equipped with two handles at the bottom left and right sides to lift the CRxVision out of the packing and to carry it to another location. Caution: The center of gravity is located in the rear of the CRxVision.

- Page 19 Do not lift the CRxVision by holding the input or output table. Observe the center of gravity, which is located in the rear. When transporting the CRxVision from one location to another, do not lift it at the input and output tables. Observe the center of gravity.

-

Page 20: Labels

Labels Always take into account the markings and labels provided on the inside and outside of the CRxVision. A brief overview of these markings and labels and their meaning is given below. Safety warning, indicating that the CRxVision manuals should be consulted before making any connections to other equipment. -

Page 21: Safety Instructions For Laser Products

Safety Instructions for Laser Products The CRxVision is a Class 1 Laser Product. It uses one laser diode of a 80 mW type, classification class IIIb, wavelength 658 nm. The laser beam’s deflection frequency is 157 Hz (medium resolution mode) or 92 Hz (high resolution mode). -

Page 22: Cleaning Of Image Plates

Preventive maintenance has to be done by a qualified field service engineer. Not performing the regular maintenance by appropriately certified people can have impact on warranty commitments. Quality Control Apply regular quality control according local regulations. CRxVision Operating Manual V1.2... -

Page 23: Environmental Protection

If your equipment or replaced spare parts contain batteries or accumulators please dispose of them separately according to local regulations. For battery replacements please contact your local sales organization. CRxVision Operating Manual V1.2... -

Page 24: Safety Directions

Changes, additions or maintenance to the product carried out by persons without appropriate qualifications and training. Using unapproved spare parts. Caution: Position the CRxVision so that it is possible to disconnect the mains power connection if required. CRxVision Operating Manual V1.2... -

Page 25: General Safety Instructions

Only trained service personnel must make repairs. Only authorized service personnel must make changes to the CRxVision. If there is any visible damage to the CRxVision casing, do not start nor use the CRxVision. Do not override or disconnect the integrated safety features. -

Page 26: Getting Started With The Crxvision

4 Getting started with the CRxVision CRxVision Operating Manual V1.2... -

Page 27: Starting The Digitizer Remote Display

Note: The connection status is either “connected” or “offline”. Starting Rhythm RT Start Rhythm RT and select CRxVision from the available scanner pull down menu. Enter component, technique and study data before proceed with scanning. Change over to the CRxVision Digitizer Interface: Note: For more details on Rhythm RT configuration please consult the online help manual. -

Page 28: Starting The Crxvision

The workstation is running the appropriate acquisition software. Do not insert an image plate if the CRxVision is switched off or starting up. 1. Press the power button. POWER The CRxVision starts the following sequence: ... -

Page 29: Scanning An Image

4. Check that the CRxVision is ready for operation. The status indicator on the CRxVision constantly lights up in green. 5. Put the image plate on the table with the white (IPS / IPS2/ IPC2 for CRxVision) or blue (IPU for CRxVision) side facing up. - Page 30 Rhythm acquisition system by selecting Save All Images. You can close the dialog by selecting the Close option when complete. Be ware that the digitizer acquisition will be cleared on close of the dialog. After successful scan, images can be sent over to Rhythm Review for post processing. CRxVision Operating Manual V1.2...

-

Page 31: Stopping The Crxvision

Stopping the CRxVision Before Switching Off Check that the CRxVision is not scanning an image plate. If the CRxVision is scanning an image plate, the status indicator is blinking green. Switching Off It is recommended to switch off the CRxVision at the end of the day. -

Page 32: Operating The Crxvision

5 Operating the CRxVision CRxVision Operating Manual V1.2... -

Page 33: Scanning Multiple Image Plates

Scanning multiple Image Plates Note: The following images illustrate the CRxVision operation in a dark room condition. Warning: Take care that only image plates with the same sensitivity and type are scanned in multiple mode. Mixing up of different plate types and resolution modes without adaptation of scan parameters may lead to lower image quality. -

Page 34: Re-Erasing An Image Plate

If within one minute no image plate is entered, the CRxVision returns to the standby mode. Put the image plate on the input table with the white (IPS / IPS2 / IPC2 for CRxVision) or blue (IPU for CRxVision) side facing up. -

Page 35: Cleaning The Optics Unit

Cleaning the Optics Unit Cleaning the optics unit is required if stripes parallel to the image plate movement can be seen in the image. When you recognize this type of artifact, when using the CRxVision, clean the optic unit using the cleaning brush. - Page 36 Caution: Damage of the image plate possible if cleaning brush is not in its home position. Always drive back the cleaning brush to the home position. 10. Using the medium size Phillips screwdriver, drive the cleaning brush to its end position and back again. CRxVision Operating Manual V1.2...

- Page 37 11. Remount the CRxVision in reverse order. Note: When mounting the Input Unit take care to insert the two flaps into the frame. 12. Verify the re-mounting by scanning an unexposed image plate. CRxVision Operating Manual V1.2...

-

Page 38: Troubleshooting

Connection status and IP address Connection Problems In case the status indicator of the CRxVision is blinking red, the user should look at the “status” of the Digitizer Remote Display to decide whether CRxVision internal problems or connection problems occurred. -

Page 39: Removing A Jammed Image Plate

Removing a jammed image plate To remove a jammed image plate, proceed as follows: 1. Switch off the CRxVision (A). 2. Disconnect the network cable (B). 3. Disconnect the power cable (C). 4. Turn the handle (D). 5. Remove the output table (E). - Page 40 During operation the Erasure Unit is hot: Risk of burns. Avoid contact with the Erasure Unit. Observe the relevant sticker on the Erasure Unit. 12. Pull out the IP Transport Unit with Erasure Unit. Erasure Unit IP Transport Unit CRxVision Operating Manual V1.2...

- Page 41 After a jam, the image plate can be used again if it is not damaged. After removing a jammed image plate, erase the image plate before the next exposure. 14. Mount in reverse order. 15. Verify the re-mounting by scanning an unexposed image plate. CRxVision Operating Manual V1.2...

-

Page 42: Technical Specifications

CRxVision Model number 5177/100 Original equipment manufacturer Agfa HealthCare N.V., Mortsel - Belgium Labeling CE, cNRTLus, KC, C-Tick, EAC Dimensions 132,0 cm 53,8 cm 47,6 cm 44,9 cm 39,5 cm 36,6 cm 53,8 cm 36,6 cm CRxVision Operating Manual V1.2... - Page 43 22 W configuration During operation 110 V - 240 V / 50- max. 140 W 60 Hz configuration Environmental conditions CRxVision during operation Room temperature recommended: 20 °C - 25 °C allowed: 15 °C - 30 °C Maximum temperature change <...

- Page 44 Environmental conditions CRxVision during transport Climatic conditions CRxVision during IEC 60721-3-2 (1997): class 2K2 transport Mechanical conditions CRxVision IEC 60721-3-2 (1997): class 2M2 during transport Physical emissions Heat emission standby Standby 22 W ≈ 75 BTU/h Peak heat emission scanning 140 W ≈...

-

Page 45: Image Plates

Expose temperature -25 °C to + 55 °C Relative humidity 10 % - 85 % Mechanical conditions for transport In packaging: IEC 721-3-2 (1997): class 2M2 Shock specifications In packaging: IEC TR 60721-4-5 (1997): class 5M2 CRxVision Operating Manual V1.2...