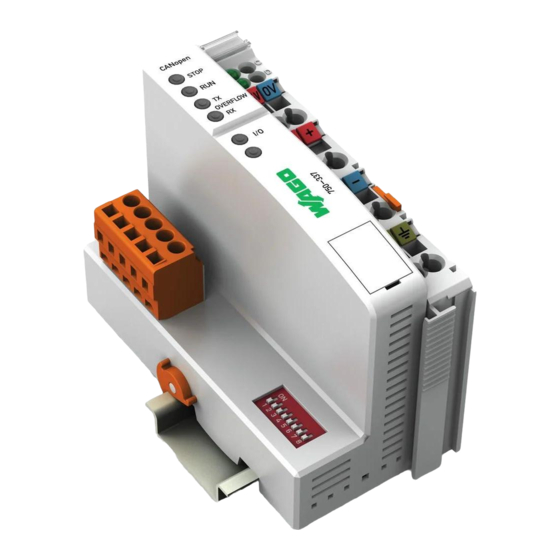

WAGO 750-337 Fieldbus Coupler CANopen Manuals

Manuals and User Guides for WAGO 750-337 Fieldbus Coupler CANopen. We have 2 WAGO 750-337 Fieldbus Coupler CANopen manuals available for free PDF download: Technical Description, Instruction Manual

WAGO 750-337 Technical Description (192 pages)

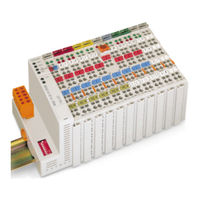

Modular I/O System CANopen

Brand: WAGO

|

Category: I/O Systems

|

Size: 2.12 MB

Table of Contents

Advertisement

WAGO 750-337 Instruction Manual (34 pages)

Connection Procedure of Bus Coupler and Pro-face display units supporting CANopen master for WAGO-I/O-SYSTEM 750

Brand: WAGO

|

Category: Industrial Electrical

|

Size: 0.66 MB

Table of Contents

Advertisement