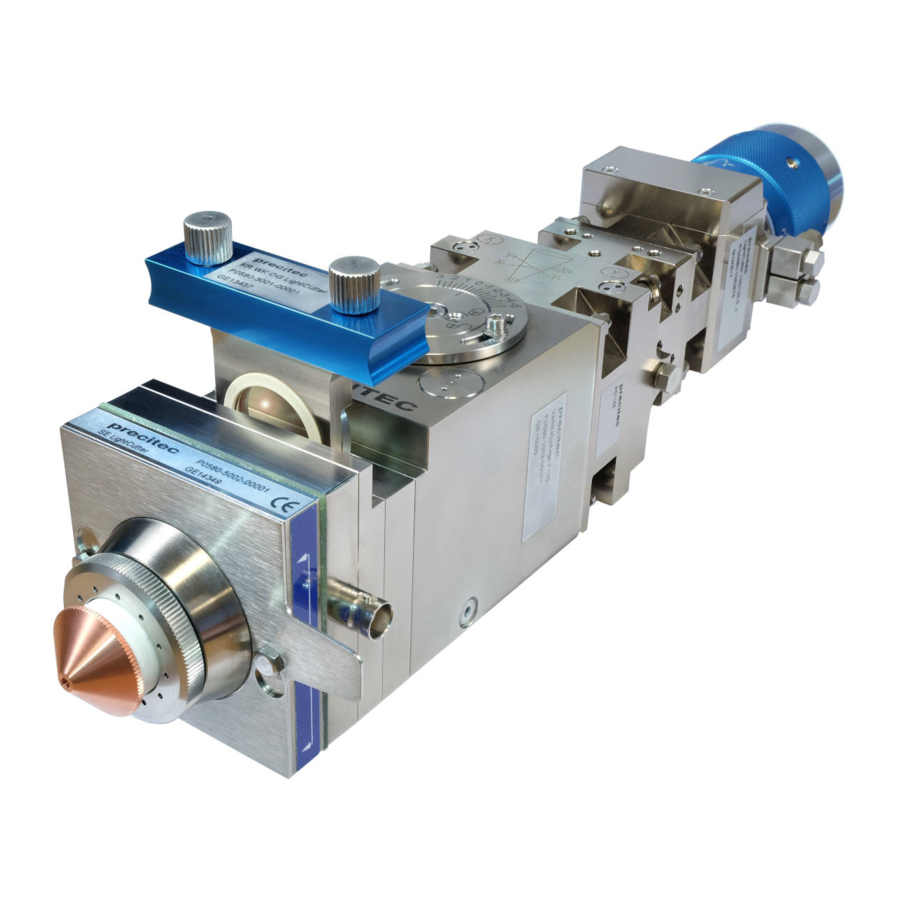

PRECITEC Lasermatic LightCutter Manuals

Manuals and User Guides for PRECITEC Lasermatic LightCutter. We have 1 PRECITEC Lasermatic LightCutter manual available for free PDF download: Operating Instructions Manual

PRECITEC Lasermatic LightCutter Operating Instructions Manual (82 pages)

Cutting head for fibre-coupled lasers

Table of Contents

Advertisement

Advertisement