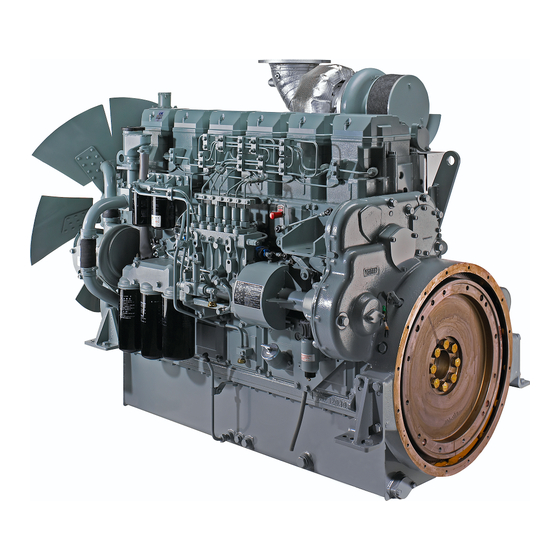

Mitsubishi S6R Series Manuals

Manuals and User Guides for Mitsubishi S6R Series. We have 2 Mitsubishi S6R Series manuals available for free PDF download: Service Manual, Operation & Maintenance Manual

Mitsubishi S6R Series Service Manual (318 pages)

Brand: Mitsubishi

|

Category: Engine

|

Size: 34.41 MB

Table of Contents

-

Section 1

17-

-

Overlap35

-

-

Section 2

36 -

-

-

-

-

-

Tappet - Inspect102

-

Overlap105

-

-

Piston Weight109

-

-

-

-

-

Piston- Install139

-

-

Pickup - Install150

-

-

Tappet - Install152

-

-

-

-

-

-

-

-

Engine - Adjust289

-

Advertisement

Mitsubishi S6R Series Operation & Maintenance Manual (118 pages)

Brand: Mitsubishi

|

Category: Engine

|

Size: 7.16 MB

Table of Contents

-

-

Battery24

-

Left Side29

-

Right Side29

-

Instruments31

-

Start46

-

Run47

-

Stop48

-

Engine Oil53

-

Base Number57

-

Acid Number57

-

Flash Point57

-

Insoluble57

-

Genuine LLC59

-

Fig59

-

-

Check69

-

Basic Engine77

-

Fuel System82

-

Safety Work107

-

Troubleshooting107

-

Output Decrease110

-

Overheating115

-

Oil Filter117

-