Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for SICK CLV 480

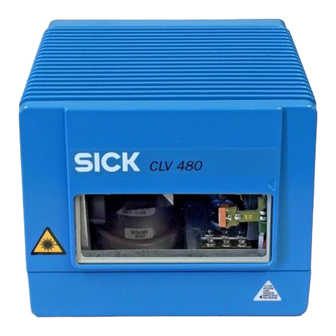

- Page 1 C L V 4 8 0 B a r C o d e S c a n n e r A d v a n c e d l i n e...

-

Page 2: Sick Ag · Division Auto Ident · Germany · All Rights Reserved

Microsoft Corporation in the USA and other countries. Latest manual version For the latest version of this manual (PDF), see www.sick.com. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 3: Finding Information

Chapter 6.4 Configuring (parameterization) the CLV, Page 6-5 • Troubleshooting – Chapter 8 Troubleshooting, Page 8-1 • Finding information – Table of contents, Page I – Index, Page 10 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... - Page 4 18. Save the parameter set as a configuration file "*.scl" in the "CLV-Setup" program. The CLV can then be operated with the application-specific settings. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005...

-

Page 5: Table Of Contents

Mounting the AMV/S 60 Connection Module............4-10 4.4.2 Mounting the external reading pulse sensor............4-10 4.4.3 Installing incremental encoder ...................4-11 4.4.4 Mounting the sensors for detecting the object distance.........4-12 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... - Page 6 Displaying and editing operating data ..............6-36 6.5.7 Reading diagnosis ......................6-36 6.5.8 Monitor Host Interface....................6-37 6.5.9 Auxiliary input........................6-39 6.5.10 Code statistics for RDT 400..................6-39 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005...

- Page 7 CLV.........10-24 10.3.6 Meaning of the LEDs ....................10-25 10.3.7 Error messages ......................10-25 10.3.8 Replacing a CLV......................10-25 10.4 Optional heating........................10-26 10.4.1 Features...........................10-26 10.4.2 Design ..........................10-26 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005...

- Page 8 10.13.1 Angle bracket, single no. 2 013 824..............10-57 10.13.2 Articulated bracket No. 2 018 435..............10-57 10.13.3 Quick clamping device No. 2 016 110............... 10-57 10.14 Supplementary documentation ..................10-58 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005...

- Page 9 CLV 480 Bar Code Scanner 10.14.1 CLV Connect ........................10-58 10.15 Glossary..........................10-59 10.16 EC Declaration of Conformity ..................10-67 10.17 Index ............................10-68 10.18 Bar code example ......................10-73 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005...

- Page 10 Table 5-21: Combination of the functions of the "IN 0" to "IN 4" switching inputs..5-20 Table 5-22: Pin and terminal assignment for "Result 1" to "Result 4" switching outputs ......................5-21 © SICK AG · Division Auto Ident · Germany · All rights reserved I-10 8 010 080/O824/10-02-2005...

- Page 11 Table 10-3: Overview of specification diagrams for the line scanner with oscillating mirror ......................10-2 Table 10-4: External parameter memory ................... 10-22 Table 10-5: CLV system messages....................10-28 © SICK AG · Division Auto Ident · Germany · All rights reserved I-11 8 010 080/O824/10-02-2005...

- Page 12 Table 10-16: Accessories: plug-in connections ................10-55 Table 10-17: Accessories: incremental encoder................10-56 Table 10-18: Accessories: network controller ................10-56 Table 10-19: Supplementary documentation in English language ........10-58 © SICK AG · Division Auto Ident · Germany · All rights reserved I-12 8 010 080/O824/10-02-2005...

- Page 13 ......................9-4 Fig. 10-1: CLV 480-0010/-0011 (line scanner): Reading field height as a function of the reading distance and resolution ............ 10-3 © SICK AG · Division Auto Ident · Germany · All rights reserved I-13 8 010 080/O824/10-02-2005...

- Page 14 Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.50 mm (19.7 mil) and an aperture angle of 50°...........................10-18 © SICK AG · Division Auto Ident · Germany · All rights reserved I-14 8 010 080/O824/10-02-2005...

- Page 15 Fig. 10-39: Copy of the Declaration of Conformity (Page 1, scaled down) ..... 10-67 Fig. 10-40: Scannable bar codes with various module widths (print ratio 2:1)..... 10-73 © SICK AG · Division Auto Ident · Germany · All rights reserved I-15...

- Page 16 Figures and tables Operating Instructions CLV 480 Bar Code Scanner © SICK AG · Division Auto Ident · Germany · All rights reserved I-16 8 010 080/O824/10-02-2005...

-

Page 17: Notes On This Document

For further information on the design of the bar code scanner or on bar code technology in general, please contact the Division Auto Ident at SICK AG. Internet address: www.sick.com. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 18: Symbols

An action must be performed. This symbol characterizes single-step operating instructions. Multiple-step operating instructions are characterized by sequential numbers. Here you select a function of the "CLV-Setup" user interface. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 19: Safety Information

OTC 400 Omni Tracking Controller. Any warranty claims vis-à-vis SICK AG will be rendered invalid if the device is used for any other purpose or if changes are made to the device, also as part of the mounting and electrical installation procedures. -

Page 20: General Safety Instructions And Protection Measures

The additional laser warnings in English applicable to the USA are positioned on the co- ver of the mirror and on the front side of the decive at the bottom. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 21: Fig. 2-1: Laser Warning Labels On The Clv

In the Percentage Evaluation mode, Adjusting mode and Show CP-limits as well as in the Free-running Reading mode the laser diode is constantly activated. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 22: Quick Stop And Quick Restart

(electronic scrap). See also Chapter 7.3 Disposal, Page 7-2. SICK AG currently does not accept delivery of unusable or irreparable devices. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 23: Product Description

(HTML files) – "CLV-Connect" PC software (HTML files showing terminal diagrams) – CLV 480 Operating Instructions in English and German as PDF edition as well as additional publications (connections module, other SICK bar code scanners) – freely available "Acrobat Reader" PC software for reading PDF files... - Page 24 AMV 200-011 (no. 6 021 106) for 18 to 30 V DC, enclosure rating max. IP 65 – or – Alternatively, a non-SICK Power pack with a voltage output of 18 to 30 V DC pursuant to IEC 742 (functional extra-low voltage pursuant to IEC 364-4-41) and a minimum po- wer output of 20 W.

-

Page 25: Product Features And Functions (Overview)

CLV with heater The following are required to start up and operate the CLV 480 with heater: 1. A SICK Connection Module from the AMV 100 or AMV 200 series to provide the power supply and connect the data and function interfaces. - Page 26 Serial terminal interface (RS 232) as auxiliary data interface with special diagnosis and statistics functions • CAN interface for integration in the SICK CAN Scanner Network or a CANopen network, and for OTS operation • 6 switching inputs for external reading pulse, focus control, encoder increment and spe- cial function (teach-in) •...

-

Page 27: Design

Blind hole thread M6, 7 mm (0.28 in) ➏ "I/O" connector, deep, for securing the device 15-pin D Sub HD socket Design of the Fig. 3-1: CLV 480 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 28: Method Of Operation

"CLV-Setup" software or via the host interface/terminal interface using command strings. System and error messages help you to configure the device and to locate the source of errors during startup and reading mode. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 29: Event-Controlled Dynamic Focus Control

(parame- trized) conditions. To separate bar codes of the same type with identical contents, an incre- mental encoder must be connected to the CLV. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 30: Scan Procedure Variants

Due to the V-principle of beam generation, the reading field height is dependent on the reading distance. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 31: Additional Components

The LEDs are located on the rear of the device (Fig. 3-5, Page 3-10). If the optional external parameter memory is connected, the LEDs also indicate whether the memory was successfully accessed. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 32: Table 3-2: Meaning Of Leds: Clv Without External Parameter Memory

"CLV-Setup" program. Download to CLV! TART WITH THE INTERNAL ARAMETERS EVICE ONFIGURATION Table 3-2: Meaning of LEDs: CLV without external parameter memory © SICK AG · Division Auto Ident · Germany · All rights reserved 3-10 8 010 080/O824/10-02-2005... -

Page 33: Table 3-3: Meaning Of Leds: Clv With External Parameter Memory

Page 8-3 2) Stops blinking when you switch from Reading mode to Parameterization mode Table 3-3: Meaning of LEDs: CLV with external parameter memory © SICK AG · Division Auto Ident · Germany · All rights reserved 3-11 8 010 080/O824/10-02-2005... - Page 34 • Blinks bright/dark alternately, in the frequency with which the scan line is (partially) Show CP-limits Sensor Green masked out Table 3-3: Meaning of LEDs: CLV with external parameter memory (contd.) © SICK AG · Division Auto Ident · Germany · All rights reserved 3-12 8 010 080/O824/10-02-2005...

-

Page 35: Installation

(not included in the scope of supply of the CLV) 4.2.3 Required auxiliary parts • 2 screws M6 for securing the SICK mounting bracket to the base. The screw length depends on the wall thickness of the base. • Set of laser warning labels (if necessary) •... -

Page 36: Replacing The Laser Warning Label

The CLV can be mounted at a maximum distance of 1,200 m (3,937 ft) from the host without a connection to the SICK network or a bus. In practice, however, the distance de- pends on the physical configuration of the host interface and the data transfer rate (see Table 5-7, Page 5-9). -

Page 37: Mounting Accessories

Line scanner: Mounting possibilities of the CLV The dimensions of the mounting brackets are shown in Chapter 10.13 Dimensioned draw- ings of the accessories, Page 10-57 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 38: Distance Between The Clv And The Bar Code

Due to the V-principle of beam deflection, the reading field height (for evaluating the useful length of the scan line) depends on the readling distance. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 39: Table 4-1: Permissible Reading Angles Between The Scan Line And Bar Code

The device can only be flush-mounted with the conveyor belt with limited deflection ranges. Otherwise, the device must also be mounted at an angle of 15° to ensure that the deflection ranges are symmetric. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 40: Count Direction Of The Code Position Cp And Code Angle Cw

TFS dialog box is displayed. ARAMETER 3. In the list field, click the CP and/or CW parameters. CP and/or CW then appears in the top line. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 41: Mounting And Adjusting The Device

– The LED is lit continuously if the reading quality is > 90 % The scanning frequency in the default setting is 800 Hz. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... - Page 42 13. Move objects carrying bar codes into the CLV reading field manually under realistic conditions and check the reading result. If the objects are aligned randomly, or if the bar © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005...

-

Page 43: Help Functions For Adjusting The Clv

For activation of this operating mode and for checking, See Chapter 6.5.4 Show CP-limits, Page 6-30. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 44: Mounting The External Components

Bar code at the start of the object (Top view) b < a b < a Fig. 4-10: Line scanner: mounting example for the external reading pulse sensor © SICK AG · Division Auto Ident · Germany · All rights reserved 4-10 8 010 080/O824/10-02-2005... -

Page 45: Installing Incremental Encoder

3. Connect incremental encoder to "IN4" switching input of the CLV. See Chapter 5.5.8 Connecting the "IN 0" to "IN 4" switching inputs, Page 5-18. © SICK AG · Division Auto Ident · Germany · All rights reserved 4-11 8 010 080/O824/10-02-2005... -

Page 46: Mounting The Sensors For Detecting The Object Distance

Chapter 4.3.2 Adjusting the CLV, Page 4-7, choose the standard deco- der and start Percentage Evaluation mode temporarily. 7. Perform a temporarily download to the CLV. © SICK AG · Division Auto Ident · Germany · All rights reserved 4-12 8 010 080/O824/10-02-2005... -

Page 47: Dismantling The Device

When removing the device from service for the last time, please dispose of it in an environmentally-friendly manner, as described in Chapter 7.3 Disposal, Page 7-2. © SICK AG · Division Auto Ident · Germany · All rights reserved 4-13 8 010 080/O824/10-02-2005... - Page 48 Chapter 4 Installation Operating Instructions CLV 480 Bar Code Scanner Notes © SICK AG · Division Auto Ident · Germany · All rights reserved 4-14 8 010 080/O824/10-02-2005...

-

Page 49: Electrical Installation

Electrical installation Installation sequence • Connect the CLV to a SICK Connection Module from the series AMV/S, BMV/BMH 10 or BMS 20, or using a customer-specific wiring configuration • Connect the data and function interfaces of the CLV in the module •... -

Page 50: Electrical Connections And Cables

Table 5-2: Cables for connecting the CLV For technical data on the cables, see Chapter 10.12.4 Cables, external parameter memo- ries and plug cover, Page 10-53. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 51: Connections/Cables For The Amv/S 60 Connection Module

The module can be used to establish a connection to the host (point-to-point) or integrate the device in a SICK network or daisy-chain configu- ration (pass-through or master/slave configuration). The module is available in several vari-... -

Page 52: Connections/Cables For The Bus Connection Modules

Operating Instructions for the "BMV/BMH 10 for Ethernet Connection Module" (no. 8 009 398) • Technical Information for the "BMS 20 for Interbus-S Bus Connection Module" (no. 8 007 546) © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 53: (Connection To Amv/S Or Bmv 10/Bms 20)

CLV terminals, but without wires for CAN interfaces), no. 2 021 298 • With two open cable ends, without wires for CAN interfaces, no. 2 021 267 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... - Page 54 –40 °C (–40 °F). Recommendation Use the external parameter memory no. 2 020 267 (open cable ends) for connecting the device to non-Sick Power packs/wiring configurations. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005...

-

Page 55: Connector Pin Assignment

1) Pin 1 is jumpered with Pin 1 of the "Host/Term" connection in the CLV Table 5-4: Pin assignment of the 15-pin D Sub HD "I/O" socket © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 56: External Parameter Memory No. 2 020 307/No. 2 021 689/No. 2 027 543

1) Pin 1 is jumpered with Pin 1 of the "Host/Term" connection in the CLV 2) not connected Table 5-6: Pin assignment of the 15-pin D Sub HD "I/O" cable socket © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 57: Preparations For Electrical Installation

Power-up delay The selected device number (default: 1) affects the power-up delay of the device. This is useful if a large number of CLVs (e. g. in the SICK network) are to be supplied from one power source. Table 5-9 contains a list of the available intervals. -

Page 58: Non-Sick Power Supply Unit/Connections Without The Connection Module

5.4.3 Non-SICK Power supply unit/connections without the Connection Module Power output If an non-Sick Power supply unit is used instead of the AMS 60, it must be capable of providing the following voltage and power values: • For CLV without heater: 18 to 30 V DC, min. 20 W continuous power output •... -

Page 59: Table 5-11: Wire Color Assignment Of The Cable No. 2 020 264

2 020 981. Connect the free cable ends accordingly. The wire color assignments are shown in Table 5-12 Table 5-13. CLV with heater: Available on request. © SICK AG · Division Auto Ident · Germany · All rights reserved 5-11 8 010 080/O824/10-02-2005... -

Page 60: Table 5-12: Wire Color Assignment Of Cable 1 For External Parameter

1) Pin 1 is jumpered with Pin 1 of the "Host/Term" connection in the CLV Table 5-13: Wire color assignment of cable 2 for external parameter memory no. 2 020 981 © SICK AG · Division Auto Ident · Germany · All rights reserved 5-12... -

Page 61: Table 5-14: Wire Color Assignment Cable 1 For Connector Cover No. 2 021 267

Grey-brown TxD (RS 232), Host – – Shield Orange Table 5-15: Wire color assignment cable 2 for connector cover no. 2 021 267 © SICK AG · Division Auto Ident · Germany · All rights reserved 5-13 8 010 080/O824/10-02-2005... -

Page 62: Electrical Installation Procedure

5.5.3 Connecting the supply voltage a) SICK AMV/S and BMV 10 Connection Modules If the CLV is powered via the SICK Connection Modules, the supply voltage does not have to be wired separately. Connecting the CLV without external parameter memory: 1. -

Page 63: Connecting The Host Interface

RS 422 RS 485: Connection diagram for SICK Network see "CLV Connect" program on CD-ROM CAN-Network: Connection diagram for SICK CAN Scanner Network see "CLV Connect" program on CD-ROM Fig. 5-2: Connecting the host interface Risk of damage to the interface module Electrical components in the CLV may be damaged if the host interface is connected incorrectly. -

Page 64: Connecting The Can Interface

Instructions for the connection of CAN-interface 1 and for configuration of the CLV to use the device in the SICK-specific CAN Scanner Network or in a CANopen network see the Operating Instructions “Application of the CAN interface“ (no. 8 009 180, English edition). -

Page 65: Connecting The "Sensor" Switching Input

Operating Instructions Electrical installation Chapter 5 CLV 480 Bar Code Scanner 3. Switch on the PC and power supply to the SICK Connection Module. 4. Set the communication parameters (see Chapter 10.6.3 Starting CLV-Setup, Page 10-32). In the default configuration, the terminal interface outputs the reading result in reading diagnosis mode. -

Page 66: Connecting The "In 0" To "In 4" Switching Inputs

= +18 to +30 V DC for CLV without heater, 24 V DC +20 % /–10 % for CLV with heater for IN X see Table 5-18 Fig. 5-5: Connections of the "IN 0" to "IN 4" switching inputs © SICK AG · Division Auto Ident · Germany · All rights reserved 5-18 8 010 080/O824/10-02-2005... -

Page 67: Table 5-18: Pin And Terminal Assignment For "In 0" To "In 4" Switching Inputs

DC 1 1 0 1 0 1 N 22 DC 8 DC 1 Table 5-20: Dynamic focus control: switching inputs/distance configuration assignment table © SICK AG · Division Auto Ident · Germany · All rights reserved 5-19 8 010 080/O824/10-02-2005... -

Page 68: Table 5-21: Combination Of The Functions Of The "In 0" To "In 4" Switching Inputs

GURATION Click the A 3 and I 4 drop-down list and choose the required SSIGNMENT OF NPUTS function. Download all changes to CLV. © SICK AG · Division Auto Ident · Germany · All rights reserved 5-20 8 010 080/O824/10-02-2005... -

Page 69: Connecting The "Result 1" To "Result 4" Switching Outputs

Table 5-23: Characteristic data of the "Result 1" to "Result 4" switching outputs Note If the "Device Ready" function is chosen, the CLV outputs a static pulse in Reading mode. © SICK AG · Division Auto Ident · Germany · All rights reserved 5-21 8 010 080/O824/10-02-2005... - Page 70 To check the switching functions using a high-impedance digital voltmeter, connect a load to the outputs to prevent incorrect voltage values/switching statuses from being displayed. © SICK AG · Division Auto Ident · Germany · All rights reserved 5-22 8 010 080/O824/10-02-2005...

-

Page 71: Operation

CLV-Setup prints out the complete set of default settings in the form of a table. The header contains the company and user names that were entered during the CLV-Setup installation routine. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 72: Default Settings Of The Line Scanner Clv 480 (All Variants)

Fixed position 50 CW (corresponds to an angle of deflection of 105°) Table 6-2: Extract: Default parameter settings of the line scanner with oscillating mirror CLV 480 © SICK AG · Division Auto Ident · Germany · All rights reserved... -

Page 73: Quick Start

The device can be switched off without the configuration data being lost as no changes have been made to the parameter set. Fig. 6-1: Bar code pattern (Code 39; module width 0.35 mm (13.8 mil); Print ratio 2:1) © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 74: Table 6-3: Reading Distances For Default Settings

1,000 mm (39.4 in) CLV 480 (all variants) Line scanner with oscillating mirror approx. 1,000 mm (39.4 in) Table 6-3: Reading distances for default settings © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 75: Configuring (Parameterization) The Clv

CLV, this first has to be loaded to CLV-Setup from the CLV. This procedure is referred to as an upload ("Upload from CLV" in the CLV 480 menu or [F3] key) during which CLV-Setup always loads a complete copy of the current CLV parameter set. - Page 76 2. Enter the file name in the dialog box (file name extension "*.scl") and confirm the entry. The new parameter set is now stored in CLV-Setup in the subdirectory "data". © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005...

-

Page 77: Function Of The Tabs In Clv-Setup (Overview)

Active physical interface (RS 422/485 or RS 232) • Data format and transmission rate • Data transmission protocol • Start and stop characters of the interface protocol © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... - Page 78 CLV-Setup Online Help contains a detailed description of the functions of the parameters and their valid entries (see Chapter 10.6.8 CLV-Setup Help, Page 10-36 for calling up Help). © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005...

-

Page 79: Guide To Parameterization Menu

The minimum and maximum values for the active evaluation range of the scan line (M ) can be checked in the S mode. OSITION LIMITS Chapter 6.5.4 Show CP-limits, Page 6-30. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 80: Table 6-5: Guide: Parameterizing Oscillating Mirror Functions

SCILLATING IRROR section RIGGER – Reading Trigger Pulse or – Switching input or – Serial Interface Table 6-5: Guide: Parameterizing oscillating mirror functions © SICK AG · Division Auto Ident · Germany · All rights reserved 6-10 8 010 080/O824/10-02-2005... -

Page 81: Fig. 6-2: Oscillating Mirror: "Oscillating With Fixed Amplitude" Mode

The minimum/maximum values that can be set for the deflection range for fast applications ensure that the scan line only sweeps areas that © SICK AG · Division Auto Ident · Germany · All rights reserved 6-11... -

Page 82: Fig. 6-3: Oscillating Mirror: "Oscillating With Variable Amplitude" Mode

Possible trigger sources for One-Shot: • "IN 3" or "IN 4" switching input • Command string (via serial interface) • Start of reading interval © SICK AG · Division Auto Ident · Germany · All rights reserved 6-12 8 010 080/O824/10-02-2005... -

Page 83: Fig. 6-4: One-Shot: Object Tracking (Bar Code Read From Front)

Line scanner Reduced reading range through One-Shot function Line scanner with oscillating mirror Fig. 6-4: One-Shot: Object tracking (bar code read from front) © SICK AG · Division Auto Ident · Germany · All rights reserved 6-13 8 010 080/O824/10-02-2005... -

Page 84: Table 6-6: Overview: Clv Applications In Stand-Alone Configuration Or In

The size of the reading field is determined by the distance between the start and stop sen- sors in conveying direction (see Fig. 3-4, Page 3-8). © SICK AG · Division Auto Ident · Germany · All rights reserved 6-14 8 010 080/O824/10-02-2005... -

Page 85: Table 6-7: Guide: Parameterizing The Reading Trigger For Start/Stop Mode In Stand-Alone Configuration

– Timeout Note: Connect the external sensor to "Sensor“ switching input! Table 6-7: Guide: Parameterizing the reading trigger for start/stop mode in stand-alone configuration © SICK AG · Division Auto Ident · Germany · All rights reserved 6-15 8 010 080/O824/10-02-2005... - Page 86 Connect sensor 1 to "Sensor“ switching input and sensor 2 to "IN 4“ switching input! Table 6-7: Guide: Parameterizing the reading trigger for start/stop mode in stand-alone configuration (contd.) © SICK AG · Division Auto Ident · Germany · All rights reserved 6-16 8 010 080/O824/10-02-2005...

- Page 87 If you are using an incremental encoder, the "Sensor“ and "IN 4" switching inputs for the beginning and end of the reading interval can also be debounced for specific paths. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-17...

-

Page 88: Table 6-8: Guide: Parameterizing Focus Control In The Clv For Master/Slave Arrangement With

– Index – No. of valid configurations: 1 Table 6-8: Guide: Parameterizing focus control in the CLV for master/slave arrangement with OTC 400 © SICK AG · Division Auto Ident · Germany · All rights reserved 6-18 8 010 080/O824/10-02-2005... -

Page 89: Table 6-9: Guide: Parameterizing Reading Trigger Mode In The Clv For

For functions to be parametrized in the OTC 400: see "OTS 400 Omni Tracking System“ Operatings Instructions (no. 8 008 869, English edition). © SICK AG · Division Auto Ident · Germany · All rights reserved 6-19 8 010 080/O824/10-02-2005... -

Page 90: Table 6-12: Guide: Parameterizing Focus Control In The Clv For Master/Slave

CLV 480 Bar Code Scanner B2. Tracking mode (controlled by increment) Note SICK AG can design and preconfigure more complex omni-portal systems to fulfill the customer's reading requirements and then provide appropriately trained personnel to install, test and put these systems into operation. -

Page 91: Table 6-13: Guide: Parameterizing Reading Trigger Mode In The Clv For

– Automatic or – Fixed Tolerance: value Table 6-14: Guide: Parameterizing tracking mode in the CLV for Object Tracking mode with OTC 400 © SICK AG · Division Auto Ident · Germany · All rights reserved 6-21 8 010 080/O824/10-02-2005... -

Page 92: Otc 400

For functions to be parametrized in the OTC 400: see "OTS 400 Omni Tracking System“ Operatings Instructions (no. 8 008 869, English edition). © SICK AG · Division Auto Ident · Germany · All rights reserved 6-22 8 010 080/O824/10-02-2005... -

Page 93: Table 6-17: Guide: Parameterizing The Laser Timeout

The necessary calculations are provided in Chapter 10.8.3 Calculating the necessary bar code distance if several bar codes are read on each object, Page 10-44. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-23 8 010 080/O824/10-02-2005... - Page 94 Parameterizing the terminal interface (auxiliary interface) • UXILIARY NTERFACE i) Defining the start option for accessing the parameter set • EVICE ONFIGURATION TART WITH © SICK AG · Division Auto Ident · Germany · All rights reserved 6-24 8 010 080/O824/10-02-2005...

-

Page 95: Operating Modes And Outputing The Reading Result

In the Reading mode the CLV deflects (by default) the scan line about the position CW = 50 at a frequency of 1 Hz and a maximum angle of ±20°. 50 CW corresponds to an angle of deflection of 105°. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-25 8 010 080/O824/10-02-2005... -

Page 96: Fig. 6-5: Clv-Setup: Displaying The Reading Result In The Terminal Emulator

Fig. 6-5: CLV-Setup: Displaying the reading result in the Terminal Emulator © SICK AG · Division Auto Ident · Germany · All rights reserved 6-26 8 010 080/O824/10-02-2005... -

Page 97: Fig. 6-6: Reading Result Of The Terminal Interface: Structure For Good Read

= Special parameter for SICK-Service 3rd. line: no code! = No. bar codes found! Fig. 6-7: Reading result of the terminal interface: structure for No Read © SICK AG · Division Auto Ident · Germany · All rights reserved 6-27 8 010 080/O824/10-02-2005... -

Page 98: Percentage Evaluation

”Fixed position” mode, however the scan line’s selected position remains unchanged. 1. Choose the C tab. ONFIGURATION 2. In the D section, choose S ECODER TANDARD 3. Perform a download to the CLV. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-28 8 010 080/O824/10-02-2005... -

Page 99: Fig. 6-8: Clv-Setup: Displaying The Percentage Evaluation In The Terminal Emulator

The output format of the reading result is the same as that of the Reading mode. Fig. 6-6, Page 6-27 explains the structure and function of the reading diagnosis data. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-29 8 010 080/O824/10-02-2005... -

Page 100: Adjusting Mode

1 second. The part of the scan line that remains active for the reading procedure is the section between CP and CP © SICK AG · Division Auto Ident · Germany · All rights reserved 6-30 8 010 080/O824/10-02-2005... -

Page 101: I/O Monitor In Increment Trigger

The function itself has no effect on the CLV, apart from the temporary change of the terminal interface operating mode. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-31 8 010 080/O824/10-02-2005... -

Page 102: Fig. 6-10: Clv-Setup: Selection Of The Signals To Be Displayed In I/O Monitoring

8. To cancel the display, click C in the I/O M dialog box and exit the S LOSE ONITORING IGNAL dialog box by clicking C HOICE LOSE © SICK AG · Division Auto Ident · Germany · All rights reserved 6-32 8 010 080/O824/10-02-2005... -

Page 103: Fig. 6-11: Clv-Setup: Example Of Output In The "I/O Monitoring" Dialog Box

CLV. RANSMIT A time stamp is displayed next to this. Other functions are not possible in this mode of just the display. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-33 8 010 080/O824/10-02-2005... - Page 104 I 1 and T 1 of the table. NCREMENT 3. Press the right mouse button again. The second measurement cursor appears. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-34 8 010 080/O824/10-02-2005...

- Page 105 Click the START button. CLV-Setup returns to the continuous display of the signal conditions. Any enlargements of areas of the plot diagram are undone. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-35 8 010 080/O824/10-02-2005...

-

Page 106: Displaying And Editing Operating Data

ARAMETERS 3. Choose the P storage option in the dialog box. ERMANENT The terminal interface is now set to the "Read Diagnostics" mode. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-36 8 010 080/O824/10-02-2005... -

Page 107: Monitor Host Interface

Fig. 6-1, Page 6-3. 5. Click the SW-T button or press [F8]. RIGGER CLV-Setup outputs the reading result in the Terminal Emulator. Example: "O 0123412345". © SICK AG · Division Auto Ident · Germany · All rights reserved 6-37 8 010 080/O824/10-02-2005... -

Page 108: Fig. 6-13: Clv-Setup: Displaying The Reading Result Of The Host Interface In The Terminal Emulator With Direction Identifier At The Beginning (In This Case: O = Output)

4. Confirm the entries made by clicking OK. 5. Repeat this procedure for the "Code-Info/Separator", "Splitter" und "Terminator" blocks. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-38 8 010 080/O824/10-02-2005... -

Page 109: Auxiliary Input

CLV-Setup copies the parameter to the CLV temporarily. The terminal interface then operates in "Code statistics for RDT 400" mode until the CLV is switched off again. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-39 8 010 080/O824/10-02-2005... -

Page 110: Self-Test

Chapter 8.3.1 CLV without external parameter memory, Page 8-2, lists the error keys together with the associated corrective measures. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-40 8 010 080/O824/10-02-2005... -

Page 111: Executing Clv Functions Interactively

Show CP-limits has been started. Fig. 6-15: CLV-Setup: Dialog box for executing Show limits © SICK AG · Division Auto Ident · Germany · All rights reserved 6-41 8 010 080/O824/10-02-2005... -

Page 112: Clv Messages

CLV-Setup: Displaying the system messages in the Terminal Emulator when starting the Chapter 10.5 System messages, Page 10-28 explains the meaning of the messages. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-42 8 010 080/O824/10-02-2005... -

Page 113: Error Messages

3. Make the necessary entries in the dialog box and confirm these. CLV-Setup prints out the current configuration file in the form of a table. © SICK AG · Division Auto Ident · Germany · All rights reserved 6-43 8 010 080/O824/10-02-2005... - Page 114 Chapter 6 Operation Operating Instructions CLV 480 Bar Code Scanner Notes © SICK AG · Division Auto Ident · Germany · All rights reserved 6-44 8 010 080/O824/10-02-2005...

-

Page 115: Maintenance

Side reading window Fig. 7-1: Cleaning the reading window Note Don’t open the device. The producer warranty will be forfeited if the device is opened. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 116: Maintenance

5. Send the chassis and cover (aluminium) to be recycled. 6. Send the electronic modules for disposal as problem waste. At present, SICK AG does not accept any unusable or irreparable devices. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 117: Troubleshooting

CLV outputs the message: "Laser safety timeout" on the terminal interface. The reading interval must be terminated by resetting the trigger signal. The laser diode is activated again by the next reading trigger. © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 118: Error Messages

CAN I section. NTERFACE NTERFACE UNCTION Download the parameter set to the CLV! Table 8-1: Error messages output on the terminal interface © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 119: Led Error Messages For The External Parameter Memory

2) Flashing stops when the device switches from Reading mode to Parameter mode (e. g. during download from CLV-Setup). Table 8-2: LED error messages for access to the external parameter memory © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... - Page 120 CLV briefly and monitor the "Device Ready" LED as described under 1. Table 8-2: LED error messages for access to the external parameter memory (contd.) © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005...

-

Page 121: Messages For Errors Accessing The External Parameter Memory

RAM the SICK Service department. Table 8-3: Messages for problems accessing the external parameter memory © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... - Page 122 CLV are set to the default values. If these parameters are necessary, edit the values in the relevant tabs in CLV-Setup and download them to the CLV and the external memory. Table 8-3: Messages for problems accessing the external parameter memory (contd.) © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005...

-

Page 123: St Error Status In The Reading Result Of A Bar Code

C32 bar codes (output as 9- digit decimal values). Table 8-4: Meaning of the ST error status in the reading result © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... - Page 124 N UMBER OF ODES INIMUM Table 8-4: Meaning of the ST error status in the reading result (contd.) © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005...

-

Page 125: General Malfunctions: Clv Not Ready

10 min. (default setting) after the start of Table 6-17, Page 6-23. the current reading pulse (trigger mode: sensor input/serial interface) Table 8-5: Troubleshooting: restoring operation (Reading mode) © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 126: Malfunctions In Reading Mode: Reading Trigger Errors

Chapter 4.4.2 Mounting the external rea- conveyor running. ding pulse sensor, Page 4-10 Table 8-6: Troubleshooting: reading trigger errors in Reading mode (CLV in stand-alone configuration) © SICK AG · Division Auto Ident · Germany · All rights reserved 8-10 8 010 080/O824/10-02-2005... - Page 127 Chapter 6.5.8 Monitor Host Inter- face, Page 6-37. Download temporarily to the CLV. Table 8-6: Troubleshooting: reading trigger errors in Reading mode (CLV in stand-alone configuration) (contd.) © SICK AG · Division Auto Ident · Germany · All rights reserved 8-11 8 010 080/O824/10-02-2005...

- Page 128 • Laser timeout exceeded. • See remedy in Table 8-5, Page 8-9. Table 8-6: Troubleshooting: reading trigger errors in Reading mode (CLV in stand-alone configuration) (contd.) © SICK AG · Division Auto Ident · Germany · All rights reserved 8-12 8 010 080/O824/10-02-2005...

- Page 129 I PERATION MODE NCREMENT selected? CONTROLLED Table 8-7: Troubleshooting: reading trigger errors in Reading mode (CLV integrated in OTS 400 Omni Portal System) © SICK AG · Division Auto Ident · Germany · All rights reserved 8-13 8 010 080/O824/10-02-2005...

-

Page 130: Malfunctions In Reading Mode: Result Output Errors

Optional "Oscillating Mirror Extrema“ se- lected? Table 8-8: Troubleshooting: result output errors in Reading mode (CLV in stand-alone configuration) © SICK AG · Division Auto Ident · Germany · All rights reserved 8-14 8 010 080/O824/10-02-2005... - Page 131 Check settings in I NTER section. FACE ROTOCOL Table 8-8: Troubleshooting: result output errors in Reading mode (CLV in stand-alone configuration) (contd.) © SICK AG · Division Auto Ident · Germany · All rights reserved 8-15 8 010 080/O824/10-02-2005...

- Page 132 OTC 400 if the conveyor speed is not constant (parameterize switching input accordingly) Table 8-9: Troubleshooting: result output errors in Reading mode (CLV integrated in OTS 400 Omni Portal System) © SICK AG · Division Auto Ident · Germany · All rights reserved 8-16 8 010 080/O824/10-02-2005...

-

Page 133: Malfunctions In Reading Mode: Errors In The Result Status Output

IN 3 or GNMENT OF NPUTS IN 4: is trigger One-Shot selected? Table 8-11: Troubleshooting: oscillating mirror errors in Reading mode © SICK AG · Division Auto Ident · Germany · All rights reserved 8-17 8 010 080/O824/10-02-2005... -

Page 134: Sick Support

The telephone numbers and email addresses are listed on the back page of this manual. For postal adresses see also www.sick.com. Please contact SICK before sending the device for repair. © SICK AG · Division Auto Ident · Germany · All rights reserved 8-18 8 010 080/O824/10-02-2005... -

Page 135: Technical Data

1) Default setting, in Reading mode with the "Switching input sensor" and "Serial interface pulse" types. 2) Reading interval: time window generated internally for evaluating the code. Table 9-1: Technical specifications of the CLV 480-0010 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 136: Data Sheet Clv 480-1010 Bar Code Scanner

–35 to +35 °C/–20 to +70 °C (–31 to +95 °F/–4 to +158 °F) Ambient operating/storage temperature Table 9-3: Technical specifications of the CLV 480-0011 © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 137: Data Sheet Clv 480-1011 Bar Code Scanner

Line scanner (standard device) without /with heater CLV 480-0010 CLV 480-0011 All dimensions in mm (in) Fig. 9-1: Dimensions of the CLV 480 line scanner, front reading window © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 138: Line Scanner With Oscillating Mirror (Without/With Heater)

CLV 480-1010 CLV 480-1011 All dimensions in mm (in) Fig. 9-2: Dimensions of the CLV 480: line scanner with oscillating mirror, side reading window © SICK AG · Division Auto Ident · Germany · All rights reserved 8 010 080/O824/10-02-2005... -

Page 139: Appendix

> 75 % Table 10-1: Reading conditions for specification diagrams Note The min. and max. reading distances from the CLV are measured radially. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-1 8 010 080/O824/10-02-2005... -

Page 140: Overview Of Diagrams

CLV 480-1010/-1011 Line scanner with oscillating mirror Min. and max. reading distance (DOF) for 0.30 mm (12 mil)/50° 10-14 CLV 480-1010/-1011 Line scanner with oscillating mirror Min. and max. reading distance (DOF) for 0.35 mm (13.8 mil)/40° 10-15 CLV 480-1010/-1011 Line scanner with oscillating mirror Min. and max. reading distance (DOF) for 0.35 mm (13.8 mil)/50° 10-16 CLV 480-1010/-1011 Line scanner with oscillating mirror Min. -

Page 141: Reading Performance Data Of Line Scanner

10.2.3 Reading performance data of line scanner Fig. 10-1: CLV 480-0010/-0011 (line scanner): Reading field height as a function of the reading distance and resolution © SICK AG · Division Auto Ident · Germany · All rights reserved 10-3 8 010 080/O824/10-02-2005... - Page 142 Focus position Fig. 10-2: CLV 480-0010/-0011 (line scanner): Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.25 mm (9.8 mil) and an aperture angle of 40° Line scanner (front reading window): CLV 480-0010/-0011 Resolution: 0.25 mm (9.8 mil)

- Page 143 Focus position Fig. 10-4: CLV 480-0010/-0011 (line scanner): Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.30 mm (12 mil) and an aperture angle of 40° © SICK AG · Division Auto Ident · Germany · All rights reserved...

- Page 144 Focus position Fig. 10-5: CLV 480-0010/-0011 (line scanner): Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.30 mm (12 mil) and an aperture angle of 60° © SICK AG · Division Auto Ident · Germany · All rights reserved...

- Page 145 All dimensions in mm (in) Fig. 10-6: CLV 480-0010/-0011 (line scanner): Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.35 mm (13.8 mil) and an aperture angle of 40° © SICK AG · Division Auto Ident · Germany · All rights reserved...

- Page 146 All dimensions in mm (in) Fig. 10-7: CLV 480-0010/-0011 (line scanner): Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.35 mm (13.8 mil) and an aperture angle of 60° © SICK AG · Division Auto Ident · Germany · All rights reserved...

- Page 147 All dimensions in mm (in) Fig. 10-8: CLV 480-0010/-0011 (line scanner): Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.5 mm (19.7 mil) and an aperture angle of 40° © SICK AG · Division Auto Ident · Germany · All rights reserved...

- Page 148 All dimensions in mm (in) Fig. 10-9: CLV 480-0010/-0011 (line scanner): Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.5 mm (19.7 mil) and an aperture angle of 60° © SICK AG · Division Auto Ident · Germany · All rights reserved...

- Page 149 Focus position All dimensions in mm (in) Fig. 10-10: CLV 480-0010/-0011 (line scanner): Min. and Max. radial reading distance as a function of the focus position at a resolution of 1.00 mm (39.4 mil) and an aperture angle of 40°...

- Page 150 Focus position All dimensions in mm (in) Fig. 10-11: CLV 480-0010/-0011 (line scanner): Min. and Max. radial reading distance as a function of the focus position at a resolution of 1.00 mm (39.4 mil) and an aperture angle of 60°...

-

Page 151: Reading Performance Data Of Line Scanner With Oscillating Mirror

10.2.4 Reading performance data of line scanner with oscillating mirror Fig. 10-12: CLV 480-1010/-1011 (line scanner with oscillating mirror): Reading field height as a function of the reading distance and resolution © SICK AG · Division Auto Ident · Germany · All rights reserved... - Page 152 All dimensions in mm (in) Focus position Fig. 10-13: CLV 480-1010/-1011 (line scanner with oscillating mirror): Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.30 mm (12 mil) and an aperture angle of 40°...

- Page 153 All dimensions in mm (in) Fig. 10-15: CLV 480-1010/-1011 (line scanner with oscillating mirror): Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.35 mm (13.8 mil) and an aperture angle of 40°...

- Page 154 All dimensions in mm (in) Fig. 10-16: CLV 480-1010/-1011 (line scanner with oscillating mirror): Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.35 mm (13.8 mil) and an aperture angle of 50°...

- Page 155 All dimensions in mm (in) Fig. 10-17: CLV 480-1010/-1011 (line scanner with oscillating mirror): Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.50 mm (19.7 mil) and an aperture angle of 40°...

- Page 156 All dimensions in mm (in) Fig. 10-18: CLV 480-1010/-1011 (line scanner with oscillating mirror): Min. and Max. radial reading distance as a function of the focus position at a resolution of 0.50 mm (19.7 mil) and an aperture angle of 50°...

- Page 157 All dimensions in mm (in) Fig. 10-19: CLV 480-1010/-1011 (line scanner with oscillating mirror): Min. and Max. radial reading distance as a function of the focus position at a resolution of 1.00 mm (39.4 mil) and an aperture angle of 40°...

- Page 158 All dimensions in mm (in) Fig. 10-20: CLV 480-1010/-1011 (line scanner with oscillating mirror): Min. and Max. radial reading distance as a function of the focus position at a resolution of 1.00 mm (39.4 mil) and an aperture angle of 50°...

-

Page 159: Fig. 10-21: Clv 480-1010/-1011 (Line Scanner With Oscillating Mirror): Deflection Range As A Function Of Radial Reading Distance, Deflection Angle And Resolution

Table 10-1, Page 10-1 All dimensions in mm (in) Fig. 10-21: CLV 480-1010/-1011 (line scanner with oscillating mirror): deflection range as a function of radial reading distance, deflection angle and resolution © SICK AG · Division Auto Ident · Germany · All rights reserved... -

Page 160: Installing And Operating The External Parameter Memory

Fig. 10-22: External parameter memory, installed on the CLV Notes If the CLV 480 is used to replace a CLV 265/CLV 295 equipped with a connector cover (pa- rameter memory), the CLV 480 cannot store its extensive parameter set in this external pa- rameter memory (too small). -

Page 161: Installation And Electrical Connection

The "Device Ready" LED blinks for approx. 10 s and then lights up constantly. The data in the CLV is lost when the device is switched off. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-23... -

Page 162: Switching On The Device For The First Time

Adjust the parameter set in the external parameter memory as described in Chapter 6.4.1 Configuring the CLV via the user interface of CLV-Setup, Page 6-5. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-24 8 010 080/O824/10-02-2005... -

Page 163: Meaning Of The Leds

CLV to CLV-Setup and then download it again to the CLV with the P ERMANENT storage option. When asked to do so, adjust the external memory again. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-25 8 010 080/O824/10-02-2005... -

Page 164: Optional Heating

The temperature enables the operating voltage for the CLV internally [°F] [°C] Time [min] Fig. 10-25: CLV with heater: temperature curve inside the housing © SICK AG · Division Auto Ident · Germany · All rights reserved 10-26 8 010 080/O824/10-02-2005... -

Page 165: Electrical Installation

If the CLV with integrated heater is used outdoors, it should be installed in a protective hou- sing to prevent the front window from being damaged by rain, snow, or dust. The housing also acts as a wind protector. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-27 8 010 080/O824/10-02-2005... -

Page 166: System Messages

When the CLV was started, the internal parameter set was external memory" successfully copied to the external parameter memory. Table 10-6: Additional CLV system messages for the connected parameter memory © SICK AG · Division Auto Ident · Germany · All rights reserved 10-28 8 010 080/O824/10-02-2005... -

Page 167: Installing And Operating The "Clv-Setup" Program

5. Select CLV, ICR, OPS S in the listing. ETUP OFTWARE A table with CLV-Setup information is displayed. 6. Select D under S OWNLOAD OFTWARE FILE © SICK AG · Division Auto Ident · Germany · All rights reserved 10-29 8 010 080/O824/10-02-2005... - Page 168 You can install the new version and still keep the old version (parallel installation) – or – • You can install the new version over the old version (overwrite) © SICK AG · Division Auto Ident · Germany · All rights reserved 10-30 8 010 080/O824/10-02-2005...

- Page 169 The new version of CLV-Setup is installed. The configuration files of the old version can be used again. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-31 8 010 080/O824/10-02-2005...

-

Page 170: Starting Clv-Setup

The default setting the first time the device is used is the CLV 41x. The soft- ware then loads the internal device description for this CLV type and displays the default va- lues on the tabs. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-32 8 010 080/O824/10-02-2005... -

Page 171: Fig. 10-26: Clv-Setup: Result Display Of The Autobaud Detect Function

CLV-Setup then uploads the current parameter set from the RAM of the CLV to its database and displays the values on the tabs. You can edit the current parameter set on the tabs. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-33 8 010 080/O824/10-02-2005... -

Page 172: User Interface

Frame for displaying the navigation tree of the tabs (on left-hand side) • Frame for displaying the tabs for CLV 480 (Reading Configuration, Device Configuration, etc.) (on right-hand side). The numbers of displayed tabs depends on the selected items in the navigation tree on the left side. The parameters on the tabs are grouped according to their function. -

Page 173: Functions

Exporting the configuration files in RTF format • Exporting the command strings contained in the profile bar codes in ASCII format • Printing the parameter set in the form of profile bar codes (not for CLV 480) • Organizing logically serveral scanners in projects •... -

Page 174: Opening And Closing Tabs

5. In the left frame click on the desired entry in the navigation tree. CLV-Setup Help then displays the associated help text in the right-hand frame and jumps to the parameter heading. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-36 8 010 080/O824/10-02-2005... -

Page 175: Transferring Parameter Sets Between Clv-Setup And The Clv

If the program detects an error, it outputs a warning and enters the problem parameter/ value in the window on the E tab. XTRAS © SICK AG · Division Auto Ident · Germany · All rights reserved 10-37 8 010 080/O824/10-02-2005... -

Page 176: 10.6.11 Log File In The Terminal Emulator

In this way, for example, you can prevent CLV-Setup from attempting to establish a connection when a CLV is not connected. 10.6.13 The CLV Assistant The CLV assistant is not suitable for parameterizing the CLV 480. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-38 8 010 080/O824/10-02-2005... -

Page 177: Configuring A Clv With Command Strings

The CLV answers with an echo if the command was syntactically correct (in most cases). Example: The command "3?LT" causes the CLV to display the parameter values of the reading trigger in coded form in output window © SICK AG · Division Auto Ident · Germany · All rights reserved 10-39 8 010 080/O824/10-02-2005... - Page 178 If the commands are sent from the host/PLC to the CLV for configuration, note that "3 EEW" has to be sent as the last command to ensure that they are permanently transferred to the CLV (EEProm). © SICK AG · Division Auto Ident · Germany · All rights reserved 10-40 8 010 080/O824/10-02-2005...

-

Page 179: Calculating Parameter Values For Setting The Clv

Code window s = l – l n = 75 Fig. 10-30: Line scanner: calculating the number of scans for fence-type bar code arrangements © SICK AG · Division Auto Ident · Germany · All rights reserved 10-41 8 010 080/O824/10-02-2005... -

Page 180: Fig. 10-31: Line Scanner With Oscillating Mirror: Calculating The Number Of Scans For Fence-Type Bar Code Positioning

---------------------- 1.26 Hz n = 476 Fig. 10-31: Line scanner with oscillating mirror: calculating the number of scans for fence-type bar code positioning © SICK AG · Division Auto Ident · Germany · All rights reserved 10-42 8 010 080/O824/10-02-2005... -

Page 181: Calculating The Start Position And Mirror Speed For The Forward And Return Phase Of The One-Shot Function

Check the theoretically calculated values on site and adapt them if required. Fig. 10-32: One-Shot: Line scanner with oscillating mirror: calculating the number of scans for fence-type bar code positioning © SICK AG · Division Auto Ident · Germany · All rights reserved 10-43 8 010 080/O824/10-02-2005... -

Page 182: Calculating The Necessary Bar Code Distance If Several Bar Codes Are Read On Each Object

(depends on ODE CONFIGURATION application). Fig. 10-33: Required distance between the bar codes on an object © SICK AG · Division Auto Ident · Germany · All rights reserved 10-44 8 010 080/O824/10-02-2005... -

Page 183: Tables

Table 10-8: Formulas for calculating the code length of a bar code © SICK AG · Division Auto Ident · Germany · All rights reserved 10-45... -

Page 184: 10.10 Special Applications And Procedures

OWNLOAD ARAMETER CLV-Setup copies the parameter temporary to the CLV. The terminal interface then operates temporarily in "Auxiliary input" mode. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-46 8 010 080/O824/10-02-2005... -

Page 185: Fig. 10-35: Clv-Setup: Auxiliary Input On The Terminal Emulator

6. Once the active reading pulse has ended, the CLV sends the data received from the PC to the host via the host interface. Fig. 10-35: CLV-Setup: auxiliary input on the Terminal Emulator © SICK AG · Division Auto Ident · Germany · All rights reserved 10-47 8 010 080/O824/10-02-2005... -

Page 186: Table 10-9: Communication Parameters On The Terminal/Pc For The Auxiliary Input

Once the active reading pulse has ended, the CLV sends the data received from the PC to the host via the host interface. If you connect a SICK Hand-held Scanner from the IT 38xx/46xx/48xx/58xx series, set the communication parameters and data output (data + terminator) as shown in Table 10-10. -

Page 187: Daisy-Chain Configuration (Data Forwarding Or Master/Slave Arrangement)

See Operating Instructions "Application of the CAN interface" (no. 8 009 180). 10.10.9 Integration in an OPS reading system See Operating Instructions "OTS 400 Omni Tracking System " (no. 8 008 869). © SICK AG · Division Auto Ident · Germany · All rights reserved 10-49 8 010 080/O824/10-02-2005... -

Page 188: Replacing A Clv (Copying The Parameter Set)

Check whether all of the parameter settings used are necessary to configure the CLV for the current reading application. If necessary, replace the software version in the new device. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-50 8 010 080/O824/10-02-2005... -

Page 189: 10.11.2 Importing The Parameter Set From The External Memory

© SICK AG · Division Auto Ident · Germany · All rights reserved 10-51... -

Page 190: 10.12 Accessories

1 017 134 AMV 60-011 Connection Module for one CLV 480 without heater, with 1 x 15-pin D Sub HD device socket/plug, terminal strips (signal distributor) for connecting the data and function interfaces, internal 9-pin D Sub "Service" plug, strain-relief clamps, polycarbonate housing, enclosure rating IP 30 (max. IP 54), operating voltage 18 to 30 V DC, operating temperature 0 to +40 °C (+32 to +104 °F) -

Page 191: 10.12.3 Bus Connection Modules

20 to 30 V DC, operating temperature 0 to +40 °C (+32 to +104 °F) 6 020 893 BMH 10-0111 Bus module for connection of one CLV 480 to Profibus DP; with terminal screws, a 9-pin D-sub bus socket, no housing, for top-hat-rail installation, enclosure rating max. IP 20, operating voltage 10 to 30 V DC, operating temperature 0 to +40 °C (+32 to +104 °F) - Page 192 Table 10-14: Accessories: cables and connector covers for the CLV without heater (contd.) Note Other cable lengths/types for CLV without heater available on request. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-54 8 010 080/O824/10-02-2005...

-

Page 193: 10.12.5 Plug-In Connections

Table 10-16: Accessories: plug-in connections 10.12.6 Reading pulse generators The SICK catalog "SENSICK Sensors for Automation" (no. 8 006 530, English edition) con- tains a large selection of photoelectric switches and photoelectric proximity switches as well as the associated accessories (brackets, connection cables). -

Page 194: 10.12.7 Incremental Encoder

CLX 200 Network controller with LCD, touch-sensitive keypad, integrated power pack and 9-pin D-Sub connections for network, host and terminal, enclosure rating IP 31 Table 10-18: Accessories: network controller © SICK AG · Division Auto Ident · Germany · All rights reserved 10-56 8 010 080/O824/10-02-2005... -

Page 195: 10.13 Dimensioned Drawings Of The Accessories

(0.63 in) No. 2 013 824 Fig. 10-38: Front view of quick clamping device No. 2 016 110 with angle braket No. 2 0130824 © SICK AG · Division Auto Ident · Germany · All rights reserved 10-57 8 010 080/O824/10-02-2005... -

Page 196: 10.14 Supplementary Documentation

“CLV Connect“ PC program. This software is available on the “Manuals & Software“ CD-ROM, which is included in the scope of delivery of the CLV 480. The software can also be downloaded from the SICK home page (www.sick.de) at “Service&Support/Downloadpool“. -

Page 197: 10.15 Glossary

Current deflection range of he scan line (oscillating mirror) perpendicular to the scan direction when a bar code is recorded. Calculated by the CLV for each scan and used, for © SICK AG · Division Auto Ident · Germany · All rights reserved 10-59... - Page 198 Angle about each side of the center position CW = 50 (equal to 0°) that the scan line sweeps when it is deflected by the oscillating mirror. Also referred to as the oscillating angle. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-60 8 010 080/O824/10-02-2005...

- Page 199 Identifier output with the reading result by the CLV for errors that were diagnosed while the bar code was being read. The entry for the host interface is made in the separator of the data output string and must be enabled using the parameters (for the CLV 480 disabled by default).

- Page 200 One-Shot). Master/slave configuration Special arrangement for connecting up to max. 10 SICK bar code scanners in the CAN Scan- ner Network to one reading station (e. g. left/right read). Thanks to the master, the entire network appears as one device to the host.

- Page 201 Only output on the host interface if enabled on the D TRING in the "CLV-Setup" program (for the CLV 480 disabled by default). © SICK AG · Division Auto Ident · Germany · All rights reserved 10-63 8 010 080/O824/10-02-2005...

- Page 202 Special, high performance network of max. 31 CLVs with high data transfer rates on the RS 485 interface. The CLVs are coordinated (polling) and connected to the host via the CLX 200 Network Controller. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-64 8 010 080/O824/10-02-2005...

- Page 203 "CLV-Setup" program to the CLV so that it can operate and configure the device. Also used to output system and error messages. Can be assigned various functions. © SICK AG · Division Auto Ident · Germany · All rights reserved 10-65...

- Page 204 Contains up to 10 elements, consisting of reading diagnosis data and/or constants (control characters, letters, digits), depending on the configuration. The "Termina- tor" block is empty in the default setting of the CLV 480. Tracking mode With this type of continuous reading pulse, several objects are located consecutively in the reading field.

-

Page 205: 10.16 Ec Declaration Of Conformity

EC Declaration of Conformity (page 1). Complete copy of EC Declaration of Conformity on request. Fig. 10-39: Copy of the Declaration of Conformity (Page 1, scaled down) © SICK AG · Division Auto Ident · Germany · All rights reserved 10-67 8 010 080/O824/10-02-2005... -

Page 206: 10.17 Index

- Log file for serial communication....... 10-38 Download - Starting................. 10-32 - Functions ...................6-5 - Tabs (overview) ..............6-7 - Start Download ...............6-6 © SICK AG · Division Auto Ident · Germany · All rights reserved 10-68 8 010 080/O824/10-02-2005... - Page 207 - Preparations ................4-1 - Functions ...................3-6 - Reading pulse sensor ............4-10 Incremental encoder Mounting bracket - Application.................3-2 - Dimensioned drawings ..........10-57 © SICK AG · Division Auto Ident · Germany · All rights reserved 10-69 8 010 080/O824/10-02-2005...

- Page 208 - Trigger modes .................3-6 - Upload..................6-5 - Triggering via Terminal Emulator ........6-26 Parameterization - Troubleshooting ..............8-10 - Calculating parameter values ........10-41 Reading window © SICK AG · Division Auto Ident · Germany · All rights reserved 10-70 8 010 080/O824/10-02-2005...

- Page 209 Windows................... 3-2 - Limit values................4-5 SMART decoder................3-6 Software versions ................I-2 Specification diagrams.............10-1 Splitter ....................6-38 Start/stop mode - Function ..................3-7 - Parameterization..............6-14 Start-up .....................6-3 © SICK AG · Division Auto Ident · Germany · All rights reserved 10-71 8 010 080/O824/10-02-2005...

- Page 210 Chapter 10 Appendix Operating Instructions CLV 480 Bar Code Scanner © SICK AG · Division Auto Ident · Germany · All rights reserved 10-72 8 010 080/O824/10-02-2005...

-

Page 211: 10.18 Bar Code Example

0.35 mm (13.8 mil) 0.5 mm (19.7 mil) 1.0 mm (39.4 mil) Fig. 10-40: Scannable bar codes with various module widths (print ratio 2:1) © SICK AG · Division Auto Ident · Germany · All rights reserved 10-73 8 010 080/O824/10-02-2005... - Page 212 Phone +81 (0)3 3358 1341 E-Mail info@sick.jp More representatives and agencies K o r e a Phone +82-2 786 6321/4 in all major industrial nations at E-Mail kang@sickkorea.net www.sick.com SICK AG • Auto Ident • Waldkirch/Reute • Germany • www.sick.com...

Need help?

Do you have a question about the CLV 480 and is the answer not in the manual?

Questions and answers