Table of Contents

Advertisement

Advertisement

Table of Contents

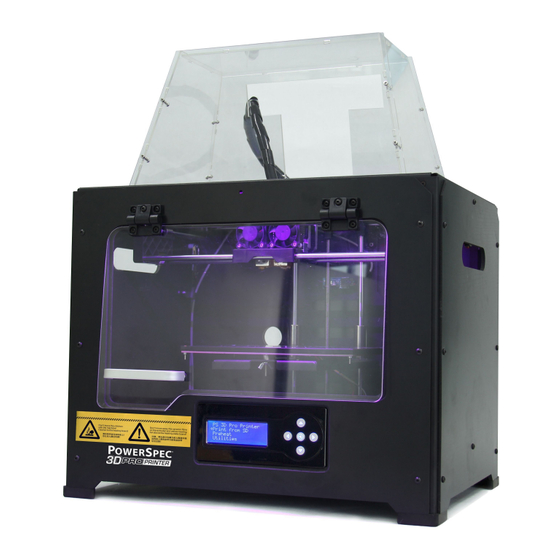

Summary of Contents for PowerSpec Pro 3D Printer

- Page 1 PowerSpec Pro 3D Printer Start-up Guide...

-

Page 2: Table Of Contents

Contents 1 What's Included in the Box? 2 Un-boxing 3 Initial Hardware Installation 4 Software Installation 5 USB Connection & Temperature Setting 6 Filament 6.1 Install Filament 6.2 Feeding the Filament Using the LCD Screen 6.3 Withdrawing the Filament Using LCD Screen 6.4 Feeding the Filament Using Replicator G Control Panel 6.5 Setting Parameters 7 Initial Print... - Page 3 PRECAUTIONS: Please make sure to read this page carefully prior to setting up and operating the 3D Printer. No need to switch the power voltage as we use universal AC input/full range power supply. The 3D Printer is very sensitive to static electricity, so please make sure you contact a grounded object before operating the machine.

-

Page 4: What's Included In The Box

What's Included in the Box? Along with your 3D printer, the box also contains the following: In the two long boxes on the top of the package, you’ll find: Power cord x 1pc, USB A to B cable x 1pc, ... - Page 5 Then pull out the EPE foam packing that encloses the 3D Printer. Now you can see the top of the printer along with more boxes inside. The large box with the black wire is the accessory box. This contains the dual extruder heads, SD card and other important components.

- Page 6 Now, open the accessory box and remove the accessory sleeve. You will find the dual extruder heads in the protective packaging along with the black cable, carefully remove it and place it on your work surface. Remove the cardboard packing material and take the accessory box from the printer, set it aside for later.

- Page 7 To do this, remove the EPE foam in the front, and then in the middle and take out the two boxes. Finally cut down ties between the X axis and front metal frame. You have now finished unboxing! The next task is to setup the hardware. 5...

-

Page 8: Initial Hardware Installation

Initial Hardware Installation You need the two shortest silver screws from the kit found in the accessory box, and the appropriate hex wrench. First, lower the build platform by using one of the methods described in the previous section. Holding the extruder by both sides, take it out of the accessory sleeve and position it on the extruder seat with the fan facing forward. - Page 9 Next, with the power switch in the position, confirm that the power cord is plugged into the power outlet next to the power switch. Now plug the USB A to B cable into the USB B-type port, do not plug the other end in yet. Finally install the filament on the spool holder and screw in the nut.

-

Page 10: Software Installation

Software Installation SPECIAL NOTES TO WIN 8 USERS BEFORE SOFTWARE INSTALLATION Win 8 users please make sure that you have disabled the Driver Signature Enforcement setting before installing the ReplicatorG software. Below is a video link showing you how to accomplish this: http://www.youtube.com/watch?v=NM1MN8QZhnk ReplicatorG0040 is the ideal software to use with the dual extruder 3D Printer. - Page 11 After opening ReplicatorG software, click on Machine to select your Machine Type. Choose The Replicator Dual for 3D Printer dual extruder machine. After selecting the appropriate machine type, click on GCode on the top navigation bar, and under GCode Generator, select Skeinforge(50).

- Page 12 When the object is imported you may find that it is not on the virtual build platform or even on the screen, using the function keys indicated by the blue boxes in the illustration above, you can change the camera angle and reposition the object onto the center of the build platform.

- Page 13 support. Exterior means surface support. Full support means all support. D. Object infill: where 100% is a solid print, is a hollow object. The recommended setting is 10%; this will save time and filament. Low infill also can reduce the corners lift up issue during ABS printing. E.

- Page 14 Click File > Preferences, then click Select Python interpreter under the Advanced tab. A window will pop up. Navigate to the Python installation directory, and select python.exe and click Open. Last, click Close on the Preferences menu and you are done! 12...

-

Page 15: Usb Connection & Temperature Setting

The machine will now work as normal when generating Gcode, and the Python error message will not pop up again.In the next section, we will start a preliminary test on the machine’s connections, and heat the platform and extruder so that the extruder is ready for its first print. - Page 16 Locate the software driver shown in the blue box above. Right click and select Update Driver Software. Click Browse my computer for driver software to find the location of ReplicatorG0040 on your system. 14...

- Page 17 Click FTDI USB Drivers in the driver folder before confirmation and click OK. The drivers will then be installed. The next step is to link the printer. Rescan the serial ports and select the one that appears on your machine (on our test machine the port was COM10, but different computers vary).

-

Page 18: Filament

Input the following target values: 220°C for the extruder and 115°C for the heating platform. After entering the values, the platform will start to warm up. When the extruder temperature reaches 50°C, the cooling fan will be activated and the current temperature value will display to the right as shown below. Filament To make the process of feeding or withdrawing the filament easy, please follow the next few steps carefully: After inserting the filament into the feeding hole, do not push it further until the extruder temperature reaches 200°C... -

Page 19: Feeding The Filament Using The Lcd Screen

When you have removed the guide tube you can remove the filament that is inside the guide tube. To avoid any blockages during printing, please ensure that the two threads are loaded from the middle. There are two wire trays, one runs clockwise and the other one runs counter - clockwise, as shown below: There are two ways of feeding the filament into the extruder head, one is using the LCD screen on the printer itself and the other is by using the control panel on the Replicator G software. -

Page 20: Feeding The Filament Using Replicator G Control Panel

Feed operation with LCD screen Select Change Filament; press the OK key of the keypad. The display will show: ▶ Load Right Unload Right Load Left Unload Left Select the appropriate side of the extruder you wish to load(Left or Right for models with dual extruders). Press the OK key again on the keypad. -

Page 21: Setting Parameters

To heat the right extruder and feed material, click the right extruder on the upper right corner of the control panel and manually modify the temperature in the “Right Target” setting for the extruder temperature control changing the temperature to 220°C. A red line will be plotted in the temperature map. When the actual (Current) temperature reaches 220°C you can pull the filament out. - Page 22 If your machine has factory firmware, Go to Utilities>Level Build Plate , Leveling Your Platform. Pay close attention: leveling your platform is very important to print quality! Here’s the first screen. Actually you will find the printer only has three knobs on the bottom of the platform, just inside the plastic arms that hold it up.

- Page 23 If your platform is too low, your prints might not stick to the surface, and if it's too high, the nozzles could tear the Kapton tape on the platform surface. If you're having trouble, or if you just need to level your platform again, you can always get back to the leveling script in the menu by going to Utilities >...

- Page 24 Next click Generate GCode, a dialogue box will pop up, after inputting your chosen parameters the Gcode will be generated. Please refer to EXPLANATION OF GCODE SETTINGS. A loading bar will then appear showing the progress of the Gcode generation. 22...

-

Page 25: Dual Extruder Print

After the Gcode is generated, the temperature of the bottom plate needs to be changed if you print PLA filament. See below for the required modification. First, select Gcode as shown highlighted in the illustration below and change M109 S110 to M109 to set the HBP temperature at 50°C. - Page 26 Click on the first Browse button to locate and select the file for left extruder; and then click on the second Browse button for right extruder. For example, you can find the examples folder in its installation path. Open the folder examples select Two_color_world_a.stl for...

-

Page 27: Troubleshooting

In both boxes you need to remove the tick in front of the 'use raft/support' option. If you want to print dual colors with PLA filament, then perform the following settings: If you want to print dual colors with filament, select Replicator slicing defaults under the Slicing Profile... - Page 28 below and change HBP temperature to if you are printing with PLA and save this modification by going to File > Save. Click on the following button to export .x3g file for SD card print. 26...

Need help?

Do you have a question about the Pro 3D Printer and is the answer not in the manual?

Questions and answers