Table of Contents

Advertisement

Read and follow these instructions and all

safety blocks carefully.

Have only trained and qualified persons

install, operate, or service this unit.

Call your distributor if you do not understand

the directions.

cover 8/92 – SA-145 666-B

OWNER'S

MANUAL

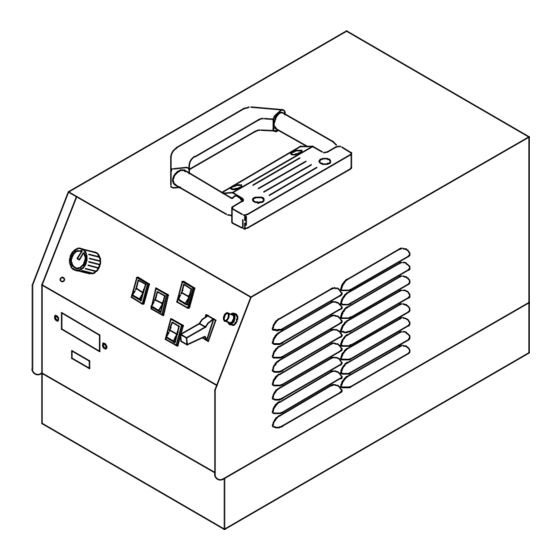

Maxstar 152 And 175

CC/DC Welding Power Source

For GTAW And SMAW Welding

120 A At 25 V Or 140 A At 25.6 V, 100% Duty Cycle

152 Model: Single-Phase; 175 Model: Three-Phase Input Power

Thermostat Protection Against Overheating

Touch Start For GTAW Welding

14-Pin Remote Control Receptacle

June 1993

Form: OM-206C

Effective With Serial No. KD375312

Give this manual to the operator.

For help, call your distributor

or: MILLER ELECTRIC Mfg. Co., P.O. Box

1079, Appleton, WI 54912

414-734-9821

PRINTED IN USA

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Miller Maxstar 152

- Page 1 Have only trained and qualified persons For help, call your distributor install, operate, or service this unit. Call your distributor if you do not understand or: MILLER ELECTRIC Mfg. Co., P.O. Box the directions. 1079, Appleton, WI 54912 414-734-9821 cover 8/92 – SA-145 666-B...

- Page 2 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 3: Table Of Contents

EMF INFORMATION Considerations About Welding And The Effects Of Low Frequency Electric And NOTE Magnetic Fields The following is a quotation from the General Conclusions Section of To reduce magnetic fields in the workplace, use the following procedures: the U.S. Congress, Office of Technology Assessment, Biological Effects of Power Frequency Electric &... -

Page 5: Section 1 - Safety Information

SECTION 1 – SAFETY INFORMATION mod1.1 2/93 Read all safety messages throughout this manual. Obey all safety messages to avoid injury. Learn the meaning of WARNING and CAUTION. Safety Alert Symbol Signal Word WARNING means possible death or serious injury can happen. WARNING CAUTION CAUTION means possible minor... -

Page 6: Volt-Ampere Curves

2-1. Volt-Ampere Curves The volt-ampere curves show the minimum and maximum voltage and amperage output capabilities of the welding power source. Curves of other settings fall be- tween the curves shown. A. 152 Model B. 175 Model ssb1.1 10/91 – SB-151 604 / SB-143 476-B Figure 2-1. -

Page 7: Section 3 - Installation

SECTION 3 – INSTALLATION 3-1. Typical Process Connections SMAW Welding Power Source Work Remote Control 14 Pin GTAW Welding HF Unit Power Source Work GTAW Scratch Start Pulse Control Pulsed GTAW 14 Pin GTAW Welding Power Source Work Figure 3-1. Typical Process Connections 3-2. -

Page 8: Selecting And Preparing Weld Output Cables

3-3. Selecting And Preparing Weld Output Cables Weld Output Cable Determine total cable length in weld circuit and maximum welding amperes. Use Table 3-1 to select proper cable size. Use shortest cables possible. Do not use damaged cables. Terminal Lug Use lugs of proper amperage capacity and hole size for connect- ing to work clamp or electrode... -

Page 9: Connecting To Weld Output Receptacles

3-4. Connecting To Weld Output Receptacles WARNING ELECTRIC SHOCK can kill; ARCING can burn skin or damage electrical equipment. • Do not touch live electrical parts. • Turn Off welding power source before making any weld output connections. • Do not change position of welding cable connectors while welding. •... -

Page 10: Connecting Input Power

3-6. Connecting Input Power WARNING ELECTRIC SHOCK can kill. • Do not touch live electrical parts. • Turn Off welding power source, and disconnect input power before inspecting or installing. • Have only qualified persons install unit. • Installation must meet National Electrical Code and all other codes. swarn3.1 2/93 A. - Page 11 Have only qualified persons make this installation. Remove wrapper. Line Disconnect Device Of Proper Rating Input Conductors Grounding Conductor Select size and length using Table 3-2. Conductor rating must comply with national, state, and lo- cal electrical codes. Strip 3/8 in (10 mm) insulation off all conductors.

-

Page 12: Section 4 - Operation

SECTION 4 – OPERATION WARNING ELECTRIC SHOCK can kill. ARC RAYS can burn eyes and skin; • NOISE can damage hearing. Always wear dry insulating gloves. • • Wear welding helmet with correct shade of filter. Insulate yourself from work and ground. •... - Page 13 WARNING ELECTRIC SHOCK can kill. • Do not touch live electrical parts. • Do not touch weld output receptacles when contactor is energized. • Do not touch electrode and work clamp at the same time. swarn7.1* 10/91 Output (Contactor) Switch Use switch to select way of control- ling output.

- Page 14 Weld Process Switch Use switch to select type of weld output current. Use GTAW position for Gas Tungsten Arc Welding. Use SMAW position for Shielded Metal Arc Welding. Switch position determines the op- eration of the Touch Start switch (see Figure 4-7). Figure 4-6.

- Page 15 Amperage/Voltage Meter Meter displays amperage or volt- age output. Meter Switch Use switch to select amperage (A) or voltage (V) display. In Volts position, the meter dis- plays the voltage at the weld output receptacles. In Amperage posi- tion, the meter displays the welding current during welding, and the preset amperage when welding is not taking place.

-

Page 16: Section 5 - Maintenance & Troubleshooting

SECTION 5 – MAINTENANCE & TROUBLESHOOTING WARNING ELECTRIC SHOCK kill; MOVING PARTS can cause injury. • SIGNIFICANT DC VOLTAGE exists after Keep away from moving parts. removal of input power. • Do not touch live electrical parts. • Turn Off welding power source, disconnect input STATIC ELECTRICITY can damage parts power, wait 60 seconds, measure voltage on input on circuit boards. -

Page 17: Measuring Input Capacitor Voltage

5-3. Measuring Input Capacitor Voltage READ SAFETY BLOCKS at start of WARNING Section 5 before proceeding. Turn Off welding power source and Significant DC voltage can remain on capacitors after unit disconnect input power. is Off. Always check capacitors as shown to be sure they Remove wrapper. -

Page 18: Troubleshooting

5-5. Troubleshooting WARNING ELECTRIC SHOCK kill. MOVING PARTS can cause injury. • SIGNIFICANT DC VOLTAGE exists after Keep away from moving parts. removal of input power. • Do not touch live electrical parts. • Turn Off welding power source, disconnect input STATIC ELECTRICITY can damage parts power, wait 60 seconds, measure voltage on input on circuit boards. - Page 19 Trouble Remedy Section Wandering arc; poor control of arc di- Reduce gas flow rate. – – rection. Select proper size tungsten. Properly prepare tungsten. Tungsten electrode oxidizing and not Shield weld zone from drafts. – – remaining bright after conclusion of weld.

-

Page 20: Section 6 - Electrical Diagrams

SECTION 6 – ELECTRICAL DIAGRAMS OM-206 Page 16... - Page 21 OM-206 Page 17...

- Page 22 Figure 6-3. Wiring Diagram For 152 Model OM-206 Page 18...

- Page 23 SD-158 546-A OM-206 Page 19...

- Page 24 Figure 6-4. Wiring Diagram For 175 Model OM-206 Page 20...

- Page 25 SD-153 153-A OM-206 Page 21...

-

Page 26: Section 7 - Tungsten Electrode

SECTION 7 – TUNGSTEN ELECTRODE mod2.1 3/93 NOTE For additional information, see your distributor for a handbook on the Gas Tungsten Arc Welding (GTAW) process. Wear clean gloves to prevent contamination of tungsten electrode. 7-1. Selecting Tungsten Electrode Table 7-1. Tungsten Size ♦... -

Page 27: Preparing Tungsten

7-2. Preparing Tungsten Tungsten Electrode Balled End Ball end of tungsten before welding by applying either an ac amperage slightly higher than what is recom- 1-1/2 Times mended for a given electrode diam- Electrode Diameter eter (see Table 7-1), or a dc elec- trode positive amperage. -

Page 28: Section 8 - Parts List

SECTION 8 – PARTS LIST OM-206 Page 24... - Page 29 Quantity Model Item Dia. Part Mkgs. Description Figure 8-1. Main Assembly ....126 416 HANDLE ..........

- Page 30 Quantity Model Item Dia. Part Mkgs. Description Figure 8-1. Main Assembly (Continued) ....090 328 SWITCH, tgl DPST 40A 600VAC ......

- Page 31 Quantity Model Item Dia. Part Mkgs. Description Figure 8-2. Module, Power & Diode (Fig 8-1 Item 25 & 26) ....093 085 CAPACITOR, polye MF .0047uf 1000V .

- Page 32 Quantity Model Item Dia. Part Mkgs. Description Figure 8-2. Module, Power & Diode (Fig 8-1 Item 25 & 26) (Continued) ... PLG6 ..115 092 CONNECTOR & SOCKETS, (consisting of) .

-

Page 33: Options And Accessories

(#042 849) Maxstar 152 20 ft. (6 m) cord and 14–pin plug. end. (#042 850) Maxstar 175 RFC-E FOOT CONTROL INTERNATIONAL/CAM–LOK The Miller Expert Program is an (#042 856) ADAPTER easy–to–use computerized Lightweight, com–pact foot control. (#042 466) software program to systematically 15 ft. - Page 34 For complete information on all Note: International Connector Kit • Regulator/flowmeter (HRF–2425) Miller TIG torches and (#135 493) must be used with the 150 • Work cable with clamp (clamp Amp TIG torches listed. accessories, see Literature Index rated for 350 Amps), 12–1/2 ft.

- Page 35 Effective January 1, 2001 (Equipment with a serial number preface of “LB” or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other Warranty Questions? guarantees or warranties expressed or implied. Call LIMITED WARRANTY – Subject to the terms and conditions APT, ZIPCUT &...

- Page 36 Distributor Address City State For Service Call 1-800-4-A-Miller or see our website at www.MillerWelds.com to locate a DISTRIBUTOR or SERVICE AGENCY near you. Always provide Model Name and Serial/Style Number. Contact your Distributor for: Welding Supplies and Consumables Options and Accessories...

Need help?

Do you have a question about the Maxstar 152 and is the answer not in the manual?

Questions and answers