Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Stairmaster Crossrobics 1650 LE

- Page 1 1650 LE ® ROSSROBICS ’ WNER ANUAL...

- Page 2 © 2001 StairMaster Health & Fitness Products, Inc. StairMaster, Crossrobics and the Crossrobics logo are registered trademarks or trademarks of StairMaster Health & Fitness Products, Inc. in the United States and/or other countries. All other trademarks are trademarks of their respective companies.

- Page 3 Crossrobics 1650 LE conditioning system is warranted for a period of three years by StairMaster Health & Fitness Products, Inc. to be free of all defects in materials and workmanship. This warranty does not apply to any defect caused by negligence, misuse, accident, alteration, improper maintenance, or an “act of God.”...

- Page 4 WHAT IS THE STAIRMASTER CROSSROBICS 1650 LE CONDITIONING SYSTEM? The Crossrobics 1650 LE conditioning system is a non weight-bearing, weight- loading, exercise system. Regular use produces increased aerobic capacity as well as stronger muscles and bones. Traditional types of weight-loading...

- Page 5 PREFACE The Crossrobics Conditioning Matrix Table ® Type of Training Power Speed Strength Endurance Emphasis Speed level Fast Fast Medium Slowest Resistance Heavy Medium Heaviest Light (Weight Plates) Duration Short Medium Medium Long Primary Energy Anaerobic Anaerobic + Anaerobic + Aerobic System Aerobic...

-

Page 6: Table Of Contents

The Aerobic Training Program ..............21 The Speed Intervals Program ..............21 The Constant Heart Rate Program ............22 The Fitness Test Programs ..............23 Understanding Submaximal Exercise Testing ........23 Pretest Screening ..................25 ® The StairMaster Submaximal Fit Test ..........25 Page vii... - Page 7 CONTENTS Console Codes ................... 29 Custom Codes ..................29 Quick Scan Programming ................... 30 Machine Status Codes ................31 Quick Scan Programming ................... 32 Configuration Code ................. 32 MAINTENANCE ....................33 Helpful Hints ..................... 33 Tool List ....................33 Maintenance Records ................33 Preventive Maintenance .................

- Page 8 Figures 7-31 ....................73 Wiring Diagram 1 ..................98 LIST OF TABLES Table 1. Dimensions and Specifications for the ® ® StairMaster FreeClimber Exercise Systems ......... 4 Table 2. Fitness Rating Norms (VO ) ............28 2max Table 3. Recommended Preventive Maintenance Schedule ....38 LIST OF ILLUSTRATIONS Figure 1: Major Parts ...................

- Page 9 Figure 2: Exercise Starting Position ............9 Figure 3: Exercise Motion ................10 Figure 4: Transmitter Belt ................16 Figure 5: Crossrobics 1650 LE Console ............17 Figure 6: StairMaster ® Fitness Protocol ........... 27 Figure 7: Parts Needing Periodic Lubrication ..........73 Figure 8: Left Side View ................

-

Page 10: Safety Guidelines

SAFETY GUIDELINES HEN USING ELECTRICAL EQUIPMENT ALWAYS FOLLOW THESE BASIC PRECAUTIONS IMPORTANT SAFETY INSTRUCTIONS This symbol appearing throughout this manual means Attention! Be Alert! Your safety is involved. The following definitions apply to the words “Danger” and “Warning” found throughout this manual: DANGER - Used to call attention to IMMEDIATE hazards which, if not avoided, will result in immediate, serious personal injury or loss of life. - Page 11 4. Use this machine only for its intended use as described in this Manual. Do not use parts, attachments, or accessories other than those provided by ® StairMaster Health & Fitness Products, Inc. 5. Do not use the external power supply if it has a damaged cord or plug, or if it is not working properly, if it has been dropped or damaged, or dropped into water.

-

Page 12: Introduction

INTRODUCTION Before leaving the manufacturing facility in Tulsa, Oklahoma, your StairMaster Crossrobics 1650 LE conditioning system was thoroughly ® ® inspected and tested for proper operation. The major parts of the machine are shown in Figure 1. Figure 1: Major Parts... - Page 13 INTRODUCTION Throughout this manual, all references to the left or right side and to the front or back are made as if you were on the machine, ready to exercise. For example, the weight stack is on the right side of the machine. The dimensions and electrical specifications for a fully assembled machine are listed in Table 1.

-

Page 14: Installation Instructions

(1.98 meters) and a doorway width of 34 inches (86 cm) is required. Upon delivery, the shipping representative of StairMaster Health & Fitness Products, Inc. will place your new StairMaster Crossrobics 1650 LE conditioning system wherever you designate in your facility. The machine requires minor assembly. - Page 15 The display “SELECT WORKOUT” tells you the machine is ready to use. A selection of different length DC cables, brackets for multiple power supplies, and other accessories are available from StairMaster ® Health & Fitness Products, Inc. Refer to the Appendix for the phone number of the office nearest you.

-

Page 16: Basic Operating Instructions

Although all equipment manufactured by StairMaster ® Health & Fitness Products, Inc. has been thoroughly inspected at the manufac- turing facility prior to shipment, proper installation and regular maintenance are required to ensure safety. -

Page 17: Your First Workout

BASIC OPERATING INSTRUCTIONS ® ® YOUR FIRST WORKOUT ON THE STAIRMASTER CROSSROBICS 1650 LE CONDITIONING SYSTEM Basic Instructions for First-Time Users Warm up with light calisthenics and easy stretching exercises for at least five minutes before beginning your workout. WARNING... -

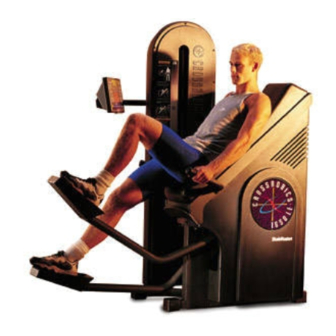

Page 18: Figure 2: Exercise Starting Position

BASIC OPERATING INSTRUCTIONS The console will prompt you to enter the workout time in one minute increments between 5 and 99 minutes. Press [1], [0], [ENTER] to exercise for ten minutes. If you do not start exercising within 60 seconds, the console will return to the start screen. Grasp both handles with your palms facing inwards. -

Page 19: Figure 3: Exercise Motion

BASIC OPERATING INSTRUCTIONS NOTE: SOME INDIVIDUALS MAY NEED ASSISTANCE TO GET THEIR FEET ONTO THE PEDALS. WHOEVER IS GOING TO PROVIDE ASSISTANCE SHOULD STAND IN FRONT OF THE MACHINE AND PUSH BOTH PEDAL ARMS DOWN AS FAR AS NECESSARY. THE EXERCISER THEN PLACES THEIR FEET ONTO THE PEDALS— ONE FOOT AT A TIME. - Page 20 BASIC OPERATING INSTRUCTIONS Exercise at an intensity that keeps the weight stack arrow suspended in the target zone. If the arrow goes too high, slow your stepping rate. If the arrow goes too low, step faster. Your legs move the pedal arms against the resistance of the weight stack at a speed set by the console.

- Page 21 BASIC OPERATING INSTRUCTIONS cool down on the machine by continuing to step. The console timer will continue to count up from the selected time, and the intensity level will default to level 3. If there is a time limit set on the console, the timer will last only until the maximum time has been met.

-

Page 22: Heart Rate Monitoring

HEART RATE MONITORING HEART RATE INPUT ® The 1650 LE console uses telemetry (e.g., Polar ) heart rate signal detection. Ensure that your console is set up for telemetry signal detection only. There is a short “lock out” period at the beginning of each workout session during which the console first detects a signal and then validates the signal type. -

Page 23: Error Messages

HEART RATE MONITORING “TELEMETRY ONLY“ - locks out contact heart rate signals and will only detect telemetry signals. Set your console to this default. “BOTH HR OFF“ - turns off the ability to detect any signal at all. Used in rare situations where there is excessive interference with the heart rate signals. -

Page 24: Telemetry Heart Rate

TELEMETRY HEART RATE TELEMETRY HEART RATE ® ® ® The StairMaster Crossrobics 1650 LE features telemetry (Polar ) heart rate monitoring. The system consists of the receiver, located on the stepper, and a transmitter belt (purchased separately) worn across your chest. The monitoring function is activated as soon as you strap on the chest belt and step within range of the receiver in the machine. -

Page 25: Maintaining The Transmitter Belt

Do not use abrasives or chemicals such as steel wool or alcohol for cleaning, as they can damage the electrodes permanently. You can order replacement belts from StairMaster, Polar Electro, Inc., or your local fitness store: StairMaster... -

Page 26: Crossrobics 1650 Le Console

CROSSROBICS 1650 LE CONSOLE ® The StairMaster Crossrobics 1650 LE console is divided into seven sections: the display window, the workout options, the numeric keypad, the entertain- ment keypad, the workout statistics, the stop key, and the intensity level keys (see Figure 5). -

Page 27: Numeric Keypad

CROSSROBICS 1650 LE CONSOLE NUMERIC KEYPAD The numeric keypad is located on the right side of the con- sole. Before the exercise program begins, the numbers are used to enter data in response to the console prompts. • Enter - Confirms workout selections and stores the informa- tion used by the console to calculate workout statistics. -

Page 28: Workout Statistics

CROSSROBICS 1650 LE CONSOLE WORKOUT STATISTICS During the exercise program, the Stats keys are used to track workout statis- tics which are then shown in the display window. Pressing the [SELECT] key turns off the scanning feature and shows the statistic of choice in the display window. -

Page 29: Exercise Program Keypad

CROSSROBICS 1650 LE CONSOLE EXERCISE PROGRAM KEYPAD The exercise keypad is located below the display window. While the console is in the “SELECT WORKOUT” mode, press one of the six exercise program keys to preview the desired workout. The standard defaults are (pressing [ENTER] without inputting data first will prompt the console to enter these values): •... -

Page 30: The Fat Burner Program

CROSSROBICS 1650 LE CONSOLE on the selected intensity level, with 2 levels equating to one vertical bar. The Fat Burner Program The Fat Burner program is a 60-interval workout designed for people just starting a weight control program. The relative intensity level is indicated on the profile and any changes in the intensity level will continue for the remainder of the program. -

Page 31: The Constant Heart Rate Program

CROSSROBICS 1650 LE CONSOLE the intensity level during an EXERCISE interval. The intensity level shown dur- ing an EXERCISE interval is indicative of your current speed. However, the cur- rent speed during a REST interval is equal to a scaled percentage of the dis- played intensity level. -

Page 32: The Fitness Test Programs

CROSSROBICS 1650 LE CONSOLE THE FITNESS TEST PROGRAM Understanding Submaximal Exercise Testing ® ® Before using the StairMaster Crossrobics 1650 LE for submaximal exercise testing, it should be noted that all submaximal fitness tests make several assumptions: • That a steady-state heart rate is obtained for each exercise workload. - Page 33 CROSSROBICS 1650 LE CONSOLE 150, external factors no longer influence heart rate, and a linear relationship exists. As the heart rate rises above 150, the heart-rate/oxygen uptake rela- tionship becomes curvilinear. The third assumption involves maximal heart rate. Maximal heart rate is the greatest heart rate that can be measured when an individual is exercis- ing to the point of volitional fatigue (i.e., exhaustion) during a graded exercise...

-

Page 34: Pretest Screening

The StairMaster Submaximal Fit Test The StairMaster branching protocol is a series of 3-minute stages of continuous exercise at increasing intensity. The first stage is a warmup at approximately 4 METs. The intensity of the remaining stages is based on the heart rate response to the warmup. - Page 35 110 to 150 beats/min range to predict VO 2max The test typically lasts from 9 to 15 minutes. In the StairMaster protocol, each work rate is performed for 3 minutes, with heart rates recorded during the final 4 seconds of the 2 and 3 minutes of each stage.

- Page 36 CROSSROBICS 1650 LE CONSOLE ® Figure 6: StairMaster Fitness Protocol FIT TEST PROTOCOL StairMaster CV Products First Work Level 4 METs If HR < 100 If 100 <= HR <= 120 If HR > 120 Second Work Level Second Work Level...

-

Page 37: Table 2. Fitness Rating Norms

CROSSROBICS 1650 LE CONSOLE Table 2. Fitness Rating Norms (VO 2max High Good Average Fair 20 – 29 >51 51 – 47 47 – 43 42 – 40 <39 30 – 39 >50 50 – 45 45 – 41 41 – 37 <37... -

Page 38: Console Codes

CROSSROBICS 1650 LE CONSOLE CONSOLE CODES There are three groups of console codes which are differentiated according to function. The first group of codes are customization codes and are used to set defaults such as units, language, heart rate input type, etc. The second group of codes are machine status codes and are used to track hours and other gen- eral usage patterns for maintenance purposes. -

Page 39: Quick Scan Programming

CROSSROBICS 1650 LE CONSOLE 2. Change the units to either Metric or USA units by pressing [LEVEL: ^], [3], [1], [ENTER]. The console will display the current units - either “USA UNITS” or “METRIC UNITS.” Use the [SELECT] key to change option, and then press [ENTER]. -

Page 40: Machine Status Codes

CROSSROBICS 1650 LE CONSOLE [SELECT] “CONTRAST ADJ” [SELECT] “MAX SPEED” - N/A- [SELECT] “CLINICAL MODE”-N/A- 7 [SELECT] “SET DEFAULTS “ Machine Status Codes [ ^ ] [ 4 ] [ 0 ] display machine run time in hours [ ^ ] [ 4 ] [ 1 ] display number of workouts... -

Page 41: Quick Scan Programming

CROSSROBICS 1650 LE CONSOLE Quick Scan Programming You can quickly access any of the custom menus by pressing [LEVEL: ^], [4], [ENTER]. The console will then display “MACHINE STATUS.” Scroll through the following options: [ SELECT ] “ RUN HOURS XXXX”... -

Page 42: Maintenance

MAINTENANCE INSTRUCTIONS HELPFUL HINTS Read all maintenance instructions thoroughly before beginning work. In some cases, an assistant is required to perform the necessary tasks. All references to the right or left side and to the front or back are made as if you were on the machine ready to exercise. -

Page 43: Preventive Maintenance

MAINTENANCE INSTRUCTIONS PREVENTIVE MAINTENANCE A schedule of the recommended preventive maintenance is shown in Table 3. This schedule assumes moderate to heavy usage in a commercial health club environment. Refer to the appropriate “Parts Removal and Replacement” section of this manual for all disassembly and assembly instructions. Initial Service Upon receiving your new machine, use a soft, clean towel to wipe off the dust that may have accumulated during shipping. -

Page 44: Maintenance Instructions

MAINTENANCE INSTRUCTIONS Remove the seat, seat tray and the left side cover. WARNING TO REDUCE THE RISK OF INJURY, DO NOT EXERCISE ON THIS MACHINE WHILE THE SIDE COVERS ARE REMOVED. DO NOT DEPRESS OR RAISE THE PEDALS WHILE ANYONE'S HANDS ARE INSIDE THE MACHINE. DO NOT WEAR LOOSE CLOTHING OR NECKTIES WHILE WORKING ON THIS MACHINE. - Page 45 Place a protective mat on the floor when you are oiling your machine. ® A rubber floor mat is available from StairMaster Health & Fitness Products, Inc. Lubricate the drive and pedal arm chains weekly using SAE 30W motor oil.

- Page 46 MAINTENANCE INSTRUCTIONS Have an assistant work the pedal arms to raise the floating pulley assembly. Remove the lower spring from the lower spring stop assembly (located on the bottom frame rail) every three months. Wipe off the old grease and apply a new coat of heavy multi-purpose grease before replacing the spring in its holder.

-

Page 47: Table 3. Recommended Preventive Maintenance Schedule

MAINTENANCE INSTRUCTIONS Table 3. Preventive Maintenance Schedule PART RECOMMENDED FREQUENCY CLEANER LUBRICANT ACTION Plastic Side Clean Daily Soap & Water N/A Cover (ext. only) Seat Clean Daily Soap & Water N/A Console Clean Daily Water Weight stack Inspect Weekly or belt and after 70 hours connectors... -

Page 48: Troubleshooting

TROUBLESHOOTING This section outlines several tests to systematically identify and isolate the cause of problems in the electrical system and the drive train. The first step is to identify the problem. This troubleshooting section is organized into three problem sections: Electrical Troubleshooting, Console Diagnostics, and mechanical Troubleshooting. -

Page 49: Electrical Troubleshooting

ELECTRICAL TROUBLESHOOTING Plug the power supply into the wall outlet. The green Light Emitting Diode (LED) on the power supply should be on. If the LED does not light up, replace the power supply. Disconnect the DC cable from the left side panel. Set the voltmeter to VDC and test for 12 to 19 VDC in pins #1 (+) and #2 (-). - Page 50 ELECTRICAL TROUBLESHOOTING If all voltage readings have been within the specified range and the console will not power up, the console should be replaced. Alternator Test Check for loose wiring connections on the alternator, diode, and load resistor. Perform the Positive Output to Field test on the alternator: •...

-

Page 51: Console Diagnostic Tests

The ® ® Crossrobics console is used on other StairMaster equipment. DIAGNOSTIC CODES [ ^ ] [ 6 ] [ 0 ] Test display [ ^ ] [ 6 ] [ 1 ] Test keyboard... - Page 52 CONSOLE DIAGNOSTICS Firmly press each button except [CLEAR]. The name of the key will be shown in the display window. Press [CLEAR] to end the test. Serial Port Test This test verifies that the RS 232 port used for linking to external C.S.A.F.E. systems (commercial entertainment systems) is working.

- Page 53 CONSOLE DIAGNOSTICS Tach Test If you do not have resistance, perform the tach test. The tach test will tell you the tach signal, in revolutions per minute (RPMs), picked up by the console. Press [ LEVEL: ^ ], [ 6 ], [ 6 ], [ENTER]. The console will display “TAR TACH ACT.”...

- Page 54 CONSOLE DIAGNOSTICS ® The Telemetry (Polar ) Heart Rate Test The telemetry heart rate system is made up of the console, the heart rate re- ceiver, and the chest strap (available separately). You can test each compo- nent by performing the following steps: You will need to put a chest strap on in order to test the telemetry heart rate.

-

Page 55: Mechanical Troubleshooting

MECHANICAL TROUBLESHOOTING If you hear a grinding or clicking noise, or experience excessive vibration during exercise, a problem exists in the drive train of your machine. Isolate the problem area by performing the following steps in the order listed below. Refer to the appropriate “Parts Removal and Replacement”... - Page 56 MECHANICAL TROUBLESHOOTING drive shaft for wear when replacing a failed clutch sprocket. Inspect the full length of the weight stack belt for fraying and verify that the belt is routed correctly over all of the weight stack belt idler pulleys (see Figure 17). Check the pedal arm shaft and pedal arm bushings by removing both pedal arms.

-

Page 57: Parts Removal And Replacement

PARTS REMOVAL AND REPLACEMENT ALTERNATOR Unscrew the DC power cable from the connector located inside the lower corner of the right rear cover. Remove the left side cover. Note the origin and color of each wire at the alternator terminals (see Wiring Diagram 1). -

Page 58: Chain Tensioning Idler Sprocket Assembly

PARTS REMOVAL AND REPLACEMENT Loosen the adjustment bolt that mounts the alternator to the slotted alternator brace. Rotate the alternator downward. Remove the Poly-V belt. Install the new belt and center it on the pulleys. Pivot the alternator up or down as necessary to allow 1/4" (0.6 cm) of belt deflection using a fingertip in either direction (see Figure 10). -

Page 59: Console

PARTS REMOVAL AND REPLACEMENT The guide bolt on the idler sprocket bracket should be loosely secured. Support the bottom of the assembly shaft with your fingers and reattach the snap ring. Reverse these procedures to complete the reassembly. CONSOLE Loosen and remove the four mounting knobs and lock washers from the back of the console (see Figure 12). -

Page 60: Covers

PARTS REMOVAL AND REPLACEMENT COVERS WARNING DO NOT OPERATE THE MACHINE WHILE THE SIDE COVERS ARE REMOVED. DO NOT DEPRESS OR RAISE THE PEDALS WHILE ANYONE’S HANDS ARE INSIDE THE MACHINE. DO NOT WEAR LOOSE CLOTHING OR NECKTIES WHILE WORKING ON THIS MACHINE WITH THE SIDE COVERS REMOVED. GEARS, SPROCKETS, CHAINS AND BELTS OPERATE AT HIGH SPEEDS AND HAVE THE POTENTIAL TO INFLICT SERIOUS BODILY INJURY. - Page 61 PARTS REMOVAL AND REPLACEMENT Left Side Cover Remove the seat and the seat tray. Remove the five fasteners along the back seam. Remove the three fasteners on the left front (the two between the pedal arms and the seat and the one on the lower left side). Remove the fastener located on the right front cover.

- Page 62 PARTS REMOVAL AND REPLACEMENT them. To install the middle seam fasteners (see Figure 13), reach inside from the front right below the pedal arms and support the seam while installing the bottom three fasteners. Next, reach in from the left side to support the covers while installing the top two fasteners. Install the left side cover, then the seat tray and seat.

-

Page 63: Drive Chain

PARTS REMOVAL AND REPLACEMENT DRIVE CHAIN Remove the left side and right rear covers. Place the open end of a 3/4" combination wrench under the idler spring bracket (the spring assembly under the lower right idler sprocket). Pry up on the bracket to slacken the chain. While support- ing the idler sprocket assembly, slide the chain off the upper left idler sprocket. -

Page 64: Drive Chain Damper Strap

PARTS REMOVAL AND REPLACEMENT DRIVE CHAIN DAMPER STRAP Remove the left side and right rear covers. The drive chain damper strap is located between the alternator and the pivot pulley assembly on the right side of the rear vertical frame rail (see Figure 9). -

Page 65: Drive Hub Assembly

PARTS REMOVAL AND REPLACEMENT DRIVE HUB ASSEMBLY Remove the drive shaft assembly. The hub assembly is held in place by eight one-inch (2.5 cm) bolts (four bolts on each side). Loosen and remove the bolts and slide the housing out of the frame (see Figure 23). Replace the hub assembly if the bearings are worn. -

Page 66: Floating Pulley Assembly

PARTS REMOVAL AND REPLACEMENT Two sprockets are located on the right side of the shaft: a 30-tooth drive sprocket and the smaller clutch sprocket. To remove the clutch sprocket, slide it off the left side of the shaft. Remove the 30-tooth sprocket by removing the snap ring from the right end of the shaft. -

Page 67: Floating Pulley Assembly Belt Idler Pulley

PARTS REMOVAL AND REPLACEMENT FLOATING PULLEY ASSEMBLY BELT IDLER PULLEY Remove the weight selector pin, lift the first three plates to create slack in the weight stack belt and remove the belt from the top two idler pulleys. Set the plates back down onto the stack. Loosen the nut and remove the bolt securing the idler pulley to the assembly (see Figure 26). -

Page 68: Handle Assembly

PARTS REMOVAL AND REPLACEMENT HANDLE ASSEMBLY Lift the seat off of the machine. Remove the two fasteners on the seat tray. Lift the seat tray off the machine. Loosen and remove the nyloc nuts (see Figure 11). Remove both handles from the frame. Reinstall the handles in the reverse order. -

Page 69: Load Resistor

PARTS REMOVAL AND REPLACEMENT When reinstalling the sprocket, use a new roll pin. Reinstall the shaft. Adjust the HTD and the alternator Poly-V belts (see the “Alternator Poly-V Belt” and “HTD Belt” sections for tensioning instructions). Adjust the HTD belt first, then the alternatorPoly-V belt. Reattach the side covers. -

Page 70: Main Cable

PARTS REMOVAL AND REPLACEMENT The bearings can now be slid off the shaft. Inspect the bearings for excess play or roughness. Replace the bearings, if necessary. Install the shaft in the reverse order of the removal procedures. Adjust the alternator Poly-V and HTD belts (see the “Alternator Poly-V Belt”... -

Page 71: Pedal

PARTS REMOVAL AND REPLACEMENT Crimp a wiring lug onto each bared wire end and attach the wires to the proper alternator terminals (see Wiring Diagram 1). Attach the wires to the alternator case or adjusting bracket with a wire tie to protect them from being damaged by moving parts. -

Page 72: Pedal Arm

PARTS REMOVAL AND REPLACEMENT WARNING TO REDUCE THE RISK OF EYE INJURY, WEAR EYE PROTECTION WHEN REMOVING SNAP RINGS. Slide or gently tap the pedal arm off the mounting post. Remove the master link from the pedal arm chain connection. Clean the pedal arm mounting post before reassembling. -

Page 73: Pedal Arm Return Spring

PARTS REMOVAL AND REPLACEMENT PEDAL ARM RETURN SPRING Remove the left (and right rear as needed) side cover. While an assistant supports the pedal arm, detach the pedal arm spring from the frame (see Figure 10). Lift the pedal arm chain off the clutch sprocket. Lower the pedal arm to the floor. -

Page 74: Selector Rod

PARTS REMOVAL AND REPLACEMENT To reassemble the pivot pulley shaft and bearings, reverse these procedures. Adjust the HTD and the alternator Poly-V belts (see the “Alternator Poly-V Belt” and “HTD Belt” sections for tensioning instructions). Adjust the HTD belt first, then the alternatorPoly-V belt. Reattach the right rear and left side covers. -

Page 75: Upper Spring Stop Assembly

PARTS REMOVAL AND REPLACEMENT The ends of the pedals should be even. Adjust the pedal arm height by rotating the shock mount clockwise (to lower the pedal arm) or counterclockwise (to raise the pedal arm). Tighten the set screw. Reattach the side cover. UPPER SPRING STOP ASSEMBLY Remove the left side cover. -

Page 76: Weight Stack Belt

PARTS REMOVAL AND REPLACEMENT Remove the other guide rod and take out the plate. Pivot the new plate into place and reinstall the guide rod. Reinstall the weight stack cover. WEIGHT STACK BELT Remove the left and right side covers and the outside weight stack cover. -

Page 77: Weight Stack Belt Idler Pulley

PARTS REMOVAL AND REPLACEMENT Lower the weight stack. Ensure that the belt is properly seated in all five idler pulleys with the proper twist between the top and bottom idler pulleys. The belt should be taut, with the spring of the lower spring stop slightly compressed ~3/4"... -

Page 78: Weight Stack Guide Rod

PARTS REMOVAL AND REPLACEMENT Remove the weight stack pin and carefully lower the top three plates of the weight stack. Ensure the weight stack belt is seated properly in the pulleys (see Figure 17). Reattach the covers. WEIGHT STACK GUIDE ROD Remove the outside weight stack cover. -

Page 79: Grounding Instructions

GROUNDING INSTRUCTIONS The machine must be grounded if you are using the external power supply or the battery charger. Grounding provides the path of least resistance for the electric current, thereby reducing the risk of electric shock. The power supply or battery charger must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances. -

Page 80: Notice Of Fcc Compliance

• Consult the dealer or an experienced radio/TV technician for help. WARNING CHANGES OR MODIFICATIONS TO EQUIPMENT NOT ® EXPRESSLY APPROVED BY STAIRMASTER HEALTH & FITNESS PRODUCTS, INC. COULD VOID THE USER'S AUTHORITY TO OPERATE THIS EQUIPMENT. CANADIAN DOC CLASS B COMPLIANCE... -

Page 81: Important Phone Numbers

For technical assistance and a list of distributors in your area, please call or fax one of the following numbers. INTERNATIONAL DIVISION ASIA PACIFIC HEADQUARTERS (425) 823-1825 Telephone/Fax:+81-45-590-5686 FAX: (425) 820-7505 E-mail: stairintl@aol.com E-Mail: intlservice@stairmaster.com EUROPE: HEADQUARTERS +41-91-827-3801 FAX: +41-91-827-8902 E-Mail: stairmasterch@swissonline.ch GERMANY: HEADQUARTERS +49-2204/610-27 FAX: +49-2204/628-90 E-Mail: stairmaster.de@t-online.de... -

Page 82: Figures 7-31

FIGURES Figure 7: Parts Needing Periodic Lubrication Page 73... - Page 83 FIGURES Figure 7: Parts Needing Periodic Lubrication Page 73...

-

Page 84: Figure 8: Left Side View

FIGURES Figure 8: Left Side View Page 74... -

Page 85: Figure 9: Right Side View

FIGURES Figure 9: Right Side View Page 75... -

Page 86: Figure 10: Reduction Belt Tension

FIGURES Figure 10: Reduction Belt Tension Page 76... -

Page 87: Figure 11: Handle Assembly

FIGURES Figure 11: Handle Assembly, Top View with Seat and Seat Tray Removed Page 77... -

Page 88: Figure 12: Console Assembly

FIGURES Figure 12: Console Assembly Page 78... -

Page 89: Figure 13: Cover Fastener Locations

FIGURES Figure 13: Cover Fastener Location Page 79... -

Page 90: Figure 14: Cover Fasteners

FIGURES Figure 14: Cover Fasteners Page 80... - Page 91 FIGURES Figure 15: Top View of the Cover Seams Page 81...

-

Page 92: Figure 16: Weight Stack Belt Assembly

FIGURES Figure 16: Weight Stack Belt Assembly Page 82... -

Page 93: Figure 17: Weight Stack Belt Path

FIGURES Figure 17: Weight Stack Belt Path Page 83... -

Page 94: Figure 18: Guide Rod Assembly

FIGURES Figure 18: Guide Rod Assembly Page 84... -

Page 95: Figure 19: Weight Stack Assembly

FIGURES Figure 19: Weight Stack Assembly Page 85... -

Page 96: Figure 20: Pedal Arm Spring Assembly

FIGURES Figure 20: Pedal Arm Spring Assembly Page 86... -

Page 97: Figure 21: Master Link

FIGURES Figure 21: Master Link Page 87... -

Page 98: Figure 22: Drive Chain Assembly

FIGURES Figure 22: Drive Chain Assembly Page 88... -

Page 99: Figure 23: Drive Shaft Assembly

FIGURES Figure 23: Drive Shaft Assembly Page 89... -

Page 100: Figure 24: Lower Reduction Shaft Assembly

FIGURES Figure 24: Lower Reduction Shaft Assembly Page 90... -

Page 101: Figure 25: Pivot Assembly

FIGURES Figure 25: Pivot Assembly Page 91... -

Page 102: Figure 26: Floating Pulley Assembly

FIGURES Figure 26: Floating Pulley Assembly Page 92... -

Page 103: Figure 27: Upper Spring Stop Assembly

FIGURES Figure 27: Upper Spring Stop Assembly Page 93... -

Page 104: Figure 28: Chain Tensioning Idler Sprocket Assembly

FIGURES Figure 28: Chain Tensioning Idler Sprocket Assembly Page 94... -

Page 105: Figure 29: Left Pedal Arm Assembly

FIGURES Figure 29: Left Pedal Arm Assembly Page 95... -

Page 106: Figure 30: Main Cable Routing

FIGURES Figure 30: Main Cable Routing Diagram Page 96... -

Page 107: Figure 31: Alternator And Resistor Mounting

FIGURES Figure 31: Alternator and Resistor Mounting Page 97... -

Page 108: Wiring Diagram 1

WIRING DIAGRAM Wiring Diagram 1: Main Cable Assembly Connections Page 98...

Need help?

Do you have a question about the Crossrobics 1650 LE and is the answer not in the manual?

Questions and answers